Composite water-soluble temporary plugging agent for oilfield steering fracturing construction

A water-soluble, temporary plugging agent technology, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems that it is difficult to increase the degree of reservoir production and cannot open new fractures, so as to prolong the shielding time and prevent Desorption and destabilization, enhanced stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

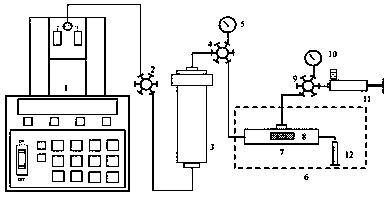

Method used

Image

Examples

Embodiment 1

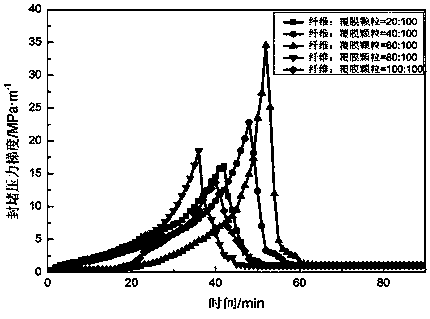

[0022] Embodiment 1 prepares composite water-soluble temporary plugging agent

[0023] The composition of the raw materials in the proportion by weight is as follows: 53.6 parts of the coating material, 29.7 parts of the temporary plugging particles, and 16.7 parts of the temporary plugging fibers.

[0024] The coating material is sodium polyacrylate. The temporary plugging particles are sea salt particles with a particle diameter of 3 mm to 4 mm. The temporary plugging fibers are polyvinyl alcohol fibers with a length of 6 mm and a diameter of 10 μm.

[0025] The preparation method is as follows: firstly uniformly coat the coating material on the surface of the temporary plugging particles to form coating particles, and then mix the temporary plugging fibers and the coating particles evenly to obtain the product.

Embodiment 2

[0026] Embodiment 2 prepares composite water-soluble temporary plugging agent

[0027] The composition of the raw materials in the proportion by weight is as follows: 45.9 parts of the coating material, 25.5 parts of the temporary plugging particles, and 28.6 parts of the temporary plugging fibers.

[0028] The coating material is sodium polyacrylate. The temporary plugging particles are sea salt particles with a particle diameter of 3 mm to 4 mm. The temporary plugging fibers are polyvinyl alcohol fibers with a length of 6 mm and a diameter of 10 μm.

[0029] The preparation method is the same as in Example 1.

Embodiment 3

[0030] Embodiment 3 prepares composite water-soluble temporary plugging agent

[0031] The composition of the raw materials in the proportion by weight is as follows: 40.2 parts of the coating material, 22.3 parts of the temporary plugging particles, and 37.5 parts of the temporary plugging fibers.

[0032] The coating material is sodium polyacrylate. The temporary plugging particles are sea salt particles with a particle diameter of 3 mm to 4 mm. The temporary plugging fibers are polyvinyl alcohol fibers with a length of 6 mm and a diameter of 10 μm.

[0033] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com