Polyester flame-retardant dense screen production process

A production process, dense mesh technology, applied in the field of polyester flame retardant dense mesh production technology, can solve the problems of short anti-aging time, weak impact resistance, weakened flame retardant effect, etc., to increase social and economic benefits, Increase the anti-aging time and increase the permanent effect of flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

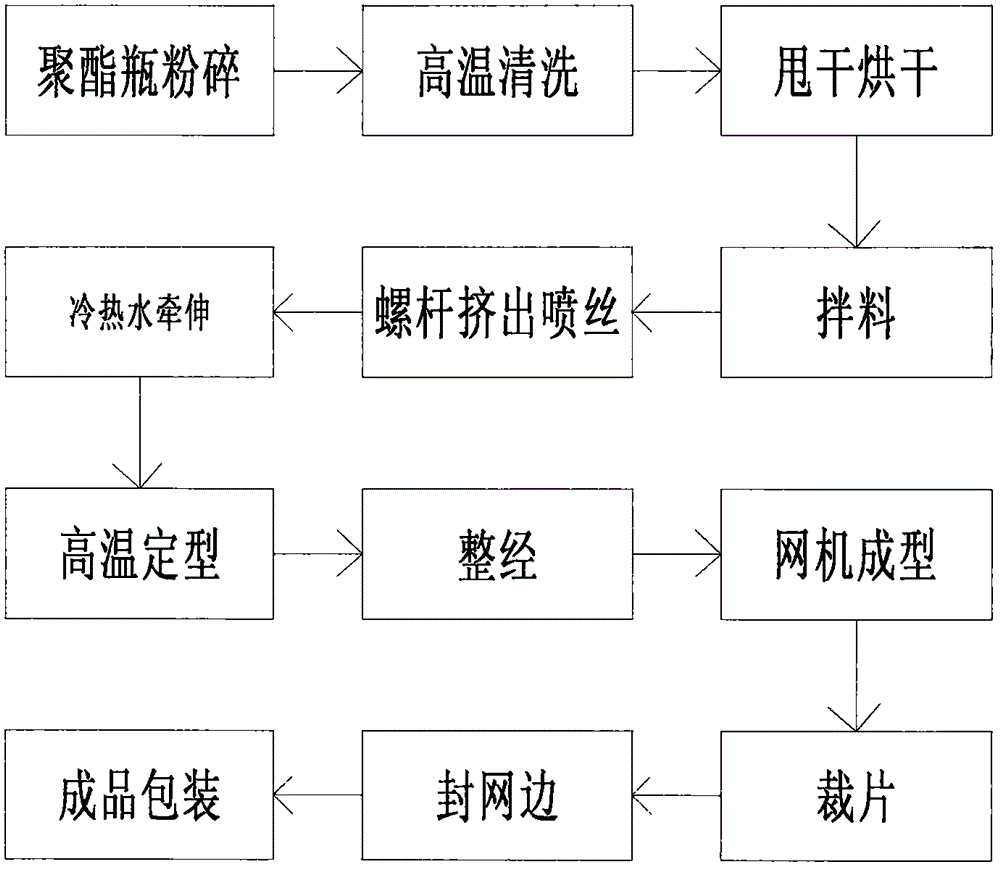

Method used

Image

Examples

Embodiment 1

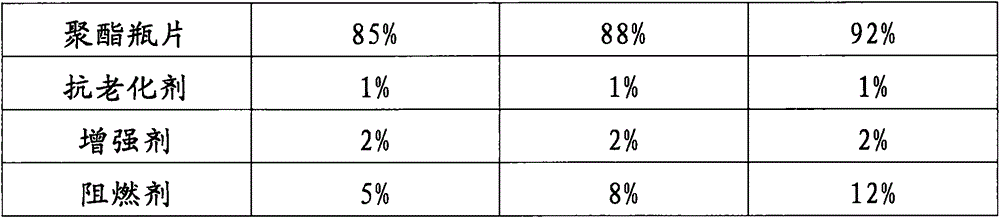

[0040] The raw material of polyester flame-retardant dense mesh is primary plastic particles high-density polyethylene or recycled materials for mineral water bottle cap materials. The raw materials are processed and crushed with a plastic crusher, and the crushed polyester bottle flakes are placed in a high-temperature washing machine at high temperature. Cleaning, the bacteria and microorganisms of the polyester bottle flakes, so as to improve the anti-corrosion ability, after the sterilization is completed, the polyester bottle material is dried, dried with a centrifugal device, and then dried by a drying device. After drying, the Put 85% polyester bottle flakes, 1% anti-aging agent, 2% reinforcing agent, and 5% flame retardant into the mixer, stir evenly to form a recycled polyester flame retardant solution, and use the wire drawing machine screw to make the recycled polyester flame retardant The solution is extruded by a screw, and passed through the spinning reaction equi...

Embodiment 2

[0045] Embodiment 2 is basically the same as Embodiment 1, the only difference is: the proportion of regenerated polyester flame retardant solution,

[0046] According to the distribution percentage table of the regenerated polyester flame retardant solution corresponding to Example 2, put in the materials, and use a mixer to stir evenly to form a regenerated polyester flame retardant solution.

Embodiment 3

[0048] Embodiment 3 is basically the same as Embodiment 1, the only difference is: the proportion of regenerated polyester flame retardant solution,

[0049] According to the distribution percentage table of the regenerated polyester flame retardant solution corresponding to Example 3, put in the materials, and use a mixer to stir evenly to form a regenerated polyester flame retardant solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com