Wide frequency high magnetic conductive ratio low loss manganese zincium soft magnetic ferrite material and preparation thereof

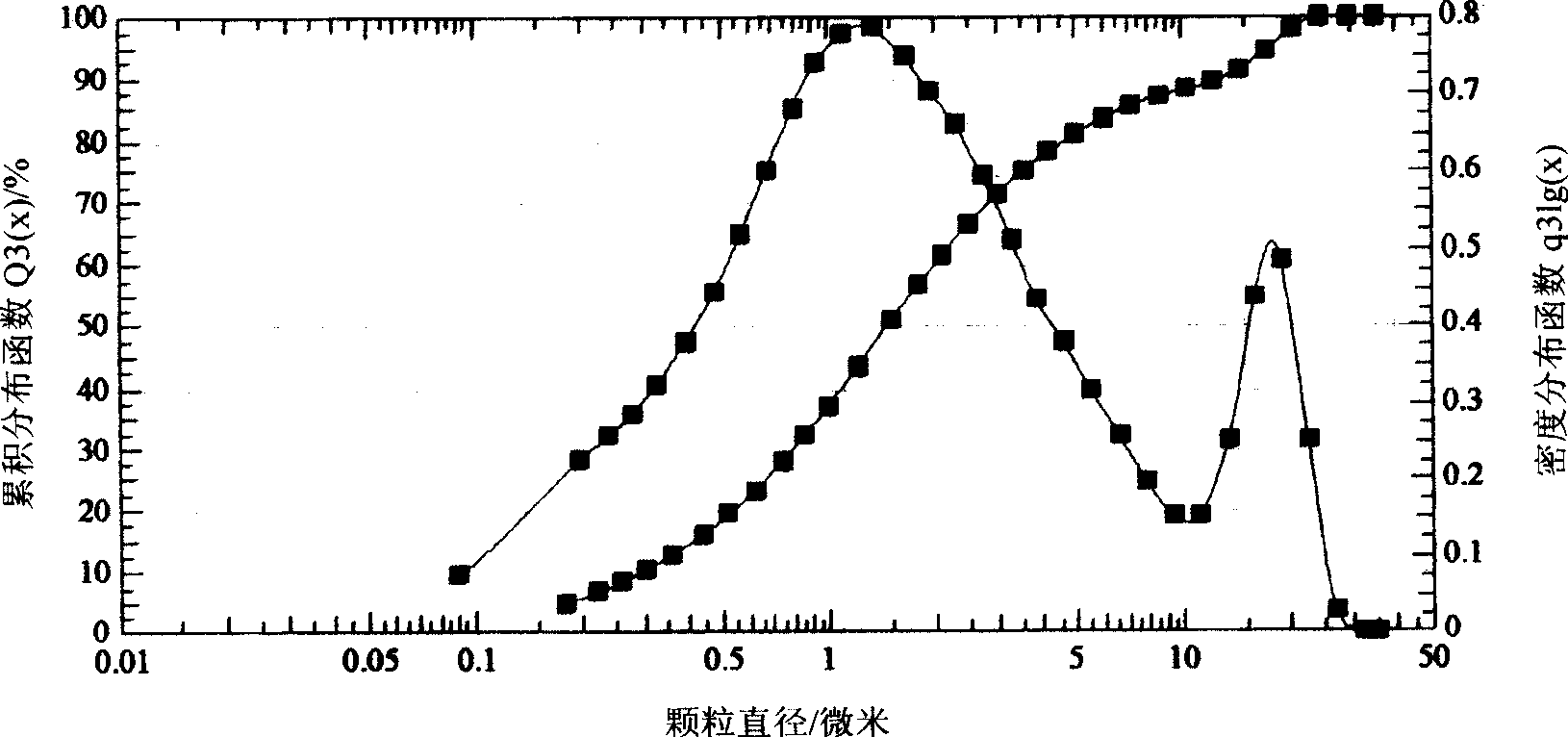

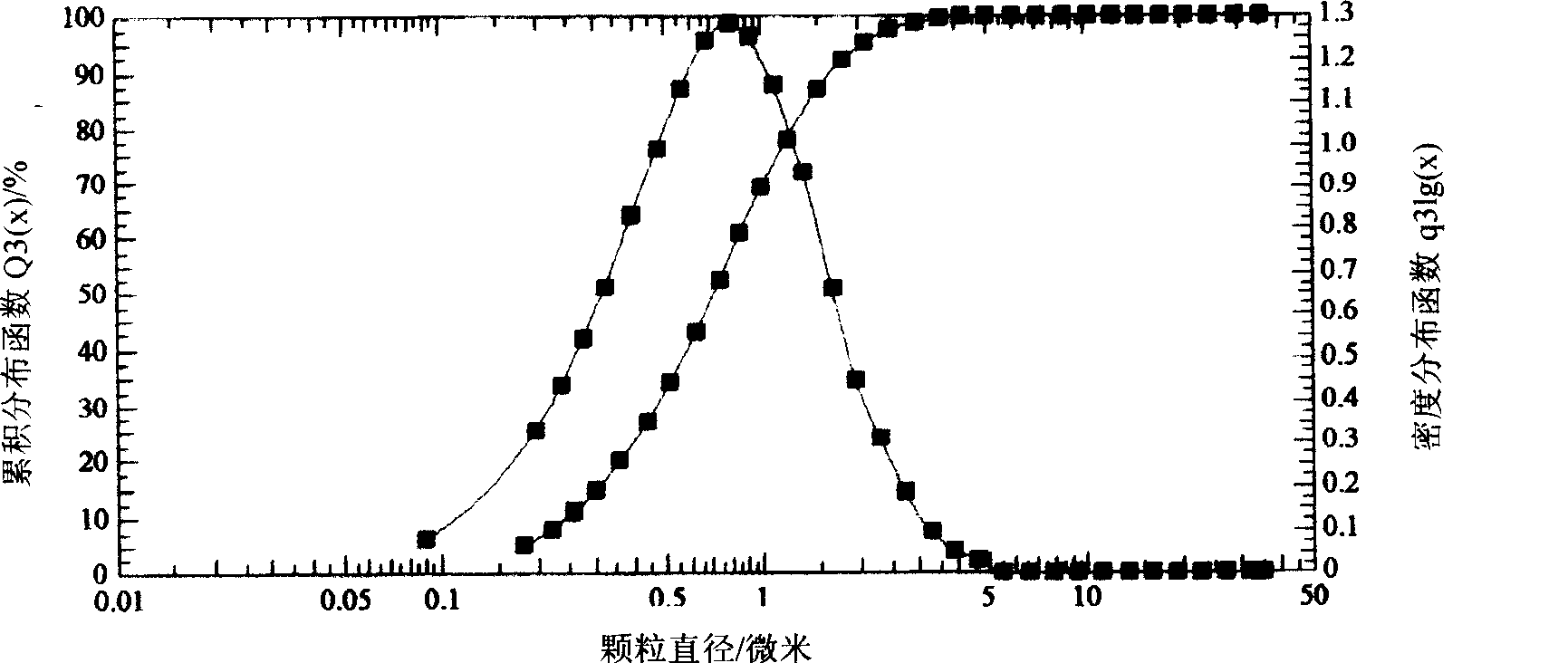

A manganese-zinc soft magnet and soft ferrite technology, which is applied in the preparation of soft ferrite materials, and in the field of manganese-zinc soft magnetic ferrite materials with high magnetic permeability and low loss, can solve the problem of high energy consumption and high yield in grinding process Low-level problems, to achieve the effect of improving practical value, narrow and uniform powder particle size distribution, and avoiding excessive refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The manganese-zinc soft magnetic ferrite material with wide frequency, high magnetic permeability and low loss of the present invention is composed of Mn-Zn series ferrite powder main component and auxiliary components; the main component of the Mn-Zn series ferrite powder includes Fe 2 o 3 , MnO, ZnO, the auxiliary components include Bi 2 o 3 , MoO, V 2 o 5 , CaCO 3 , SnO 2 Now get the soft magnetic ferrite material of 100g of the present invention, wherein contain:

[0017] Fe 2 o 3 69g

[0018] MnO 15.5g

[0019] ZnO 14.5g

[0020] Auxiliary ingredients 1g

[0021] The preparation method of the manganese-zinc soft magnetic ferrite material with wide frequency, high magnetic permeability and low loss described in the present invention has three steps. Taking the preparation of 100g finished product as an example, the specific steps are as follows:

[0022] 1) Add 69g Fe 2 o 3 , 15.5g MnO, and 14.5g ZnO are uniformly mixed, and the uniformly mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com