Ultrahigh-elasticity material and preparation method and application thereof

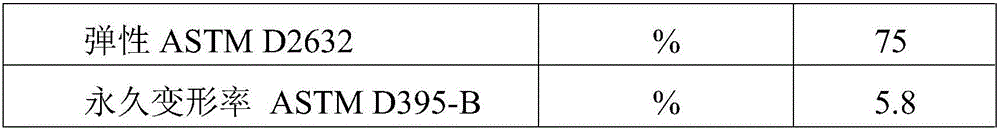

A kind of elastic material and ultra-high technology, applied in the field of ultra-high elastic material and its preparation, can solve the problem of low rebound rate and achieve the effect of high rebound rate, large support force and high elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

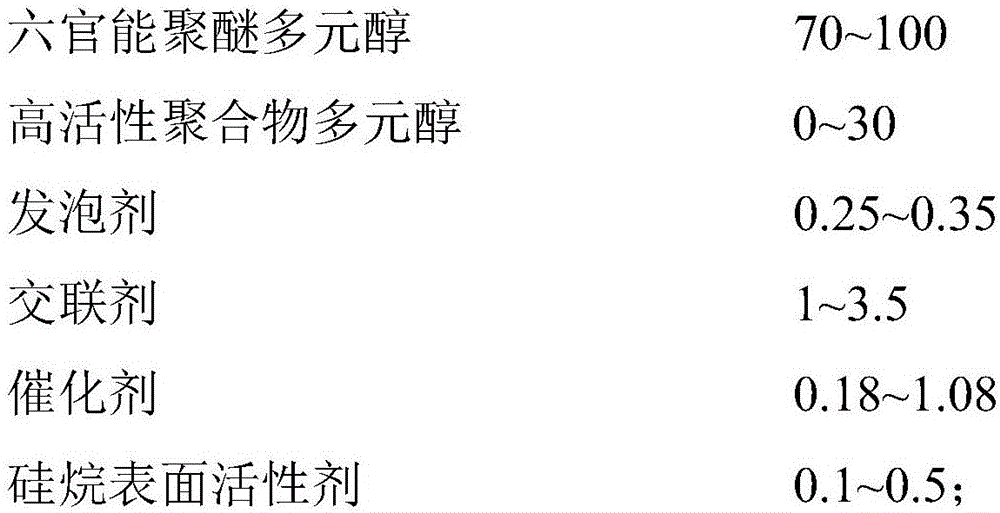

Method used

Image

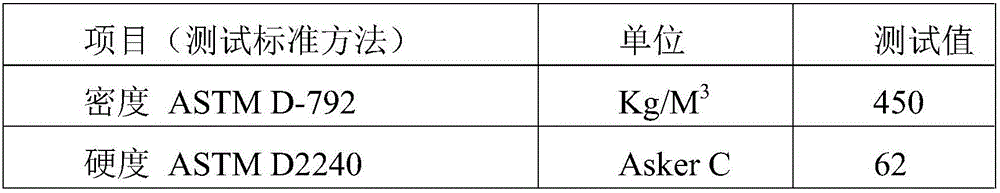

Examples

Embodiment 1

[0044] A method for preparing an ultra-high elastic material, comprising the steps of:

[0045] (1) 100 parts by weight of hexafunctional polyether polyol (molecular weight 12000, CHE-628 of Jiangsu Changhua Polyurethane Technology Co., Ltd.), 0.1 parts by weight of L3002, 2 parts by weight of triethanolamine, 0.5 parts by weight of diethanolamine, 0.5 parts by weight of triethylenediamine, 0.08 parts by weight of bis(2-dimethylaminoethyl) ether and 0.35 parts by weight of water are uniformly mixed to obtain material A; the material A also includes a colorant; the stirred material A Keep in a constant temperature room at 25°C;

[0046] (2) Prepolymer of A material and 30% polyether polyol modified diphenylmethane diisocyanate by A material weight (this prepolymer is through preheating, and the temperature of preheating is 23 ℃; The The NCO percentage of the prepolymer is 20%) and stir and mix until uniform (time 20s), the speed of stirring and mixing is 300r / min, then pour it...

Embodiment 2

[0050] A method for preparing an ultra-high elastic material, comprising the steps of:

[0051] (1) 90 parts by weight of hexafunctional polyether polyol (molecular weight 12000, CHE-628 of Jiangsu Changhua Polyurethane Technology Co., Ltd.), 10 parts by weight of CHP-H45, 0.3 parts by weight of L3002, 1.5 parts by weight of three Ethanolamine, 1.5 parts by weight of diethanolamine, 0.4 parts by weight of triethylenediamine, 0.05 parts by weight of bis(2-dimethylaminoethyl) ether and 0.3 parts by weight of water are uniformly mixed to obtain material A; Color material; the stirred material A is kept in a constant temperature room at 25°C;

[0052] (2) Prepolymer of A material and 32% polyether modified diphenylmethane diisocyanate by A material weight (this prepolymer is through preheat treatment, and the temperature of preheat treatment is 23 ℃; The prepolymer The percentage of NCO in the body is 20%) and stir and mix until uniform (time 25s), the speed of stirring and mixin...

Embodiment 3

[0056] A method for preparing an ultra-high elastic material, comprising the steps of:

[0057] (1) 80 parts by weight of hexafunctional polyether polyol (molecular weight 12000, CHE-628 of Jiangsu Changhua Polyurethane Technology Co., Ltd.), 20 parts by weight of CHP-H45, 0.45 parts by weight of L3002, 1.5 parts by weight of three Ethanolamine, 1.5 parts by weight of diethanolamine, 0.3 parts by weight of triethylenediamine, 0.05 parts by weight of bis(2-dimethylaminoethyl) ether and 0.28 parts by weight of water are uniformly mixed to obtain material A; Color material; the stirred material A is kept in a constant temperature room at 25°C;

[0058] (2) Prepolymer of A material and 32% polyether modified diphenylmethane diisocyanate by A material weight (this prepolymer is through preheat treatment, and the temperature of preheat treatment is 23 ℃; The prepolymer The NCO percentage of the body is 20%) and stir until uniform (time 28s), the speed of stirring and mixing is 600r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| resilience | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com