A polymer alloy suspension clamp

A technology of polymer alloy and suspension clamp, which is applied in the direction of cable suspension device, etc., can solve the problem of large power loss and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

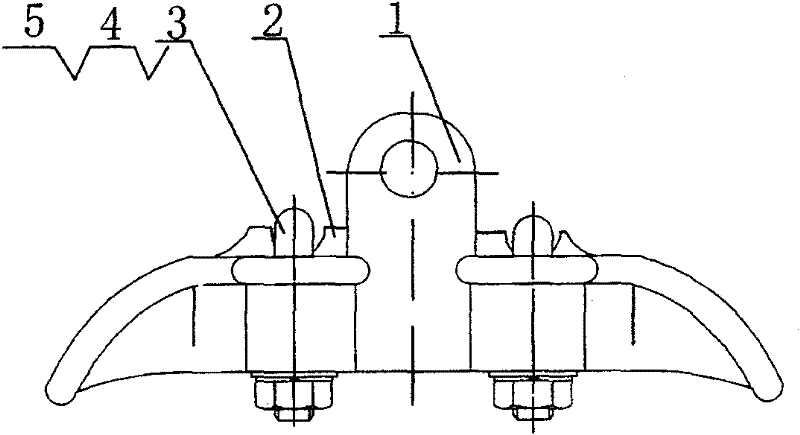

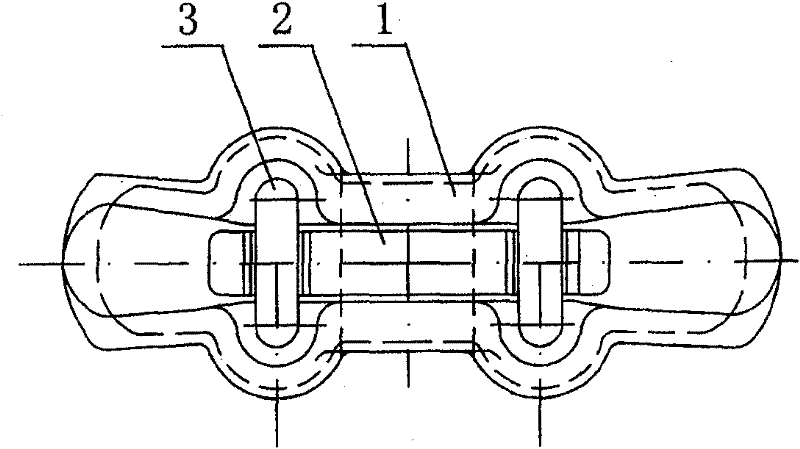

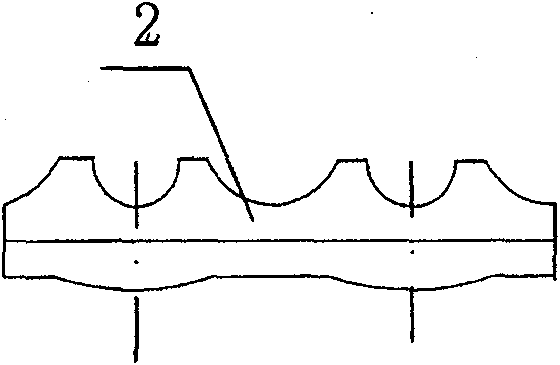

[0019] Such as figure 1 , figure 2 , image 3 , Using non-metallic non-magnetic polymer alloy material polyamide as the main material precision casting to make the main body of the wire clip 1, polymer alloy composition formula and mass percentage: polyamide 38-80%, heat-resistant anti-aging agent 3-32%, Toughening agent 5-26%, reinforcing modifier 7-50%, anti-current corrosion agent 0.1-0.5%, anti-ultraviolet light auxiliary agent 0.05-1%, metal fiber reinforcing agent 1.5-7%. Processed into a symmetrical butterfly structure. A semicircular groove is axially arranged in the middle of the clamp main body 1 . Conductive wires pass through the grooves. Non-magnetic 45MN17A13 high-manganese low-carbon steel is used as the main material to make the pressure plate by precision casting. A semicircular groove is arranged axially on the lower part of the pressing plate. 2-6 semicircular grooves are arranged radially on the upper part of the pressing plate. Match the semicircul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com