Precast dry-mix sprayed concrete

A technology of sprayed concrete and dry mixing, which is applied in the field of building materials, can solve problems such as unstable quality, environmental pollution, and high rebound rate, and achieve the effects of accelerated setting time, good heat resistance, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

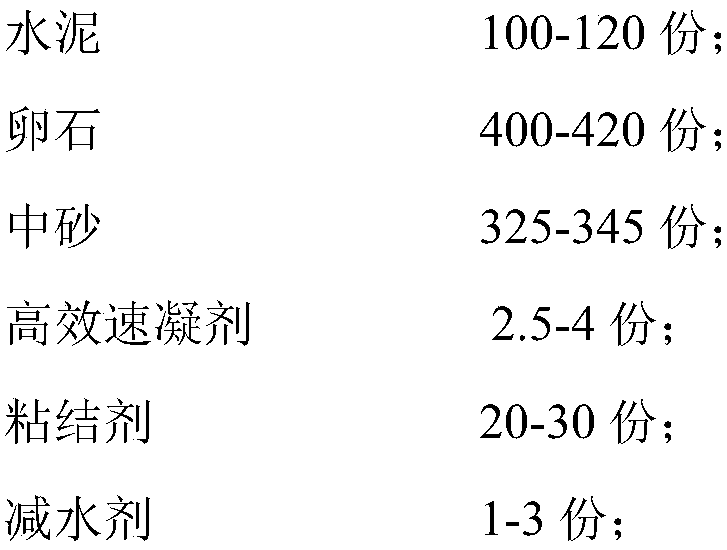

Method used

Image

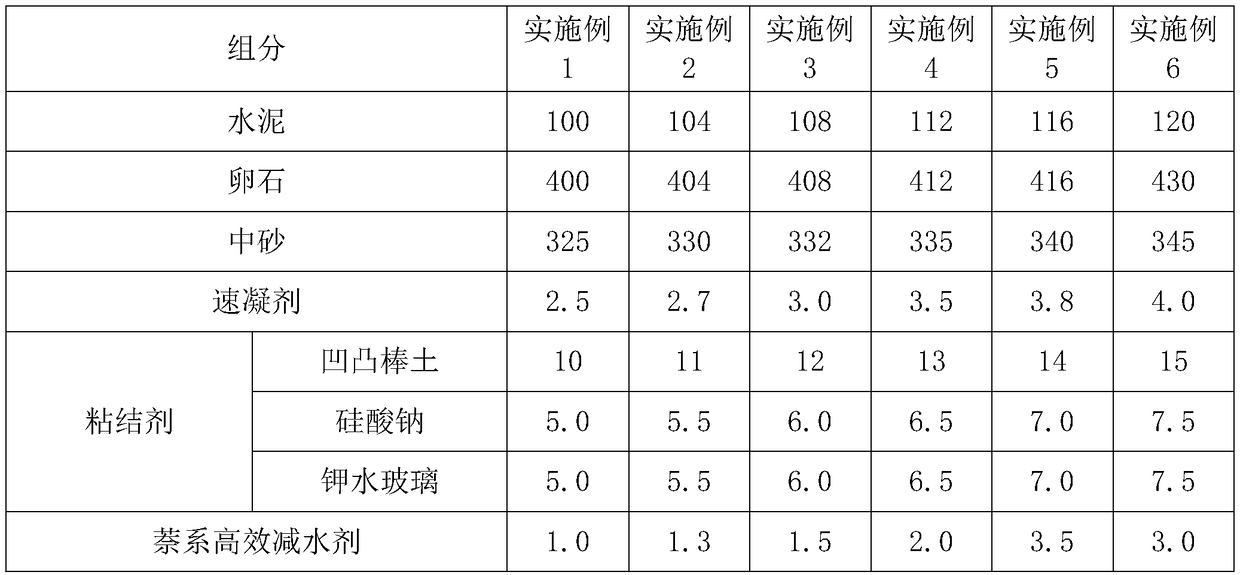

Examples

preparation example 1

[0046] Preparation Example 1: at room temperature, 20kg water and 5kg magnesium fluorosilicate were added to the four-necked flask, after the magnesium fluorosilicate was dissolved, 4kg triethanolamine and 0.5kg lauroyl diethanolamine were added, and the temperature was warming up to 60°C, After stirring at a speed of 200r / min for 15min, then add 55kg of aluminum sulfate, then continue to stir at a speed of 1000r / min for 1.5h; finally add 1kg of sodium ethylenediaminetetramethylene phosphate and stir for 20min to obtain a high-efficiency accelerator.

preparation example 2

[0047] Preparation Example 2: At room temperature, 22.5kg of water and 7.5kg of magnesium fluorosilicate were added to the four-necked flask, after the magnesium fluorosilicate was dissolved, 5kg of triethanolamine and 0.75kg of lauroyl diethanolamine were added, and the temperature was warming up to 75 ℃, after stirring at a speed of 250r / min for 12.5min, then adding 57.5kg of aluminum sulfate, and then continuing to stir at a speed of 1100r / min for 1.25h; finally adding 1.25kg of sodium ethylenediaminetetramethylene phosphate and stirring for 25min to obtain a high-efficiency Accelerator.

preparation example 3

[0048] Preparation example 3: at room temperature, 25kg water and 10kg magnesium fluorosilicate were added to the four-necked flask, after the magnesium fluorosilicate was dissolved, 6kg triethanolamine and 0.8kg lauroyl diethanolamine were added, and the temperature was warming up to 80°C, After stirring at a speed of 300r / min for 10min, then add 60kg of aluminum sulfate, and then continue to stir at a speed of 1200r / min for 1h; finally add 1.5kg of sodium ethylenediaminetetramethylene phosphate and stir for 30min to obtain a high-efficiency accelerator.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com