PU foaming shoe material capable of releasing negative ions and preparation method thereof

A technology of negative ions and negative ion additives, applied in footwear, applications, clothing, etc., can solve problems such as poor elasticity, inability to release and release negative ions, and poor balance of low-density mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

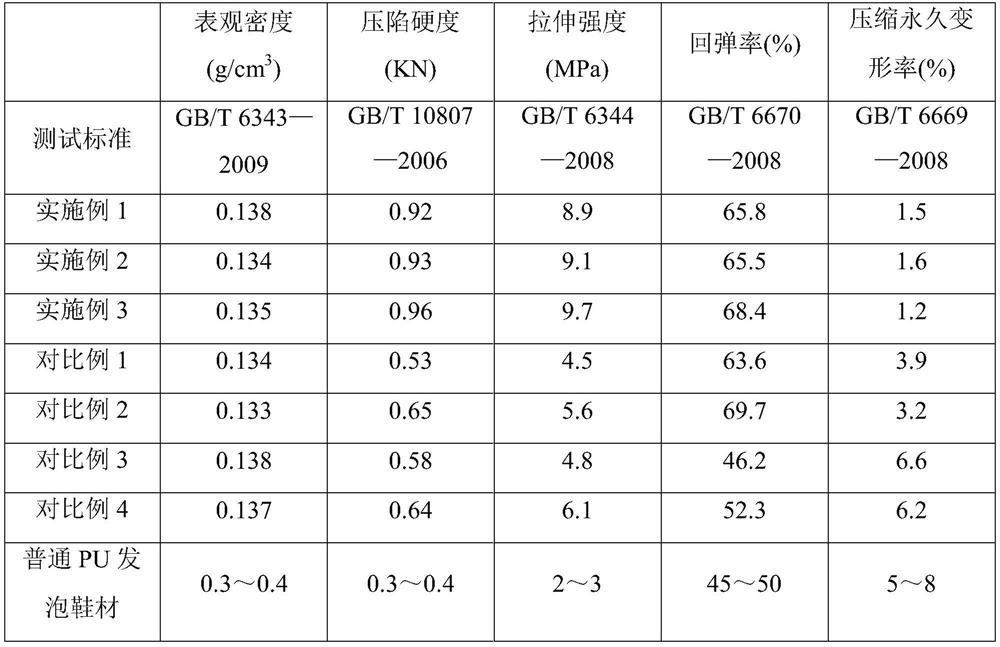

Examples

Embodiment 1

[0070] (1) Mix raw materials into the mixer:

[0071] Step 1: Weigh raw materials: 70 parts of polyester polyurethane, 12 parts of ethylene-vinyl acetate copolymer, 5 parts of styrene-ethylene-butadiene-styrene block copolymer, 4 parts of negative ion additive, 4-methyl 1.2 parts of benzenesulfonyl hydrazide, 0.45 parts of triethylenediamine, 0.08 parts of triallyl isocyanurate, 2 parts of talc powder, 2 parts of titanium dioxide, 1 part of zinc oxide, 2 parts of stearic acid, stearic acid 1.5 parts of zinc, 1.5 parts of anti-sticking agent, 2.5 parts of anti-wear agent, 2 parts of flow aid;

[0072] Wherein, the negative ion additive is a mixture of opal powder and medical stone powder, the particle size of both is preferably 0.4-0.8um, and the weight ratio of the two is 1:0.6; Adhesive;

[0073] Raw materials other than the 4-methylbenzenesulfonyl hydrazide, triethylenediamine, and triallyl isocyanurate are all dropped into an internal mixer and mixed;

[0074] Step 2: He...

Embodiment 2

[0090] (1) Mix raw materials into the mixer:

[0091] Step 1: Weigh raw materials: 80 parts of polyester polyurethane, 16 parts of ethylene-vinyl acetate copolymer, 7 parts of styrene-ethylene-butadiene-styrene block copolymer, 6 parts of negative ion additive, 4-methyl 1.7 parts of benzenesulfonyl hydrazide, 0.55 parts of triethylenediamine, 0.12 parts of triallyl isocyanurate, 3 parts of talc powder, 4 parts of titanium dioxide, 2 parts of zinc oxide, 4 parts of stearic acid, stearic acid 2.7 parts of zinc, 2 parts of anti-sticking agent, 3.5 parts of anti-wear agent, 2.8 parts of flow aid;

[0092] Wherein, the negative ion additive is a mixture of opal powder and medical stone powder, the particle size of both is preferably 0.4-0.8um, and the weight ratio of the two is 1:0.8; the anti-sticking agent is preferably organic silicon anti-sticking agent Adhesive;

[0093] Raw materials other than the 4-methylbenzenesulfonyl hydrazide, triethylenediamine, and triallyl isocyanu...

Embodiment 3

[0110] (1) Mix raw materials into the mixer:

[0111] Step 1: Weigh raw materials: 75 parts of polyester polyurethane, 14 parts of ethylene-vinyl acetate copolymer, 6 parts of styrene-ethylene-butadiene-styrene block copolymer, 5 parts of negative ion additive, 4-methyl 1.4 parts of benzenesulfonyl hydrazide, 0.5 parts of triethylenediamine, 0.11 parts of triallyl isocyanurate, 2.5 parts of talcum powder, 3 parts of titanium dioxide, 1.5 parts of zinc oxide, 3 parts of stearic acid, stearic acid 2.1 parts of zinc, 1.75 parts of anti-sticking agent, 3 parts of anti-wear agent, 2.4 parts of flow aid;

[0112] Wherein, the negative ion additive is a mixture of opal powder and medical stone powder, the particle size of both is preferably 0.4-0.8um, and the weight ratio of the two is 1:0.7; Adhesive;

[0113] Raw materials other than the 4-methylbenzenesulfonyl hydrazide, triethylenediamine, and triallyl isocyanurate are all dropped into an internal mixer and mixed;

[0114] Ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com