Patents

Literature

56 results about "Chlorinated solvent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

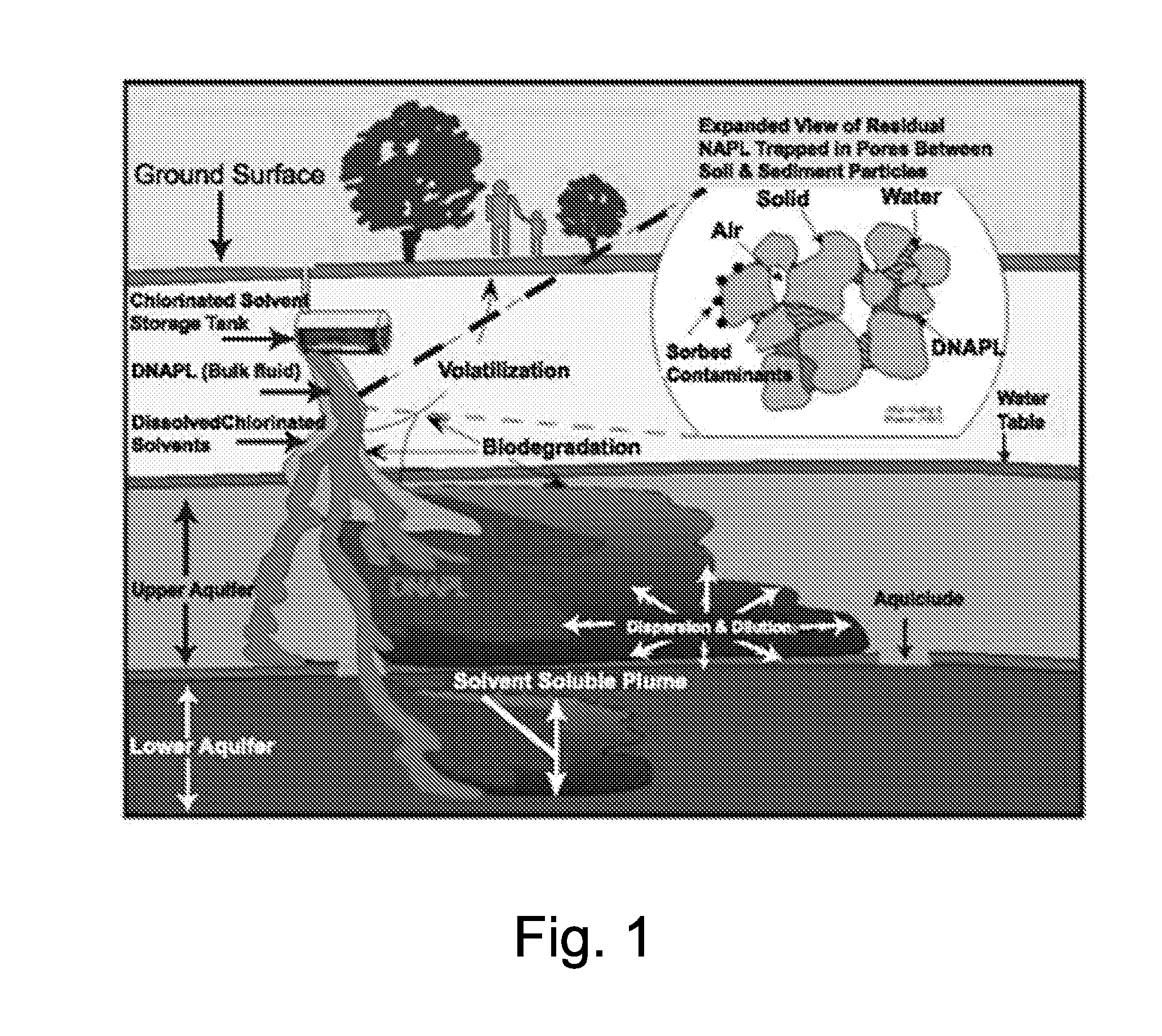

Chlorinated Solvents Chlorinated solvents are a large family of chemical compounds that contain chlorine, for example, carbon tetrachloride (carbon tet), trichloroethylene (TCE), or methylene chloride. They are used for a wide variety of commercial and industrial purposes,...

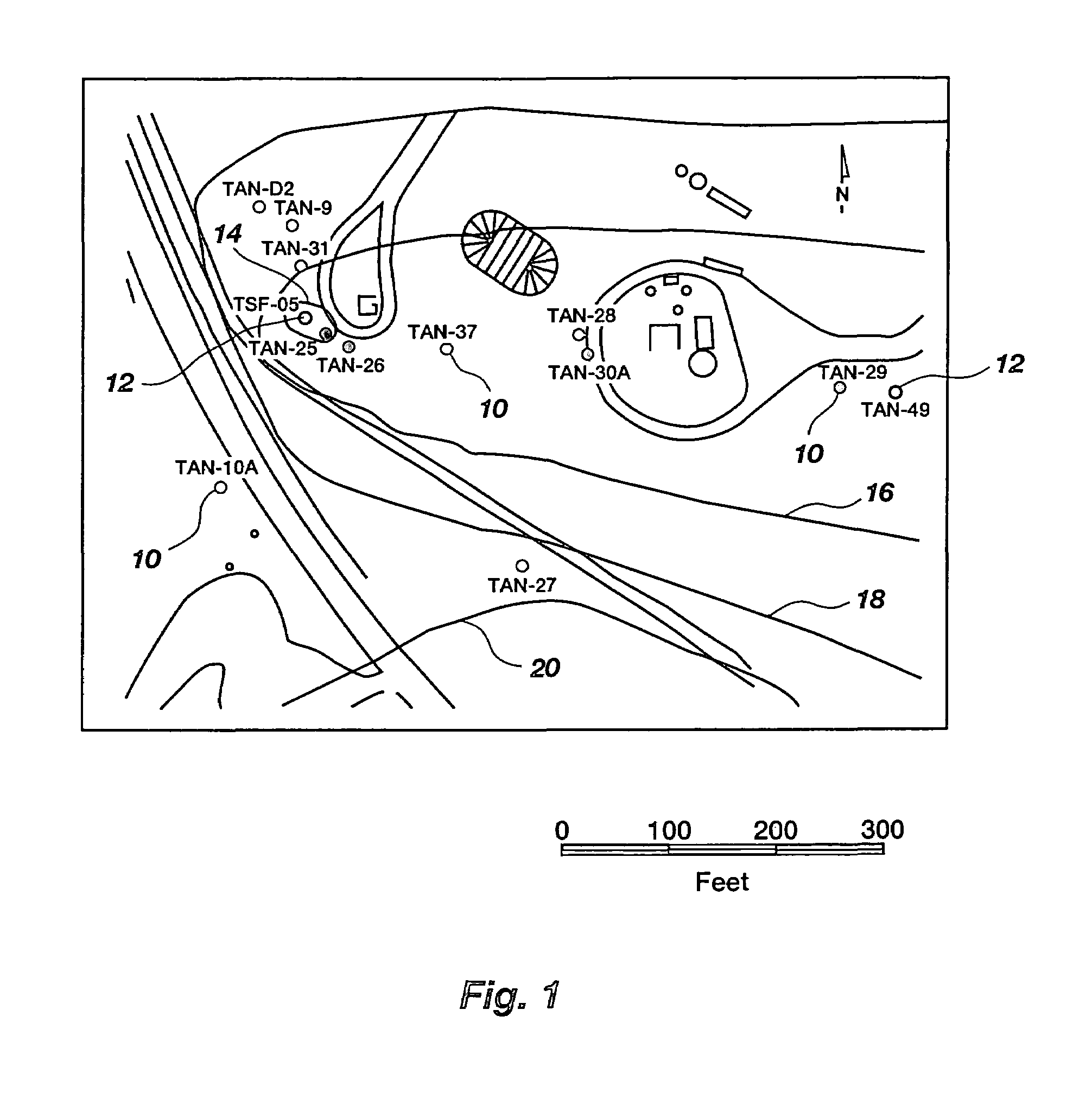

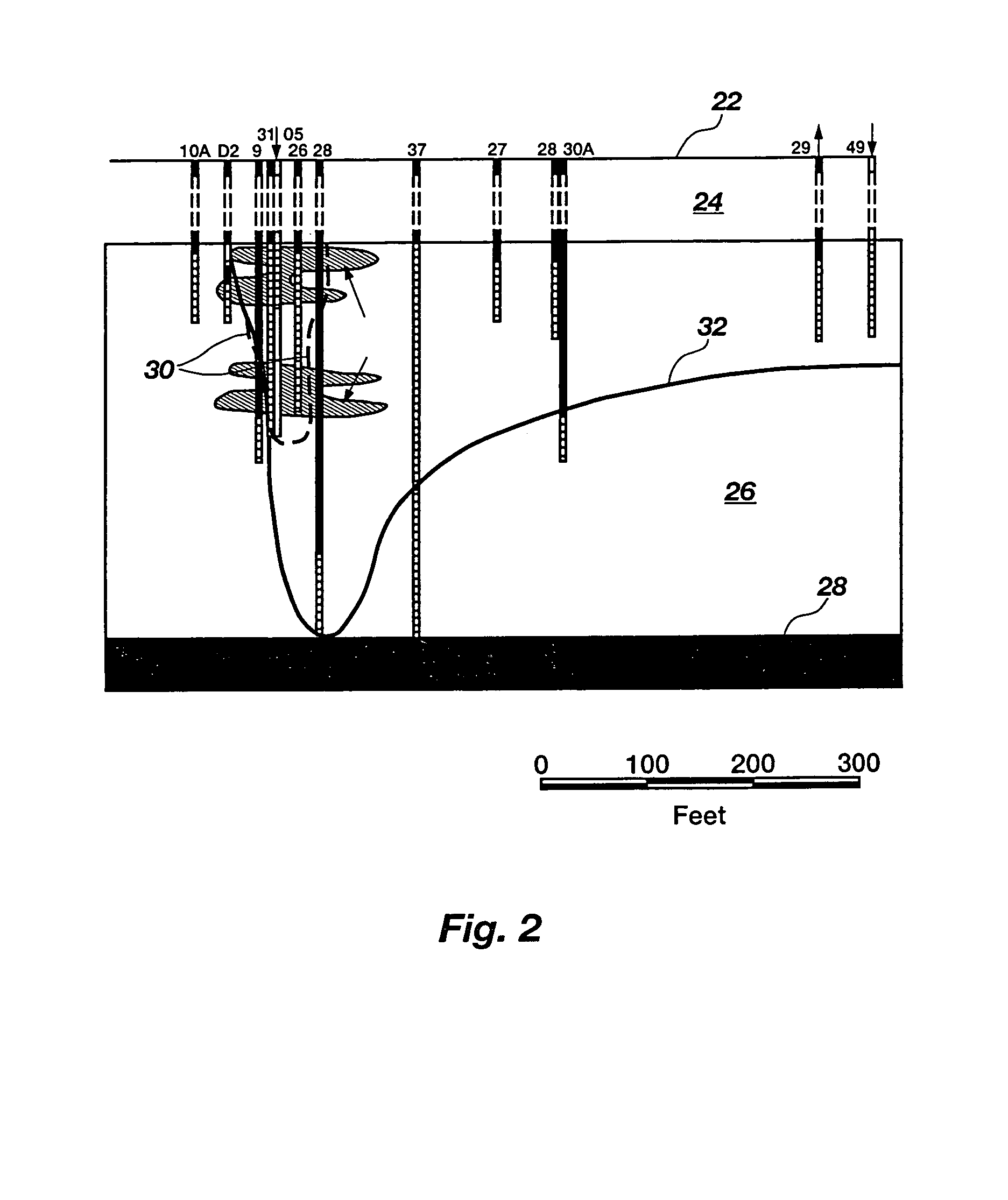

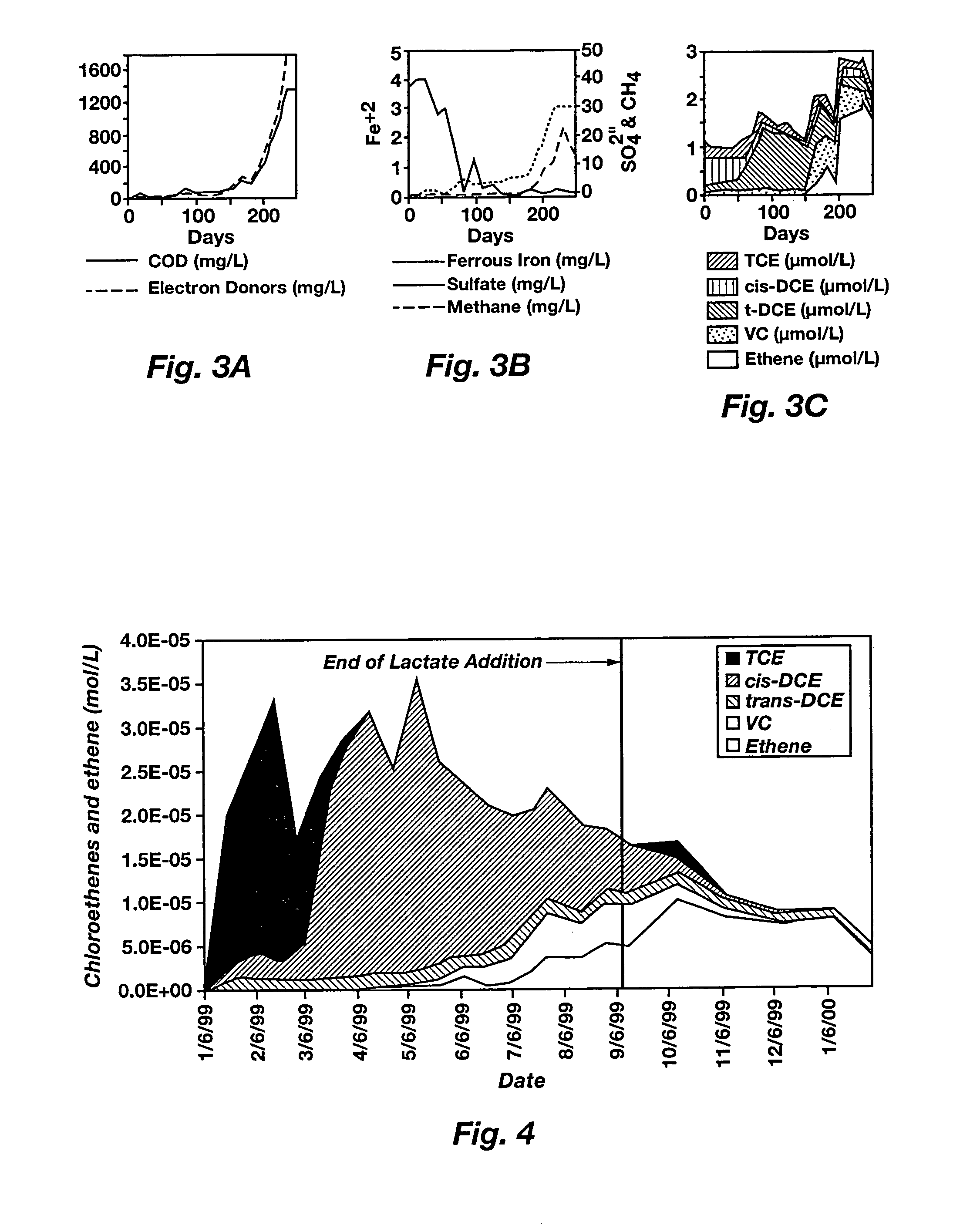

Electron donors for chlorinated solvent source area bioremediation

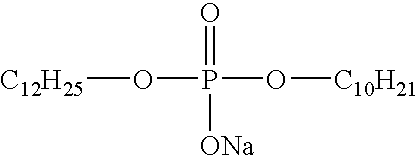

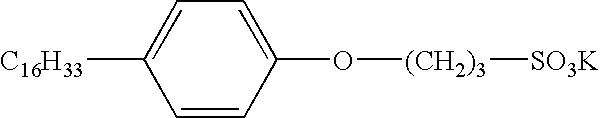

InactiveUS7045339B2Lower cost of capitalQuality improvementTreatment using aerobic processesSolid waste disposalSodium lactateElectron donor

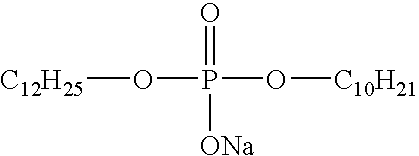

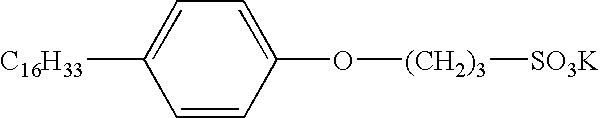

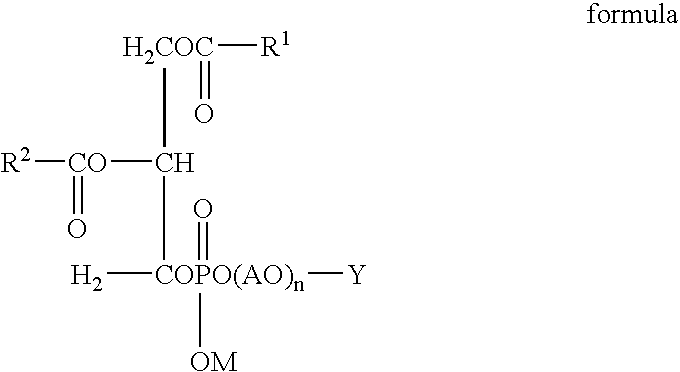

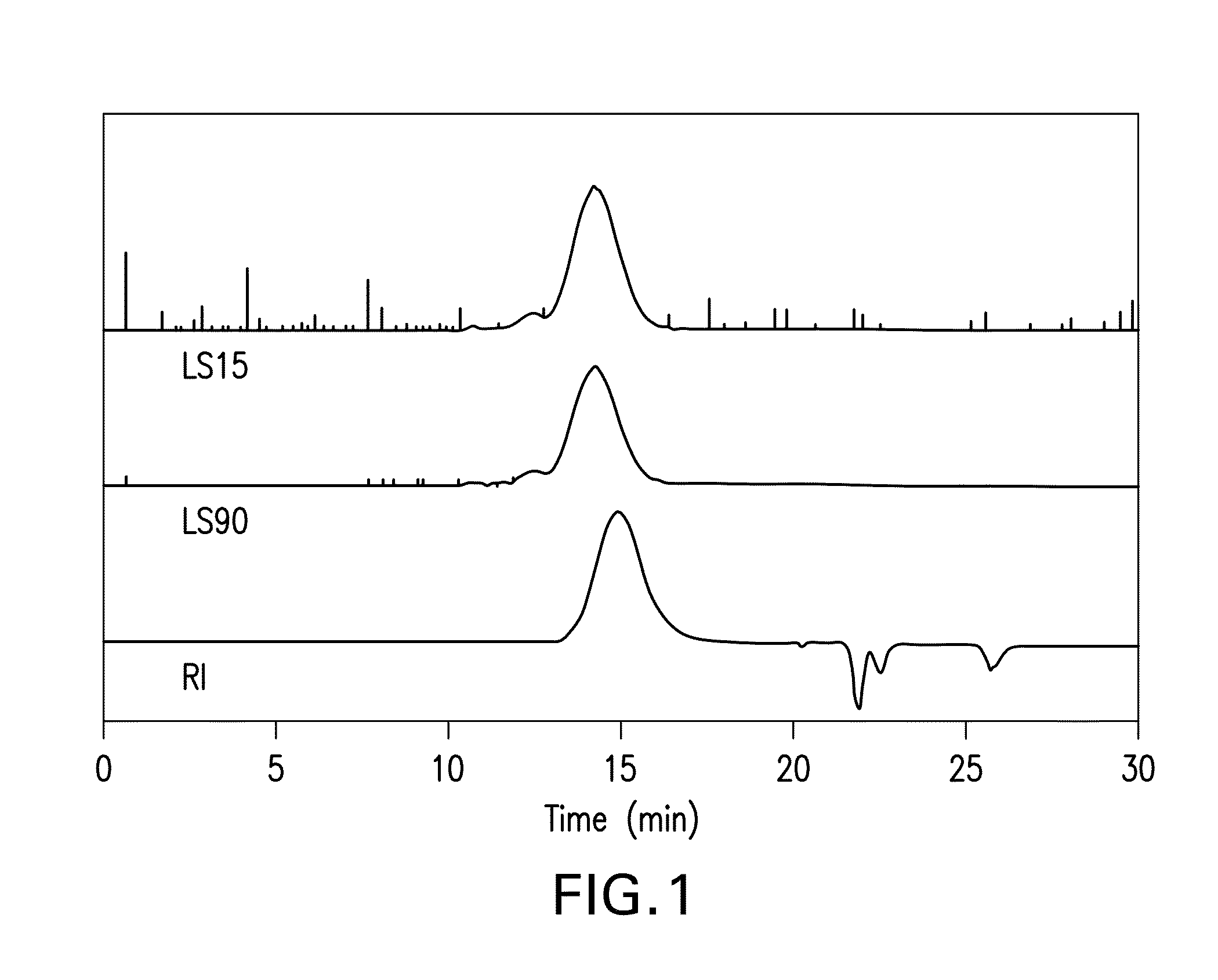

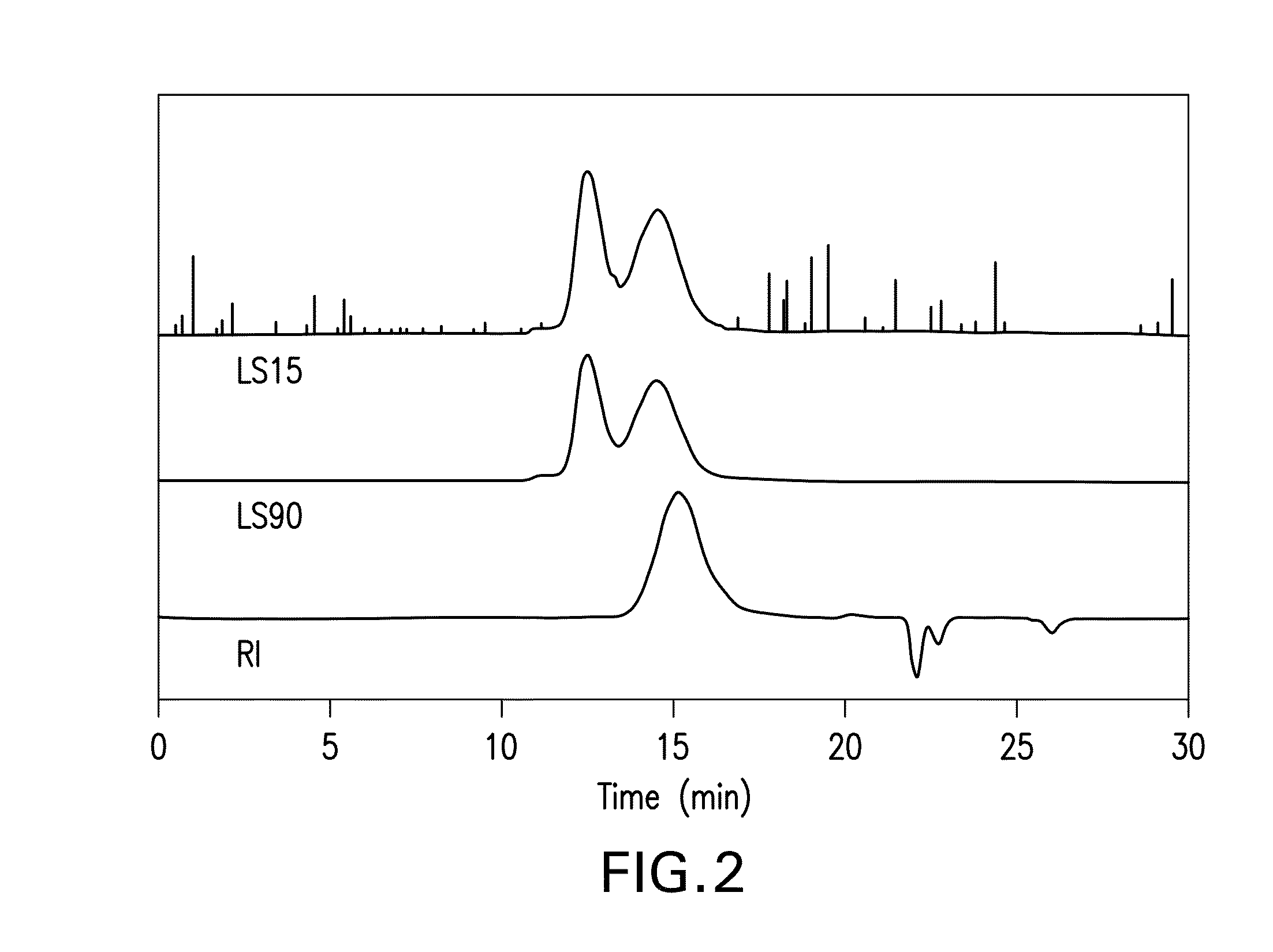

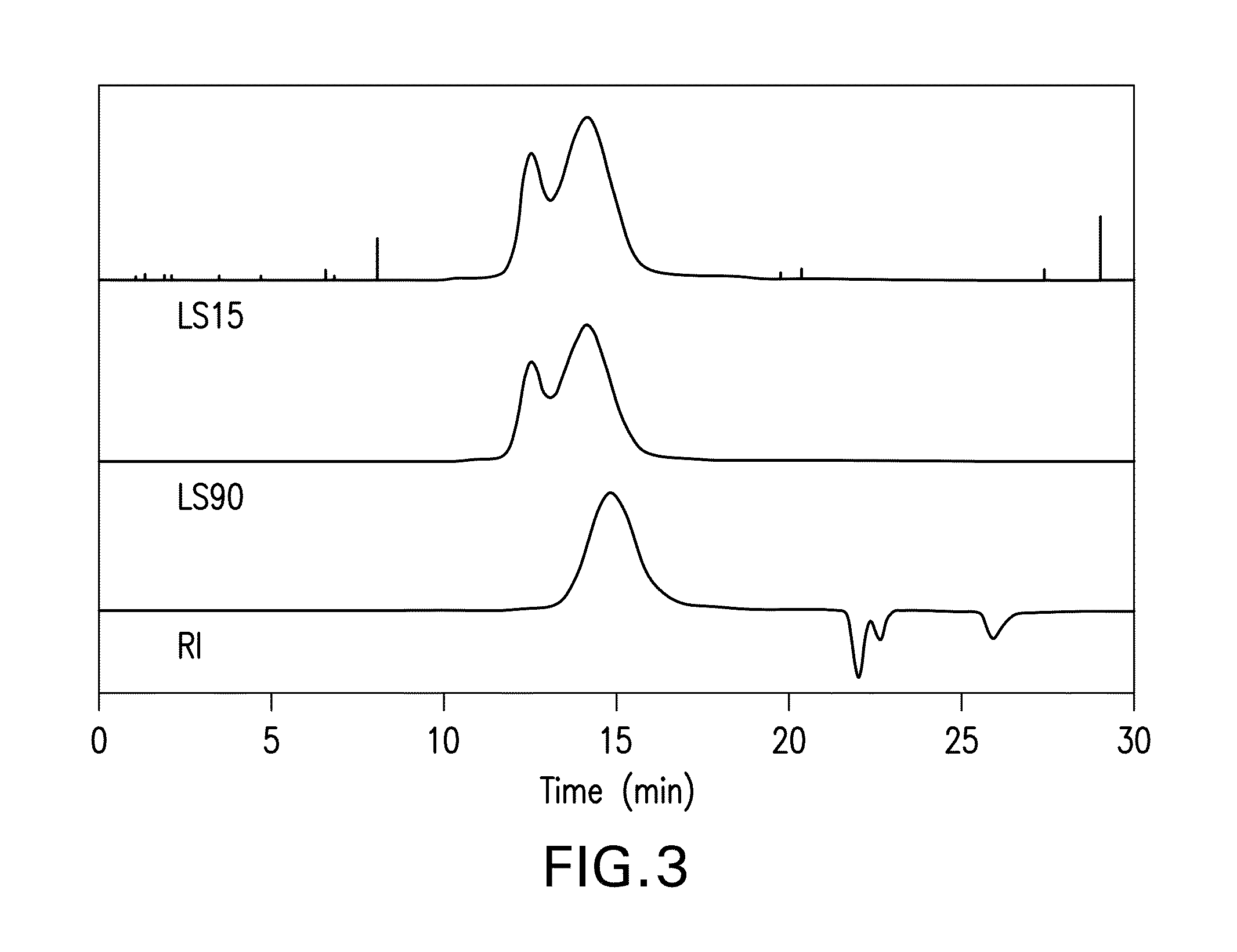

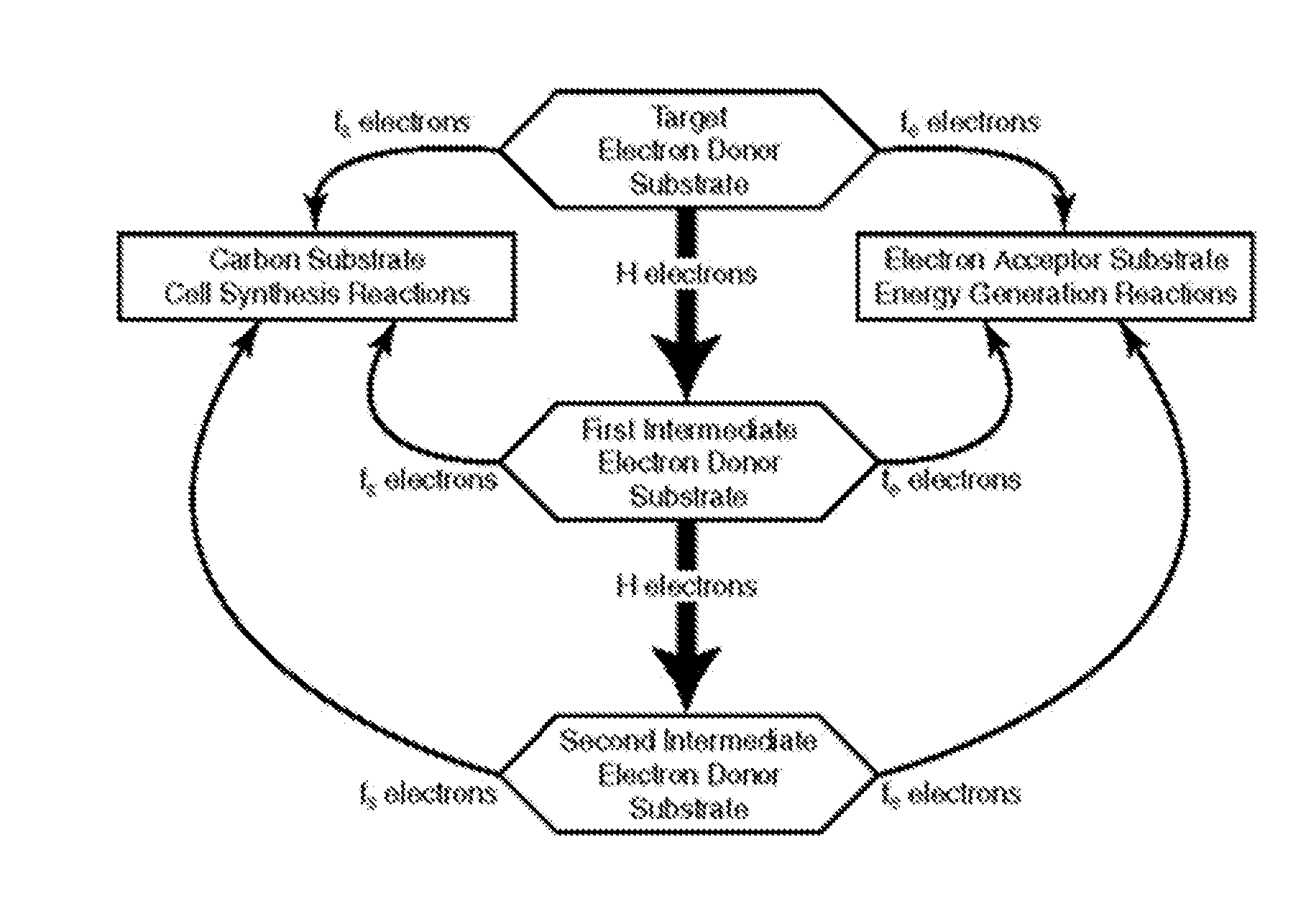

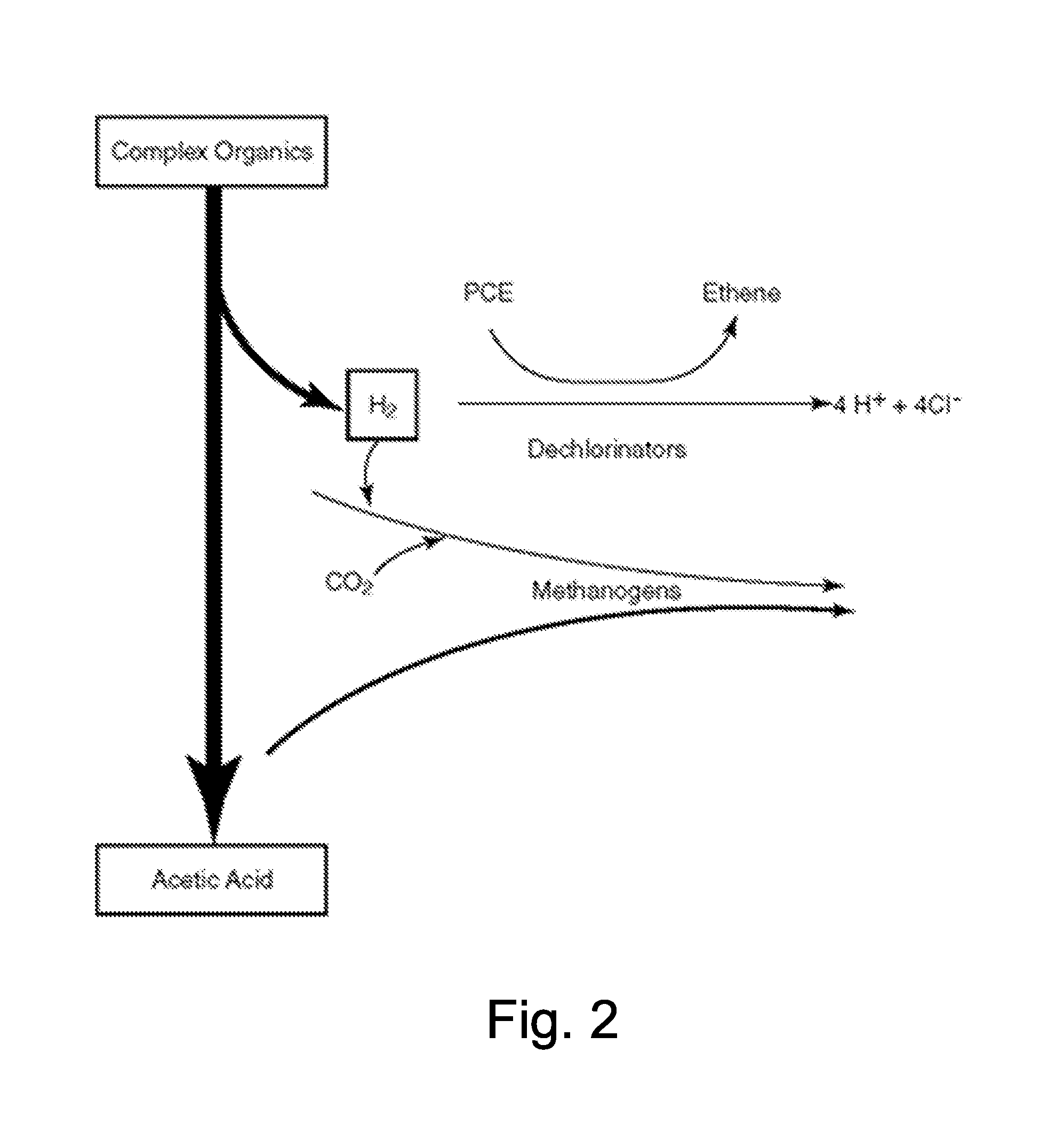

Methods for enhancing bioremediation of ground water contaminated with nonaqueous halogenated solvents are disclosed. An illustrative method includes adding a composition to the ground water wherein the composition is an electron donor for microbe-mediated reductive dehalogenation of the halogenated solvents and enhances mass transfer of the halogenated solvents from residual source areas into the aqueous phase of the ground water. Illustrative compositions effective in these methods include surfactants such as C2–C4 carboxylic acids and hydroxy acids, salts thereof, esters of C2–C4 carboxylic acids and hydroxy acids, and mixtures thereof. Other illustrative compositions according to the present invention include oleyl lactylic acid and, optionally, oleic acid and lactic acid or salts thereof. Especially illustrative compositions for use in these methods include lactic acid, salts of lactic acid, such as sodium lactate, lactate esters, and mixtures thereof. The microbes are either indigenous to the ground water, or such microbes can be added to the ground water in addition to the composition.

Owner:JRW BIOREMEDIATION +1

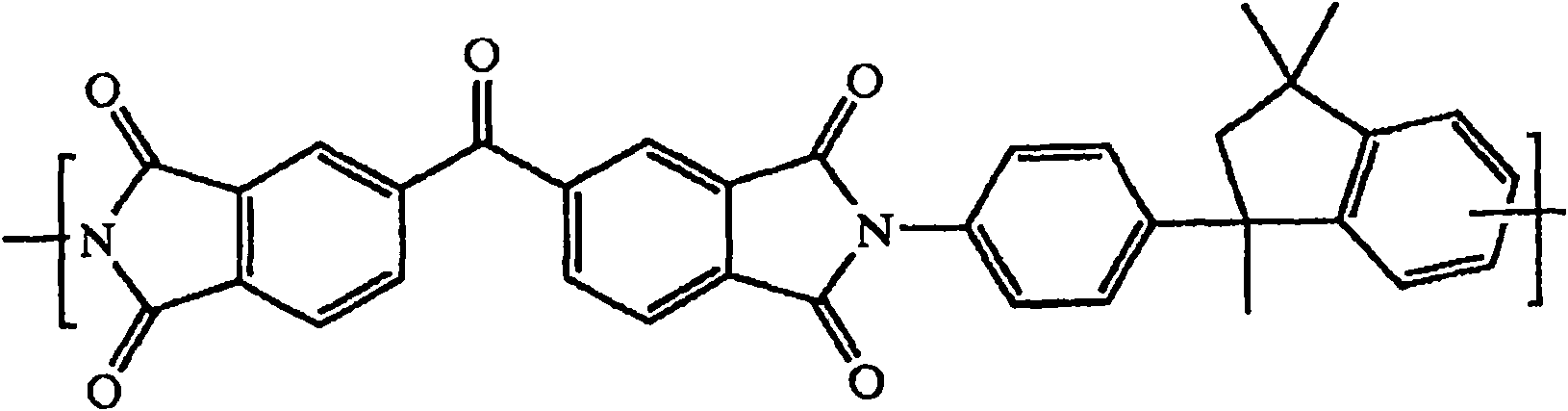

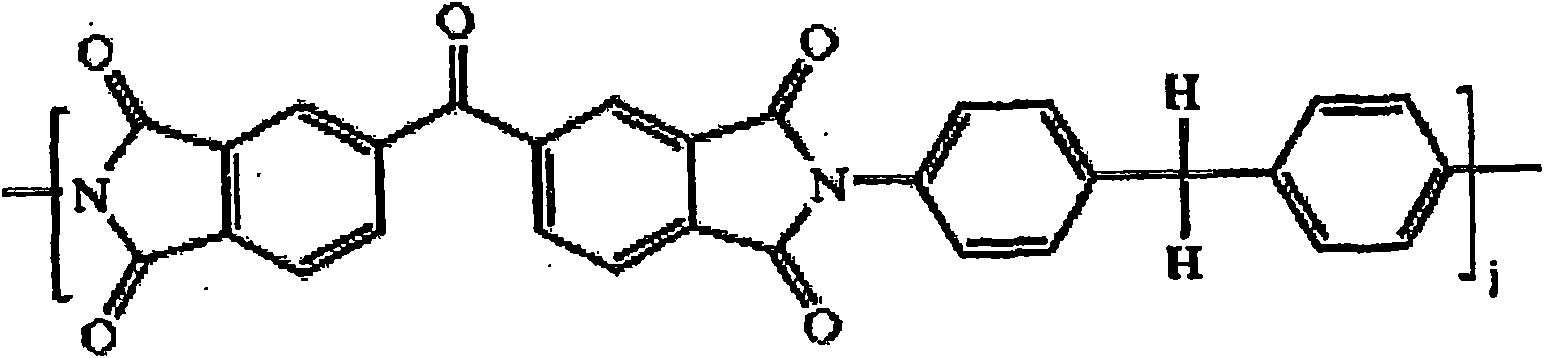

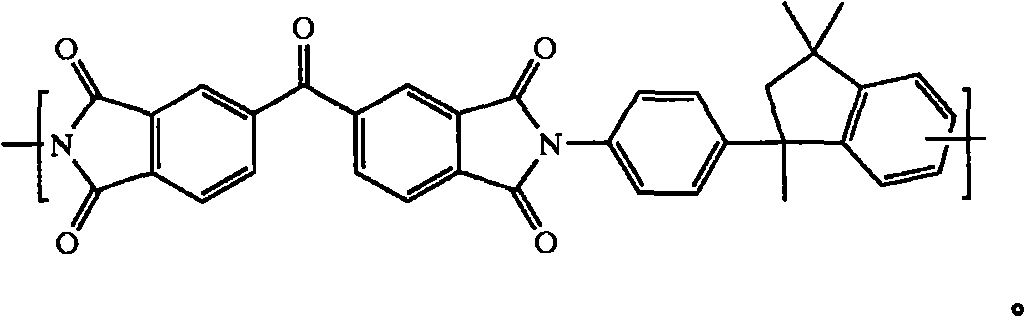

Cross-linked polyimide membranes

InactiveCN101678286AGuaranteed permeabilityGood solvent resistanceMembranesDispersed particle separationCross-linkFiltration

The present invention provides a method for improving the performance of polyimide membranes as used in solvent-resistant nanofiltration. More specifically the method of the present invention allows to imrove the solvent stability of the polyimide membranes to solvents or solvent mixtures that would dissolve polyimide under the conditions applied during the filtration, such as dimethylforrnamide (DMF), N-methylpyrrolidinone (NMP), dimethylacetamide (DMAC), tetrahydrofuran (THF), y-butyrolacton (GBL), dimethylsulphoxide (DMSO) and chlorinated solvents.

Owner:EVONIK FIBERS

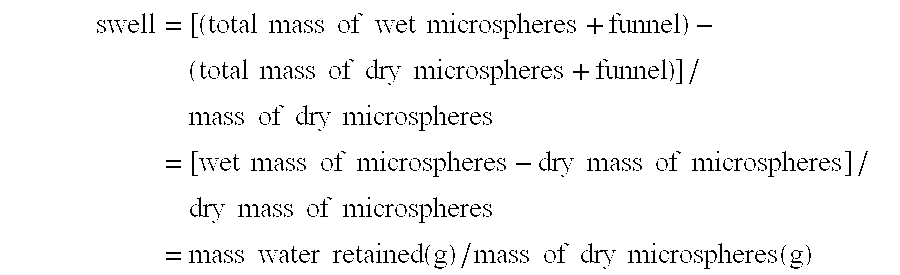

Process for preparation of swellable and degradable microspheres

InactiveUS20090041850A1Satisfies needPowder deliveryIn-vivo radioactive preparationsMicrosphereSolvent

A process for producing microspheres was developed that provides microspheres that are swellable and degradable. The process is reliable and high yielding, and makes use of a low temperature azo initiator, a small molecule chlorinated solvent as the organic phase, and a heat treatment step, and is carried out in absence of a crosslinking agent. The microsphere preparation made using the process is particularly useful as a degradable embolic material.

Owner:EI DU PONT DE NEMOURS & CO

Process for preparation of swellable and degradable microspheres

A process for producing microspheres was developed that provides microspheres that are swellable and degradable. The process is reliable and high yielding, and makes use of a low temperature azo initiator, a small molecule chlorinated solvent as the organic phase, and a heat treatment step, and is carried out in absence of a crosslinking agent. The microsphere preparation made using the process is particularly useful as a degradable embolic material.

Owner:EI DU PONT DE NEMOURS & CO

Solution of cellulose acylate dissolved in mixed solvent of ketone and ester

InactiveUS6914139B2Good storage stabilityEasy to peelPretreatment with water/steamSugar derivativesSolubilityCellulose

In a cellulose acylate solution, cellulose acylate is dissolved in an essentially non-chlorinated solvent. The essentially non-chlorinated solvent is a mixture of a ketone having a solubility parameter of 19 to 21 and an ester having a solubility parameter of 19 to 21. The solution further contains a releasing agent.

Owner:FUJIFILM HLDG CORP +1

A kind of glue spray formula and process

ActiveCN102277130AToxin-freeNo pollution in the processMineral oil hydrocarbon copolymer adhesivesFibre treatmentThermoplastic elastomerAdhesive

The invention, relating to the technical field of chemical spray adhesive, especially relates to a spray adhesive formula and a technology thereof. The spray adhesive comprises the following ingredients: 1-12 wt% of rubber, 1-5 wt% of dispersant, 10-40 wt% of tackifying resin, 10-60 wt% of varsol, 10-55 wt% of chlorinated solvent and 35-70 wt% of propellent. The technology of preparing the spray adhesive comprises the following steps: (1) adding varsol and chlorinated solvent in a stirring tank according to the amount in the formula, starting the stirring tank for stirring; (2) adding SBS thermoplastic elastomer and other rubbers with stirring until the rubbers completely dissolve; (3) then adding rosin and other tackifying resin with stirring until rosin completely dissolves, then addingorganic bentonite dispersant, continuously stirring until organic bentonite completely disappears; and (4) filtering and then canning, and carrying out sealing and then inflating the tank. The spray adhesive has no toxins and no pollution, and can be used on white fabrics without yellowing or blackening with ideal bonding effect.

Owner:吕大洋

Liposome-containing radiographic contrast medium and preparation method thereof

InactiveUS20050084453A1Efficiently conveyedHigh selectivityDispersion deliveryX-ray constrast preparationsRadiographic contrast mediaWater soluble

A radiographic contrast medium is disclosed, comprising a liposome which is comprised of vesicles including a water- and soluble nonionic iodine compound, and the contrast medium containing substantially no chlorinated solvent. There is also disclosed a method of preparing the radiographic contrast medium using supercritical or subcritical carbon dioxide.

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

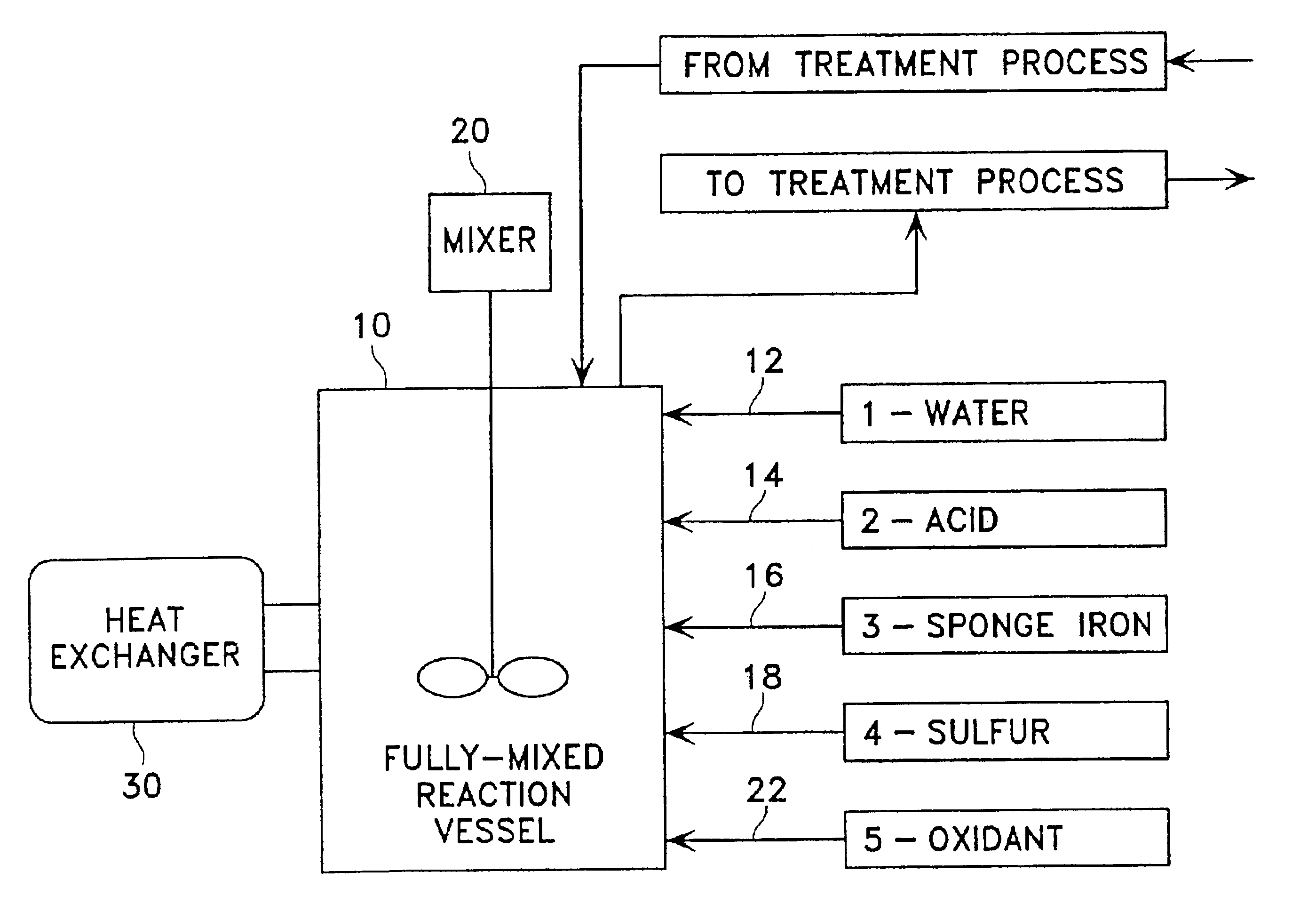

Method for removing toxic substances in water

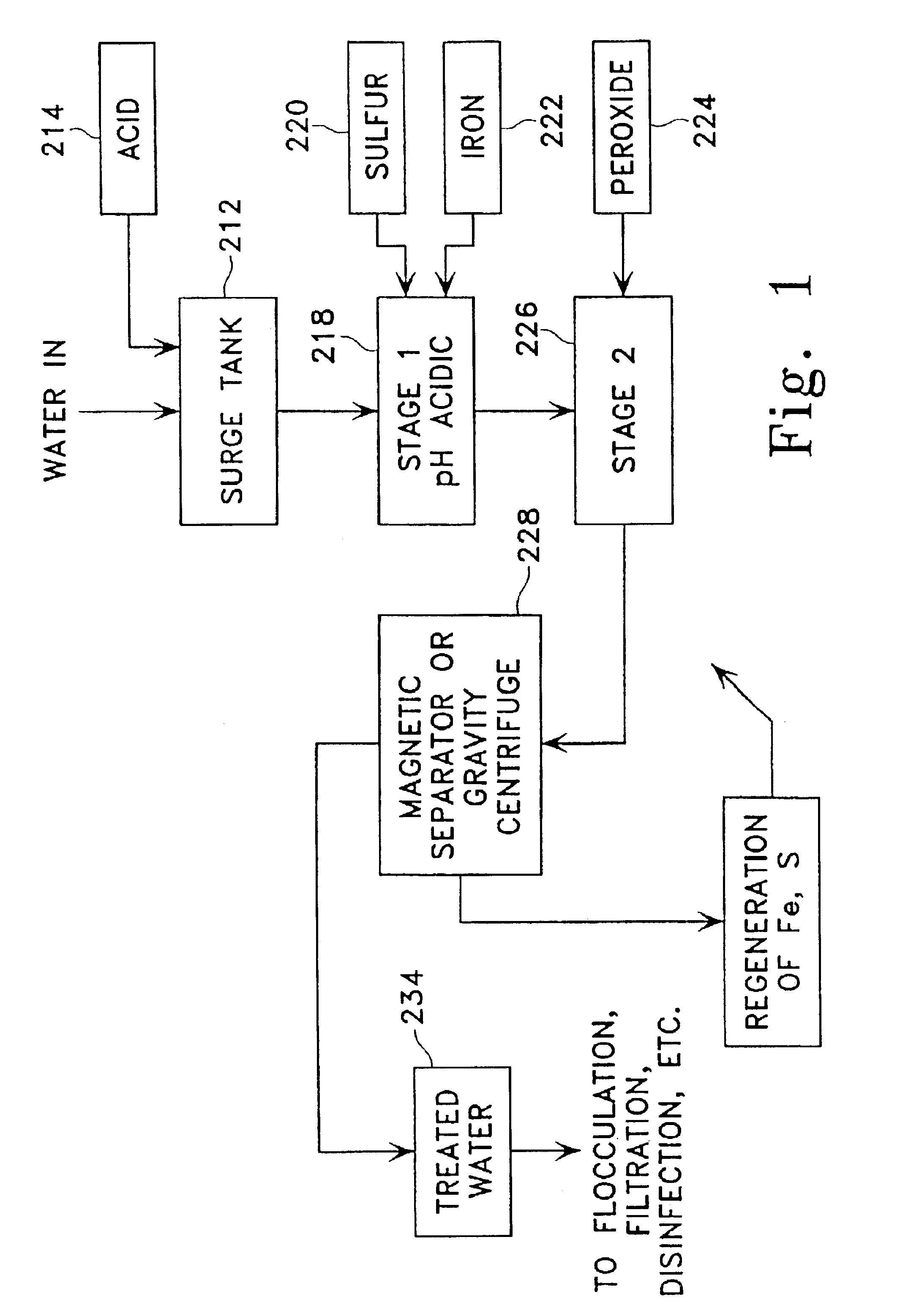

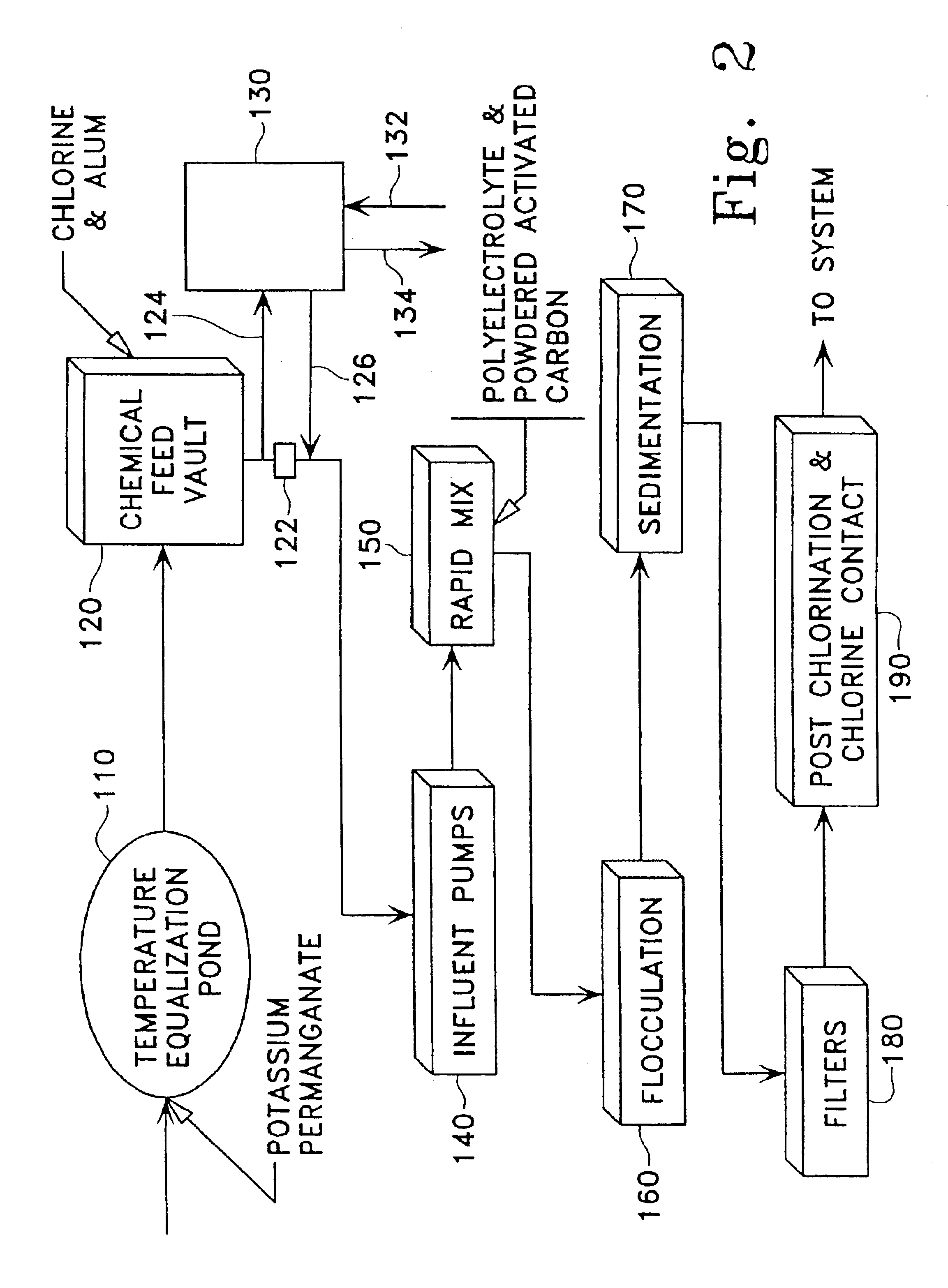

Arsenic and TOC are removed from drinking water or wastewaters by use of finely-divided metallic iron in the presence of powered elemental sulfur or other sulfur compounds such as manganese sulfide, followed by an oxidation step. A premix may be produced for this process, by adding the iron, sulfur and oxidizing agent to water in a predetermined pH range. The iron and sulfur are mixed for a period of time dependent upon the temperature and pH of the water and the presence of complexing or sequestering minerals and organic acids in the water. An oxidizing agent is added to the mixture and agitating is continued. In a preferred embodiment the oxidizing agent is hydrogen peroxide. Water is decanted from the mixture after a sufficient reaction time, to produce a concentrated premix. This premix can be added to water intended for drinking or to industrial effluents containing toxic materials. Use of various gradations and mixtures of this sulfur-modified iron (SMI) premix have been successfully demonstrated to remove the following toxic substances from water: arsenic (arsenite and arsenate); disinfection byproducts and precursors; copper; chrome VI; sulfate; and chlorinated solvents including trichloroethene. Metals removed may be present in the untreated water in either the dissolved state or as a fine particulate. SMI has been fabricated using sulfur in the amount of up to 50% of the weight of the iron. SMI premix has been manufactured using a wetted but non-fluid mix at room temperature and at elevated temperature. SMI has been successfully demonstrated in pressure and gravity contact beds in both upflow and downflow modes. It has been prepared in uniformly-graded media similar in size and gradation to commercially-available filter media. Spent SMI can be recycled as a non-hazardous material as feed material to a steel production facility.

Owner:SANTINA PETER F

Method for accelerated dechlorination of matter

InactiveUS7129388B2Accelerated dechlorinationIncreasing rate of biological mineralizationContaminated soil reclamationSolventAnaerobic microorganisms

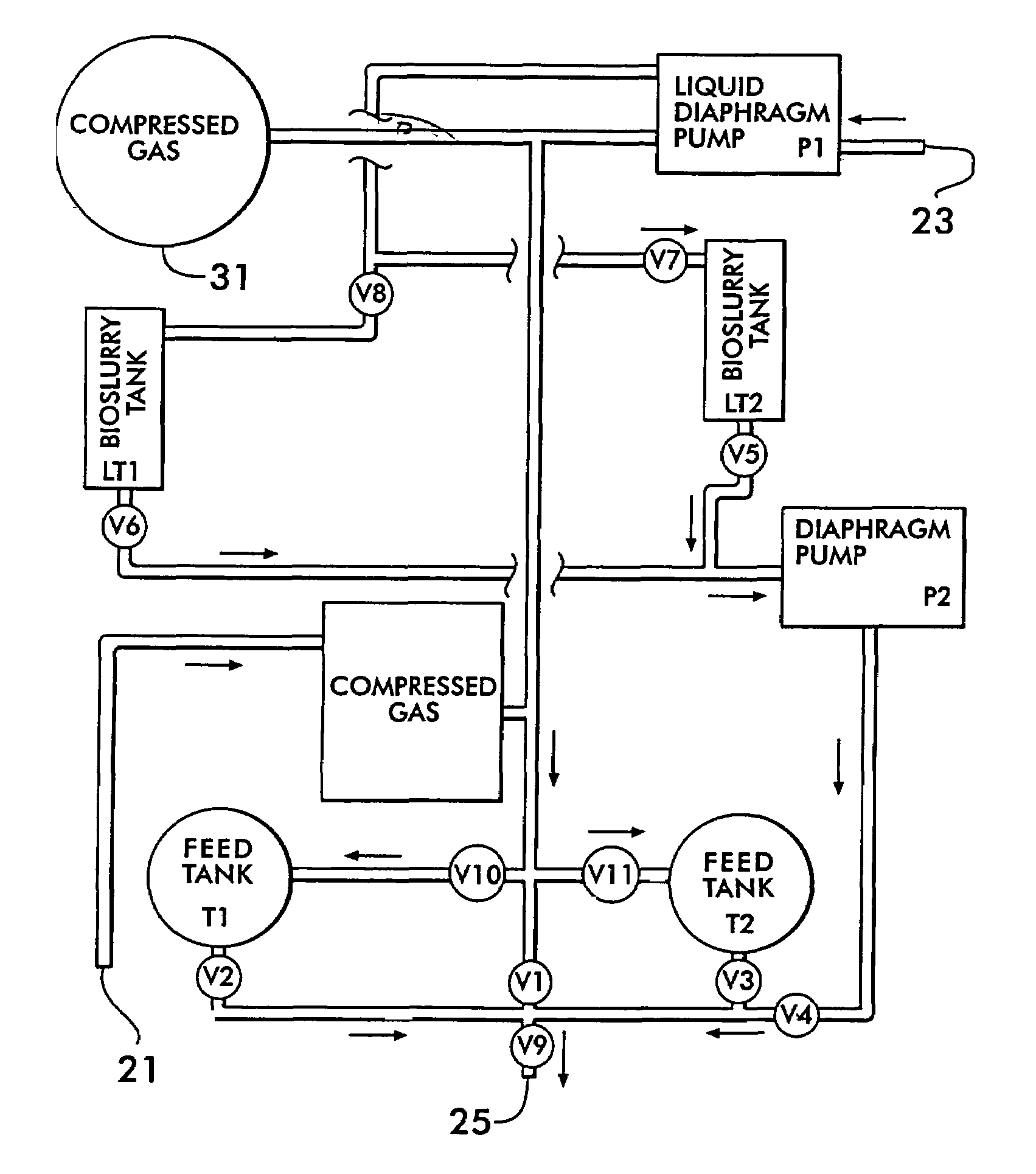

Accelerated dechlorination of soil and water contaminated with chlorinated solvents is achieved by stimulating anaerobic microorganisms and thus increasing the rate of biological mineralization of the solvents. This is accomplished by a treatment process consisting of colloidal suspension of iron powder, polylactate ester such as glycerol tripolylactate, xylitol pentapolylactate, and sorbitol hexapolylactate, chemical oxygen scavengers in solution with essential nutrients, and vitamin stimulants such as B2 and B12 delivered via compressed gases N or C02 so as not to oxygenate an environment targeted for anaerobic processes. The treatment stimulates naturally occurring microorganisms while oxidizing dissolved phase target compounds via the surface action of the iron particles resulting in the breakdown of chlorinated solvents such as tetrachloroethene, trichloroethene, carbon tetrachloride and their daughter products.

Owner:INNOVATIVE ENVIRONMENTAL TECH

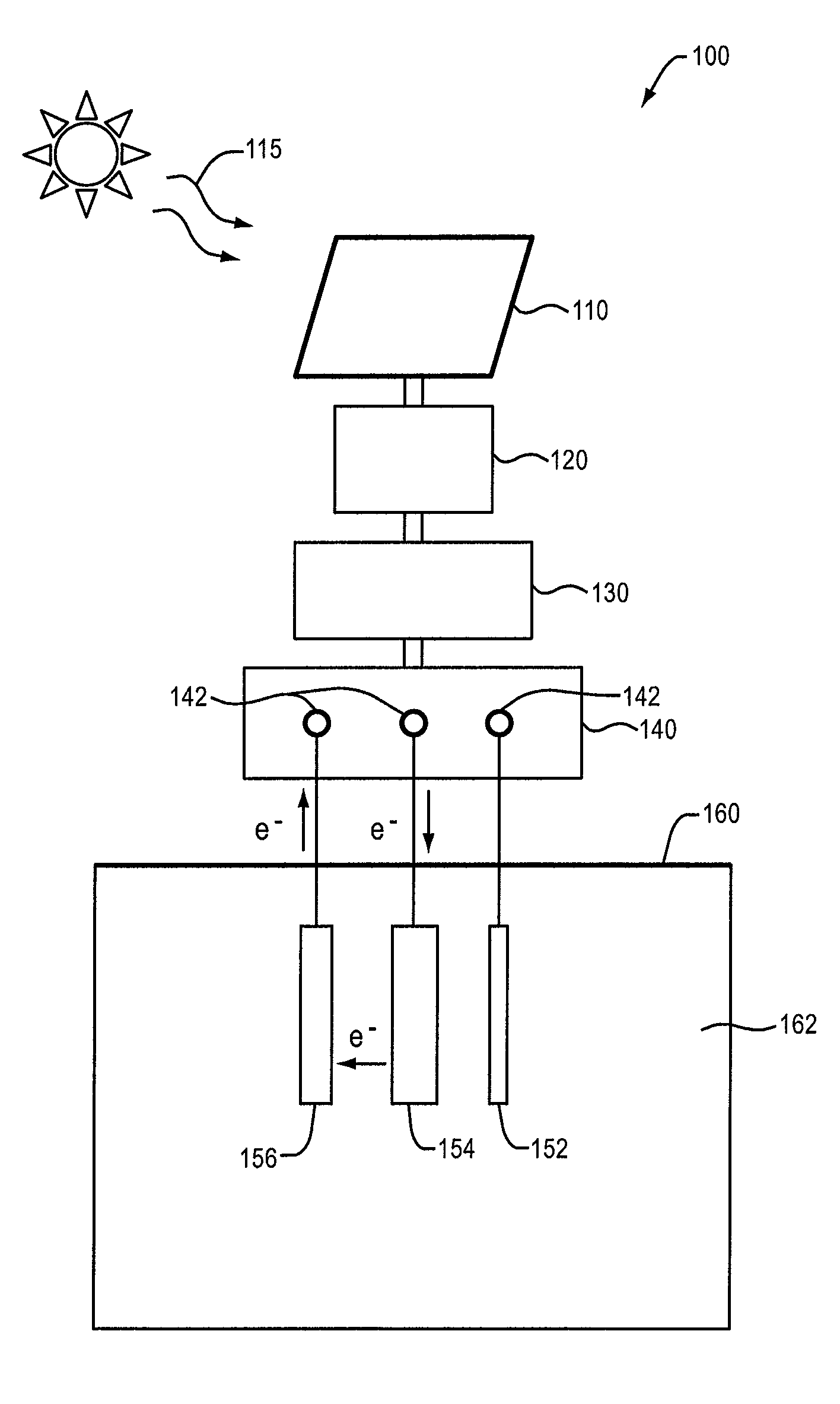

Systems and methods for microbial reductive dechlorination of environmental contaminants

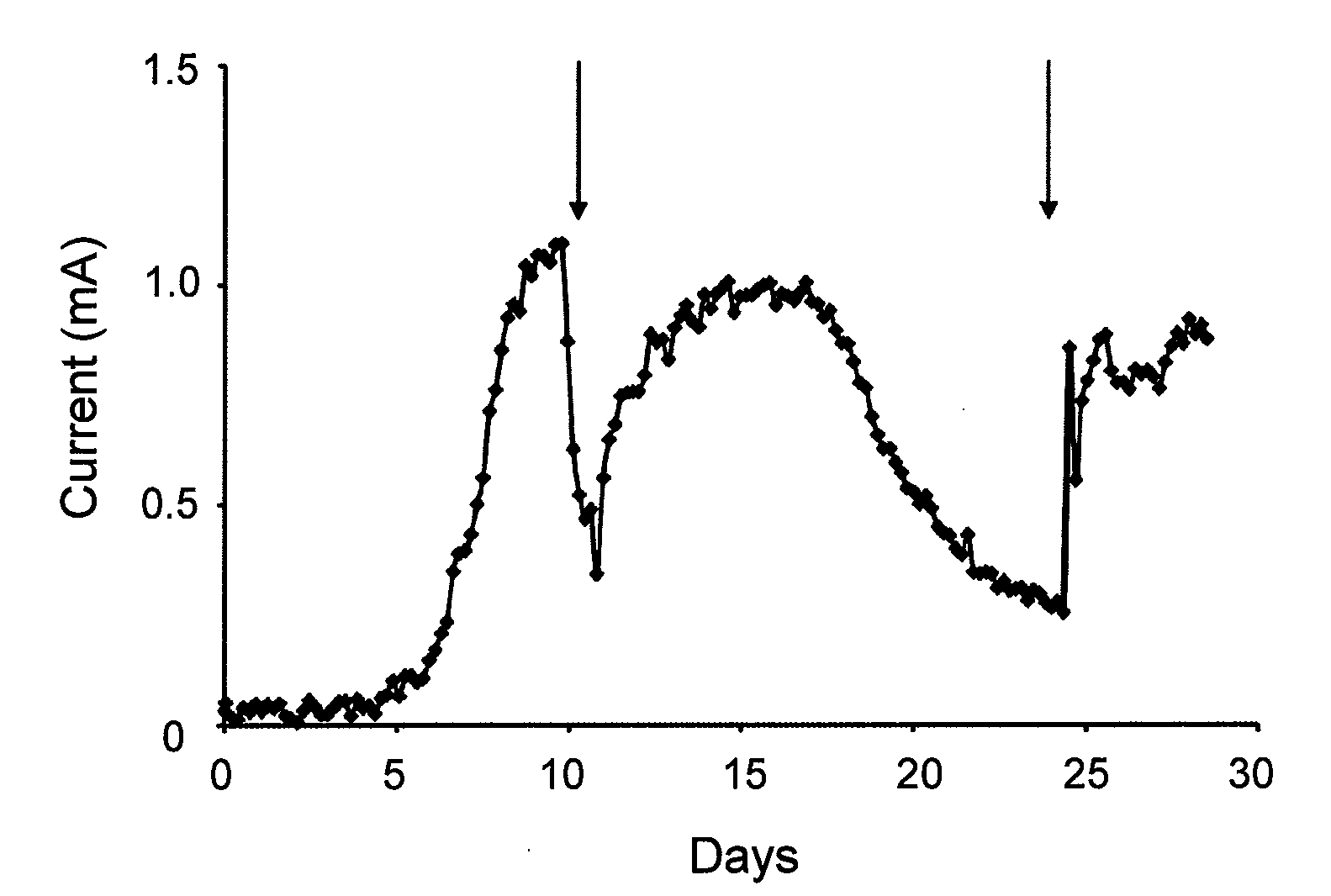

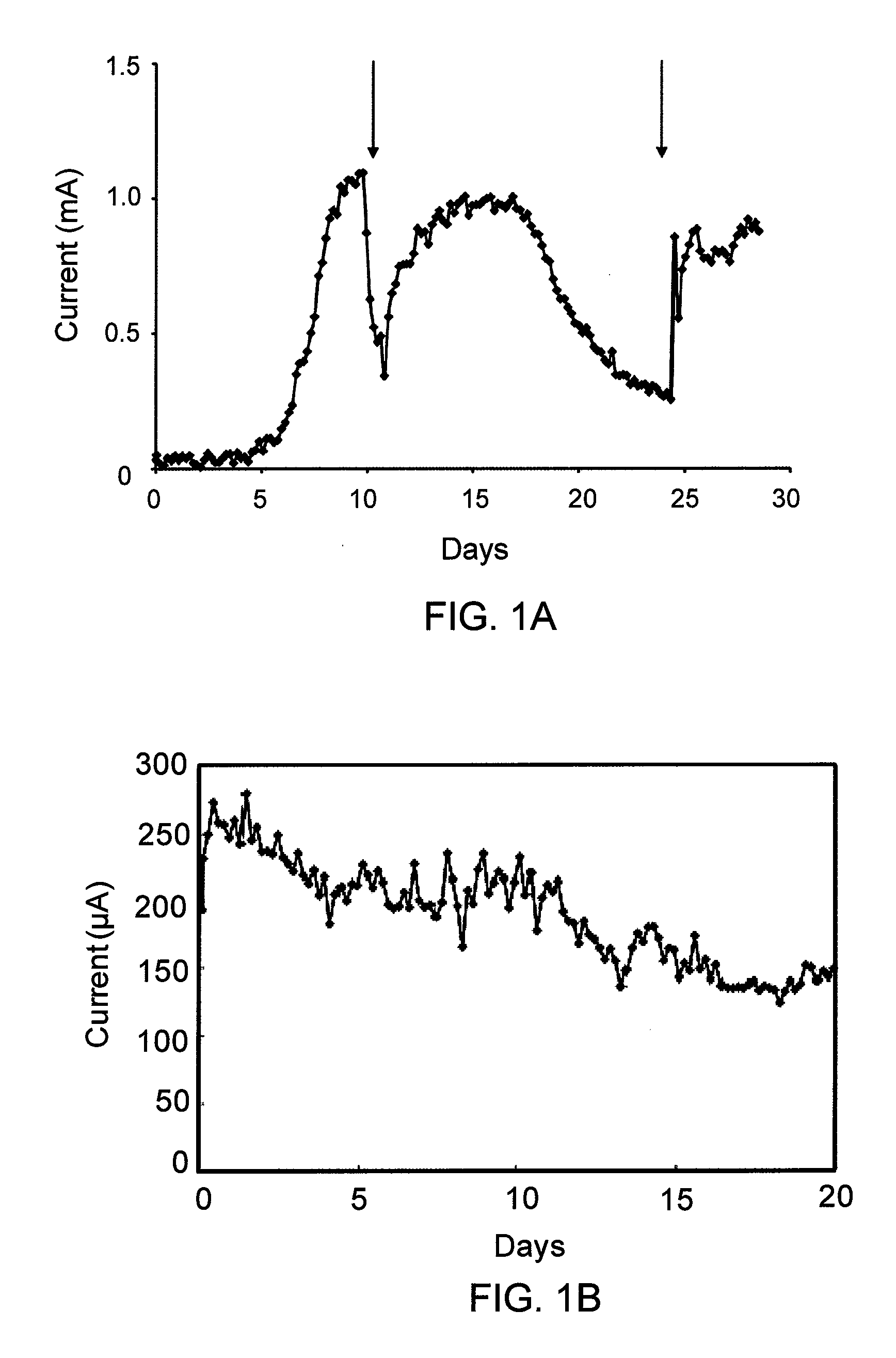

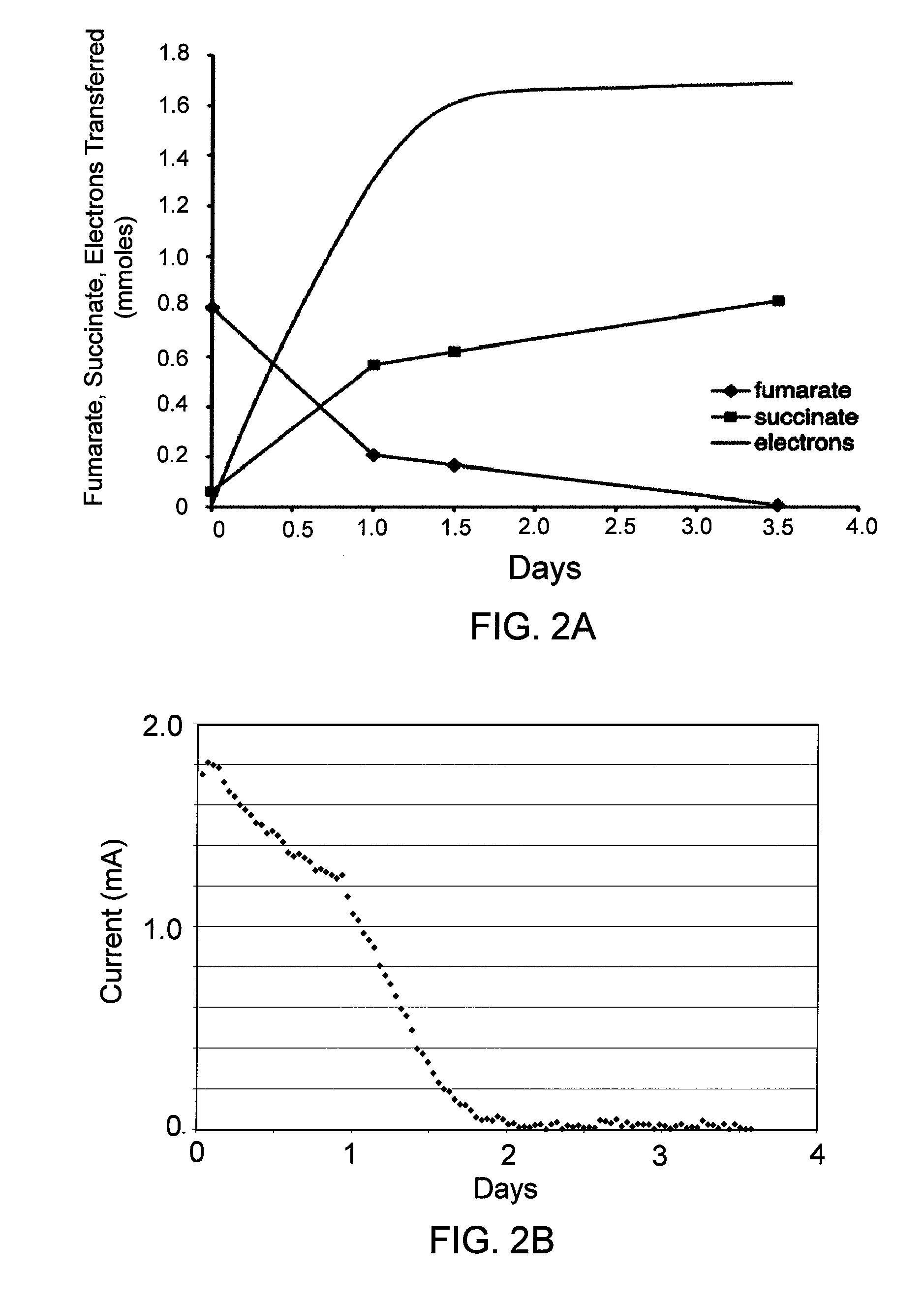

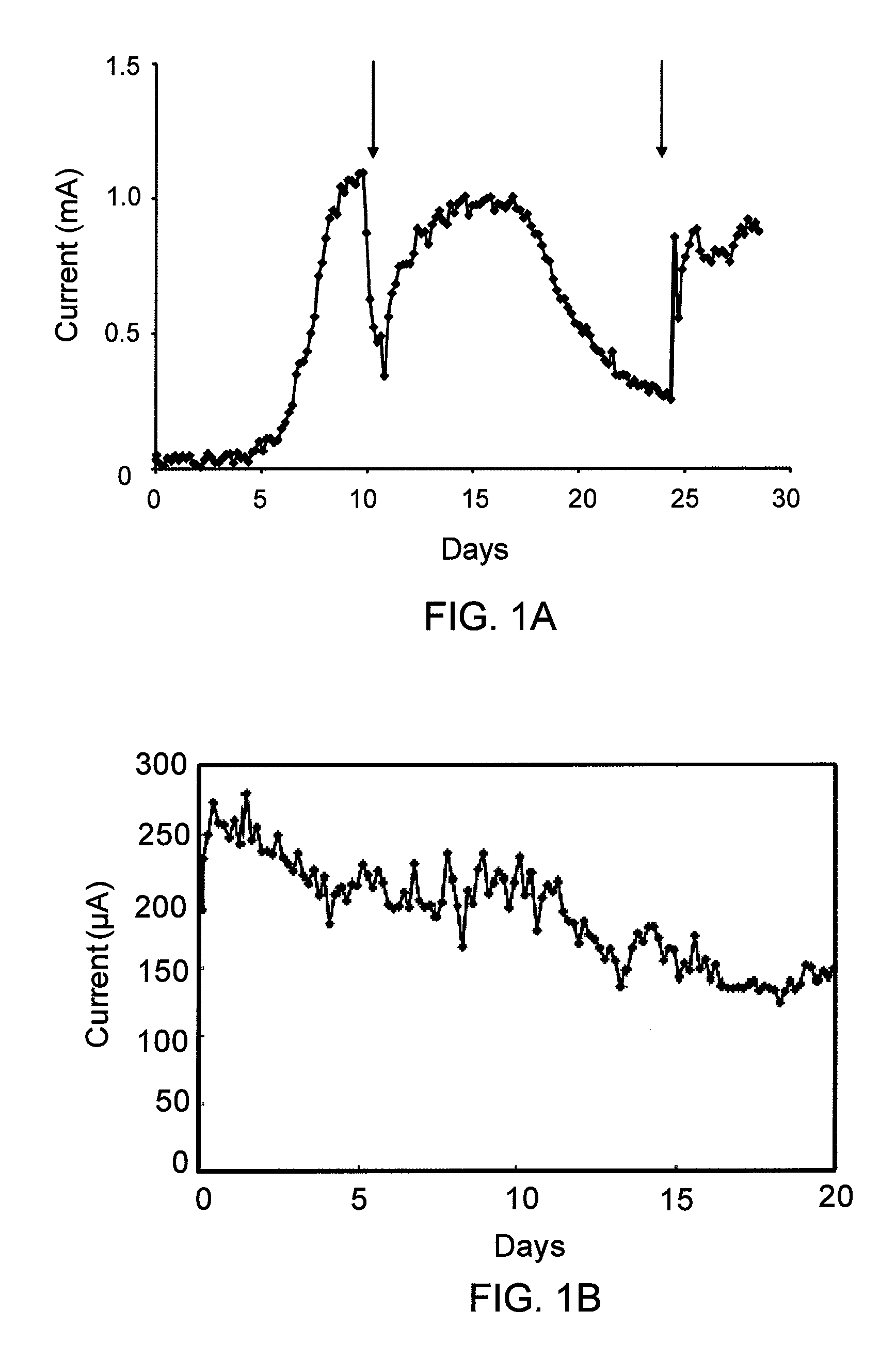

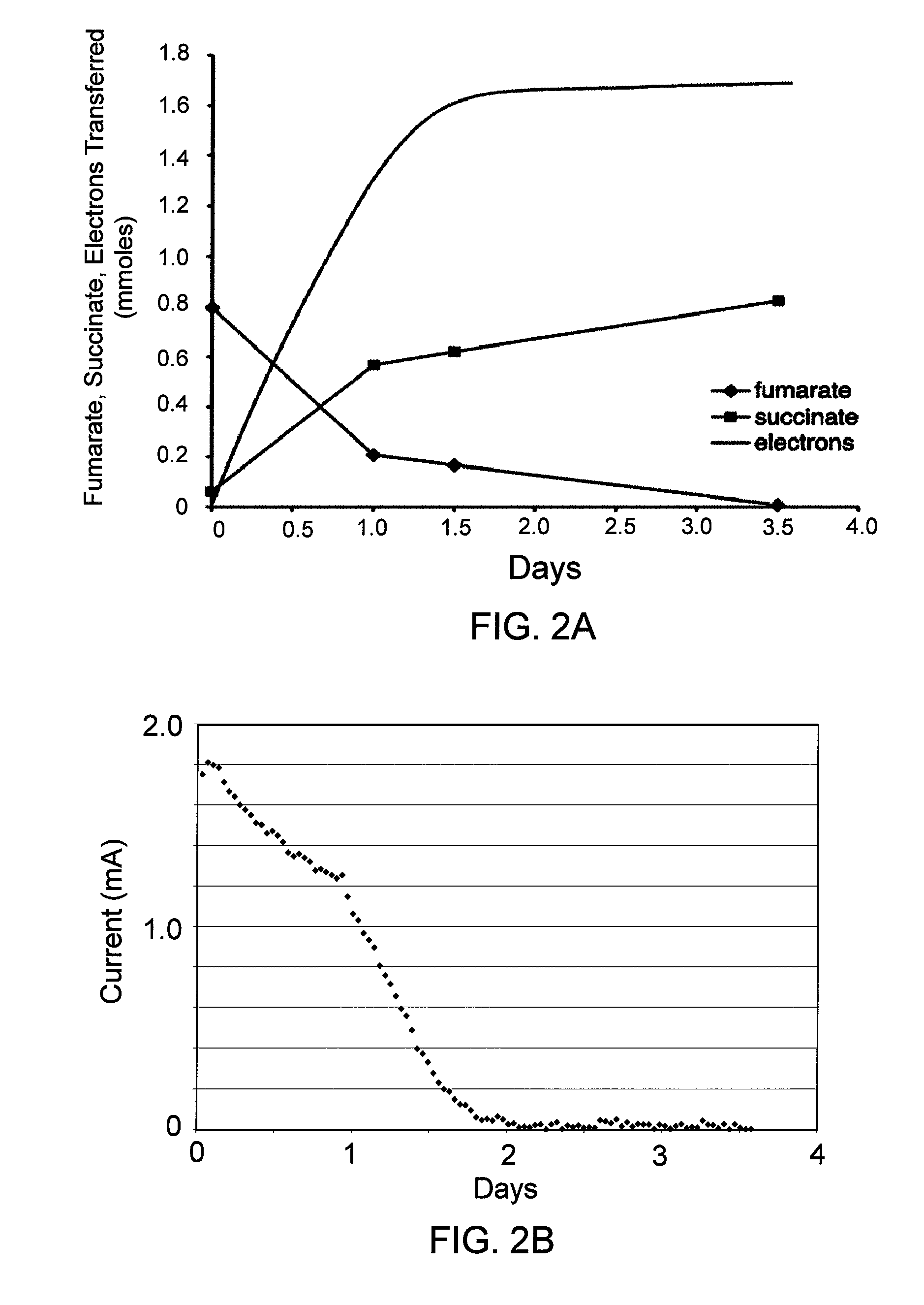

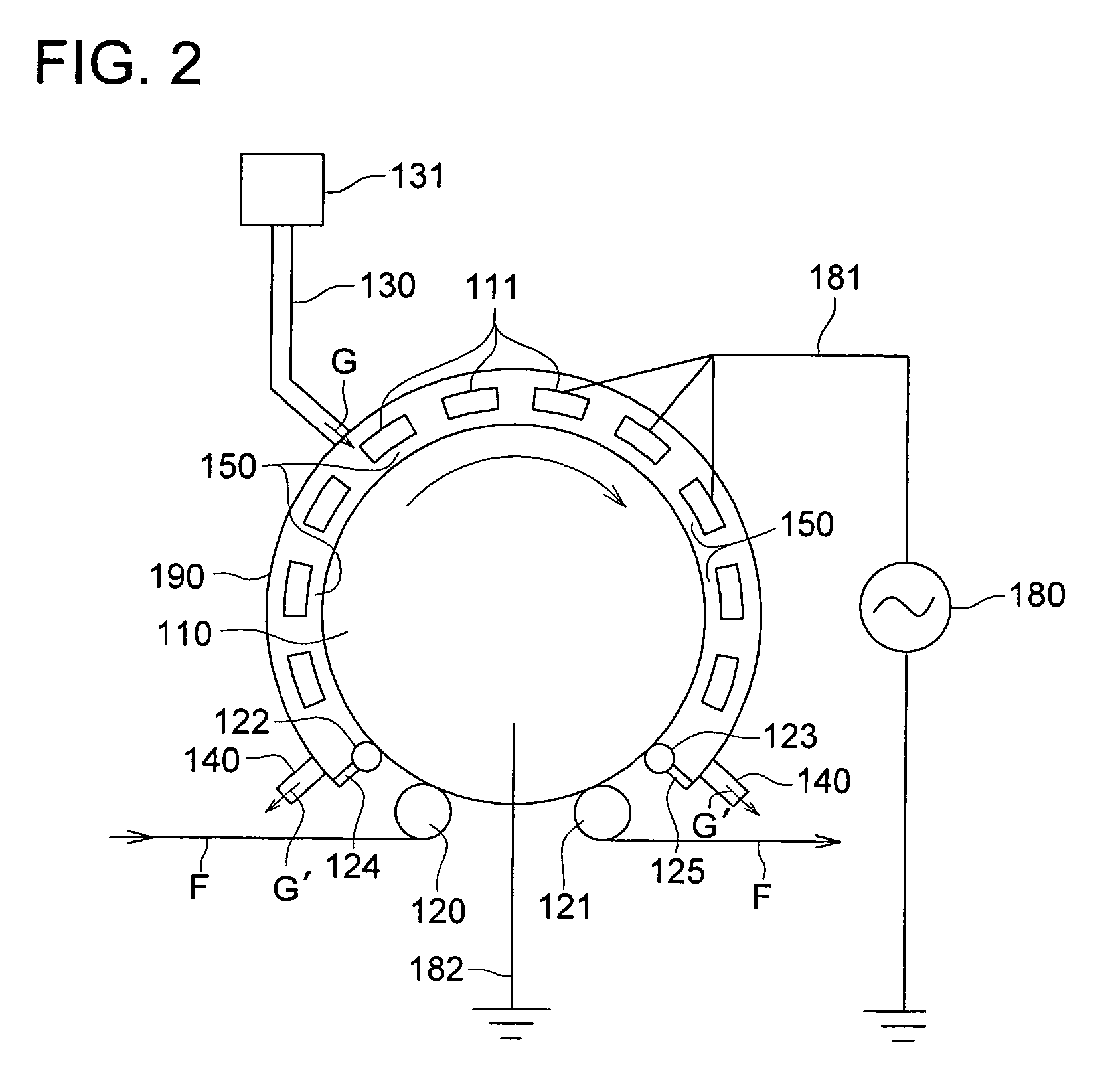

ActiveUS20100059436A1Improve solubilityHigh activityWater/sewage treatment by irradiationOther chemical processesMicroorganismIn situ bioremediation

In preferred embodiments, bioremediation systems are provided that comprise electricigenic microbes that use electrons provided directly from the anode of an electrical bioremediation system to carry out reductive dehalogenation of halogenated hydrocarbon contaminants, including chlorinated solvents. The present invention also provides methods of performing in situ bioremediation of halogenated solvents in groundwater or soil through the use of the provided systems.

Owner:UNIV OF MASSACHUSETTS +1

Solution of cellulose acylate dissolved in mixed solvent comprising ketone and ester

In a cellulose acylate solution, cellulose acylate is dissolved in an essentially non-chlorinated solvent. The essentially non-chlorinated solvent is a mixture of a ketone having a solubility parameter of 19 to 21 and an ester having a solubility parameter of 19 to 21. The solution further contains a releasing agent.

Owner:FUJIFILM HLDG CORP +1

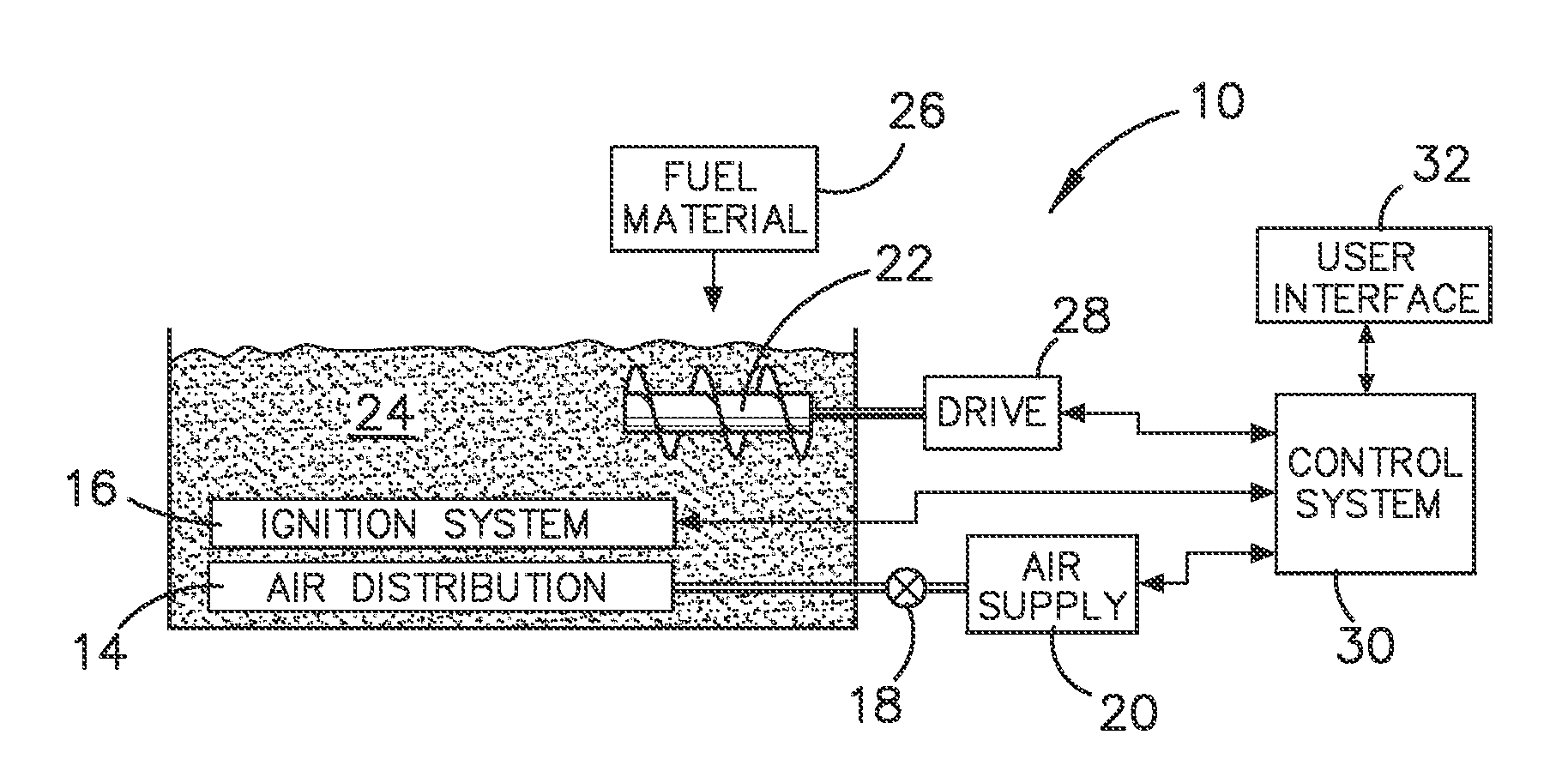

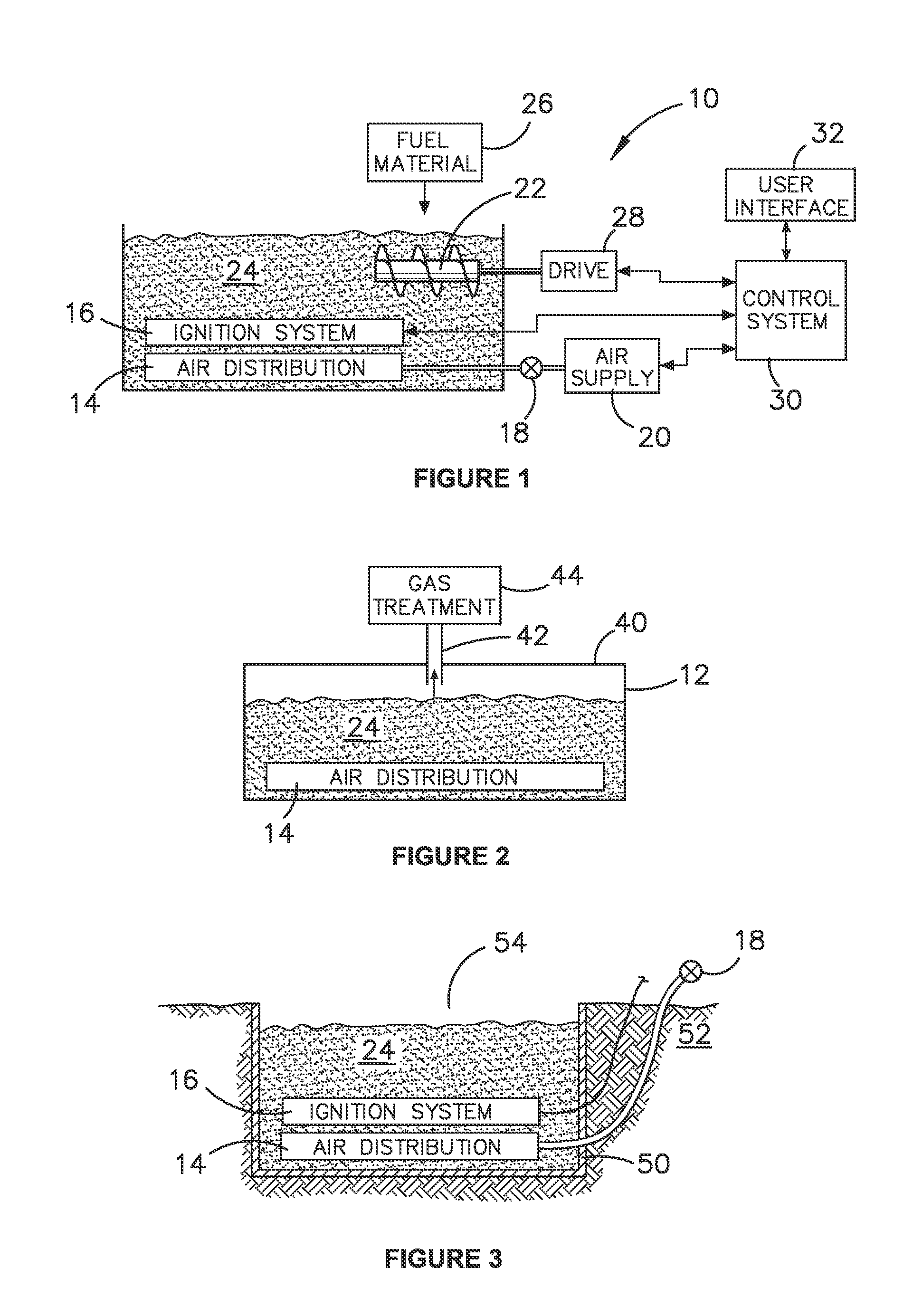

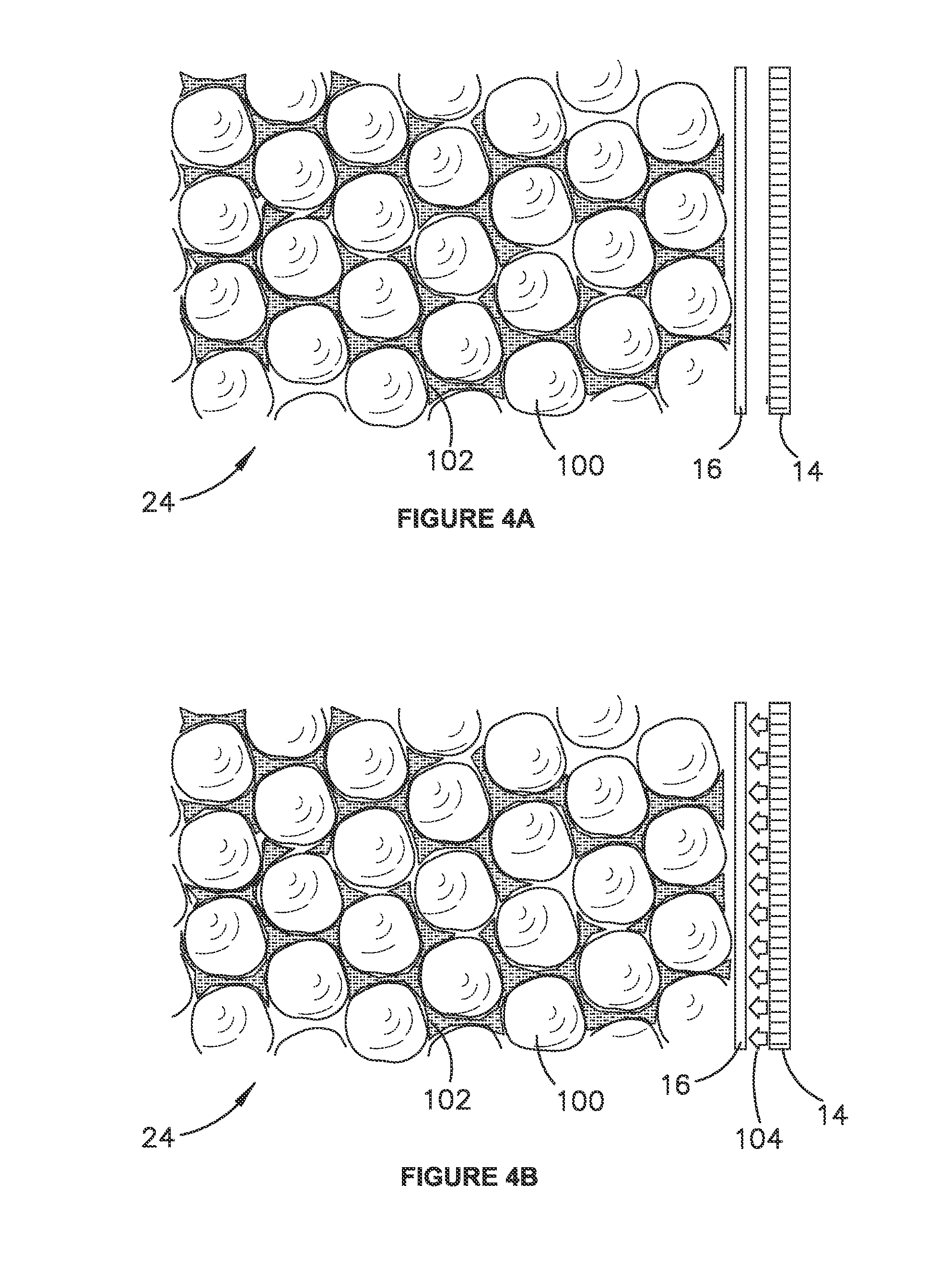

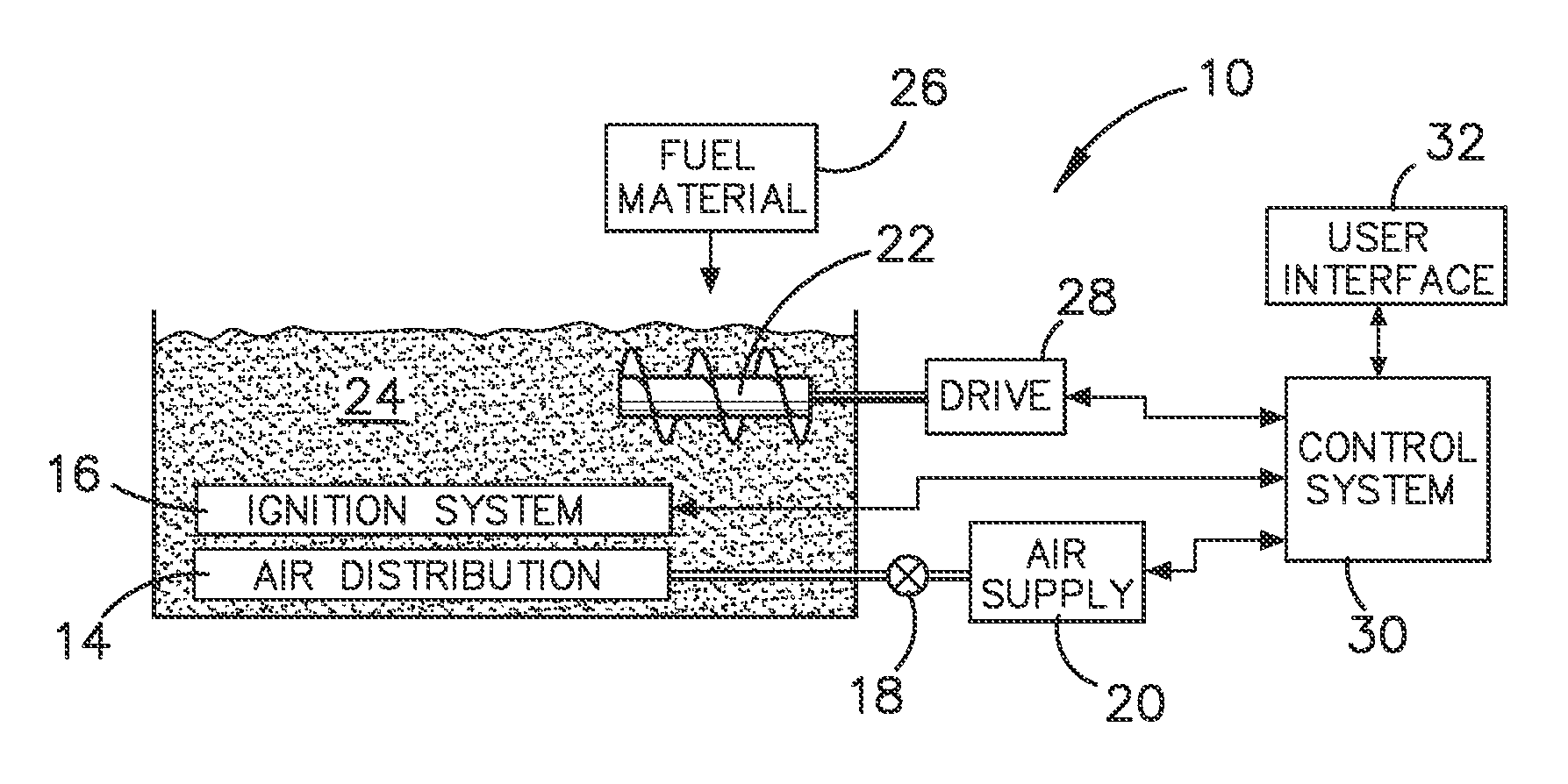

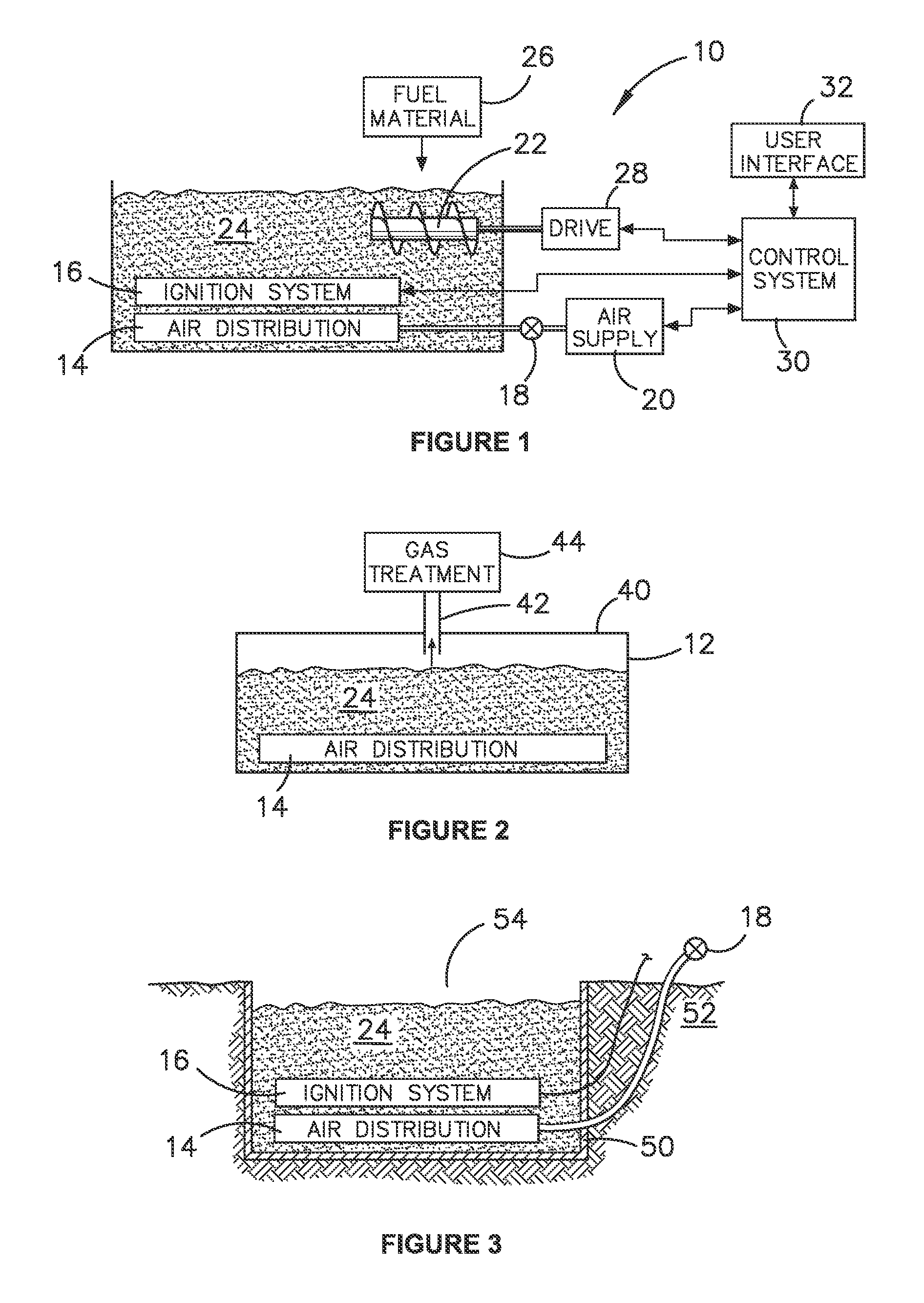

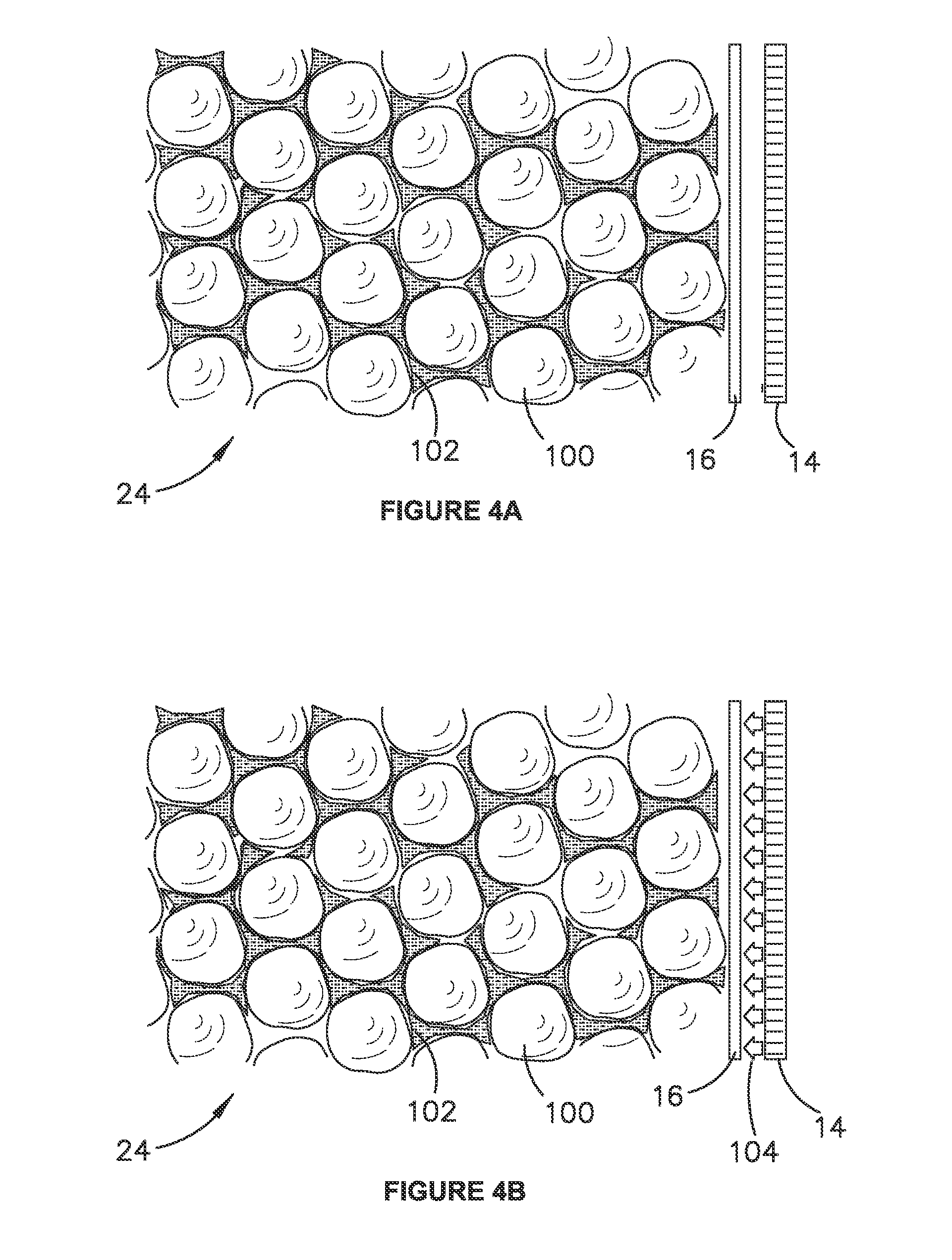

Thermal Treatment of a Contaminated Volume of Material.

ActiveUS20120288332A1Transportation and packagingContaminated soil reclamationFuranPolychlorinated biphenyl

A method is provided for remediating porous contaminated material. In the method, fuel material is combined with the contaminated material and a smoldering combustion process is initiated in the contaminated material to remediate the contaminated material. Control systems are provided to control the smoldering combustion process. The contaminated material may include oily waste, asbestos fibers, and / or at least one of a chlorinated solvent, a polychlorinated biphenyl (PCB), a dioxin, a furan and a polynuclear aromatic hydrocarbon (PAH).

Owner:CHEVROU USA INC

Systems and methods for microbial reductive dechlorination of environmental contaminants

ActiveUS8277657B2High activityFacilitating in situ bioremediationWater/sewage treatment by irradiationOther chemical processesIn situ bioremediationSolvent

Owner:UNIV OF MASSACHUSETTS +1

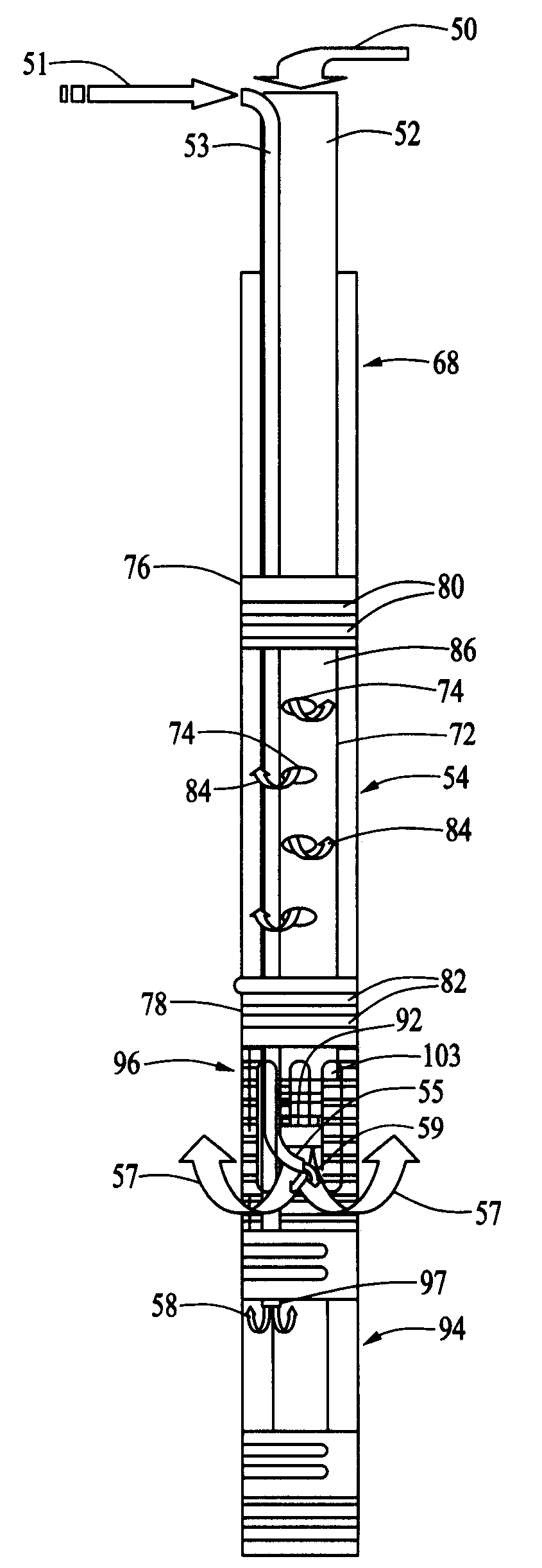

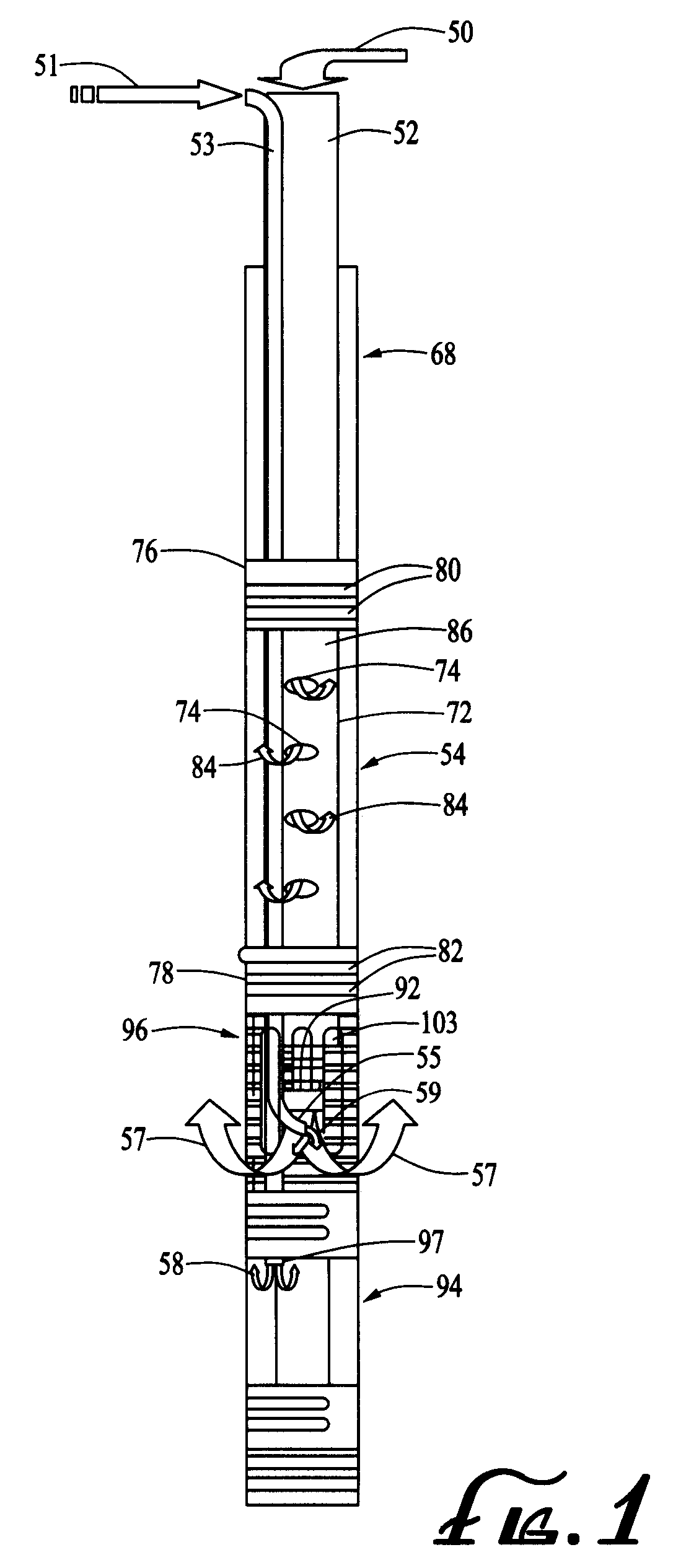

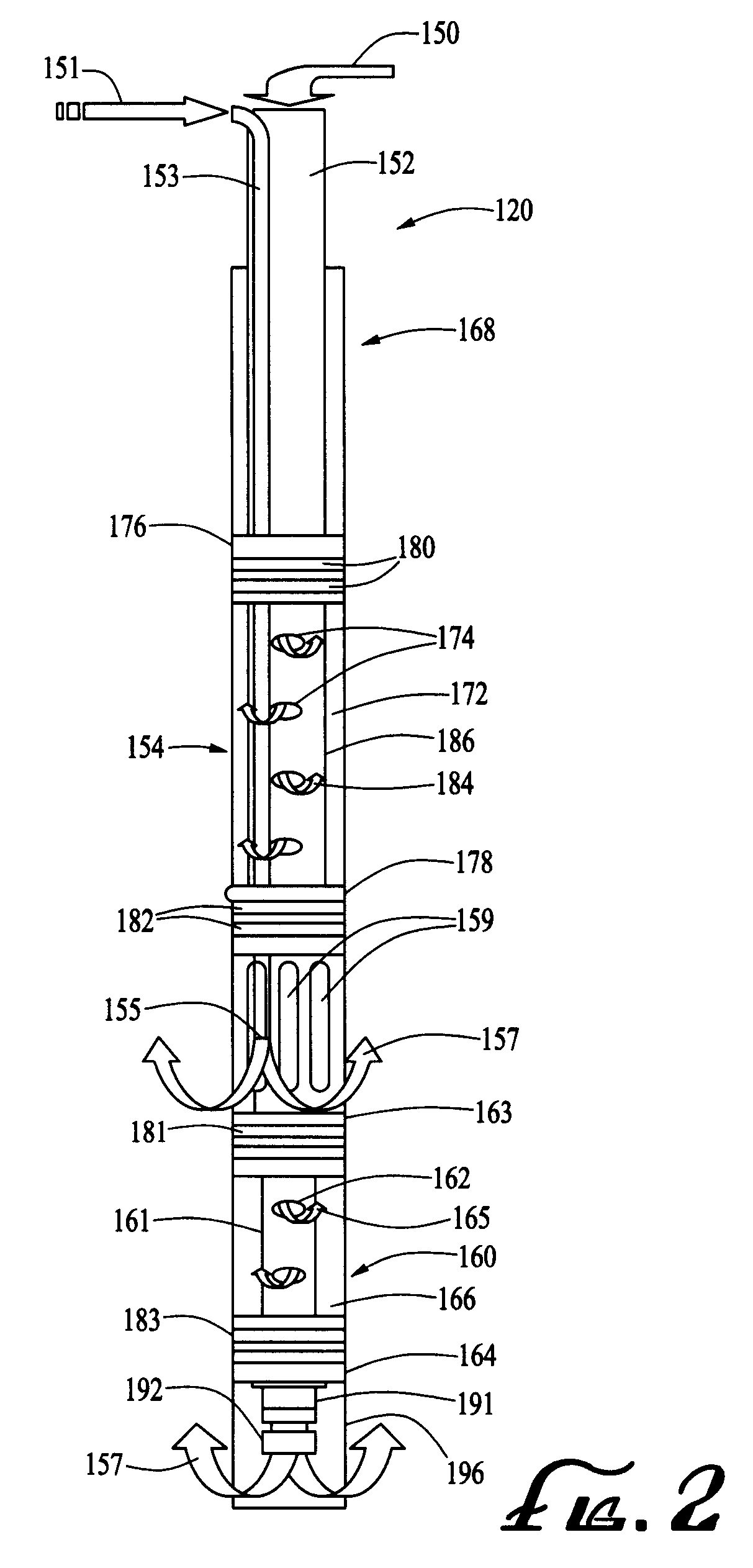

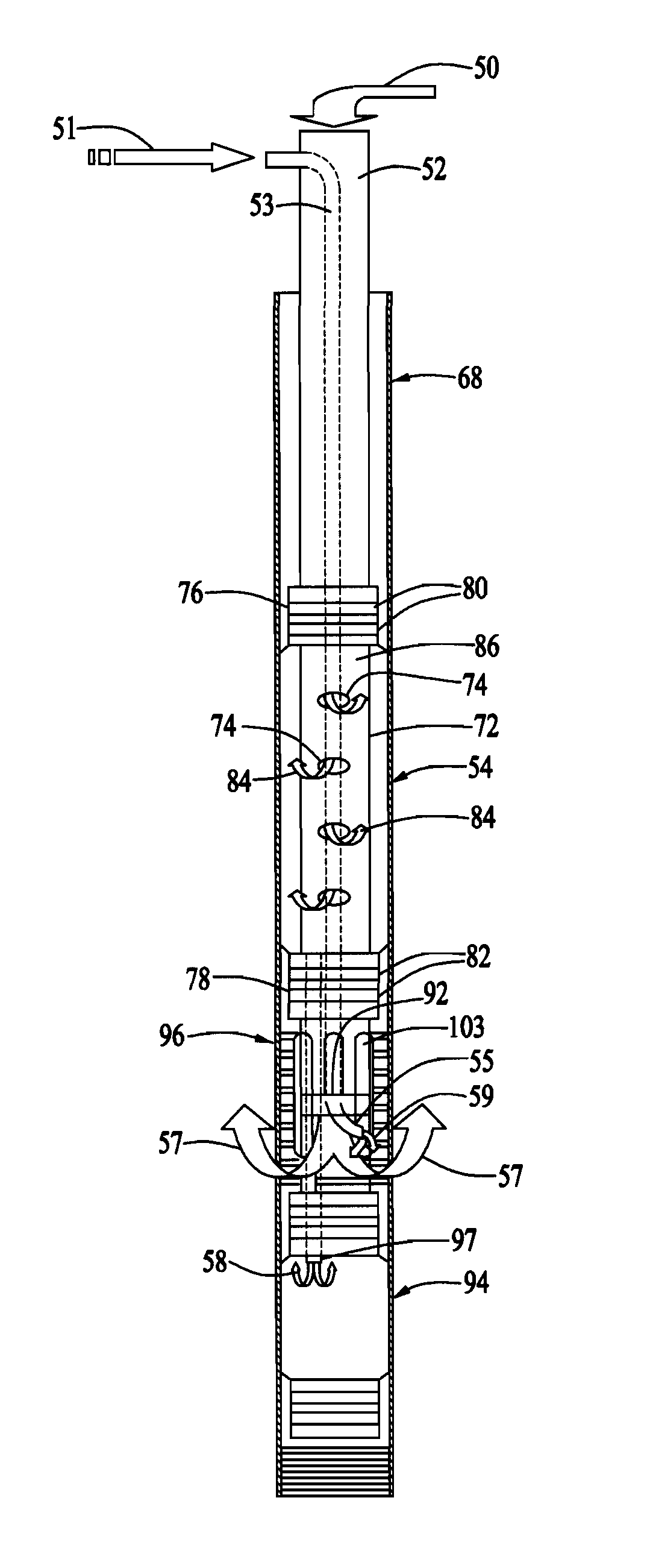

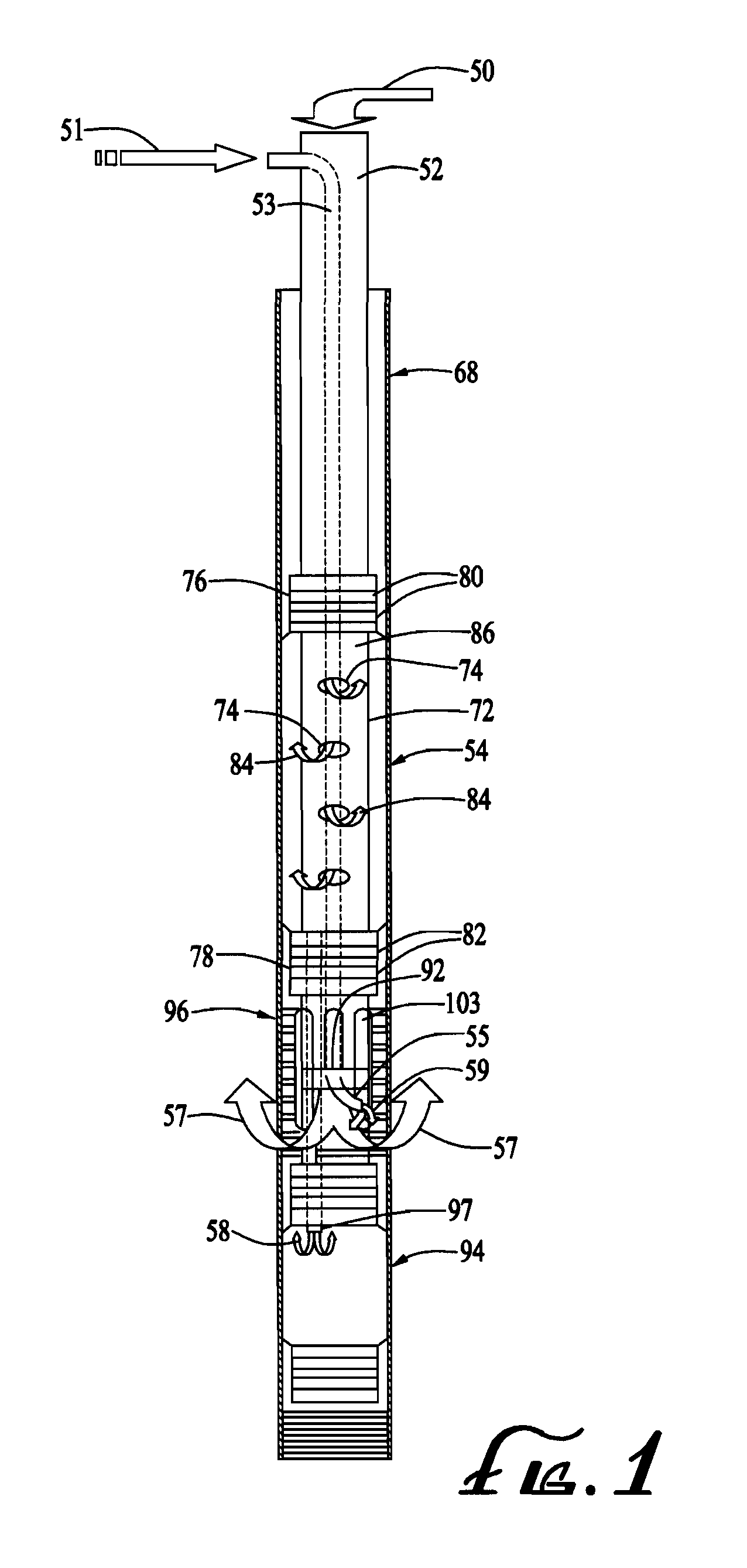

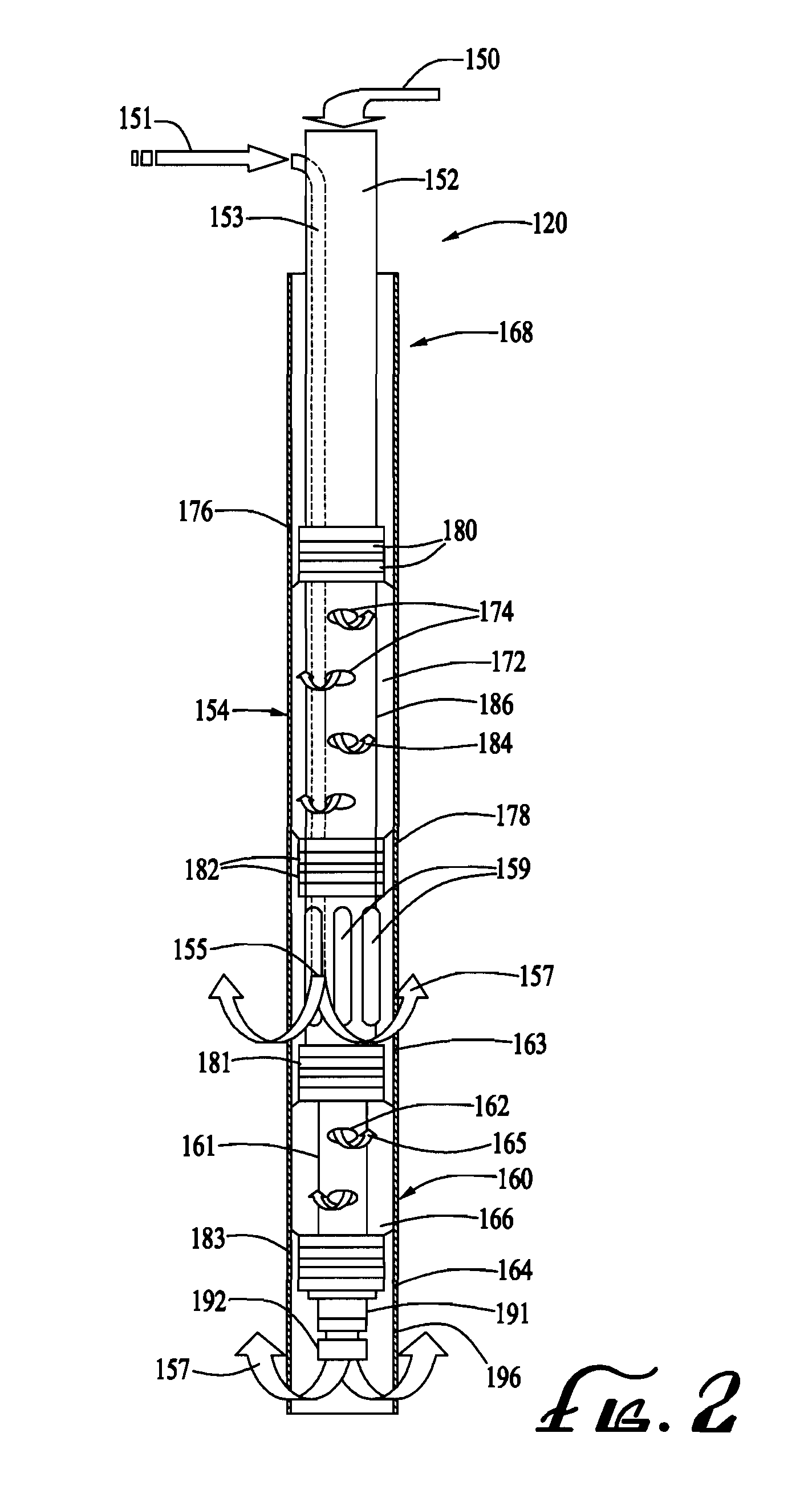

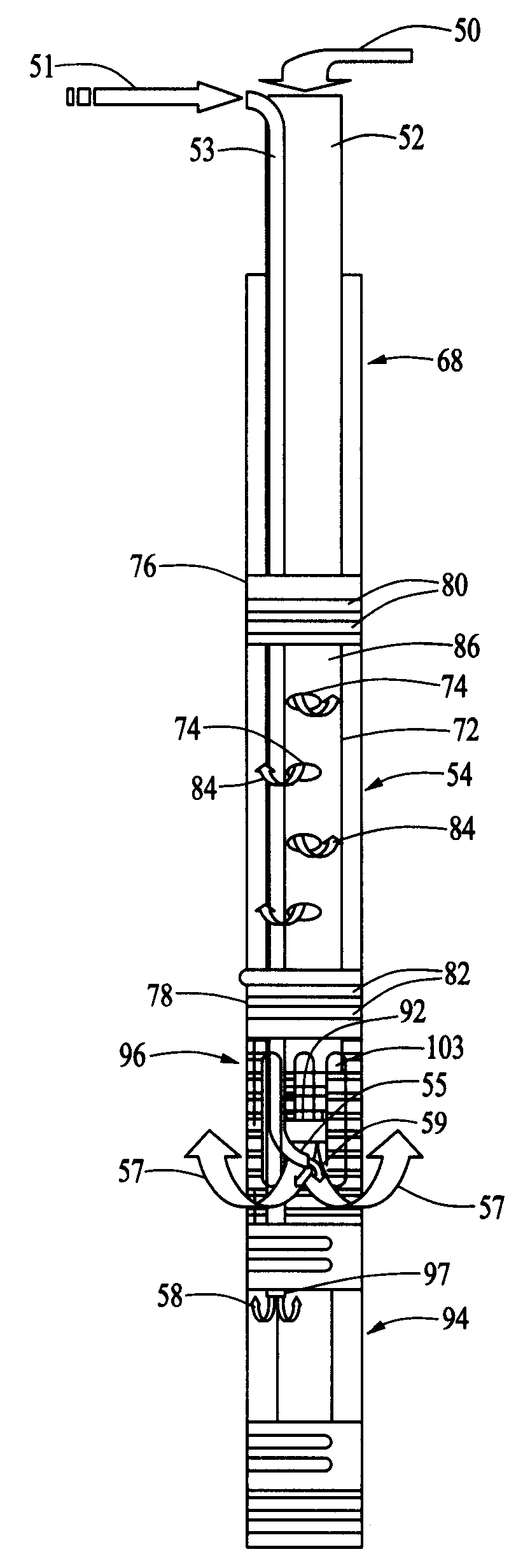

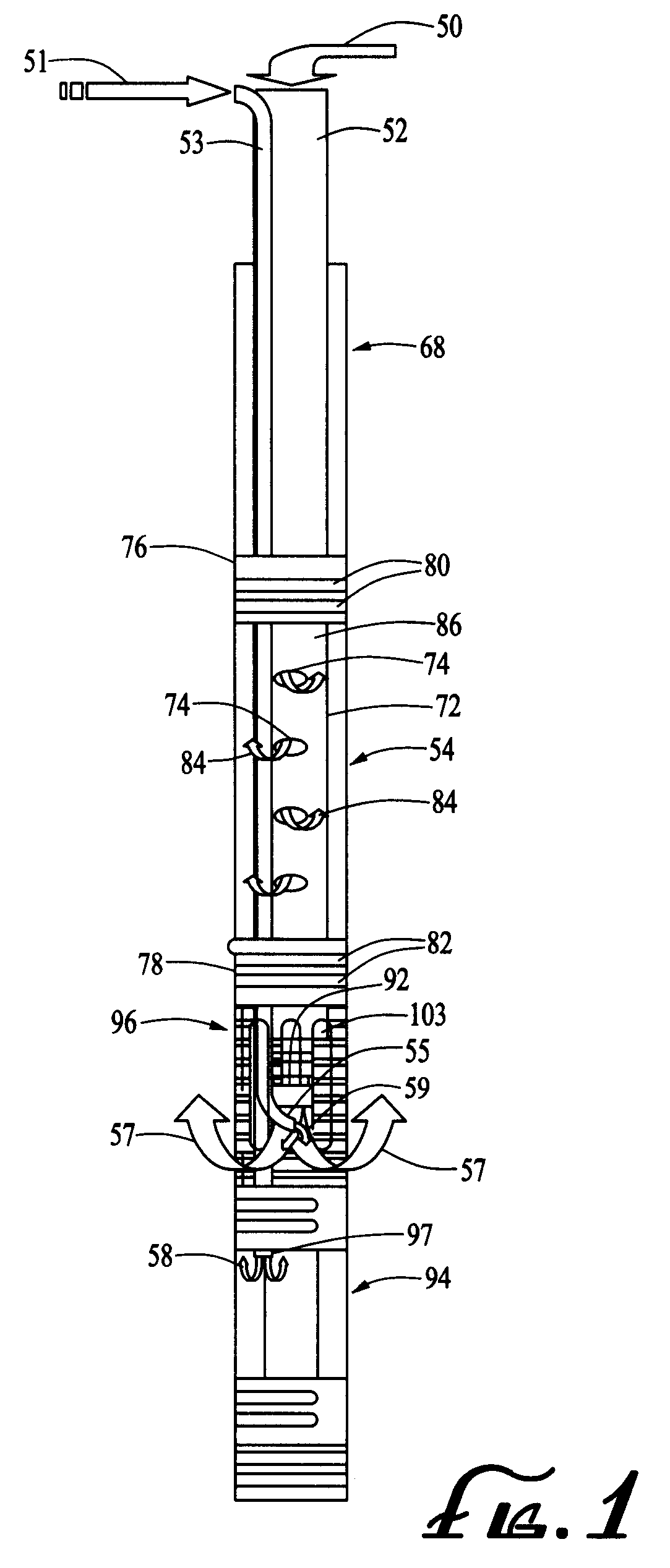

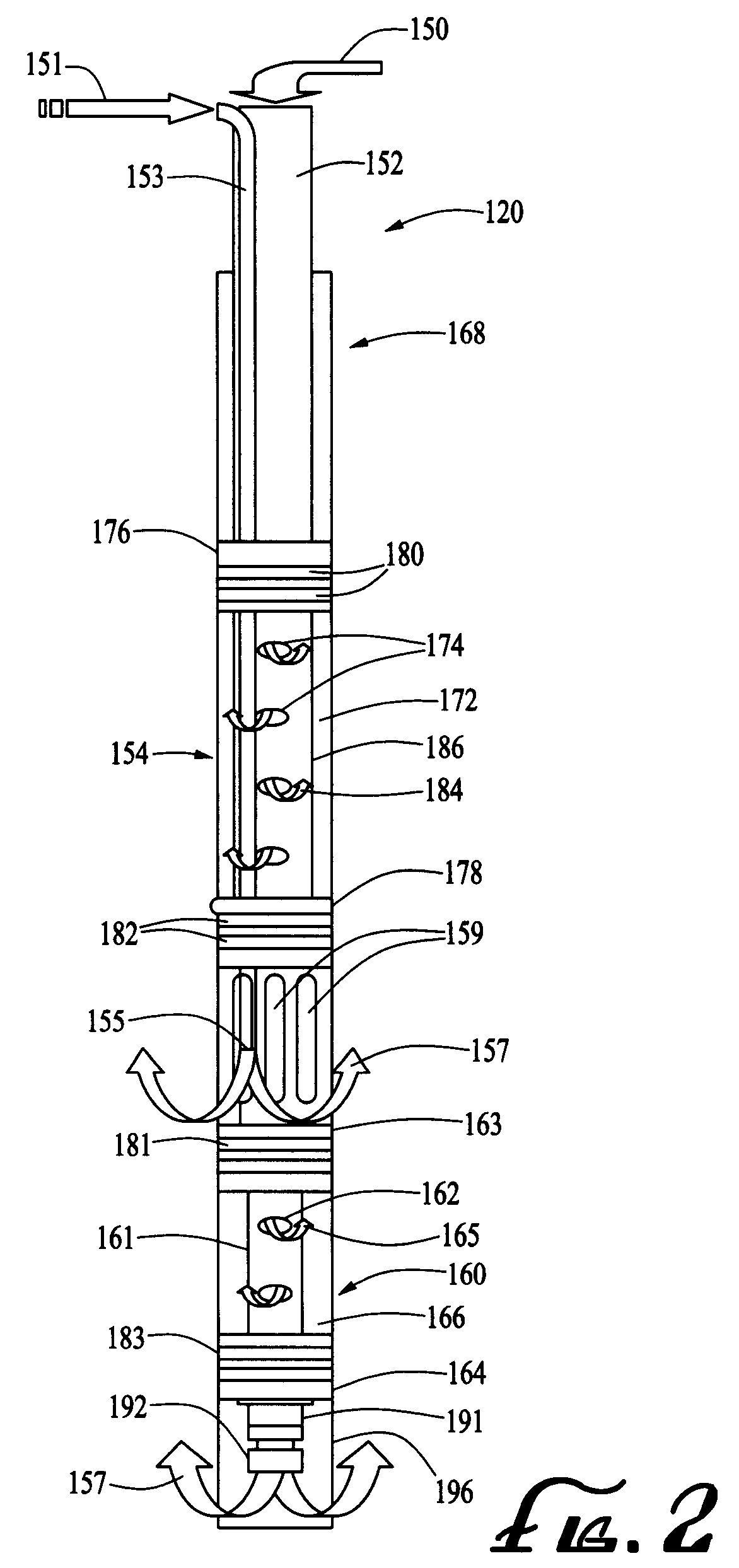

Chemical injection using an adjustable depth air sparging system

ActiveUS20090069622A1Easily damagedPrevent escapeOther chemical processesContaminated soil reclamationEngineeringInjection air

A supplemental fluid adjustable depth air sparging system which is used to remediate contaminants from groundwater within the soil. An adjustable depth air injection point injects compressed air mixed with a chemical oxidizer or nutrient into saturated or groundwater regions of the soil's subsurface to remove contaminants including chlorinated solvents from the soil's subsurface.

Owner:USA REPRESENTED BY THE SEC OF THE NAVY

Thermal treatment of a contaminated volume of material

A method and apparatus for remediating porous contaminated material. In the method, fuel material is combined with the contaminated material and a smoldering combustion process is initiated in the contaminated material to remediate the contaminated material. Control systems are provided to control the smoldering combustion process. The contaminated material may include oily waste, asbestos fibers, and / or at least one of a chlorinated solvent, a polychlorinated biphenyl (PCB), a dioxin, a furan and a polynuclear aromatic hydrocarbon (PAH).

Owner:CHEVROU USA INC

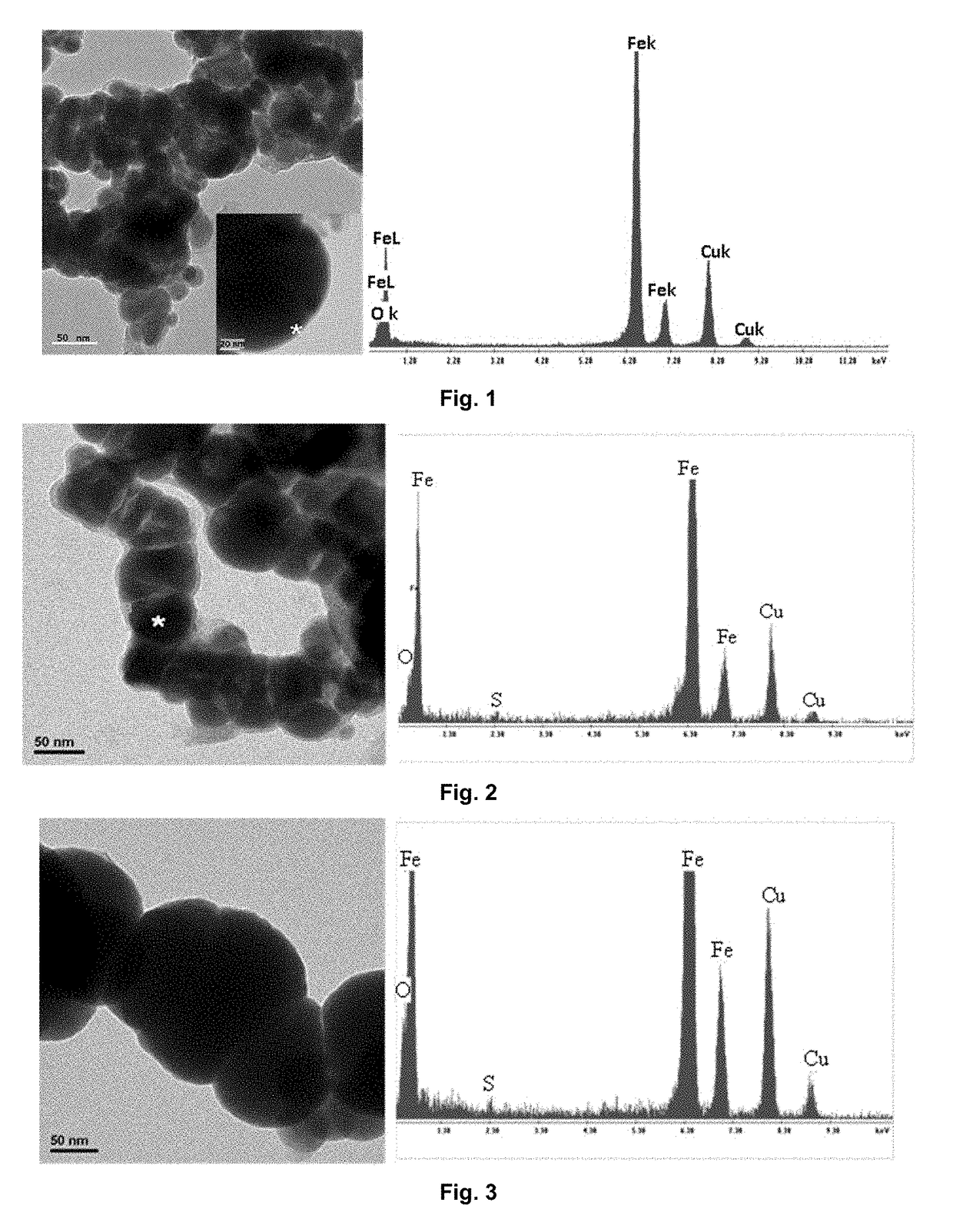

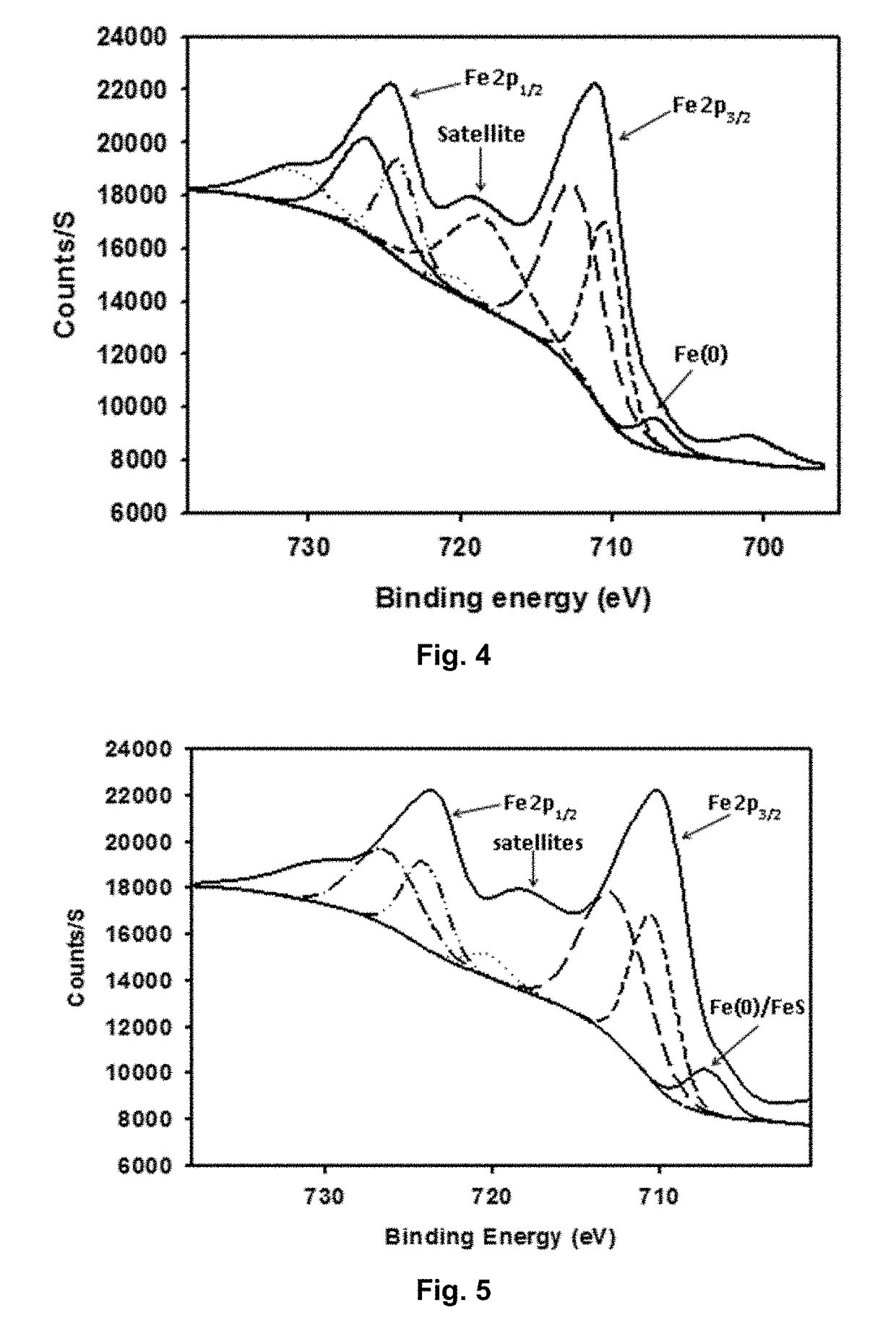

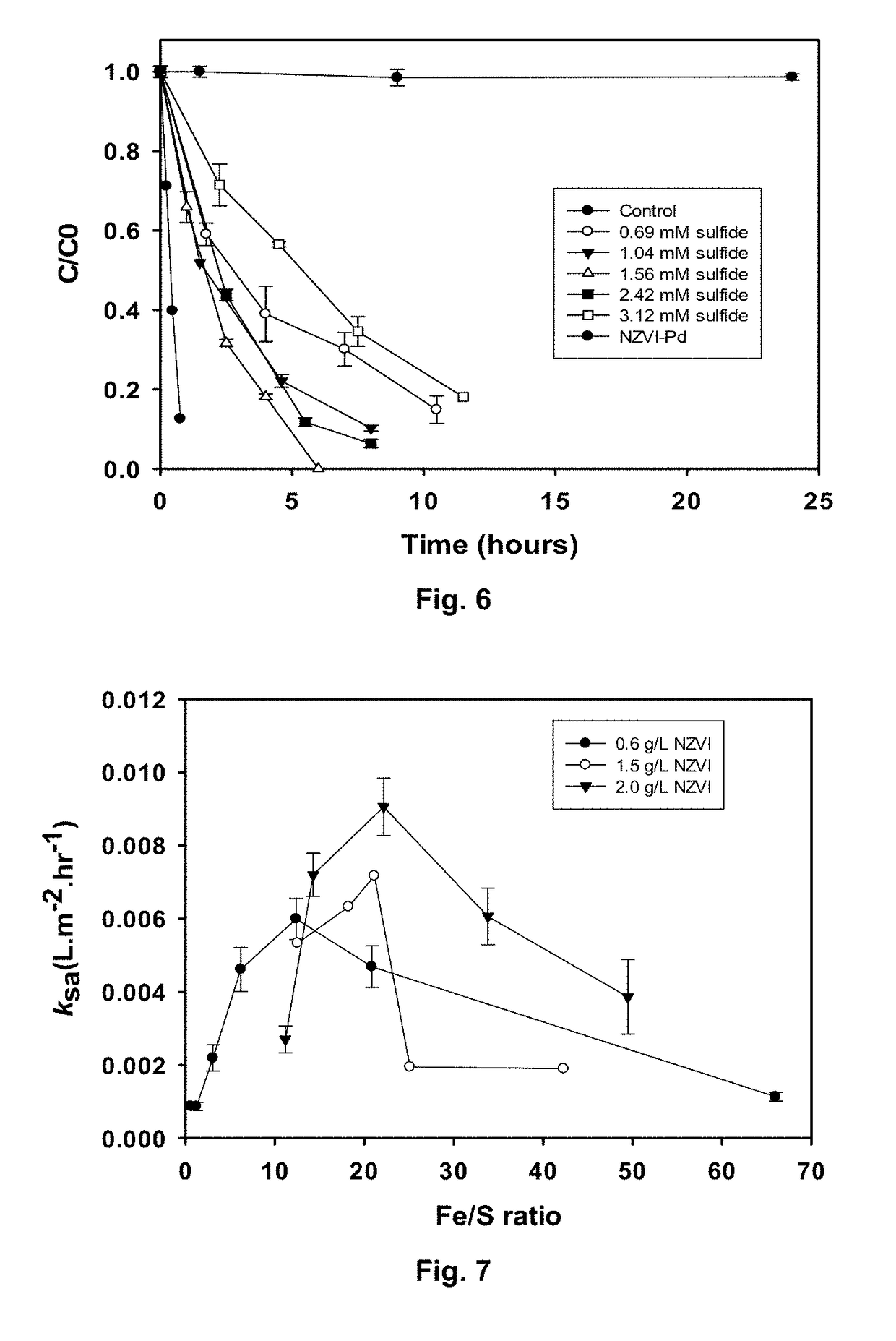

Sulfidated nanoscale zerovalent iron and method of use thereof

InactiveUS20170297931A1Increase ratingsMaterial nanotechnologyWater treatment compoundsMedicineSulfur

The present disclosure relates to sulfur-treated zerovalent iron nanoparticles and the use of same for transforming chlorinated solvent pollutants and may therefore be useful as water treatment technology for restoration of groundwater resources contaminated with toxic, chlorinated solvent pollutants.

Owner:MCGILL UNIV

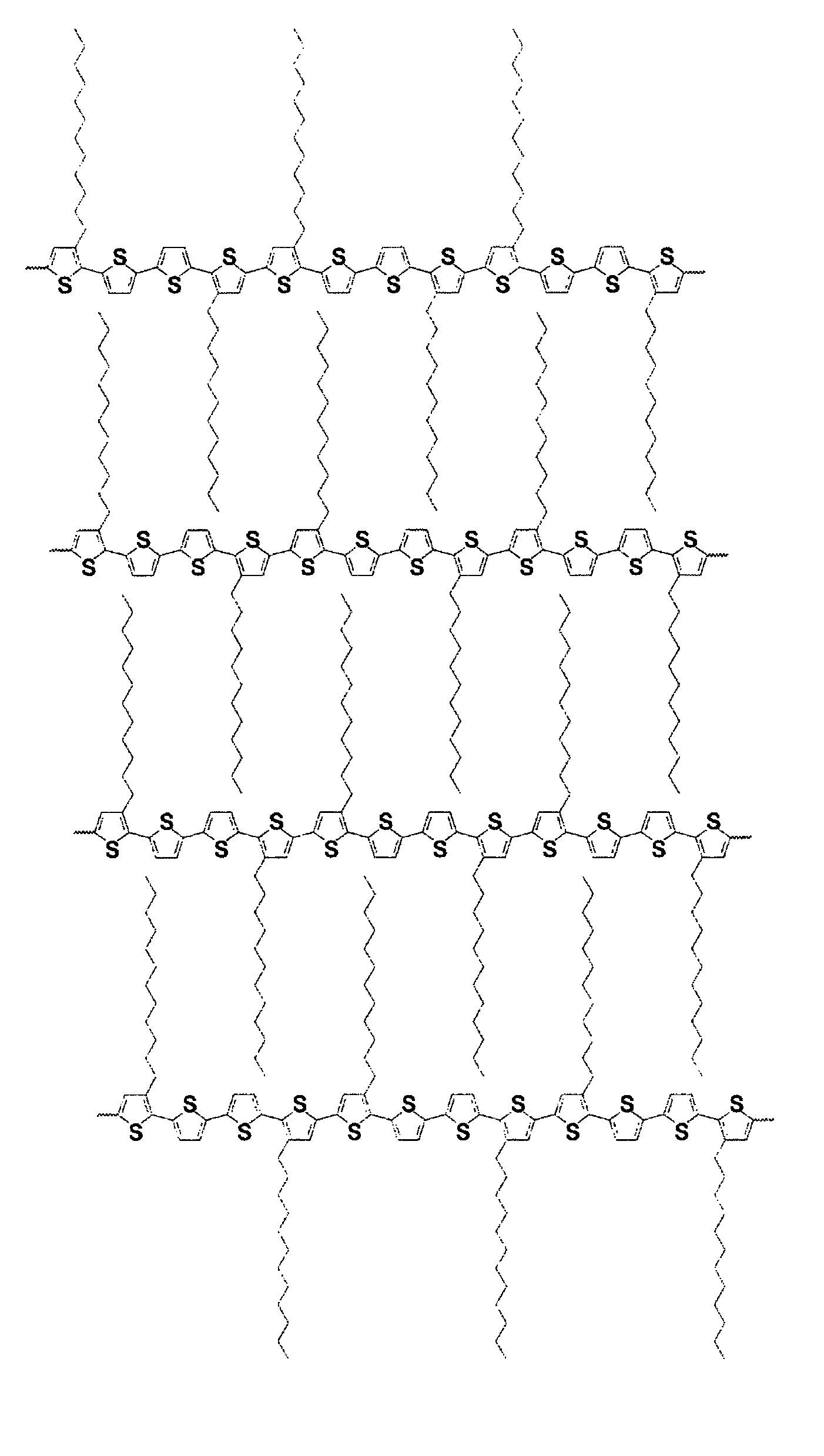

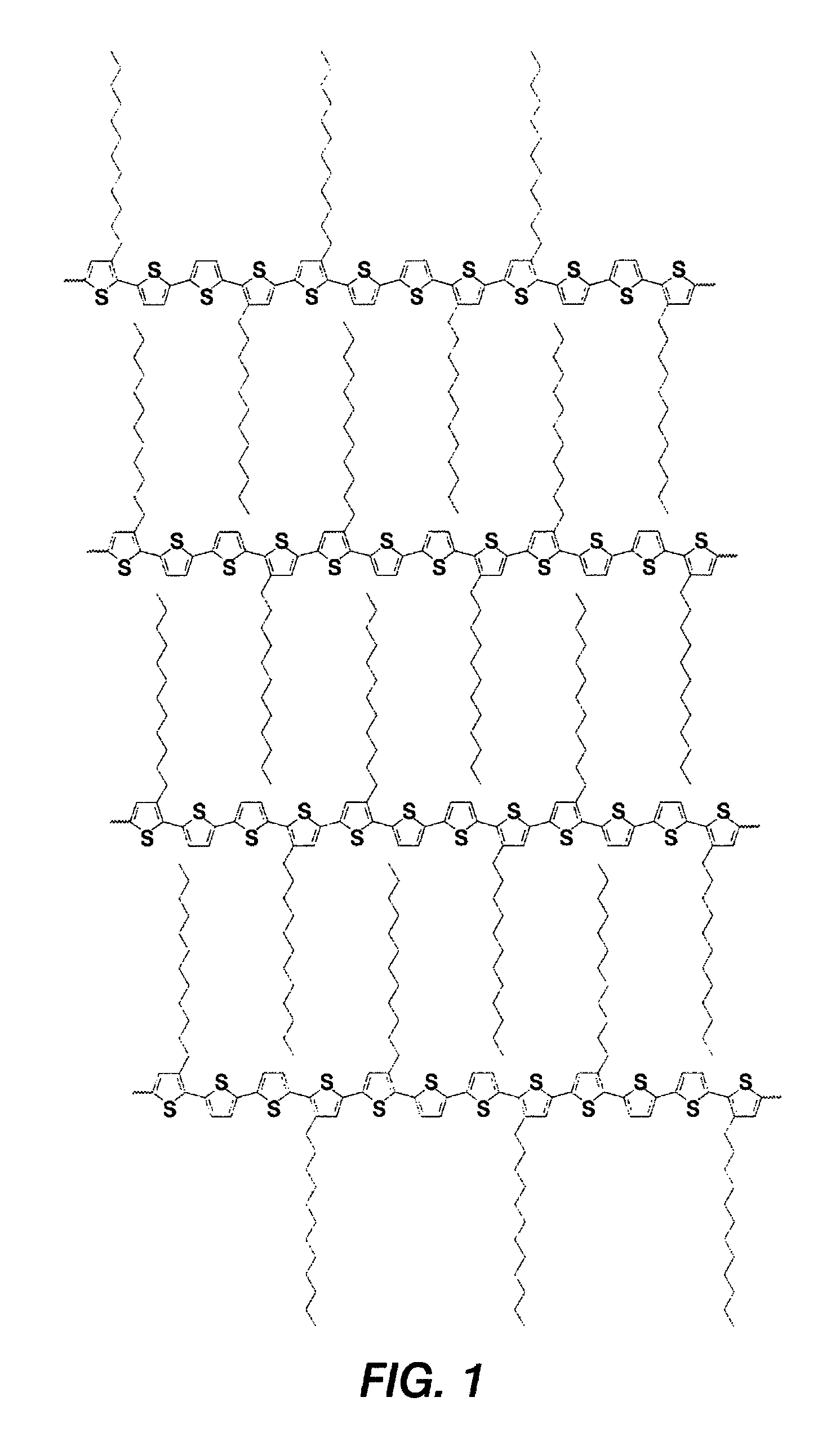

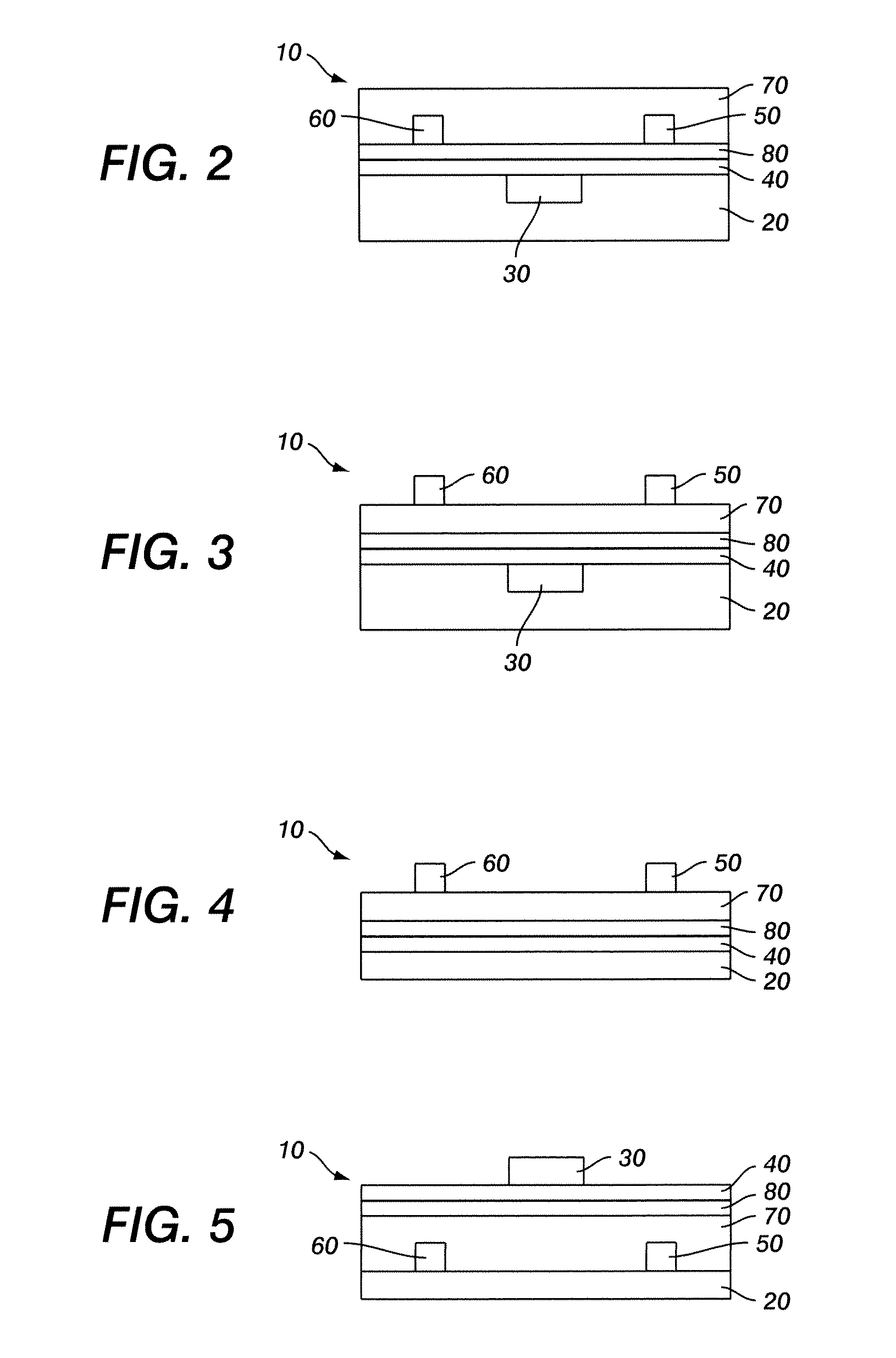

Polythiophenes and electronic devices comprising the same

ActiveUS7837903B2Improve mobilityGood on/off ratio performanceConductive materialSolid-state devicesOrganic solventChlorinated solvent

Owner:SAMSUNG ELECTRONICS CO LTD

System and method of chemical injection using an adjustable depth air sparging system

ActiveUS7828495B2Easily damagedPrevent escapeOther chemical processesContaminated soil reclamationEngineeringInjection air

A supplemental fluid adjustable depth air sparging system which is used to remediate contaminants from groundwater within the soil. An adjustable depth air injection point injects compressed air mixed with a chemical oxidizer or nutrient into saturated or groundwater regions of the soil's subsurface to remove contaminants including chlorinated solvents from the soil's subsurface.

Owner:USA REPRESENTED BY THE SEC OF THE NAVY

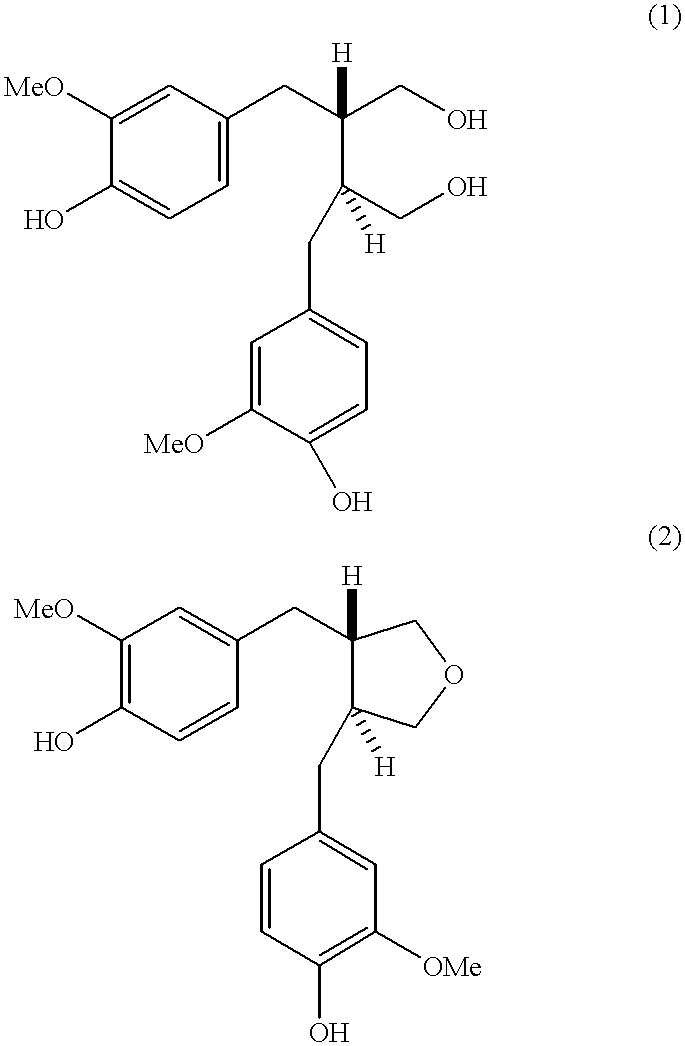

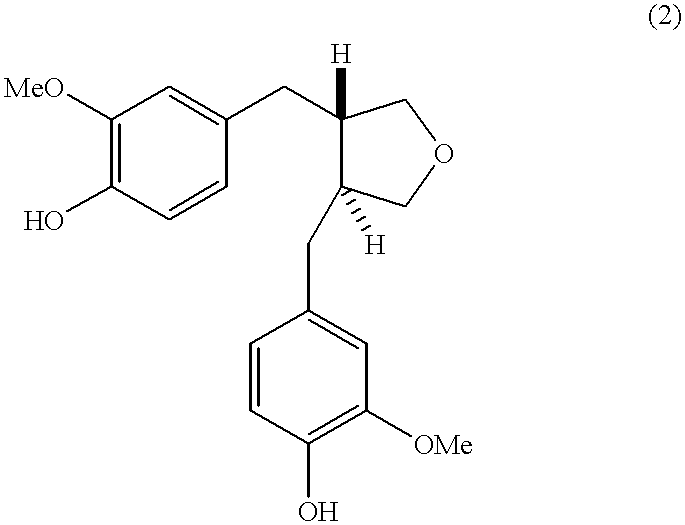

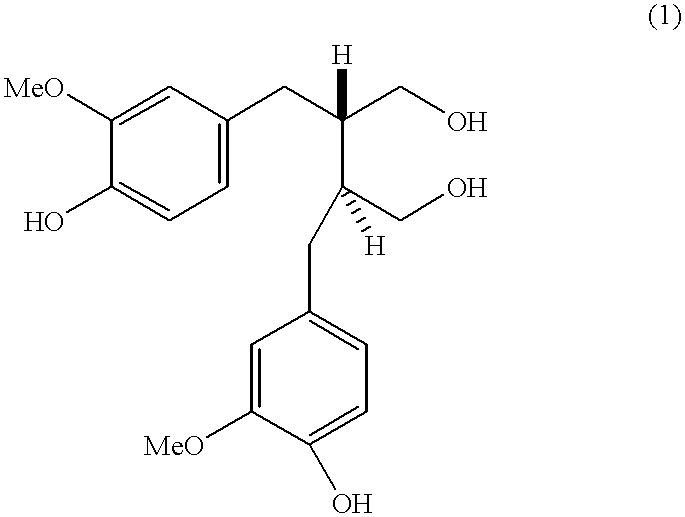

Process for the production of (-) 3,4-divanillyl tetrahydrofuran

InactiveUS6372922B1High yieldReduce usageOrganic chemistry3,4-DivanillyltetrahydrofuranSecoisolariciresinol

The present invention relates to a process for the production of (-)3,4-divanillyl tetrahydrofiran of formula (2) which comprises (a) isolating) (-) secoisolariciresinol of formula (1) from the heartwood and roots of Taxus wallichiana by an improved process which consists of partitioning of the alcoholic extract of the heartwood and roots of T. wallichiana between water and chlorinated solvent, (b) extracting the chlorinated solvent extract with alkali and (c) isolating (-) secoisolariciresinol from the alkali extract upon neutralization with mineral acid and extracting with organic solvent and (d) crystallizing it from suitable organic solvent, (e) dissolving the isolated (-) secoisolariciresinol in suitable organic solvent and (f) reacting with triphenyl phosphine halide at 0-80° C. for 1-10 hours and (g) isolating (-) 3,4-divanillyl tetrahydrofuran by column chromatography.

Owner:COUNCIL OF SCI & IND RES

High voltage electrolyte solution and lithium ion battery containing the same

InactiveCN104505534AHigh voltage resistanceRaise the precipitation potentialSecondary cellsCharge dischargeHigh voltage

The invention relates to a high voltage electrolyte solution and a lithium ion battery containing the same. The high voltage electrolyte solution contains a lithium salt and a non-aqueous organic solvent. The high voltage electrolyte solution also includes an additive, which is composed of hexamethyldisilazane, octamethylcyclotetrasiloxane, vitamin E and chloroethylene carbonate. By adding a chlorinated solvent into the lithium ion battery electrolyte solution, the voltage withstanding performance of the electrolyte solution can be greatly improved, and the electrolyte solution is not easy to decompose under high voltage. The octamethylcyclotetrasiloxane can effectively remove corrosive substances dissociating to an anode surface and in an electrolyte solution system. Adding of the hexamethyldisilazane to a lead electrode surface able to adsorb in a charge-discharge process is equivalent to improve the evolution potential of hydrogen, and can reduce hydrogen evolution. The lithium ion battery has high capacity retention rate and high capacity recovery rate under a high temperature storage condition, and has excellent cycle performance.

Owner:NINGBO VEKEN BATTERY

Non-flammable waterproofing composition

A composition of matter and a solvent system for use in providing a water resistant coating to a surface of a roof is disclosed. The solvent system comprises a chlorinated solvent blend which includes a vegetable oil. The solvent system and coating composition are non-flammable, environmentally friendly and provide an improved, consistent coating when applied to the surface of a roof.

Owner:BLAIR RUBBER

Reversible Derivatization of Poly (Aryl Ether Ketones)

A method of forming a polymer matrix composite using a soluble derivative of a poly (aryl ether ketone) (PAEK). The method includes mixing a starting PAEK polymer with a solvent and an acid, said solvent being selected from a group consisting of diethylether, tetrahydrofuran (THF), dioxin, and chlorinated solvents; reacting the PAEK mixture with a Lewis acid and a thiol compound in amounts effective to form a poly (aryl ether thioacetal) compound which comprises at least one thioacetal group; and impregnating a plurality of fibers in a solution comprising said poly (aryl ether thioacetal) compound.

Owner:CYTEC TECH CORP

Method for the treatment of ground water and soils using mixtures of seaweed and kelp

ActiveUS8147694B2Accelerated dechlorinationIncreasing rate of biological mineralizationSolid waste disposalContaminated soil reclamationAscophyllumChlorinated solvent

The induction of reducing conditions and stimulating anaerobic process through the addition of species of seaweed (Dulse, Nori, Ascophyllum nodosum, and Kelp) to accomplish accelerated dechlorinization of soil and groundwater contaminated with chlorinated solvents and heavy metals.

Owner:INNOVATIVE ENVIRONMENTAL TECH

Method for the treatment of ground water and soils using dried algae and other dried mixtures

InactiveUS7828974B2Accelerated dechlorinationIncreasing rate of biological mineralizationSolid waste disposalWater contaminantsFresh waterBlue green algae

The induction of reducing conditions and stimulating anaerobic process through the addition of dried micro-blue green algae (Spirulina, Arthorospira Platensis, Arthrospria Maxima, Aphanizomen flos-aquae, and chlorella) and seaweed (Dulse, Nori, and Kelp) to accomplish accelerated dechlorinization of soil and groundwater contaminated with chlorinated solvents and heavy metals.

Owner:INNOVATIVE ENVIRONMENTAL TECH

Use of encapsulated substrates that controlthe release rates of organic hydrogen donors

ActiveUS20140311971A1Control releaseContaminated soil reclamationTreatment with anaerobic digestion processesOrganismal ProcessHydrogen

Anaerobic reductive dechlorination processes remove chlorinated solvents from contaminated subsurface soil and ground water. The presence of organic hydrogen donors enables anaerobic microorganisms present in the subsurface soil and groundwater to accelerate the reductive dechlorination process. The present invention provides an alternative method to control the release rate of organic hydrogen donors during dechlorination. The invention utilizes encapsulated substrates to control the release rate of organic hydrogen donors, therefore accelerating the biotic process of anaerobic reductive dechlorination.

Owner:INNOVATIVE ENVIRONMENTAL TECH

Utilization of Ferric Ammonium Citrate for In Situ Remediation of Chlorinated Solvents

InactiveUS20140030797A1Promote degradationAccelerated dechlorinationSolid waste disposalWater contaminantsUltrasound attenuationIn situ remediation

Accelerated dechlorination of soil and water contaminated with chlorinated solvents in situ is achieved by delivering ferric ammonium citrate into the soils and / or water. The induction of ferric ammonium citrate into sulfate-rich reducing conditions initiates a combined abiotic and biotic mechanism for the dechlorination of subsurface contaminants. Initial and rapid removal of chlorinated solvents is achieved by way of reductive transformation, a mechanism utilizing the creation of an iron-bound soil mineral (pyrite) followed by stimulating conditions for enhanced biological natural attenuation.

Owner:INNOVATIVE ENVIRONMENTAL TECH

In-situ treatment of in ground contamination

InactiveUS20070098501A1Easy to apply into groundImprove distributionSolid waste disposalWater contaminantsWater MovementsChlorinated solvent

In systems and methods for treatment of underground contamination, ferrous sulfide is provided as a substantially insoluble material in an underground formation. The ferrous sulfide accordingly may remain substantially in place, even over long periods of time, regardless of underground water movement or diffusion. As a result, the ferrous sulfide may act continuously to chemically reduce and remove contamination. When used for treatment of chromium ore processing residue contamination, the ferrous sulfide may remain in the pores of the soil or residue. As hexavalent chromium diffuses from the soil or residue, it is reduced by the ferrous sulfide. The ferrous sulfide may be injected as a liquid into the underground formation, and then change to a more solid form. Chlorinated solvent contamination, dissolved chromium from other than COPR contamination, and other dissolved metals may also be treated.

Owner:CH2M HILL

Optical film, polarizing plate and display device utilising the film, and production method of optical film

An optical film is disclosed having minimal curl, minimal coating unevenness and no cracks. The optical film is obtained by casting a dope comprising a cellulose ester and a non-chlorinated solvent on a metal support, the cellulose ester having a total acyl substitution degree of 2.6 to 2.85 and having a ratio of a weight-average molecular weight to a number-average molecular weight of 1:1 to 3:1; drying the cast dope on the metal support so as to obtain a cellulose ester film; peeling the cellulose ester film from the metal support; further drying the cellulose ester film while providing a longitudinal stretch or a lateral stretch to the cellulose ester film; and providing a metal oxide layer on the cellulose ester film.

Owner:KONICA CORP

Chemical injection using an adjustable depth air sparging system

InactiveUS20090065408A1Easily damagedPrevent escapeWater cleaningContaminated soil reclamationInjection pointEngineering

A supplemental fluid adjustable depth air sparging system which is used to remediate contaminates from groundwater within the soil. An adjustable depth air injection point injects compressed air, and an adjustable depth chemical injection point injects a chemical oxidizer or nutrient into saturated or groundwater regions of the soil's subsurface to remove contaminants including chlorinated solvents from the soil's subsurface.

Owner:USA REPRESENTED BY THE SEC OF THE NAVY

Liposome-containing radiographic contrast medium and preparation method thereof

InactiveCN1988919AImprove transport efficiencyHigh selectivityX-ray constrast preparationsOil/fats/waxes non-active ingredientsLipid formationIodide

A liposome-containing X-ray radiopaque dye comprising a water soluble iodide compound contained in a water phase inside and outside lipid membranes. The liposomes are produced by mixing lipid membrane components for constituting lipid membranes with carbon dioxide of supercritical or subcritical condition in the presence of at least one compound having a hydroxyl or polyalkylene oxide group. The obtained X-ray radiopaque dye containing these liposomes does not contain any toxic solvents, such as chlorinated solvents, so that high safety can be ensured.

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com