Sintered colored sand and preparation method

A technology of sintering colored sand and sand grains, which is applied in the field of building materials. It can solve the problems of difficult color difference control of colored sand, high firing temperature of colored sand, and difficult process, etc., and achieves long anti-aging time, simple color control, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

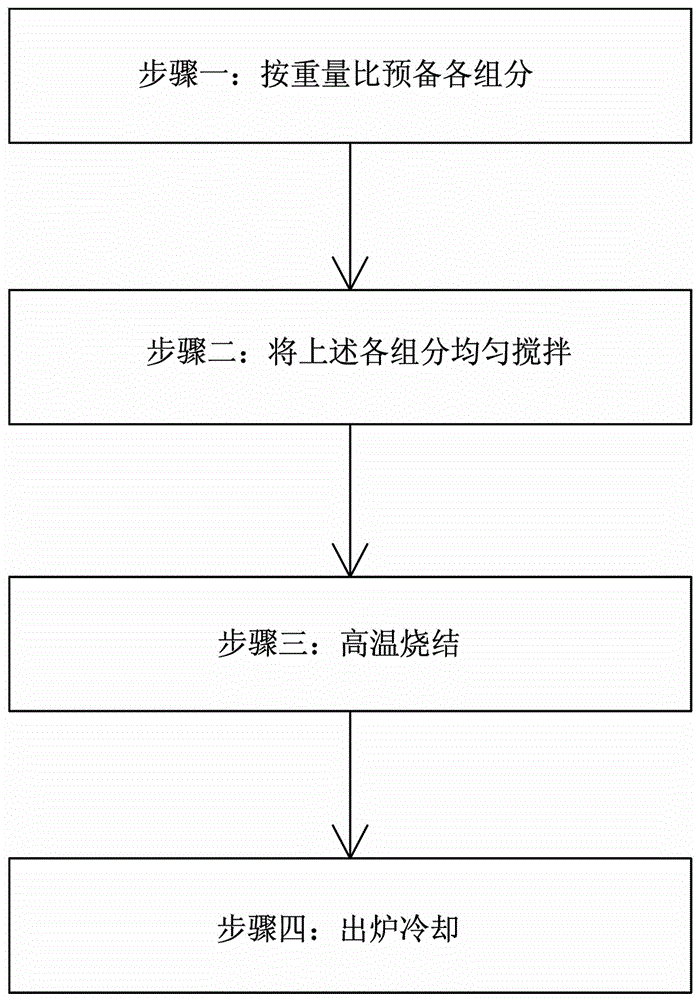

[0035] Such as figure 1 Shown, a kind of preparation method of sintered colored sand is characterized in that, comprises the steps:

[0036] Step 1, preparing each component according to the weight ratio: sand grains, binder, coloring agent and bonding agent, for subsequent use;

[0037] Step 2, the above-mentioned components are evenly stirred;

[0038] Step 3, sintering the above-mentioned uniformly stirred mixture in a rotary kiln at 200-400 degrees for 30-40 minutes to obtain a sintered product;

[0039] Step 4, the above-mentioned sintered product is taken out of the furnace and cooled to obtain sintered colored sand.

Embodiment 1

[0041] Example 1: Take 1000 parts of quartz stone, 25 parts of binder, 10 parts of coloring agent and 3 parts of caking agent, stir the above-mentioned components evenly, and sinter in a rotary kiln between 200-400 degrees for 30- For 40 minutes, finally, the sintered colored sand was obtained by cooling out of the furnace.

Embodiment 2

[0042] Embodiment 2: Take 1000 parts of quartz stone, 30 parts of binder, 15 parts of coloring agent and 5 parts of caking agent, stir the above-mentioned components evenly, and sinter in a rotary kiln between 200-400 degrees for 30- For 40 minutes, finally, the sintered colored sand was obtained by cooling out of the furnace.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com