Air pressure control valve and air pump control system using same

A technology of air pressure control and control system, applied in the direction of pump control, pump components, variable capacity pump components, etc., can solve the problems of increased power consumption, energy loss, complicated structure, etc., and achieve the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

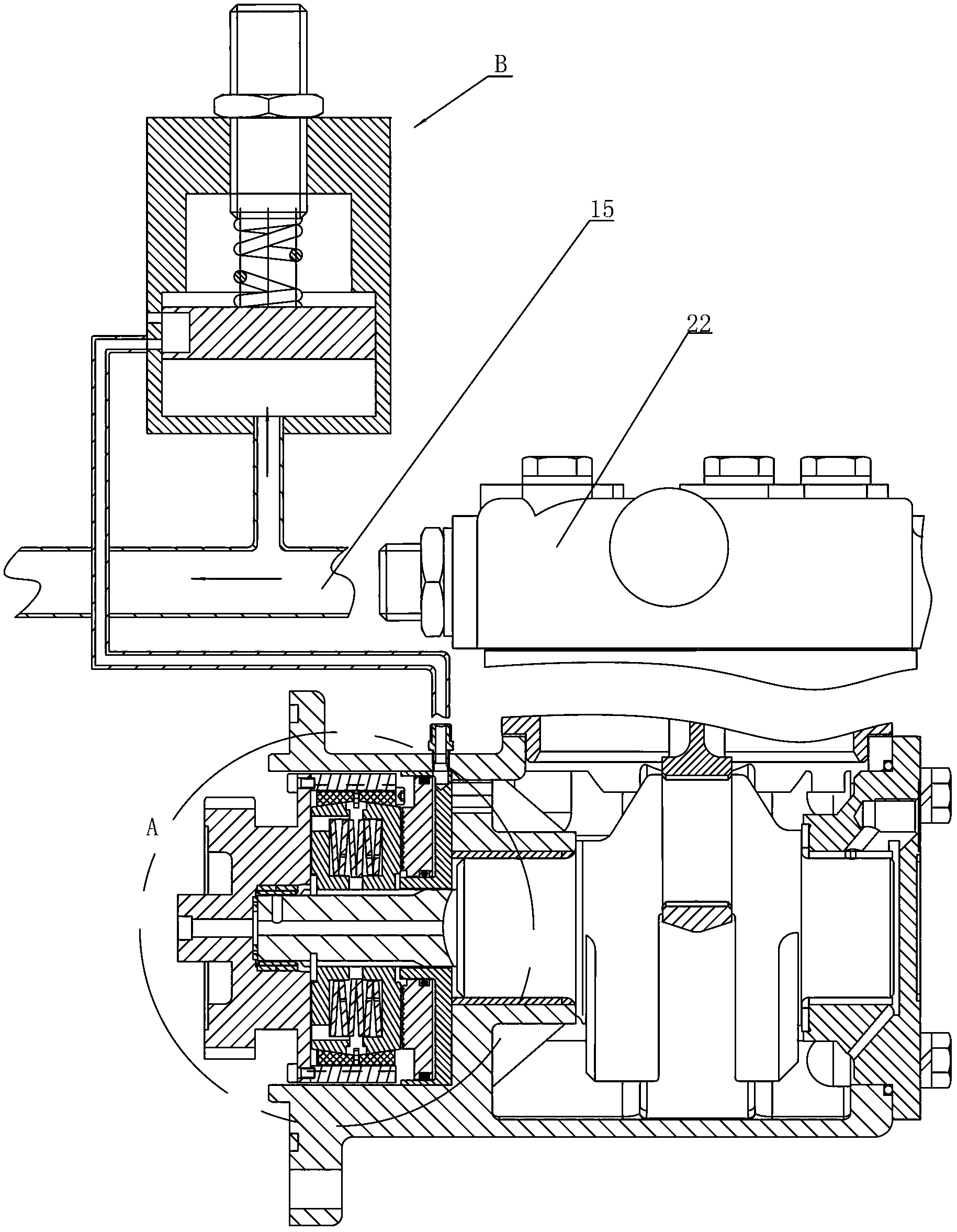

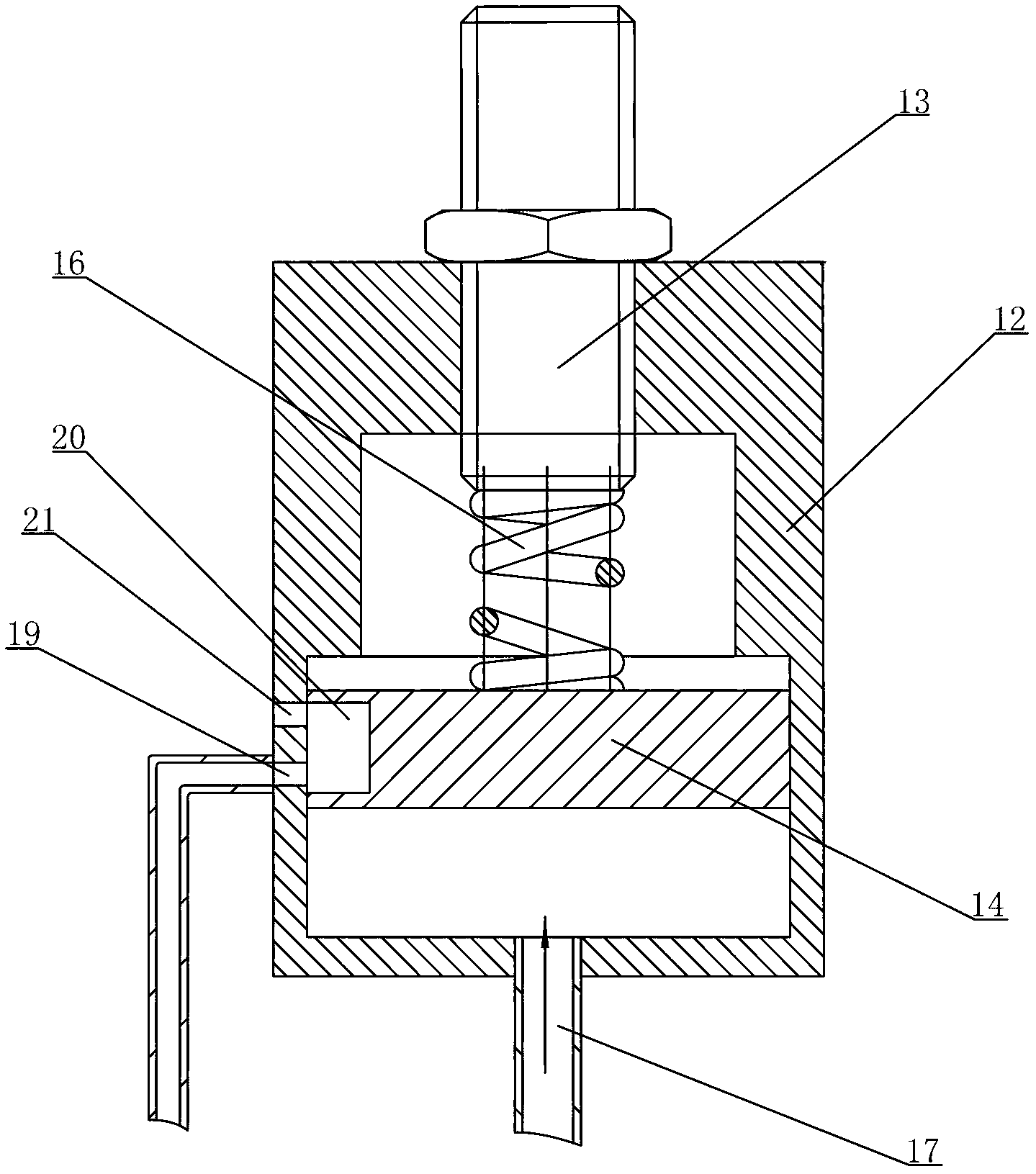

[0024] Such as figure 1 As shown, the air pump control system in this embodiment includes a friction coupling clutch (at A in the figure), an air pressure control valve (at B in the figure) and a shunt pipe 15 .

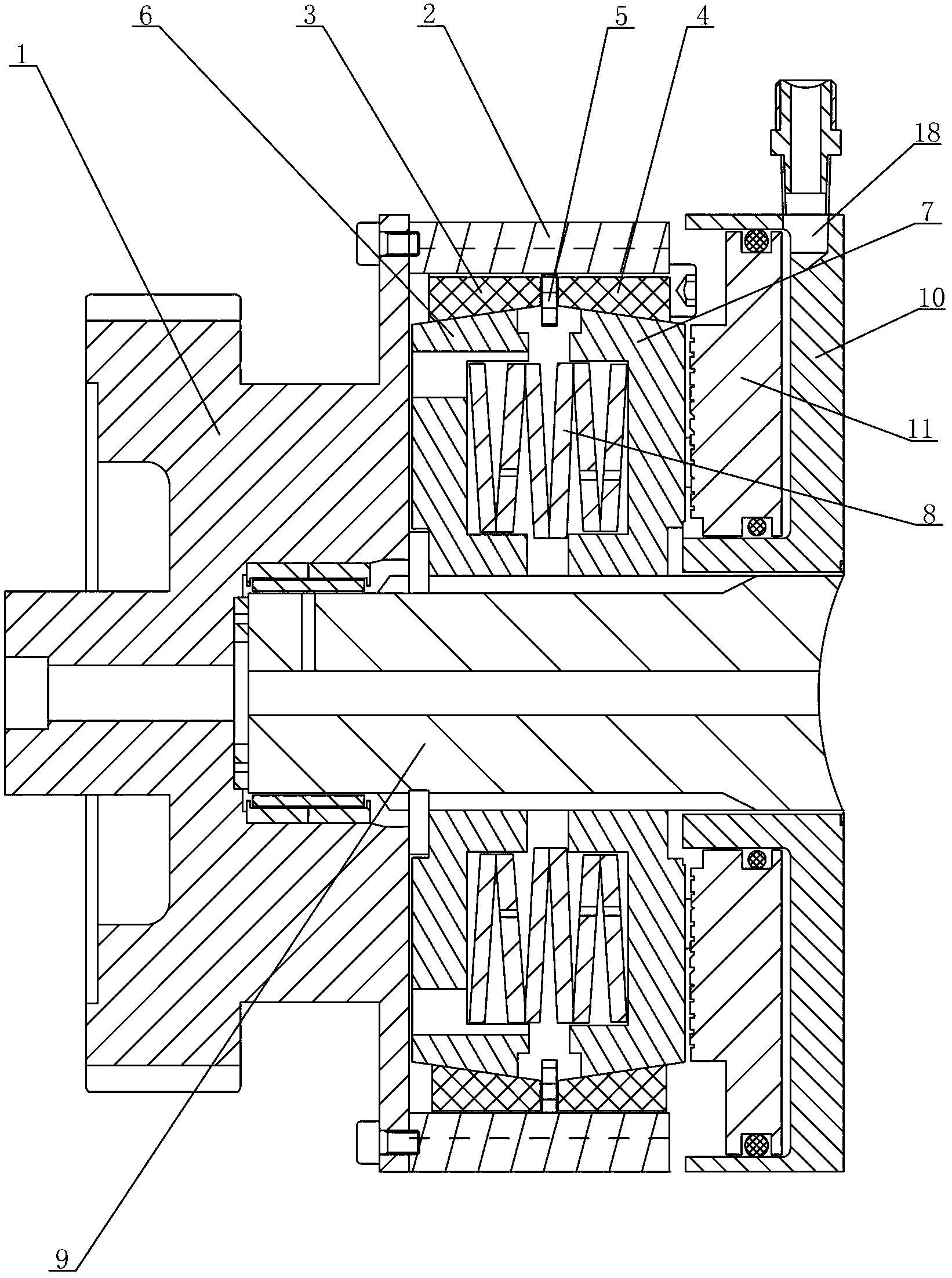

[0025] Such as Figure 2a As shown, the friction coupler includes a transmission wheel 1, a spline sleeve 2, a friction hub and a friction wheel. The transmission wheel is a gear that rotates driven by the output shaft of the engine. The spline sleeve 2 is connected with the gear 1 and rotates with the gear 1. . The friction hub is radially located inside the spline sleeve 2, and the outer surface of the friction hub has a keyway that matches the key of the spline sleeve 2, so that the friction hub can rotate together with the spline sleeve 2. The inner diameter of the friction hub extends from both ends to The middle gradually increases, and the inner surface is a left-right symmetrical conical surface structure. The friction hub is composed of a left-right symmet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com