Method for producing granular compound fertilizer through coating and pelletizing

A compound fertilizer, compound fertilizer technology, applied in fertilizer mixture, fertilization device, application and other directions, can solve the problems of less than 100% qualified rate of export materials, high maintenance cost of extrusion equipment, rough surface of particles, etc. Improved production environment, improved surface finish, and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] (2) Preparation of nucleus:

[0032] Nuclei are produced in stirring granulators, drum granulators, disc granulators, extrusion granulators, tower granulators or other equipment. Under suitable moisture conditions, granular materials with a particle size range of 0.5-4 mm can be obtained. The narrower the particle size distribution range of the particles, the more uniform the size, and the more uniform the particle size of the material at the outlet of the subsequent coating machine. Or can directly use granular urea, granular ammonium nitrate or ammonium nitrate phosphorus, granular ammonium phosphate, etc. in the raw material as the particle nucleus; or sieve a certain granular raw material, and take some particles with uniform particle size as the particle nucleus to achieve better Effect.

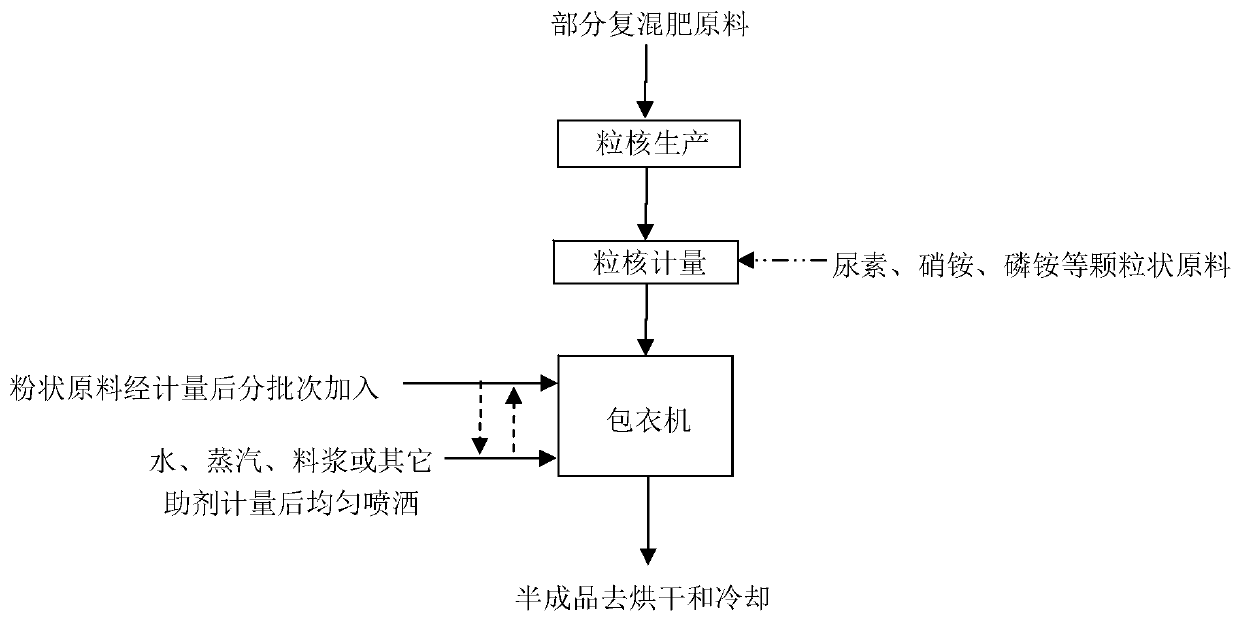

[0033] (3) Batch coating granulation

[0034] The coating and granulation process is carried out in the coating machine, and the mode of batch operation is adopted. The struct...

Embodiment 1

[0038] refer to figure 1 The shown production process, the fertilizer formula is shown in Table 1, the percentages of raw materials in the table are all mass percentages, product specifications: N-P 2 o 5 -K 2 O=15-15-15, product particle size 3-4.5mm. Batch loading capacity of coating machine: 1.5 tons.

[0039] Table 1. Raw material formula one

[0040] serial number

Types of basic fertilizers and fillers

Raw material addition per ton of product (kg)

1

Urea (N: 46%)

100

2

282

3

Monoammonium Phosphate (N: 11%P 2 o 5 : 44%)

344

4

Potassium Chloride (K 2 O>60%)

253

5

Kaolin

37

[0041] Use a stirring granulator to produce granules according to the ratio in Table 1. The particle size range of the granules is 1-2mm, no drying is required, and the required amount of batch granules is 0.1 tons; then all raw materials are measured according to the proportion an...

Embodiment 2

[0044] refer to figure 1 Shown production technological process, fertilizer formulation is shown in Table 1 with embodiment 1, product specification: N-P 2 o 5 -K 2 O=15-15-15, product particle size 3-4.5mm. Batch loading capacity of coating machine: 1.5 tons.

[0045] All the small particles of urea in the raw materials are used as particle nuclei, and the particle size of urea is 0.85-2.8mm. The rest of the raw materials other than urea are crushed to a fineness below 100 mesh as powdery raw materials; the amount of urea added in batches is 0.15 tons, The total amount of other powdery raw materials added: 1.35 tons. The powdered raw materials are added in 20 times, and a certain amount of water is added for every 67.5 kg of powdered raw materials added. The interval between powder additions is about 2 minutes, and the total amount of water added is 20-60 kg.

[0046] The powdered raw materials can be mixed and added in 20 times, or can be added into the coating machine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com