Nano-calcium carbonate modification method and application of nano-calcium carbonate to PVC (polyvinyl chloride) wood-plastic plate

A technology of nano-calcium carbonate and calcium carbonate, which is applied in the field of calcium carbonate, can solve problems such as easy agglomeration, and achieve the effects of improving interface adhesion, good stability, and improving flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

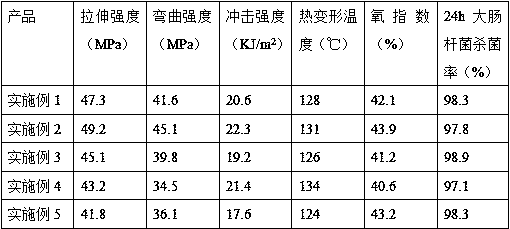

Examples

Embodiment 1

[0035] A kind of modified nano-calcium carbonate for PVC wood-plastic plate, the preparation of described modified nano-calcium carbonate comprises the steps:

[0036](1) Put quicklime and 60°C hot water into the digestion reactor according to the mass ratio of 1:5 to carry out digestion reaction, remove impurities, stand and age for 48 hours, and dilute to a specific gravity of 1.070 to obtain lime emulsion;

[0037] (2) Transport the lime emulsion to the carbonation reaction tower, feed carbon dioxide for carbonization reaction, add crystal form control agent and dispersant during the carbonization process, carbonize to pH 7, stop feeding carbon dioxide, and control calcium carbonate The specific surface area is 22.8m 2 / g, get nano-calcium carbonate slurry; Described crystal formation control agent is made up of phytic acid and disodium ethylenediamine tetraacetate that mass ratio is 2:1, and its add-on is 0.9% of calcium carbonate dry basis weight; Described dispersant is...

Embodiment 2

[0047] A kind of modified nano-calcium carbonate for PVC wood-plastic plate, the preparation of described modified nano-calcium carbonate comprises the steps:

[0048] (1) Put quicklime and 50°C hot water into the digestion reactor according to the mass ratio of 1:6 to carry out digestion reaction, remove impurities, stand and age for 36 hours, and dilute to a specific gravity of 1.065 to obtain lime emulsion;

[0049] (2) Transport the lime emulsion to the carbonation reaction tower, feed carbon dioxide for carbonization reaction, add crystal form control agent and dispersant during the carbonization process, carbonize to pH 6.5, stop feeding carbon dioxide, and control the calcium carbonate The specific surface area is 28.1m 2 / g, get nano-calcium carbonate slurry; Described crystal formation control agent is made up of phytic acid and edetate disodium that mass ratio is 1:1, and its add-on is 1.5% of calcium carbonate dry basis weight; Described dispersant is made up of po...

Embodiment 3

[0059] A kind of modified nano-calcium carbonate for PVC wood-plastic plate, the preparation of described modified nano-calcium carbonate comprises the steps:

[0060] (1) Put quicklime and 65°C hot water into the digestion reactor according to the mass ratio of 1:4 to carry out digestion reaction, remove impurities, stand and age for 24 hours, and dilute to a specific gravity of 1.070 to obtain lime emulsion;

[0061] (2) Transport the lime emulsion to the carbonation reaction tower, feed carbon dioxide for carbonization reaction, add crystal form control agent and dispersant during the carbonization process, carbonize to pH 7.5, stop feeding carbon dioxide, and control calcium carbonate The specific surface area is 20.6m 2 / g, get nano-calcium carbonate slurry; Described crystal formation control agent is made up of phytic acid and edetate disodium that mass ratio is 2:1, and its add-on is 1.2% of calcium carbonate dry basis weight; Described dispersant is made up of polyox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com