A kind of combined repairing agent formula, method and application of soil heavy metal tin and lead

A combined repair and heavy metal technology, applied in the restoration of contaminated soil, chemical instruments and methods, applications, etc., can solve the problems of high addition ratio, many types of repair materials, and large energy consumption, so as to improve firmness and durability , to achieve the effect of solidifying the foundation and improving the compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

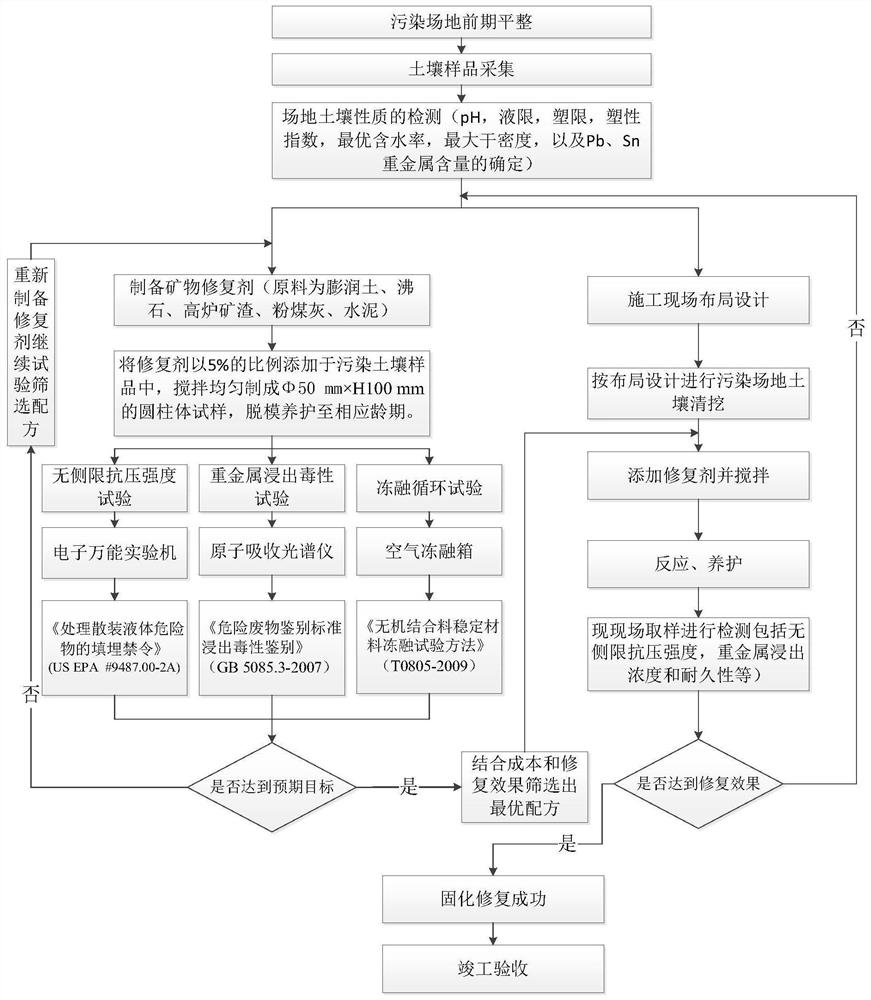

Method used

Image

Examples

preparation example Construction

[0050] (1) Preparation of restoration agent;

[0051] (2) The heavy metal contaminated soil is mixed with the remediation agent in a certain proportion;

[0052] (3) Make molds and demoulds according to industry standards, and cure for a certain period of time (7 days, 14 days, 28 days and 60 days to obtain cured samples;

[0053] (4) According to the unconfined compressive strength (UCS), freeze-thaw cycle, leaching toxicity and other indicators to test and verify the various properties of the formula, and then use it in roadbeds or some building materials at the same time, which is conducive to the restoration of high-concentration industrial pollution sites Later secondary development and utilization.

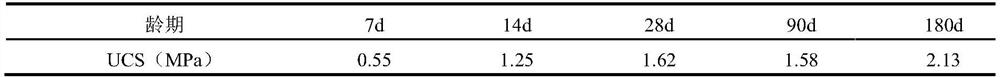

[0054] Unconfined compressive strength test, leaching concentration test and freeze-thaw test were carried out on the cured samples.

[0055] The experimental results show that: the unconfined compressive strength of the soil repaired by the method of the present invention...

Embodiment 1

[0065] The soil for the test was taken from the uncontaminated exposed red clay on the surface in Wuchuan County. The collected soil samples were air-dried, ground and passed through a 20-mesh sieve before use. Choose Pb(NO 3 ) 2 Prepare polluted soil with tin powder as the polluted raw material, prepare the polluted raw material into a solution and add it to the soil, mix Pb with the soil at an addition rate of 5000㎎ / ㎏, and mix Sn with the soil at an addition rate of 2500㎎ / ㎏, fully Stir well and air dry for later use.

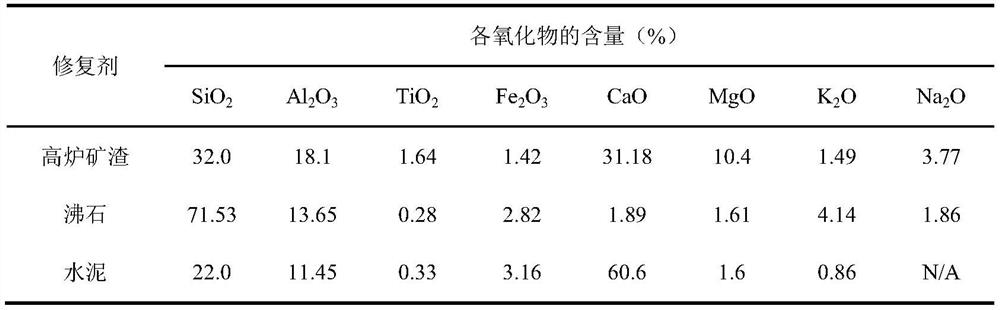

[0066] Zeolite and straw biochar (RS) were selected as the main raw materials to prepare the restoration agent. The main components of the restoration agent are shown in Table 1:

[0067] Table 1 Main components of repair agent

[0068] Element cement blast furnace slag natural zeolite bio-charcoal 1 1.3 parts by mass 1.7 parts by mass 1 part by mass 1 part by mass 2 1.3 parts by mass 1.7 parts by mass 1 part by mass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com