Screened sealing material without asbestos fiber and its prepn process

A non-asbestos fiber, sealing material technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of human body and environmental hazards, high weight gain and thickening, oil resistance, and high temperature resistance of sealing materials. Achieve good tensile strength and high oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

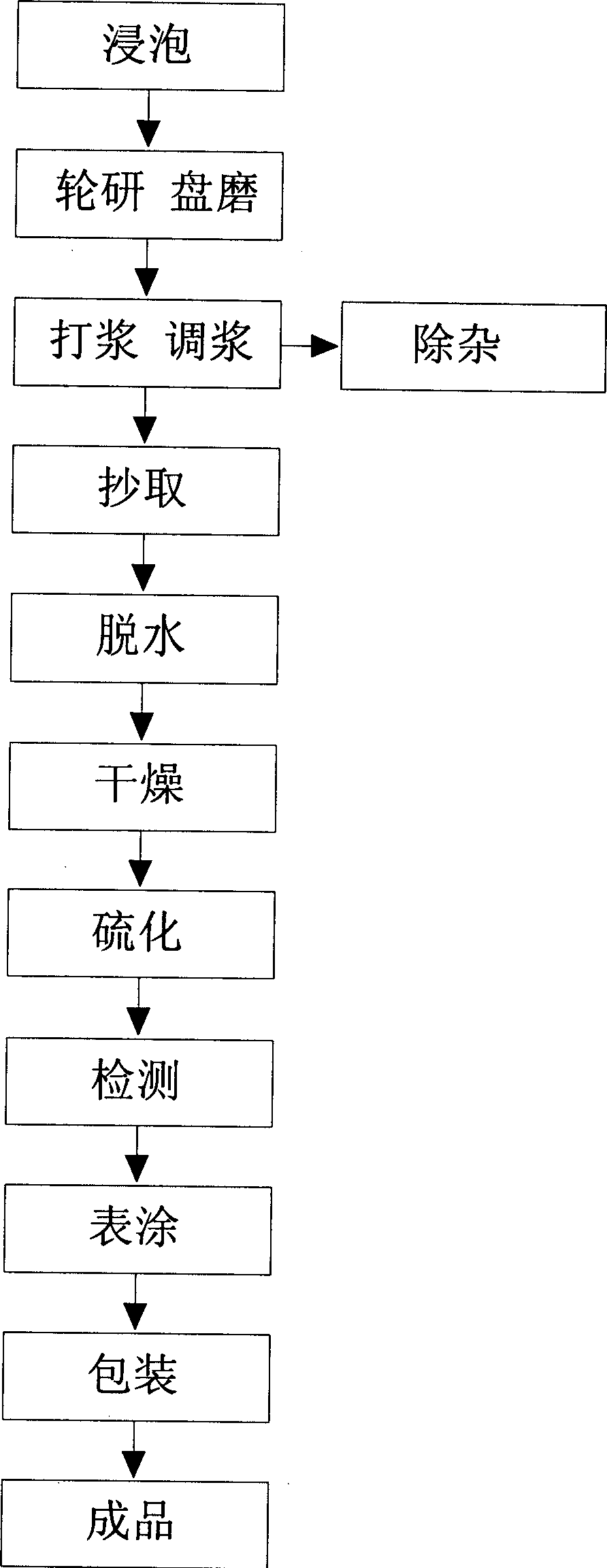

Image

Examples

Embodiment 1

[0037] The drawing sealing material (A) of non-asbestos fiber of the present invention mainly is made up of following each component and its weight percent distribution ratio is as follows:

[0038] Fiber 30wt%

[0039] Filler 50wt%

[0040] Binder 5wt%

[0041] Latex 8wt%

[0042] Compounding agent 7wt%

[0043] The manufacturing process adopted by the sealing material (A):

[0044] Calculate the actual composition of each tank according to the above formula ratio, and soak the calculated weight fibers, including mineral wool fibers, chopped glass fibers, ceramic fibers, chemical synthetic fibers, cellulose fibers, etc., in the organic chemical solution After soaking, loosen, remove impurities, and open in a beater and a grinding disc, so that the degree of percussion of various fibers can reach more than 75-80, and the concentration of the slurry is 2-8%. Then, fillers (graphite powder, clay powder, calcium carbonate, mica powder, kaolin powder, attapulgite powder, bent...

Embodiment 2

[0051]The drawing sealing material (B) of non-asbestos fiber of the present invention mainly is made up of following each component and its weight percent distribution ratio is as follows:

[0052] Fiber 40wt%

[0053] Filler 40wt%

[0054] Binder 5wt%

[0055] Latex 8wt%

[0056] Compounding agent 7wt%

[0057] Auxiliary 0.32wt% (added by dry glue)

[0058] Calculate the actual composition of each tank according to the above formula ratio, and soak the calculated weight fibers, including mineral wool fibers, chopped glass fibers, ceramic fibers, chemical synthetic fibers, cellulose fibers, etc., in the organic chemical solution After soaking, loosen, remove impurities, and open in a beater and a grinding disc, so that the degree of percussion of various fibers can reach more than 75-80, and the concentration of the slurry is 2-8%. Then, fillers (graphite powder, clay powder, calcium carbonate, mica powder, kaolin powder, attapulgite powder, bentonite, etc.) are added to ...

Embodiment 3

[0067] The drawing sealing material (C) of non-asbestos fiber of the present invention mainly is made up of following each component and its weight percent distribution ratio is as follows:

[0068] Fiber 40wt%

[0069] Filler 30wt%

[0070] Binder 8wt%

[0071] Latex 14wt%

[0072] Compounding agent 8wt%

[0073] Auxiliary 9wt% (plus)

[0074] The manufacturing process adopted by the asbestos-free fiber-free sealing material (C):

[0075] Calculate the feeding amount of the actual composition of each pool according to the above formula ratio, and soak the calculated weight fibers, including mineral wool fibers, chopped glass fibers, ceramic fibers, chemical synthetic fibers, cellulose fibers, etc., in the organic solution, and then Loosen, remove impurities, and open in the beater and grinding disc, so that the beating degree of various fibers can reach more than 75-80, and the concentration of the slurry is 2-8%. Then, fillers (graphite powder, clay powder, calcium car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Deformation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com