Composite material light energy-saving conductor spacer

A composite material and fiber composite material technology, which is applied in the field of composite material lightweight energy-saving spacer bars, can solve the problems of poor self-adhesion and mutual adhesion, difficult production of non-magnetic steel, and has not been widely promoted, and achieves mechanical strength. Large, extensive market competitiveness, long anti-aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings.

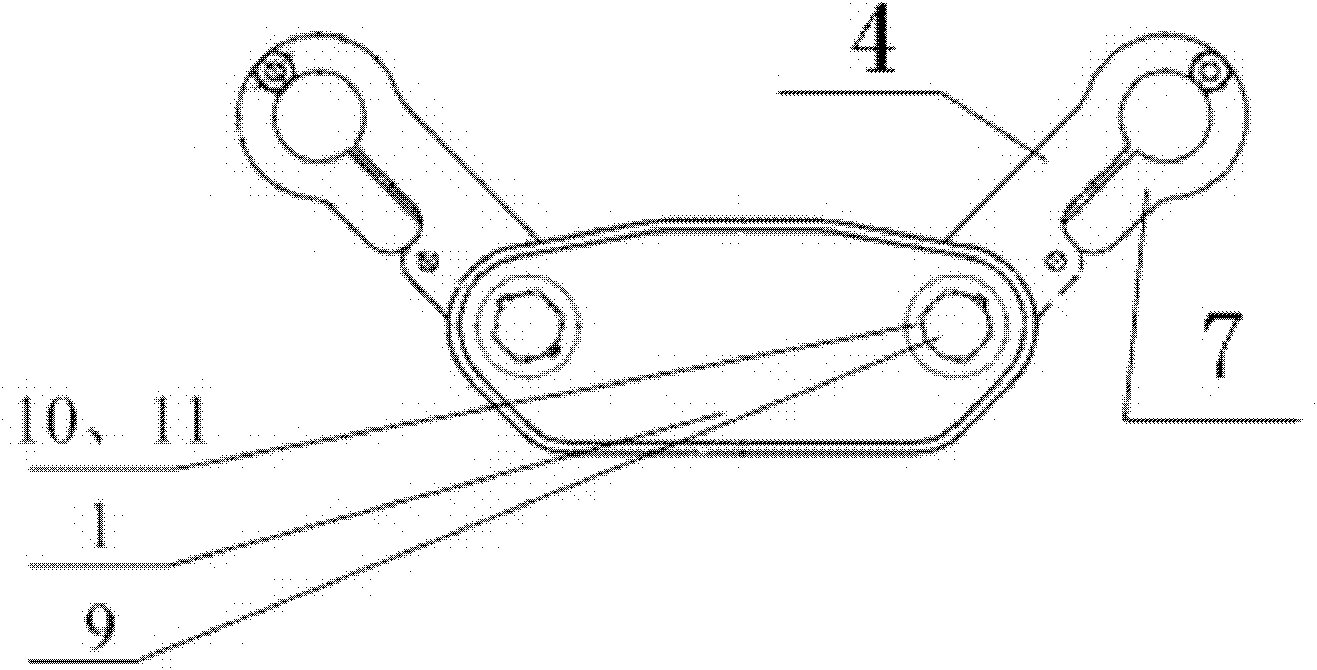

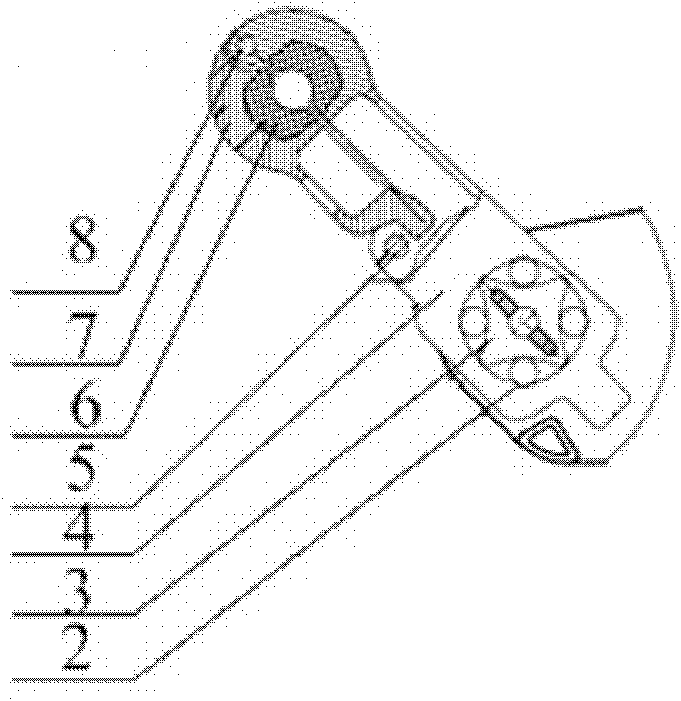

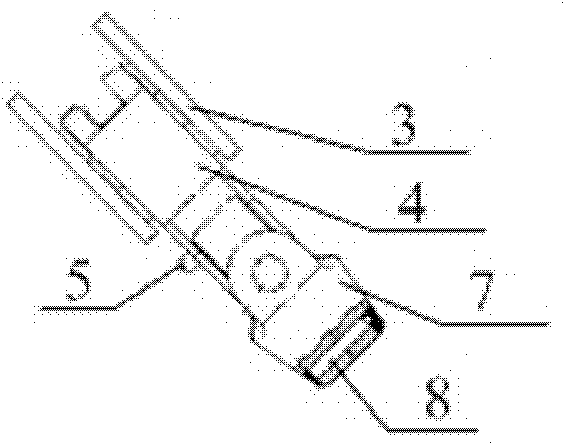

[0039] as attached Figures 1 to 6 As shown, a lightweight energy-saving spacer made of composite material is composed of a frame 1, a rubber column 2, a cross sleeve 3, a clamp body 4, a lock pin 5, a rubber pad 6, a cover plate 7, a hinge pin 8, and a bolt 9. Composed of nut 10 and washer 11, the clamp body 4 is connected to the frame 1 through the rubber column 2, the cross sleeve 3, the nut 10, the washer 11, and the bolt 9, and one end of the cover plate 7 is connected to the clamp body through the lock pin 5 4 connection, the other end of the cover plate 7 is connected with the clamp body 4 through the hinge pin 8, the clamp body 4 and the cover plate 7 form a groove for containing the wire, and rubber pads 6 are arranged around the edge of the groove, so The frame 1, the cross sleeve 3, the clamp body 4, and the cover plate 7 are made of fiber composite materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com