Environment-protection type high-performance automobile braking piece and making method

A high-performance, brake pad technology, applied in the direction of mechanical equipment, friction linings, etc., can solve problems such as the decrease of friction coefficient, affecting driving safety, and braking torque decline, and achieve the goals of reducing production costs, purifying the environment, and improving friction performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

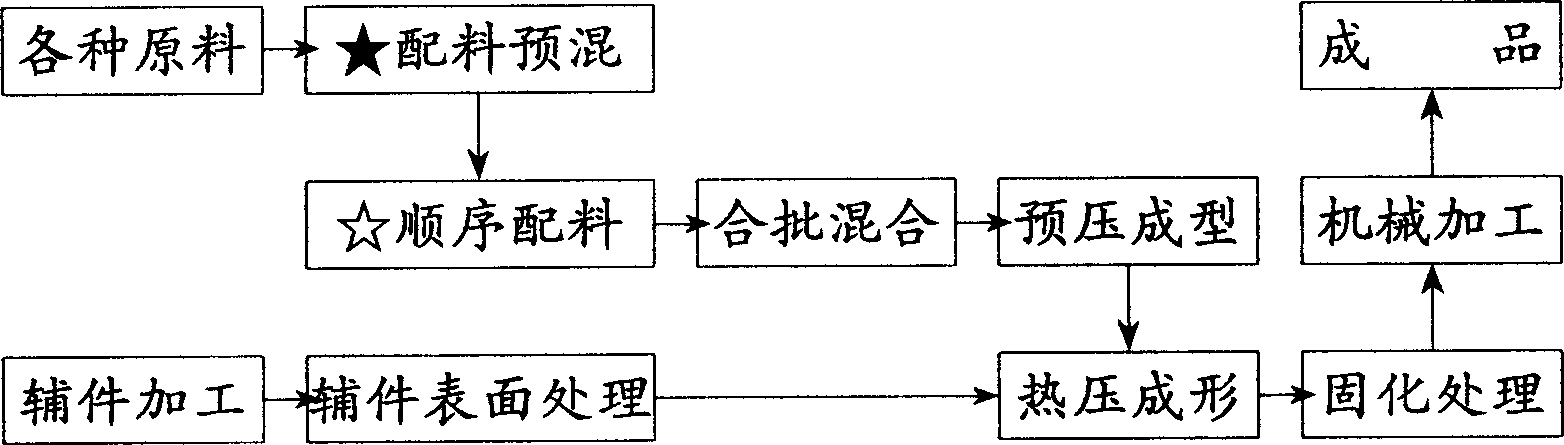

Method used

Image

Examples

Embodiment Construction

[0044] A: Examples of Changan passenger car disc brake pads:

[0045] ①According to the following formula ingredients:

[0046] Phenolic resin 9%; steel fiber 12%; brass fiber 5%; copper fiber 3%; aramid fiber 3%; glass fiber 5%; silica fume 6%; artificial graphite 5%; natural graphite 5%; ferrochrome 8% ore; 8% pyrite; 5% magnetite; 4% antimony sulfide; 10% barium sulfate; 5% dolomite; 3% calcium fluoride; 4% kaolin;

[0047] ② Use a vertical mixer for mixing to ensure that the ingredients are evenly distributed;

[0048] ③Use a hot press and specific tooling and molds to place the mixture in a mold according to a certain weight and press it into shape;

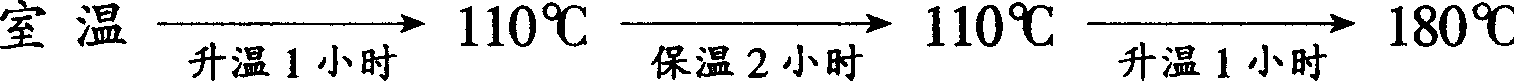

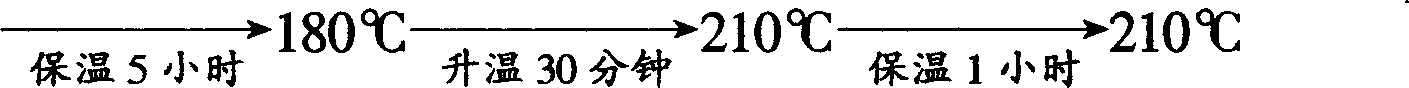

[0049] ④ Use a high-power oven to cure the phenolic resin;

[0050] ⑤ Carry out follow-up machining on the heat-treated product according to the drawing requirements;

[0051] ⑥ Packing and storage.

[0052] B: Example of Dongfeng Motor EQ153 drum brake pad

[0053] ① Formula:

[0054] Phenolic resin 15%; steel fiber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com