High-toughness inflatable TPE material and preparation method thereof

A technology with high toughness and raw materials, applied in the field of TPE materials, can solve the problems of not being widely used in high ductility toy materials, poor high and low temperature impact, poor toughness, etc., without affecting the feel and mechanical properties, good temperature and cold resistance, The effect of good rebound rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

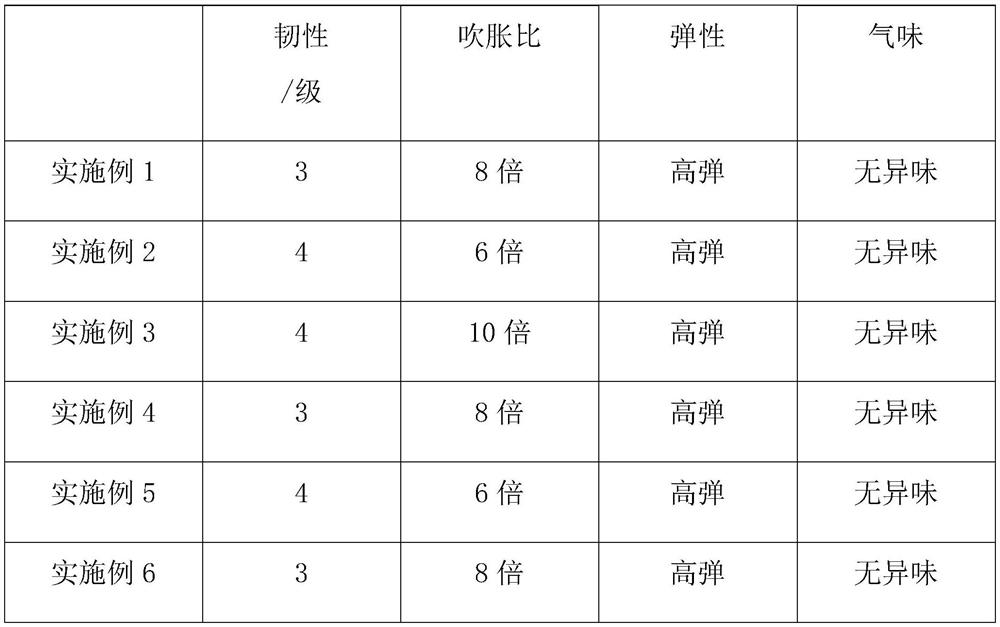

Embodiment 1

[0034] A high-toughness inflatable TPE material, the formula includes: SEBS, extender oil, toughening agent, antioxidant and anti-UV agent, and the mass percentages of each component are: 25% SEBS, 64% extender oil , 10% toughening agent, 0.5% antioxidant and 0.5% anti-UV agent.

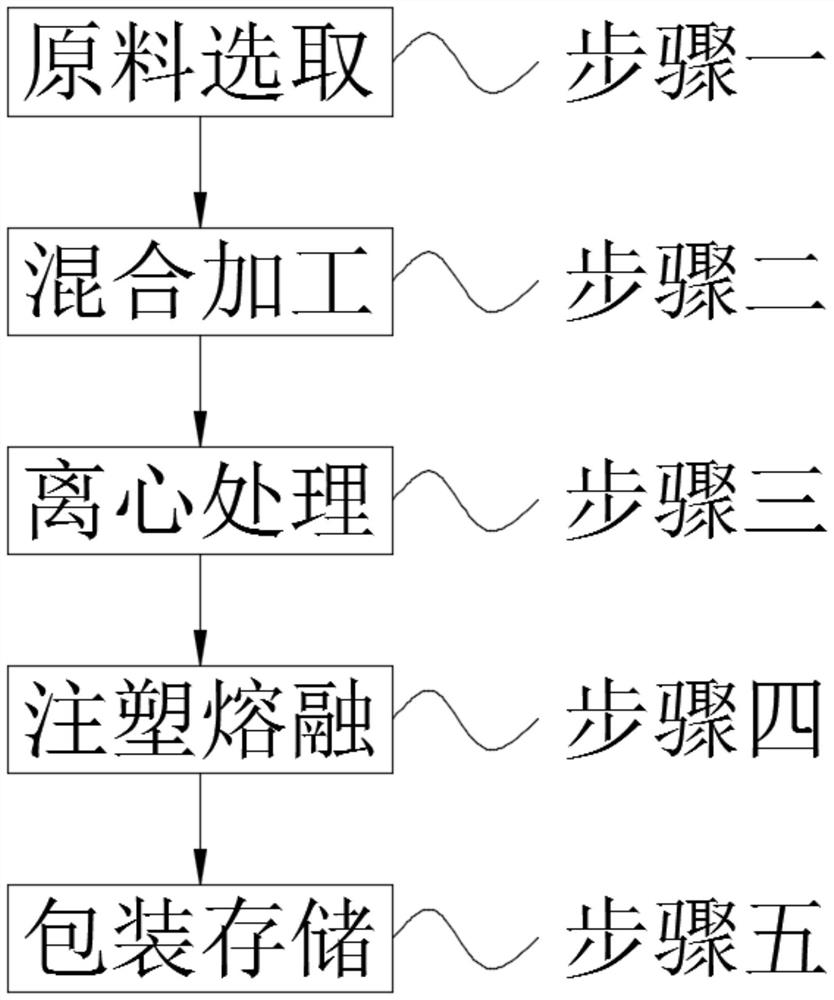

[0035] A method for preparing a high-toughness inflatable TPE material, comprising the following steps: Step 1, raw material selection; Step 2, mixing processing; Step 3, centrifugal treatment; Step 4, injection molding melting; Step 5, packaging and storage;

[0036] Wherein in above-mentioned step one, according to the mass percent content of each component respectively: 25% SEBS, 64% extender oil, 10% toughening agent, 0.5% antioxidant and 0.5% anti-UV agent carry out Select, and weigh according to the sum of the percentages by weight being 1;

[0037] Wherein in above-mentioned step two, mixed processing comprises the following steps:

[0038] 1) Manually clean the reactor, sterilize it with ul...

Embodiment 2

[0051] A high-toughness inflatable TPE material, the formula includes: SEBS, extender oil, toughening agent, antioxidant and anti-UV agent, the mass percentage of each component is: 25% of SEBS, 69% of extender oil , 5% toughening agent, 0.5% antioxidant and 0.5% anti-UV agent.

[0052] A method for preparing a high-toughness inflatable TPE material, comprising the following steps: Step 1, raw material selection; Step 2, mixing processing; Step 3, centrifugal treatment; Step 4, injection molding melting; Step 5, packaging and storage;

[0053] Wherein in above-mentioned step one, according to the mass percent content of each component respectively: 25% SEBS, 69% extender oil, 5% toughening agent, 0.5% antioxidant and 0.5% anti-UV agent carry out Select, and weigh according to the sum of the percentages by weight being 1;

[0054] Wherein in above-mentioned step two, mixed processing comprises the following steps:

[0055] 1) Manually clean the reactor, sterilize it with ultr...

Embodiment 3

[0068] A high-toughness inflatable TPE material, the formula includes: SEBS, extender oil, toughening agent, antioxidant and anti-UV agent, the mass percentage of each component is: 20% of SEBS, 69% of extender oil , 10% toughening agent, 0.5% antioxidant and 0.5% anti-UV agent.

[0069] A method for preparing a high-toughness inflatable TPE material, comprising the following steps: Step 1, raw material selection; Step 2, mixing processing; Step 3, centrifugal treatment; Step 4, injection molding melting; Step 5, packaging and storage;

[0070] Wherein in above-mentioned step one, according to the mass percent content of each component respectively: 20% SEBS, 69% extender oil, 10% toughening agent, 0.5% antioxidant and 0.5% anti-UV agent carry out Select, and weigh according to the sum of the percentages by weight being 1;

[0071] Wherein in above-mentioned step two, mixed processing comprises the following steps:

[0072] 1) Manually clean the reactor, sterilize it with ul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com