Playground track material

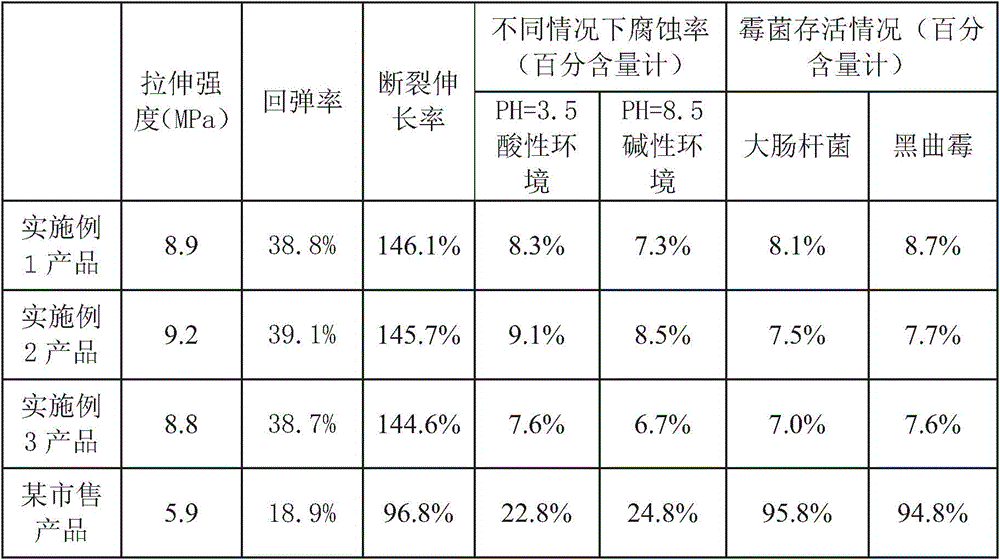

A sports field and track technology, applied in the field of sports track materials, can solve the problems that the rebound rate, tensile strength and elongation at break of the plastic track cannot be completely improved, and restrict the performance of the plastic track, so as to achieve good rebound rate and good performance. The effect of corrosion resistance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The sports field runway material in the present embodiment is made up of the following components in mass parts: 18 parts of octadecyl imidazoline, 20 parts of sodium alkylsulfonate, 16 parts of methyl vinyl silicone rubber powder, 14 parts of acrylate , 20 parts of molybdenum trioxide, 16 parts of tribasic lead sulfate, 14 parts of butadiene rubber powder, 20 parts of bisphenol A diglycidyl ether, 16 parts of metallocene polyethylene, 14 parts of isoprene rubber powder, 20 parts of dioctyl dioate, 16 parts of fluoroether rubber powder, 16 parts of dioctyl terephthalate, 14 parts of ethylene-vinyl acetate copolymer, 20 parts of furan resin, 16 parts of graphite powder, 14 parts of MBS resin powder , 20 parts of hexamethylenetetramine, 16 parts of barium sulfate, 14 parts of wollastonite powder, 20 parts of 2-mercaptobenzimidazole, 16 parts of benzothiazole, and 14 parts of ABS resin powder.

[0025] The molybdenum trioxide is composed of powders with three particle size...

Embodiment 2

[0037] The sports field track material in the present embodiment is made up of the following components in mass parts: 20 parts of octadecyl imidazoline, 22 parts of sodium alkylsulfonate, 18 parts of methyl vinyl silicone rubber powder, 16 parts of acrylate , 22 parts of molybdenum trioxide, 18 parts of tribasic lead sulfate, 16 parts of butadiene rubber powder, 22 parts of bisphenol A diglycidyl ether, 18 parts of metallocene polyethylene, 16 parts of isoprene rubber powder, 22 parts of dioctyl dioate, 18 parts of fluoroether rubber powder, 18 parts of dioctyl terephthalate, 16 parts of ethylene-vinyl acetate copolymer, 22 parts of furan resin, 18 parts of graphite powder, 16 parts of MBS resin powder , 22 parts of hexamethylenetetramine, 18 parts of barium sulfate, 16 parts of wollastonite powder, 22 parts of 2-mercaptobenzimidazole, 18 parts of benzothiazole, and 16 parts of ABS resin powder.

[0038] The molybdenum trioxide is composed of powders with three particle sizes...

Embodiment 3

[0050] The sports field track material in the present embodiment is made up of the following components in mass parts: 22 parts of octadecyl imidazoline, 24 parts of sodium alkylsulfonate, 20 parts of methyl vinyl silicone rubber powder, 18 parts of acrylate 24 parts of molybdenum trioxide, 20 parts of tribasic lead sulfate, 18 parts of butadiene rubber powder, 24 parts of bisphenol A diglycidyl ether, 20 parts of metallocene polyethylene, 18 parts of isoprene rubber powder, 24 parts of dioctyl dioate, 20 parts of fluoroether rubber powder, 20 parts of dioctyl terephthalate, 18 parts of ethylene-vinyl acetate copolymer, 24 parts of furan resin, 20 parts of graphite powder, 18 parts of MBS resin powder , 24 parts of hexamethylenetetramine, 20 parts of barium sulfate, 18 parts of wollastonite powder, 24 parts of 2-mercaptobenzimidazole, 20 parts of benzothiazole, and 18 parts of ABS resin powder.

[0051] The molybdenum trioxide is composed of powders with three particle sizes a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com