Weather-resistant simulated tree bark and method for making the same

A technology of artificial tree and weather resistance, which is applied in the field of imitation products, can solve the problems of artificial tree bark quality problems, poor physical properties of hard silicone bark, and difficult adhesion of soft silicone bark, etc., to achieve good toughness and weather resistance Strong, shapeable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] First by weight 50 parts of epoxy resin; 2 parts of polyaniline; 1 part of carboxypolysiloxane; 10 parts of double fly powder; 5 parts of fumed white carbon black; 6 parts; 7 parts of curing agent (aliphatic polyamine); 0.5 part of antioxidant (dibutyl hydroxytoluene); 0.5 part of ultraviolet absorber (nano-titanium dioxide); 3 parts of dibutyl phthalate; mixed solvent (wood The mixture of element and phenyl glycidyl ether, the weight ratio is 4:1) 10 parts, carry out raw material preparation.

[0047] The production method is to add 50 parts by weight of epoxy resin to the reaction kettle, then add 10 parts by weight of mixed solvent to dissolve, then put 2 parts by weight of polyaniline and epoxy resin into the reaction kettle to mix, stir at high speed, and control the reaction time. The pH value is 1, the reaction temperature is 20-25°C, and 1 part by weight of carboxypolysiloxane is added after 1 hour of reaction time; the reaction is continued at room temperature ...

Embodiment 2

[0049] First by weight 53 parts of epoxy resin; 2.4 parts of polyaniline; 1.4 parts of carboxypolysiloxane; 12 parts of double fly powder; 6 parts of fumed white carbon black; 7 parts of fiber; 8 parts of curing agent (aliphatic polyamine); 0.7 part of antioxidant (dibutyl hydroxytoluene); 0.7 part of ultraviolet absorber (nano-titanium dioxide); 4 parts of dibutyl phthalate; mixed solvent ( The mixture of lignin and phenyl glycidyl ether, the weight ratio is 4:1) 12 parts, for material preparation.

[0050] The production method is to add 53 parts by weight of epoxy resin to the reaction kettle, then add 12 parts by weight of mixed solvent to dissolve, then put 2.4 parts by weight of polyaniline and epoxy resin into the reaction kettle to mix, stir at high speed, and control the reaction process. The pH value is 1, the reaction temperature is 20-25°C, and 1.4 parts by weight of carboxypolysiloxane is added after 1 hour of reaction time; the reaction is continued at room tempe...

Embodiment 3

[0052] First by weight 57 parts of epoxy resin; 2.7 parts of polyaniline; 1.6 parts of carboxypolysiloxane; 14 parts of double fly powder; 7 parts of fumed white carbon black; 5.7 parts of imitation birch bark light gray paint color paste; 8 parts of glass fiber; 9 parts of curing agent (aliphatic polyamine); 0.8 part of antioxidant (dibutyl hydroxytoluene); 0.8 part of ultraviolet absorber (nano-titanium dioxide); 4 parts of dibutyl phthalate; mixed solvent (a mixture of lignin and phenyl glycidyl ether, the weight ratio is 4:1) 13 parts, for material preparation.

[0053] The production method is to add 57 parts by weight of epoxy resin to the reaction kettle, then add 13 parts by weight of mixed solvent to dissolve, then put 2.7 parts by weight of polyaniline into the reaction kettle to mix with epoxy resin, stir at high speed, and control the reaction process. The pH value is 1, the reaction temperature is 20-25°C, and 1.6 parts by weight of carboxypolysiloxane is added af...

PUM

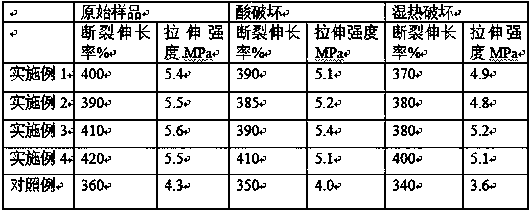

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com