Dense-phase conveying pipeline for high-concentration powder

A technology of conveying pipelines and dense phase conveying, which is applied in the field of machinery, can solve problems such as high operating costs, time-consuming and laborious, and blockages, and achieve the effect of large design margins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1: raw materials: pulverized coal, nitrogen.

[0052] In this embodiment, the screw feeder is used to transport the pulverized coal raw material, which is sent to the storage tank for storage. The conveying capacity is 2000.0kg / h, normal pressure, pulverized coal, nitrogen and special pipeline parameters are as follows:

[0053] Table 1: Raw material parameter list

[0054]

[0055] Table 2 Special type pipeline parameters

[0056]

[0057] The feeding port of the screw feeder is connected to a special-shaped pipeline, and the special-shaped pipeline is connected to the storage tank. The film gas and the carrier gas are both served by nitrogen.

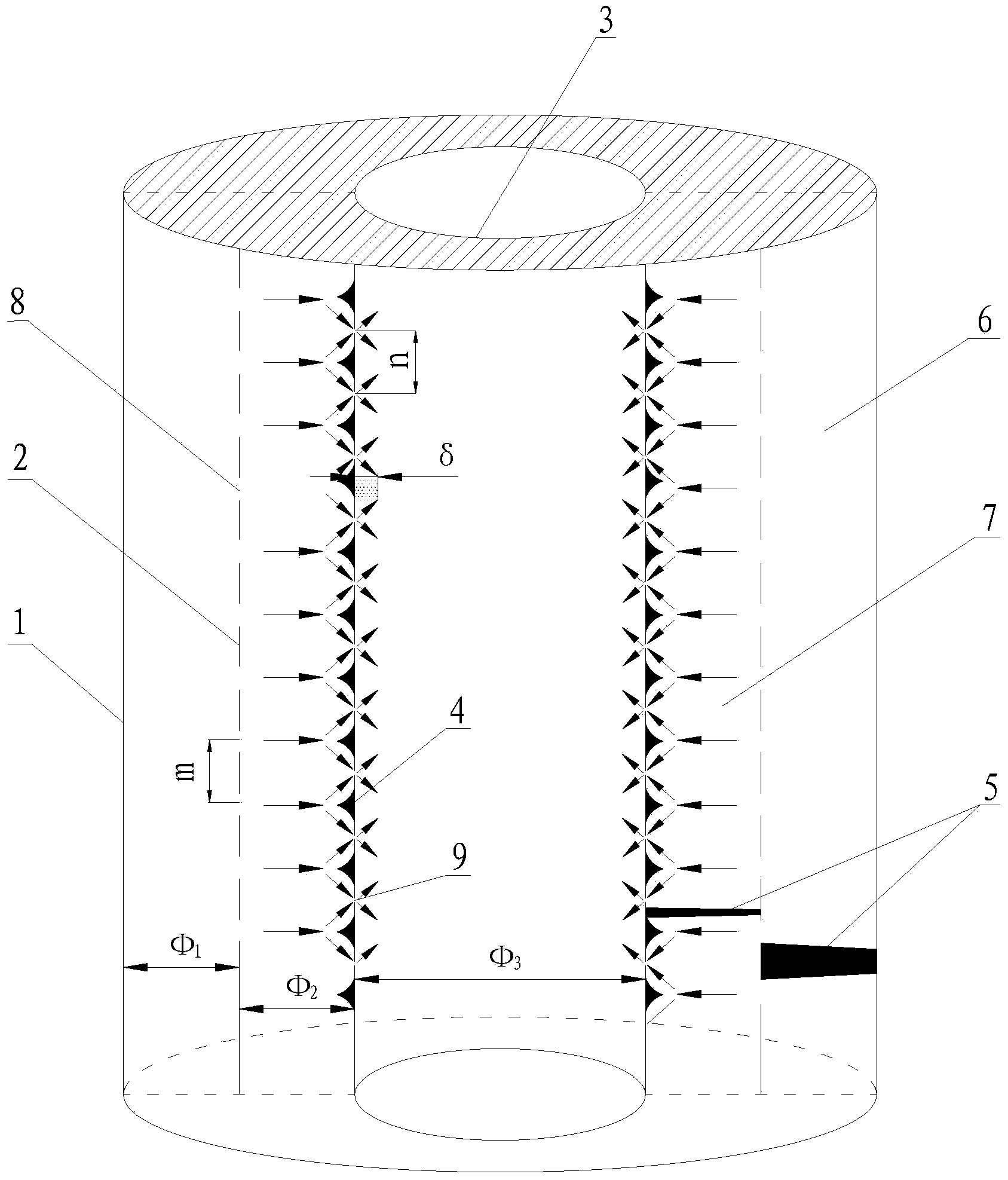

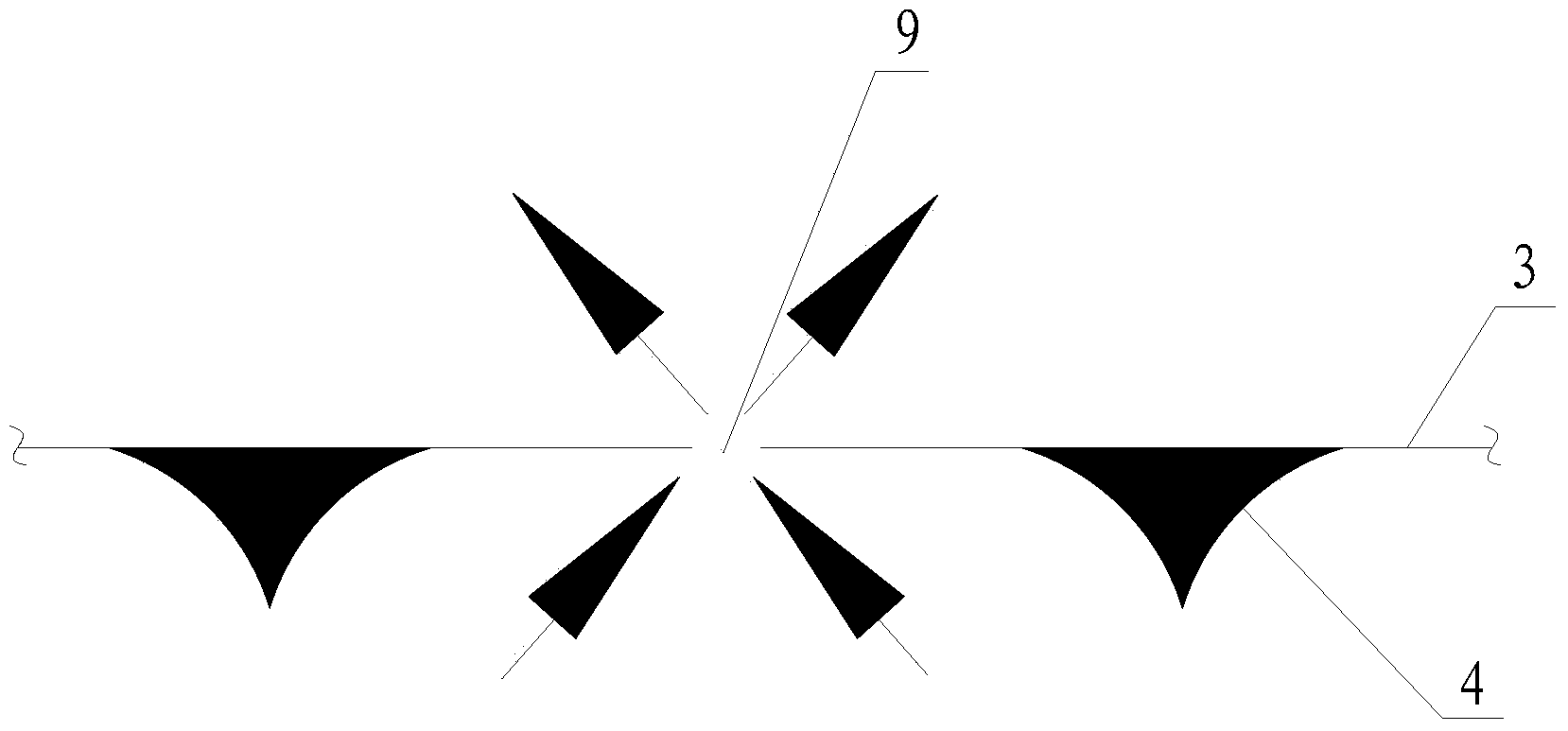

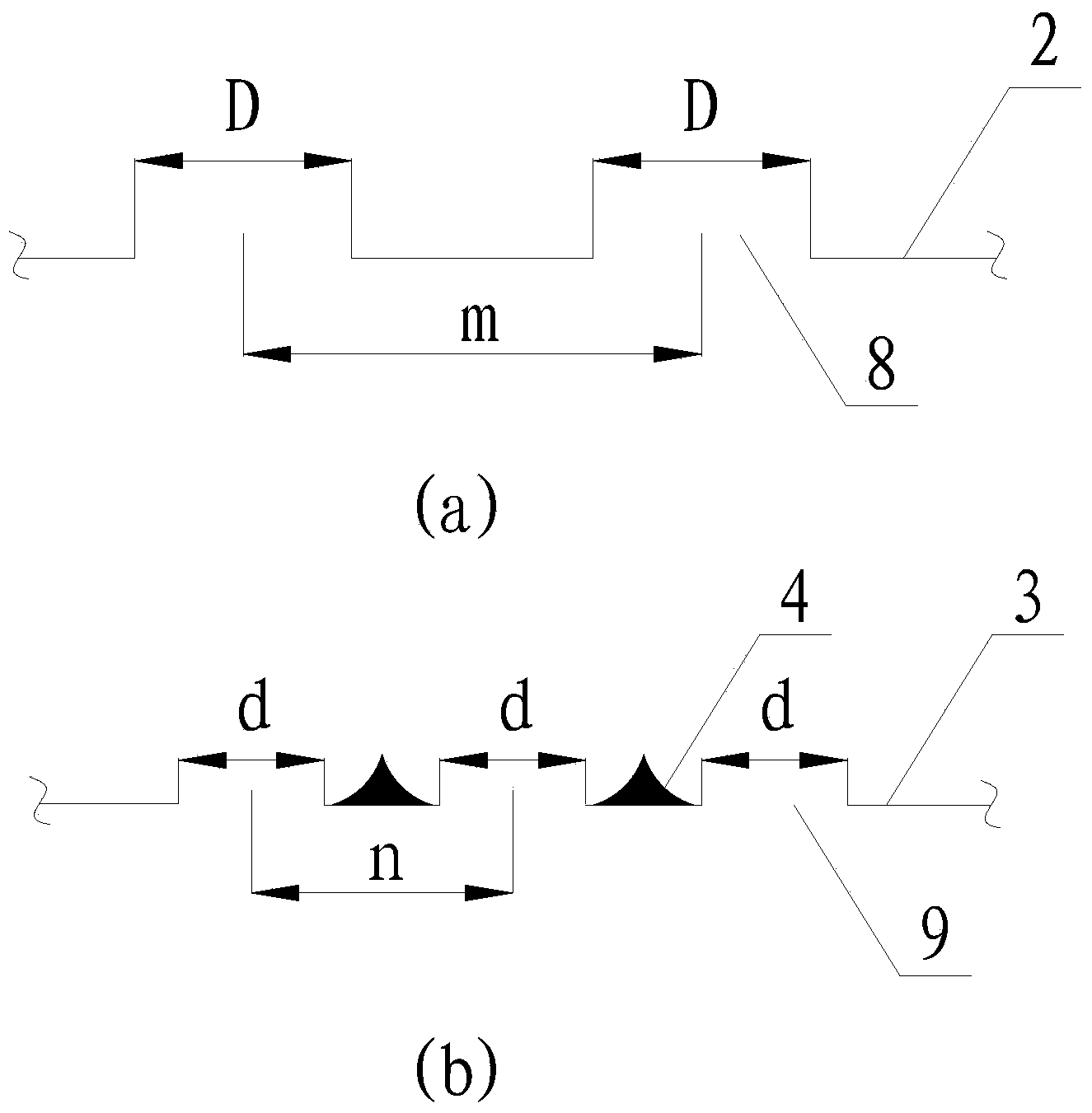

[0058] Nitrogen enters the special pipe Ф 1 =1.50mm air film air channel, and then enter the Ф through the large hole with hole diameter D=0.12mm and hole spacing m=24.0mm 2 =4.0mm film-forming channel, nitrogen is shot at the apex of the gas deflector installed on the wall of the film-forming channel, and t...

Embodiment 2

[0059] Embodiment 2: Raw materials: medicinal powder, carbon dioxide.

[0060] In this embodiment, pressurized tanks are used to transport the ground medicinal powder raw materials to the production line, with a conveying capacity of 500.0kg / h, normal pressure, medicinal powder, carbon dioxide and special pipeline parameters are as follows:

[0061] Table 3: Raw material parameter list

[0062]

[0063] Table 4: Special type pipeline parameters

[0064]

[0065] The feeding port of the pressurized tank is connected to a special-shaped pipeline, and the special-shaped pipeline is connected to the airtight container of the production line. The film gas and the carrier gas are both acted by carbon dioxide.

[0066] Carbon dioxide enters the special pipe Ф 1 =3.0mm air film gas channel, and then enter the Ф through the large hole with hole diameter D=0.30mm and hole spacing m=58.0mm 2 =8.0mm film-forming channel, the nitrogen gas shoots to the gas deflector installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com