Anti-aging anti-fogdrop greenhouse film and preparation method thereof

An anti-fog and greenhouse film technology, applied in the field of composite materials, can solve the problems of increased cost and short aging time of greenhouse film, and achieve the effect of long anti-aging time and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

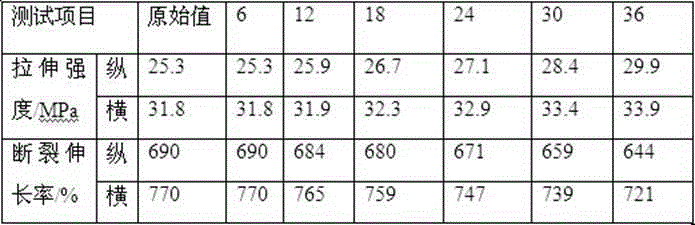

Embodiment 1

[0020] An anti-aging and anti-fog droplet greenhouse film, the components and the mass fraction of each component are as follows: polyethylene (52 parts of LDPE and 8 parts of LLDPE) 60 parts, 0.1 part of triphenyl phosphite, dilaurin thiodipropionate 0.15 part of ester, 0.05 part of 6-ethoxy-2,2,4-trimethyl-1,2-dihydroquinoline, 3 parts of sodium alkylbenzene sulfonate, 4 parts of polyvinylpyrrolidone, dibutyl sulfide 1 part of dioctyl acid, 0.1 part of antioxidant 1010.

[0021] The preparation method of the anti-aging and anti-fog droplet greenhouse film is to weigh each component in proportion, add it into a high-speed mixer, and mix at a high speed. 10min, and then extruded and granulated through a twin-screw extruder, blow-molded to obtain the finished product; the temperatures of each section of the twin-screw extruder are: 130°C for the first zone, 150°C for the second zone, and 150°C for the third zone. 160℃, four-zone temperature control 170℃, head temperature 170℃,...

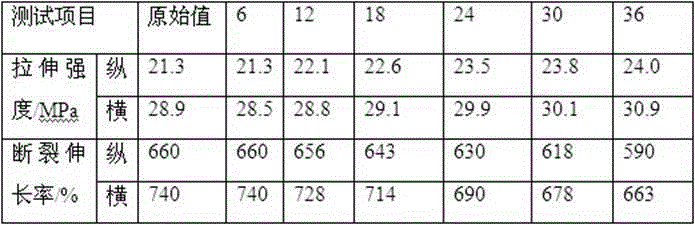

Embodiment 2

[0027] An anti-aging and anti-fog droplet greenhouse film, the components and the mass fraction of each component are as follows: 80 parts of polyethylene (67 parts of LDPE and 13 parts of LLDPE), 0.9 part of triphenyl phosphite, and dilaurin thiodipropionate 0.2 part of ester, 0.18 part of 6-ethoxy-2,2,4-trimethyl-1,2-dihydroquinoline, 6 parts of sodium alkylbenzene sulfonate, 1 part of polyvinylpyrrolidone, dibutyl sulfide 3 parts of dioctyl acid, 0.5 part of antioxidant 1010.

[0028] The preparation method of the anti-aging and anti-fog droplet greenhouse film is to weigh each component in proportion, add it into a high-speed mixer, and mix at a high speed. 10min, and then extruded and granulated through a twin-screw extruder, blow-molded to obtain the finished product; the temperatures of each section of the twin-screw extruder are: 130°C for the first zone, 150°C for the second zone, and 150°C for the third zone. 160℃, four-zone temperature control 170℃, head temperatur...

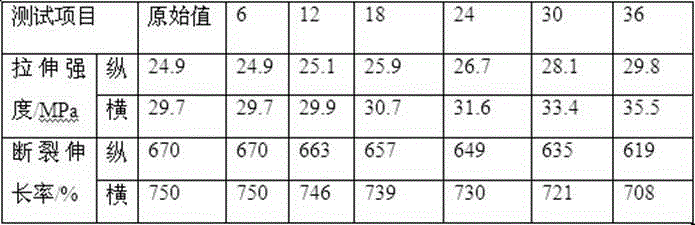

Embodiment 3

[0034] Anti-aging and anti-fogging greenhouse film, the components and the mass fraction of each component are as follows: polyethylene (61 parts of LDPE and 9 parts of LLDPE) 70 parts, triphenyl phosphite 0.5 parts, dilauryl thiodipropionate 0.18 parts parts, 0.08 parts of 6-ethoxy-2,2,4-trimethyl-1,2-dihydroquinoline, 4 parts of sodium alkylbenzenesulfonate, 2 parts of polyvinylpyrrolidone, dibutyric acid disulfide 1 part of octyl ester, 0.2 part of antioxidant DLPP.

[0035]The preparation method of the anti-aging and anti-fog droplet greenhouse film is to weigh each component in proportion, add it into a high-speed mixer, and mix at a high speed. 10min, and then extruded and granulated through a twin-screw extruder, blow-molded to obtain the finished product; the temperatures of each section of the twin-screw extruder are: 130°C for the first zone, 150°C for the second zone, and 150°C for the third zone. 160℃, four-zone temperature control 170℃, head temperature 170℃, ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com