A kind of high wear-resistant and high-temperature resistant rubber and its preparation method

A technology of high temperature resistance and high wear resistance, applied in the field of high wear resistance and high temperature resistance rubber and its preparation, can solve the problems of short service life, high cost and poor performance of the sealing ring, and achieve low production cost, high production efficiency, tearing Excellent crack strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

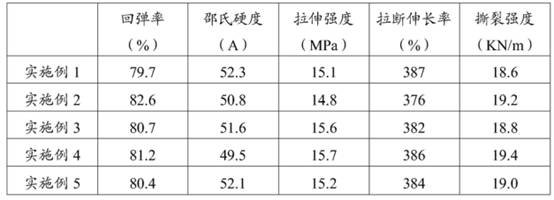

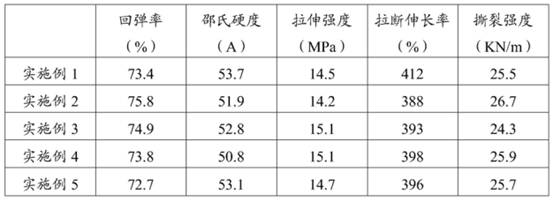

Examples

preparation example Construction

[0035] The present invention also provides a method for preparing the above-mentioned high wear-resistant and high-temperature resistant rubber, comprising the following steps:

[0036] 1) placing EPDM rubber, polyisoprene rubber, and hydroxy-terminated styrene-butadiene rubber in an internal mixer, and masticating at 120° C. to 140° C. for 6 to 8 minutes to obtain masticated rubber;

[0037] 2) adding polyethylene wax, fumed silica, serpentine, microcrystalline cellulose, alcohol ether glycoside, dilauryl thiodipropionate, pitch fiber, palm wax, charcoal to the masticated rubber obtained in step 1) Black, dipentene, anti-aging agent and accelerator, banbury at 80-100°C for 4-6min to obtain mixed rubber;

[0038] 3) adding dipentene and diisopropyl xanthate disulfide to the mixed rubber obtained in step 2), after mixing evenly, putting it into a mold, and molding;

[0039] 4) Put the molded material into the vulcanizer, and the vulcanization temperature is 60~80℃, the vulcani...

Embodiment 1

[0044] The wear-resistant rubber includes the following raw materials by weight: 200 parts of EPDM rubber, 27 parts of polyisoprene rubber, 20 parts of hydroxy-terminated styrene-butadiene rubber, 10 parts of chloroether rubber, 1 part of polyethylene wax, 5 parts of Parts of fumed silica with a particle size of 500-800nm, 24 parts of serpentine with a mesh of 100-200 meshes, 3.7 parts of microcrystalline cellulose, 1.3 parts of alcohol ether glycosides, 3.5 parts of pitch fibers, 1.6 parts of diisodisulfide Propyl xanthate, 0.5 part of dilauryl thiodipropionate, 4 parts of palm wax, 20 parts of carbon black N220 with a particle size of 200-400 nm, 1 part of dipentene and 0.7 part of antioxidant NBC.

[0045] The preparation method of wear-resistant rubber includes the following steps:

[0046] 1) placing EPDM rubber, polyisoprene rubber, and hydroxy-terminated styrene-butadiene rubber in an internal mixer, and masticating at 120° C. for 8 min to obtain masticated rubber;

[...

Embodiment 2

[0051] The wear-resistant rubber includes the following raw materials in parts by weight: 100 parts of EPDM rubber, 24 parts of polyisoprene rubber, 30 parts of hydroxy-terminated styrene-butadiene rubber, 13 parts of chloroether rubber, 1.4 parts of polyethylene wax, 7 parts of Parts of fumed silica with a particle size of 500 to 800 nm, 26 parts of serpentine with a mesh of 100 to 200, 3.4 parts of microcrystalline cellulose, 2 parts of alcohol ether glycosides, 4 parts of pitch fiber, 1 part of diisodisulfide Propyl xanthate, 0.3 part of dilauryl thiodipropionate, 5 parts of palm wax, 26 parts of carbon black N550 with a particle size of 200-400 nm, 1.4 parts of dipentene and 0.8 part of antioxidant MB.

[0052] The preparation method of wear-resistant rubber includes the following steps:

[0053] 1) placing EPDM rubber, polyisoprene rubber, and hydroxy-terminated styrene-butadiene rubber in an internal mixer, and masticating at 140° C. for 8 min to obtain masticated rubber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com