Sneaker sole with good anti-skid effect and preparation method thereof

A sports shoes, anti-skid technology, applied in the direction of soles, footwear, applications, etc., can solve the problems of inability to take into account mechanical properties such as impact strength and tensile strength, easy to slip and fall, poor shock absorption and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

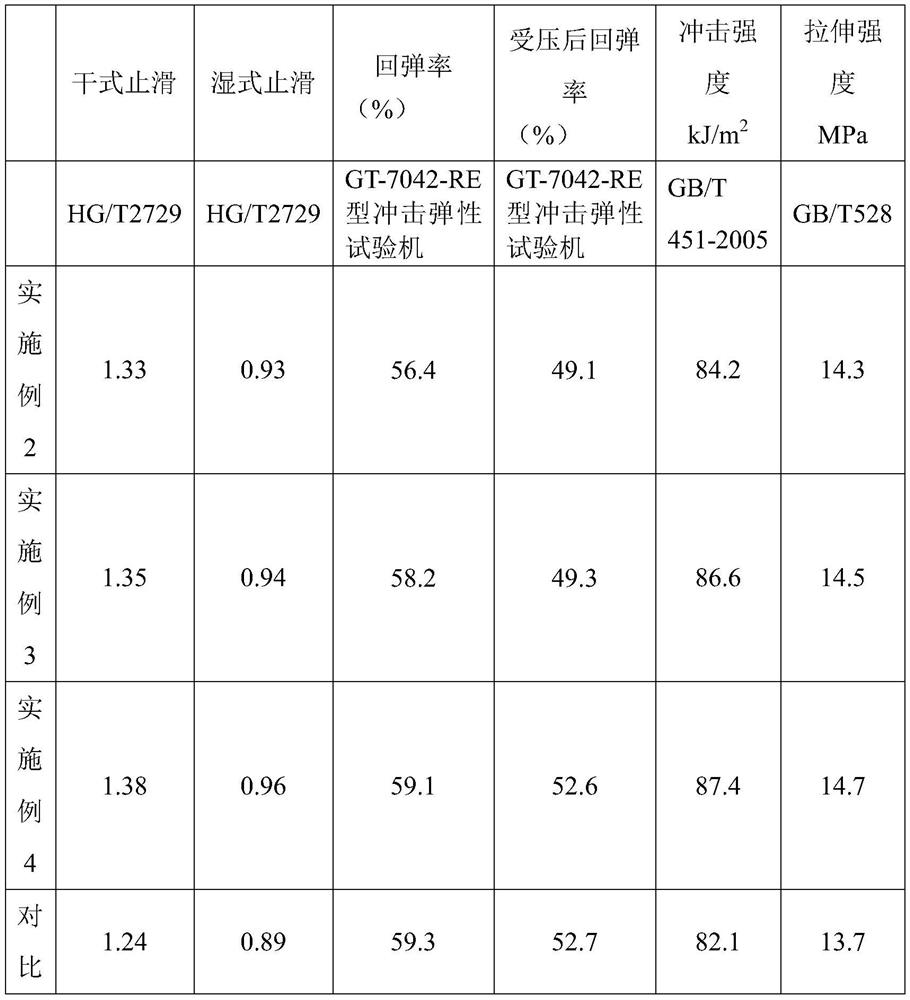

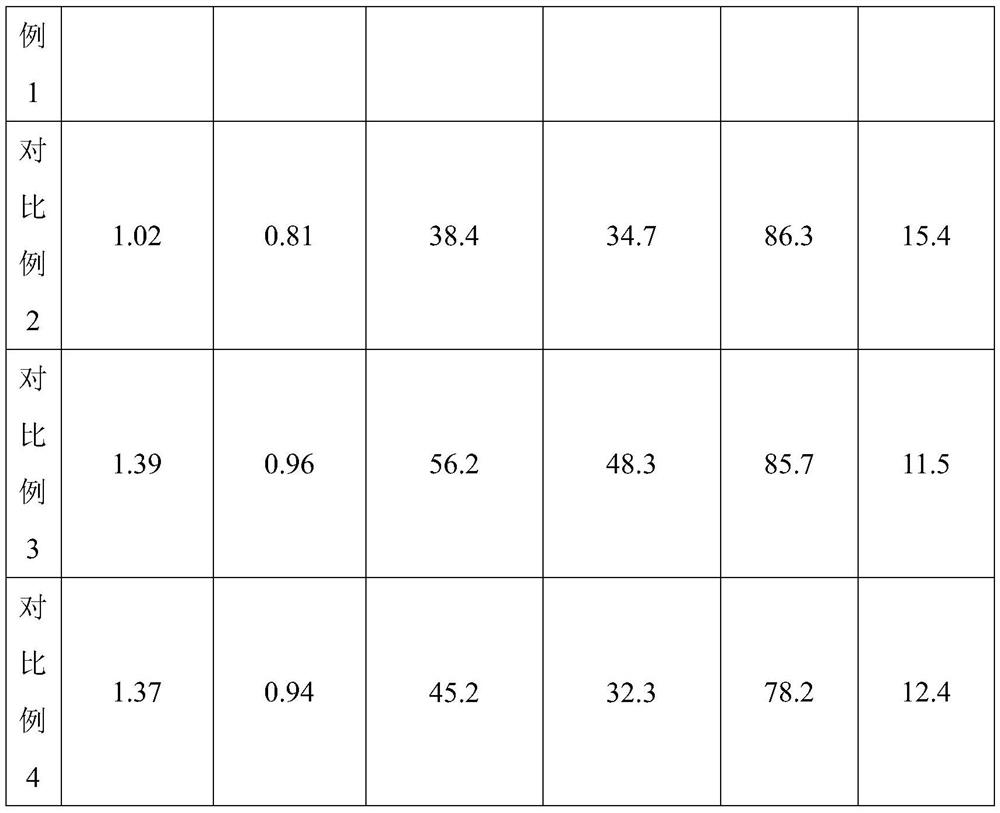

Examples

Embodiment 1

[0054] A sports shoe sole with good anti-slip effect, comprising the following raw materials in parts by weight:

[0055] 35-45 parts of natural rubber,

[0056] 18-26 parts of butadiene rubber,

[0057] 25-35 parts of polyurethane elastomer,

[0058] 6-9 parts of glass fiber,

[0059] 1 to 1.5 parts of nano-zinc oxide,

[0060] 3 to 5 parts of heat stabilizer,

[0061] 1.3-1.7 parts of cross-linking agent,

[0062] Foaming agent 1.8 to 2.5 parts.

[0063] Preferably, the sports shoe sole with good anti-slip effect includes the following raw materials in parts by weight:

[0064] 40 parts of natural rubber,

[0065] Butadiene rubber 22 parts,

[0066] 30 parts of polyurethane elastomer,

[0067] 7.5 parts of glass fiber,

[0068] Nano zinc oxide 1.25 parts,

[0069] 4 parts heat stabilizer,

[0070] 1.5 parts of cross-linking agent,

[0071] Foaming agent 2.2 parts.

[0072] Preferably, the polyurethane elastomer is made of the following raw materials in parts by w...

Embodiment 2

[0092] A sports shoe sole with good anti-slip effect, comprising the following raw materials in parts by weight:

[0093] 35 parts of natural rubber,

[0094] Butadiene rubber 18 parts,

[0095] 25 parts of polyurethane elastomer,

[0096] 6 parts of glass fiber,

[0097] Nano zinc oxide 1 part,

[0098] 3 parts heat stabilizer,

[0099] 1.3 parts of crosslinking agent,

[0100] 1.8 parts of blowing agent.

[0101] In this embodiment, the polyurethane elastomer is made of the following raw materials in parts by weight:

[0102] 70 parts of polymer glycol,

[0103] 13 parts of polyethyleneimine,

[0104] 3.5 parts of hydroxyl-terminated polymethicone oil,

[0105] 7 parts of 1,4-cyclohexanediol,

[0106] 10 parts of isocyanate.

[0107] In this embodiment, the polymer diol is a mixture of polycarbonate diol and polyether-type polytetrahydrofuran diol.

[0108] In this embodiment, the mass ratio of the polycarbonate diol to the polyether polytetrahydrofuran diol is 1...

Embodiment 3

[0121] A sports shoe sole with good anti-slip effect, comprising the following raw materials in parts by weight:

[0122] 45 parts of natural rubber,

[0123] Butadiene rubber 26 parts,

[0124] 35 parts of polyurethane elastomer,

[0125] 9 parts of glass fiber,

[0126] Nano zinc oxide 1.5 parts,

[0127] Heat stabilizer 5 parts,

[0128] 1.7 parts of crosslinking agent,

[0129] 2.5 parts of blowing agent.

[0130] In this embodiment, the polyurethane elastomer is made of the following raw materials in parts by weight:

[0131] 84 parts of polymer glycol,

[0132] 17 parts of polyethyleneimine,

[0133] 4.5 parts of hydroxyl-terminated polymethicone oil,

[0134] 10 parts of 1,4-cyclohexanediol,

[0135] 14 parts of isocyanate.

[0136] In this embodiment, the polymer diol is a mixture of polycarbonate diol and polyether-type polytetrahydrofuran diol.

[0137] In this embodiment, the mass ratio of the polycarbonate diol to the polyether polytetrahydrofuran diol ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com