Foam roller and processing method thereof

A processing method and foam technology, applied in the field of rubber and plastic products, can solve the problems of shortening the service life of foam shafts, large differences in the hardness of surface patterns, and low utilization of raw materials, achieving low cost, short production cycle, and high utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

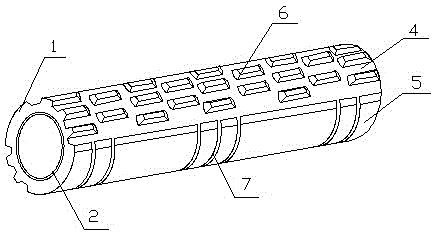

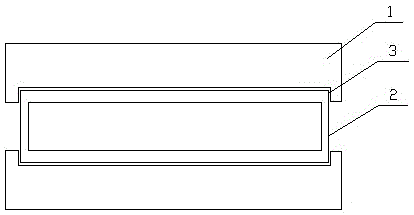

[0037] A foam shaft described in this embodiment includes an outer cladding 1 and an inner lining column 2, the outer cladding 1 is a hollow cylinder, a groove 3 is provided inside the outer cladding 1, and the inner lining column 2 is arranged in the concave In the groove 3, two groups of buffer zones 5 and massage areas 4 are arranged on the surface of the outer cladding layer 1. The surface of the buffer zone 5 is a circular arc, and interval grooves 7 are arranged in the middle intervals. The massage areas 4 are provided with staggered Massage bumps 6, the shape of the lining column 2 is a hollow cylinder.

[0038] The massage bump 6 in this embodiment is trapezoidal.

[0039] The lining column 2 in this embodiment is an EVA solid tube with both ends sealed.

[0040] A method for processing a foam shaft described in this embodiment comprises the following steps:

[0041] (1) Preparation of raw materials: its mass components are: ethylene-vinyl acetate copolymer: 60 parts...

Embodiment 2

[0049] A foam shaft described in this embodiment includes an outer cladding and an inner lining column, the outer cladding is a hollow cylinder, a groove is provided on the inner side of the outer cladding, the inner lining column is arranged in the groove, and the outer cladding The surface of the layer is provided with a set of buffer zone and massage area, the surface of the buffer zone is circular arc, interval grooves are arranged in the middle, the massage area is provided with staggered massage protruding points, and the shape of the lining column is a hollow cylinder body.

[0050] The massage convex points described in this embodiment are semicircular.

[0051] The lining column described in this embodiment is an EVA hollow tube with both ends sealed.

[0052] A method for processing a foam shaft described in this embodiment comprises the following steps:

[0053] (1) Preparation of raw materials: the mass components are: ethylene-vinyl acetate copolymer: 55 parts, ...

Embodiment 3

[0061] A foam shaft described in this embodiment includes an outer cladding and an inner lining column, the outer cladding is a hollow cylinder, a groove is provided on the inner side of the outer cladding, the inner lining column is arranged in the groove, and the outer cladding There are three groups of buffer zones and massage areas on the surface of the layer. The buffer zone surfaces are circular arcs, with interval grooves in the middle. The massage areas are provided with staggered massage bumps. The shape of the inner lining column is a hollow cylinder. body.

[0062] The massage bumps in this embodiment are in the shape of a truncated cone.

[0063] The lining column described in this embodiment is an EVA hollow tube with both ends sealed.

[0064] A method for processing a foam shaft described in this embodiment comprises the following steps:

[0065] (1) Preparation of raw materials: its mass components are: ethylene-vinyl acetate copolymer: 65 parts, N, N'-dinitr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com