Patents

Literature

49results about How to "Inhibition of hydrolysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

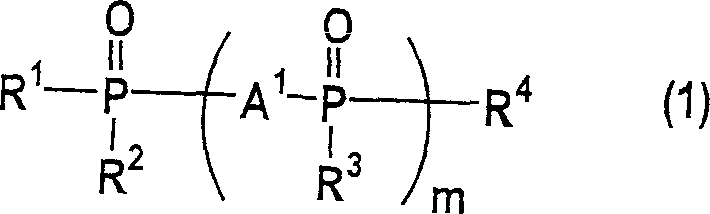

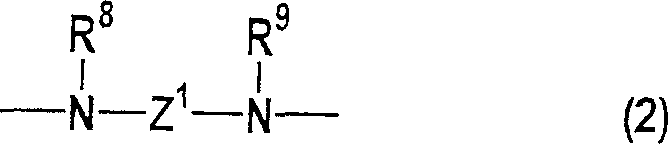

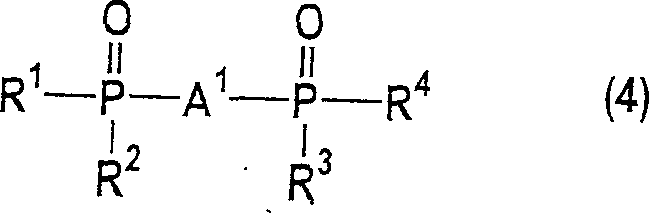

Flame-retardant resin composition

InactiveCN1599776AHigh level of flame retardancyInhibition of hydrolysisPhosphoric Acid EstersOxygen

A flame-retardant resin composition comprises a thermoplastic resin; a flame retardant comprising a phosphorus-containing compound (A), a aromatic resin (B), and at least one flame-retardant auxiliary (C) selected from a nitrogen-containing compound and a metal salt of an inorganic acid; and at least one stabilizer auxiliary (D) selected from a compound having a functional group reactive to an active hydrogen atom and a water-repellent compound. The phosphorus-containing compound may be a phosphoric ester. The aromatic resin may be a polyphenylene sulfide-series resin or a polyphenylene oxide-series resin. The nitrogen-containing compound is a salt of an amino group-containing triazine compound with an oxygen acid, a salt of an amino group-containing triazine compound with a hydroxyl group-containing triazine compound, a polyphosphoric acid amide, a cyclic urea compound, or others. The present invention provides a flame-retardant resin composition which has been flame-retarded without using a halogen-containing flame retardant.

Owner:POLYPLASTICS CO LTD

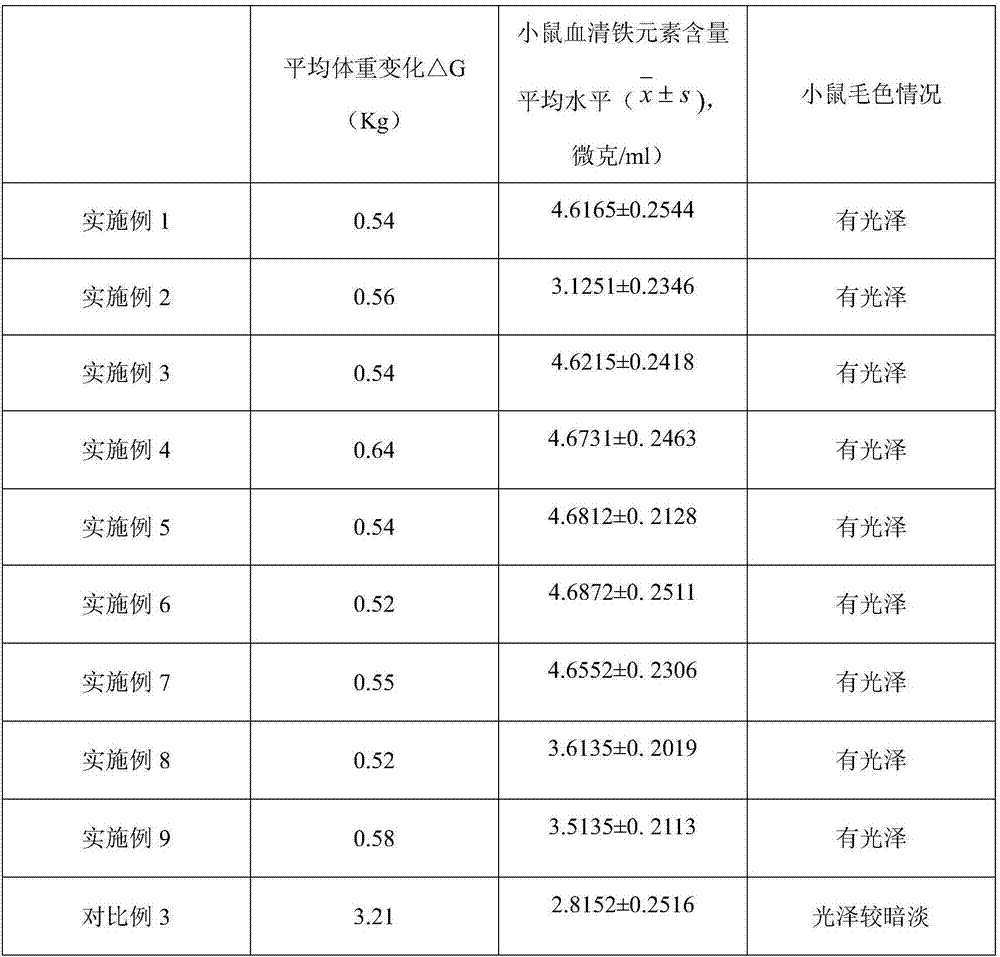

Nutritional quinoa composition, and quinoa product

The invention discloses a nutritional quinoa composition. The composition contains quinoa flour, Ficus tikoua powder and vegetable and fruit plant enzyme powder. The nutritional quinoa composition has no influences on normal diet, allows the body weight to be successfully controlled and the health to be kept while enjoying delicious foods, and makes people keep a good spirit state and a good working efficiency.

Owner:成都南野食品有限公司

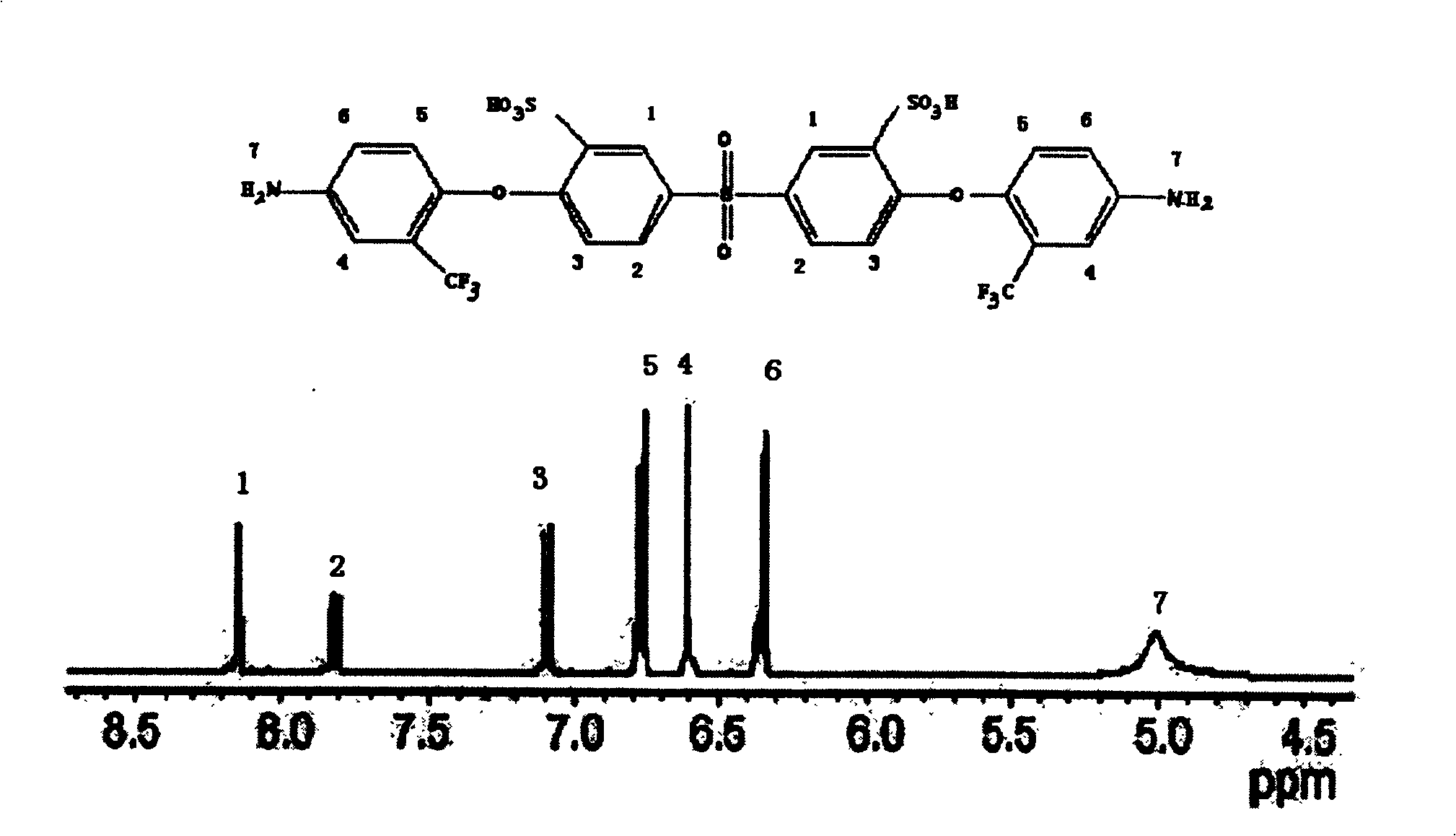

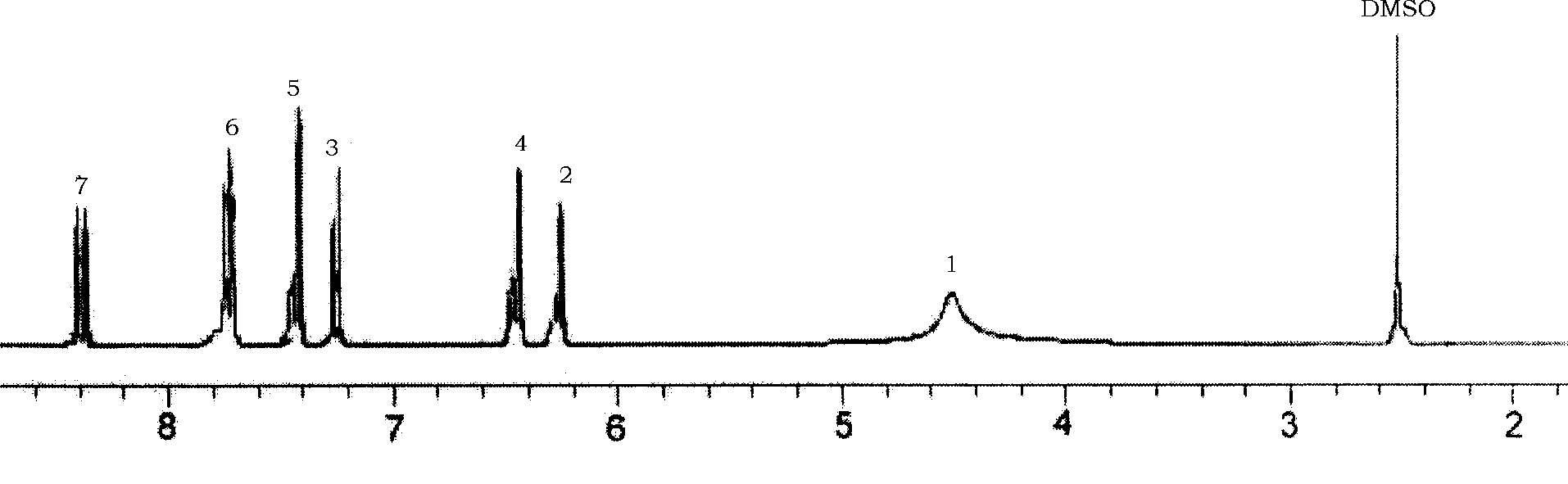

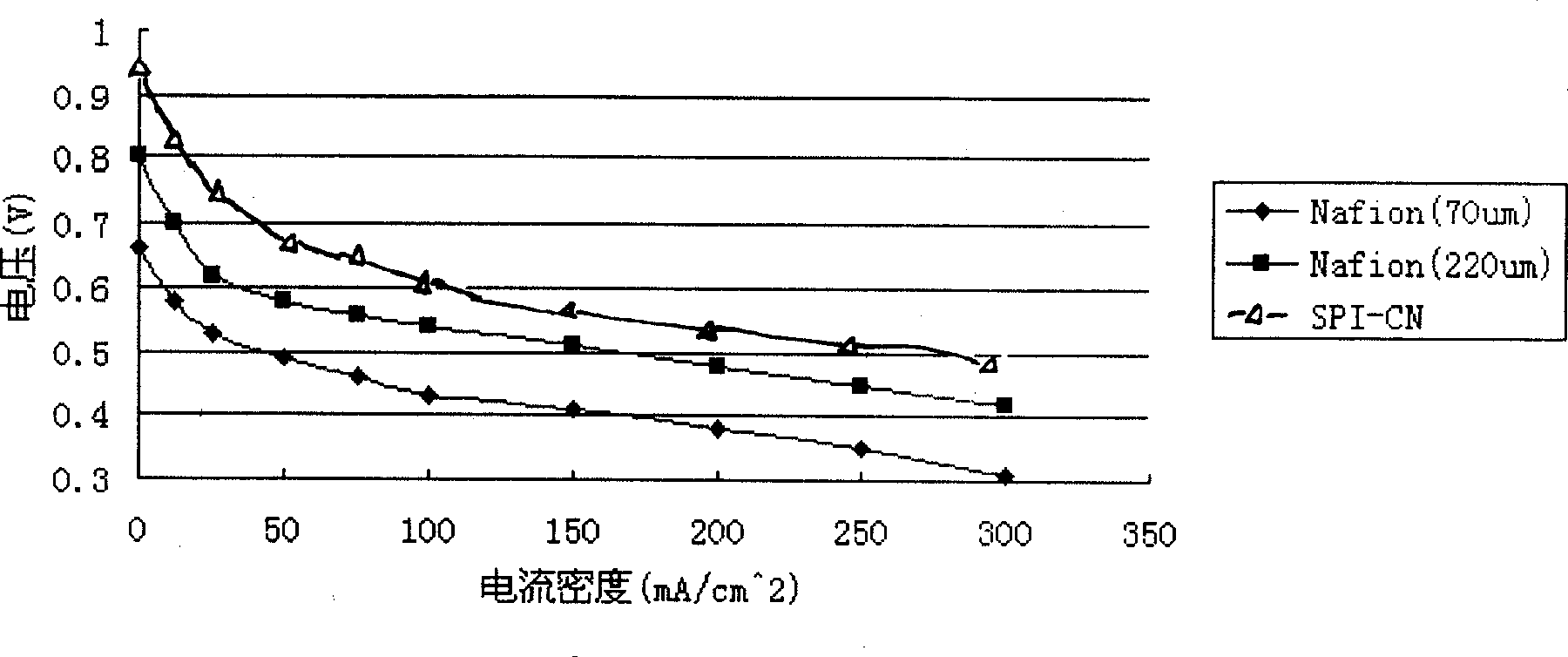

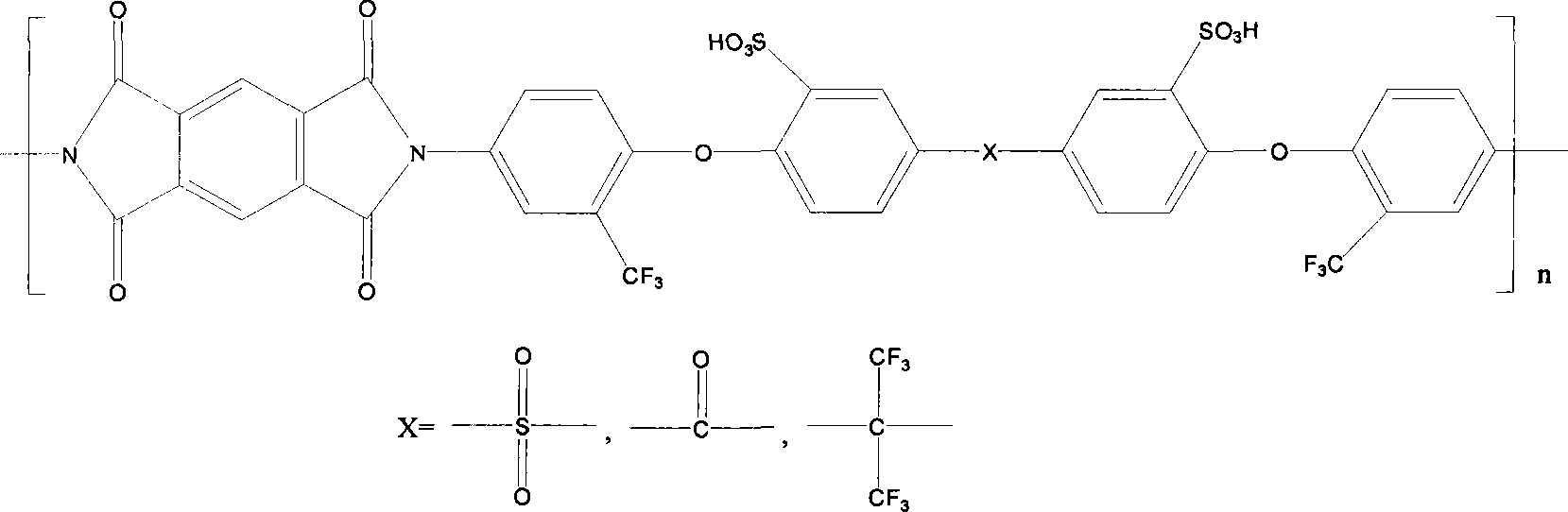

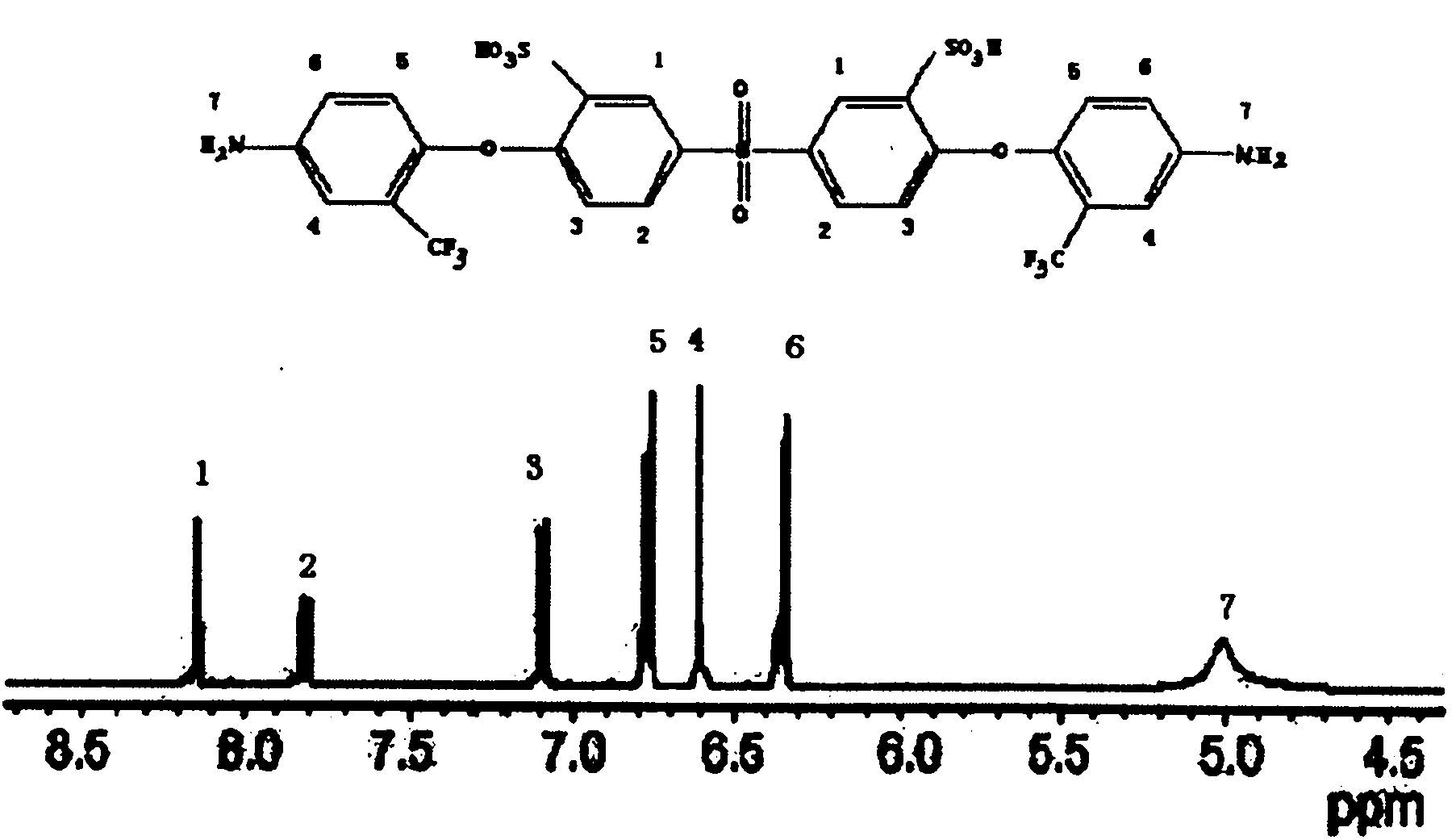

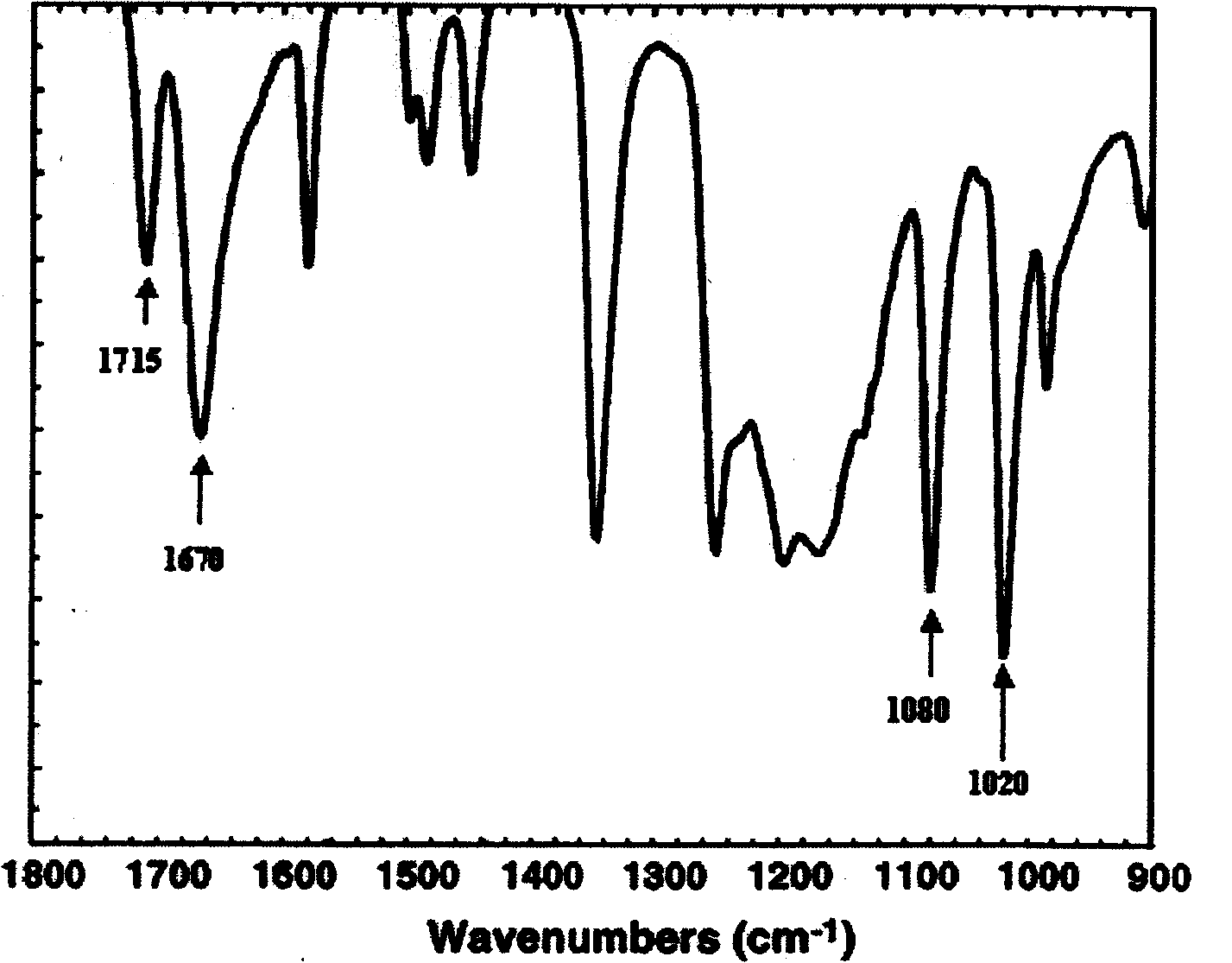

Hydrolyzation tolerant sulfonated polyimide proton exchange membrane and preparation thereof

InactiveCN101340002AImprove hydrophobicityInhibition of hydrolysisSemi-permeable membranesCell component detailsBenzeneRepeat unit

Owner:SHANGHAI APPLIED TECHNOLOGIES COLLEGE

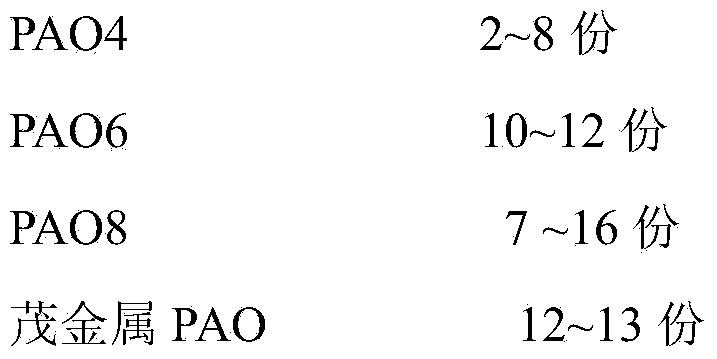

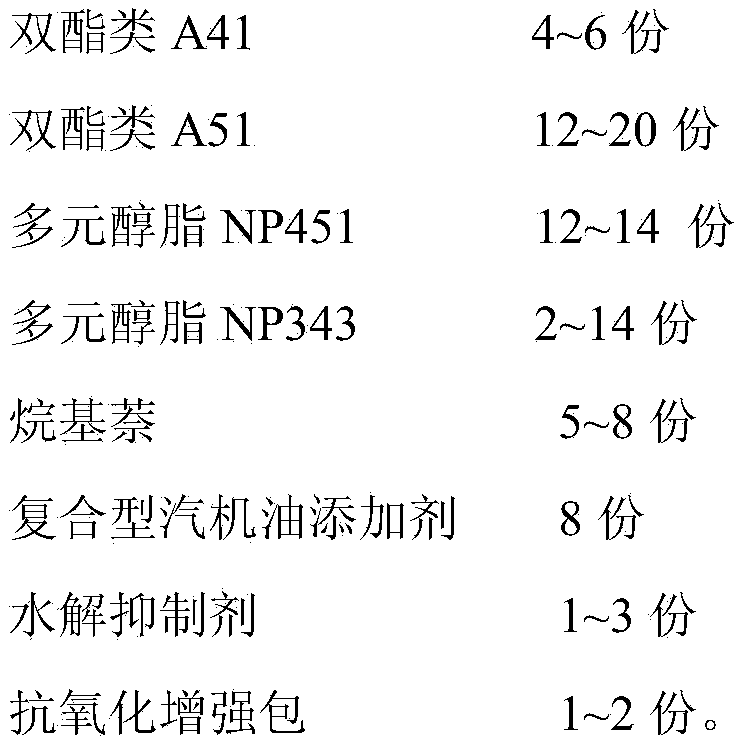

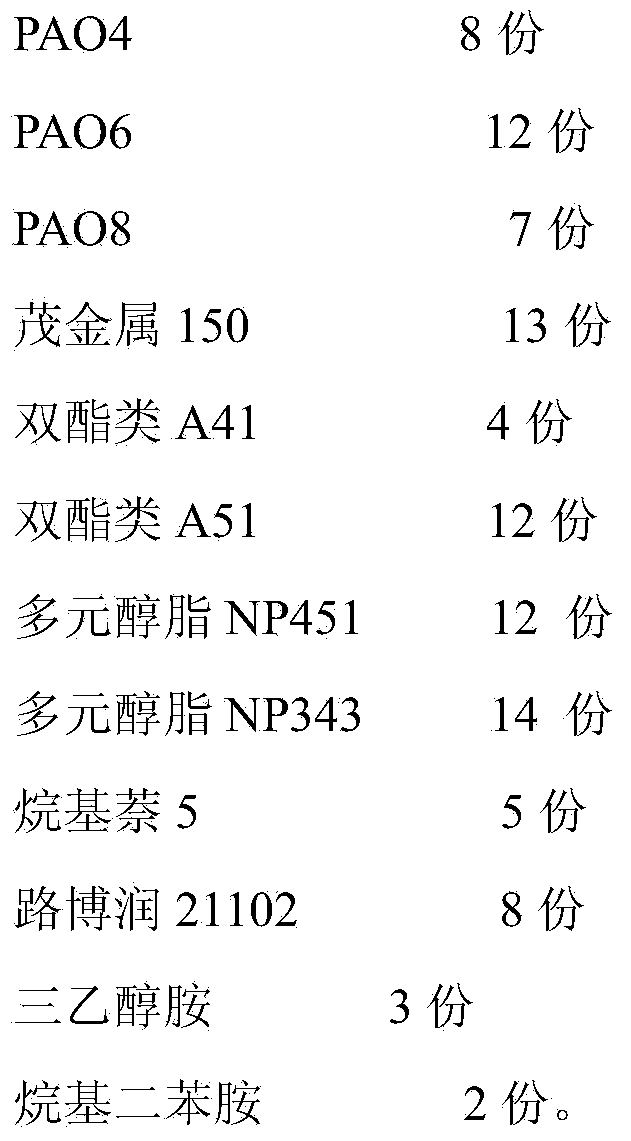

Fully synthetic ester-based gasoline-injection engine lubricating oil and preparation process thereof

The invention belongs to the field of lubricating oils, particularly relates to a fully synthetic ester-based gasoline-injection engine lubricating oil. The lubricating oil is prepared from the following raw materials: PAO4, PAO6, PAO8, metallocene PAO (Poly Alpha Olefins), diester A41, diester A51, polyalcohol ester NP451, polyalcohol ester NP343, alkyl naphthalene, a compound gasoline-injection engine oil additive, a hydrolysis inhibitor and an antioxidant enhancement package, wherein the proportion of the V-type ester-based base oil exceeds 30%, so that the lubricating oil is strong in anti-shearing capacity, namely, the lubricating oil is a fully synthetic high-performance ester-based lubricating oil which can be safely used for a long period. The invention further provides a preparation process of the fully synthetic ester-based gasoline-injection engine lubricating oil. The preparation process is reasonable. Thus, the evaporation loss of a finished product of the lubricating oil is minimized; and the high-temperature of the lubricating oil is performed before the lubricating oil is injected into an engine, so that the synergistic effects of all components of the lubricating oil are exerted well.

Owner:ZIBO LUTE LUBRICATING OIL CO LTD

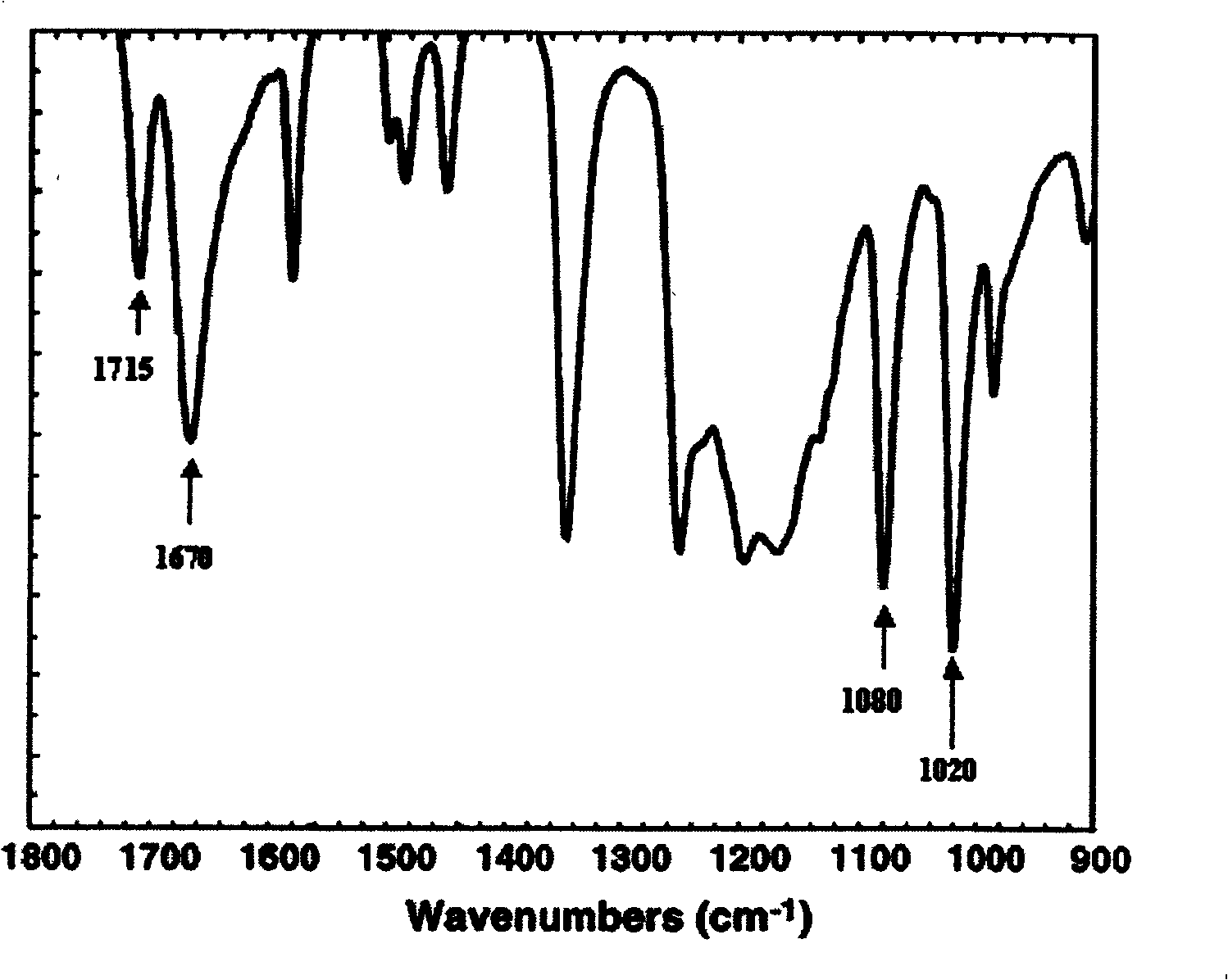

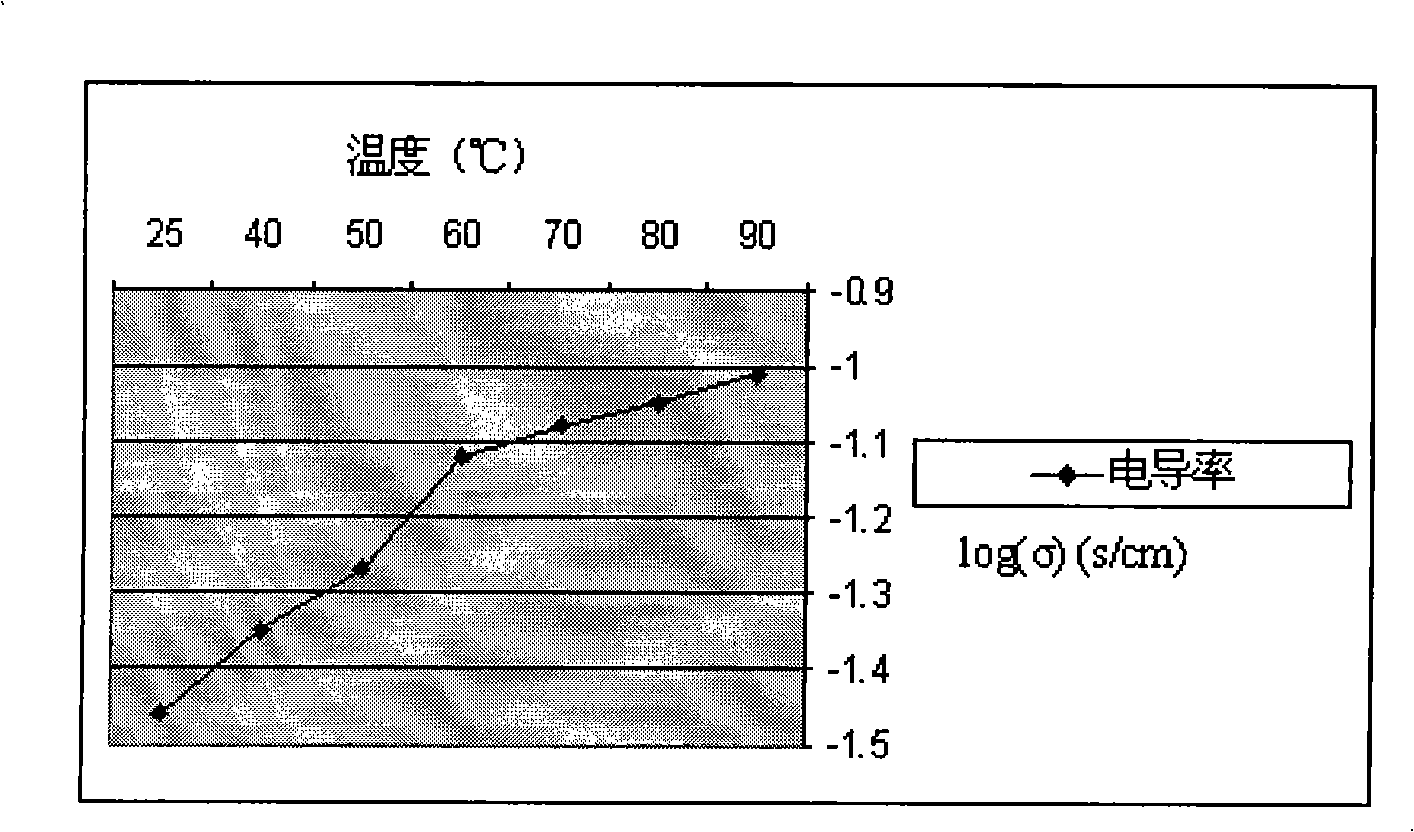

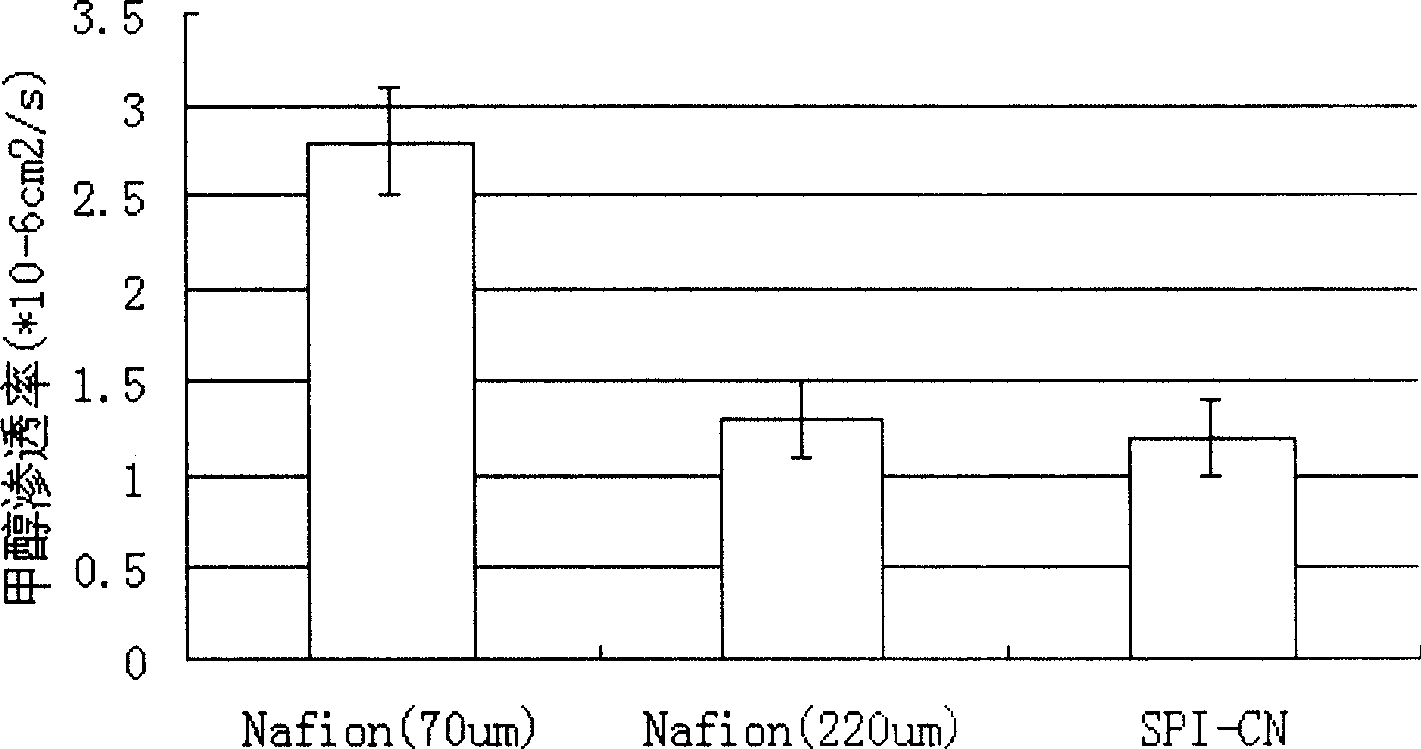

High interface compatibility sulphonation medlin proton exchange film for fuel battery and preparation method thereof

InactiveCN101442133AReduce moisture contentGood chemical stabilityCell component detailsSolid electrolyte fuel cellsSwelling capacityIon exchange

The invention discloses a high interfacial compatibility sulfonated polyimide proton-exchange membrane for a fuel battery and a preparation method thereof. The thickness of the proton-exchange membrane is between 10 and 100 micrometers; the ion exchange capacity is between 1 and 3 mmol / g; the proton conductivity at 20 DEG C and with the relative humidity of 100 percent is between 1 and 10*10<-3> S / cm; and the methanol permeability is between (0.2-3)*10<-6> cm<2> / s. The invention introduces a nitrile group into a diamine monomer which synthesizes sulfonated polyimide through condensation reaction, so as to increase the content of a nitrile group in a backbone structure, reduce the water content and the high-temperature swelling capacity of the proton-exchange membrane, strengthen the interfacial compatibility between the proton-exchange membrane and an electrode, reduce the contact resistance, and improve the electrical conductivity of the membrane. The invention improves the chemical stability of the proton-exchange membrane and realizes long-term working stability of the proton-exchange membrane.

Owner:SHANGHAI INST OF TECH

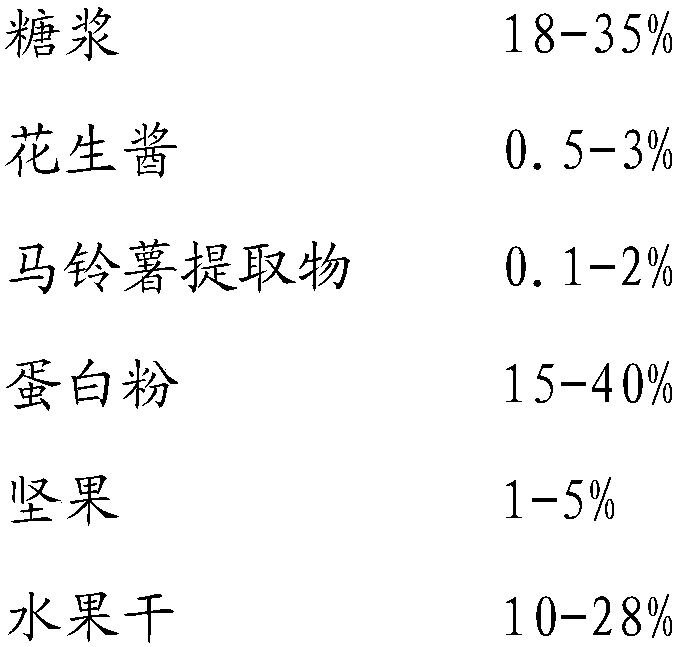

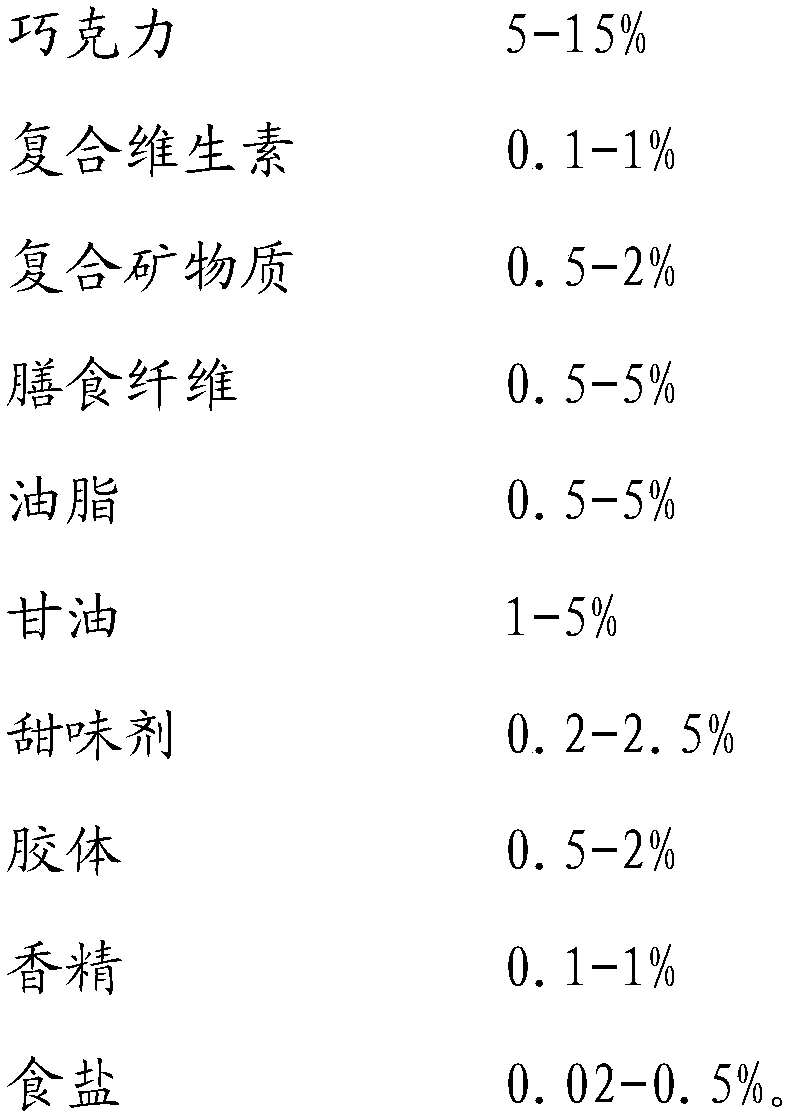

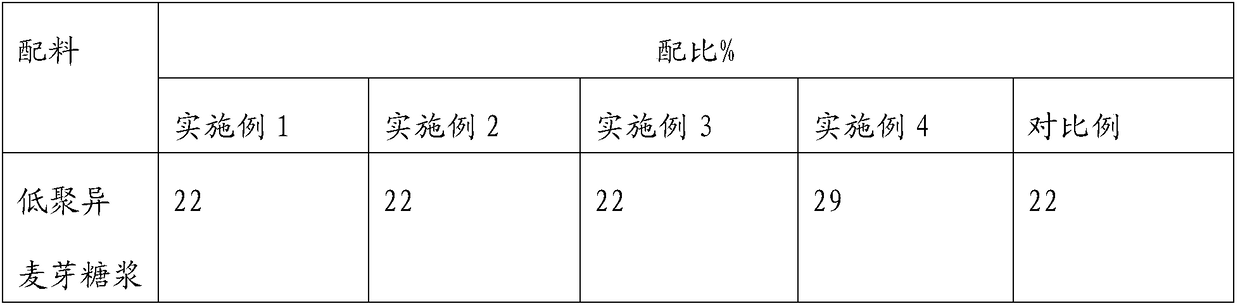

Meal replacement bar capable of reducing weight and preparation method of meal replacement bar

PendingCN108378317ALow sweetnessDo not change levelVitamin food ingredientsNatural extract food ingredientsMeal replacementThermal expansion

The invention relates to a meal replacement bar capable of reducing weight and a preparation method of the meal replacement bar. According to the meal replacement bar capable of reducing weight, a potato extract is added for the first time, and the raw materials of the meal replacement bar comprise a protease inhibitor (PI2), so that release of cholecystokinin (CCK) can be promoted, and natural satiety can be provided. The meal replacement bar capable of reducing weight is prepared by an advanced cold mixing technology and is different from a convention meal replacement bar capable of reducingweight; a technology of the conventional meat replacement bar lies in that syrup needs to be heated and then cooled, and then finished products are made under the baking condition; and the meal replacement bar disclosed by the invention lies in that mixing, shaping and dicing are directly performed at normal temperature, so that light deformation caused by thermal expansion and cold contraction of the syrup is avoided, and besides, the loss of self nutrient components of products in the heating process and in the baking process is avoided.

Owner:BEIJING TONGRENTANG HEALTH PHARMA

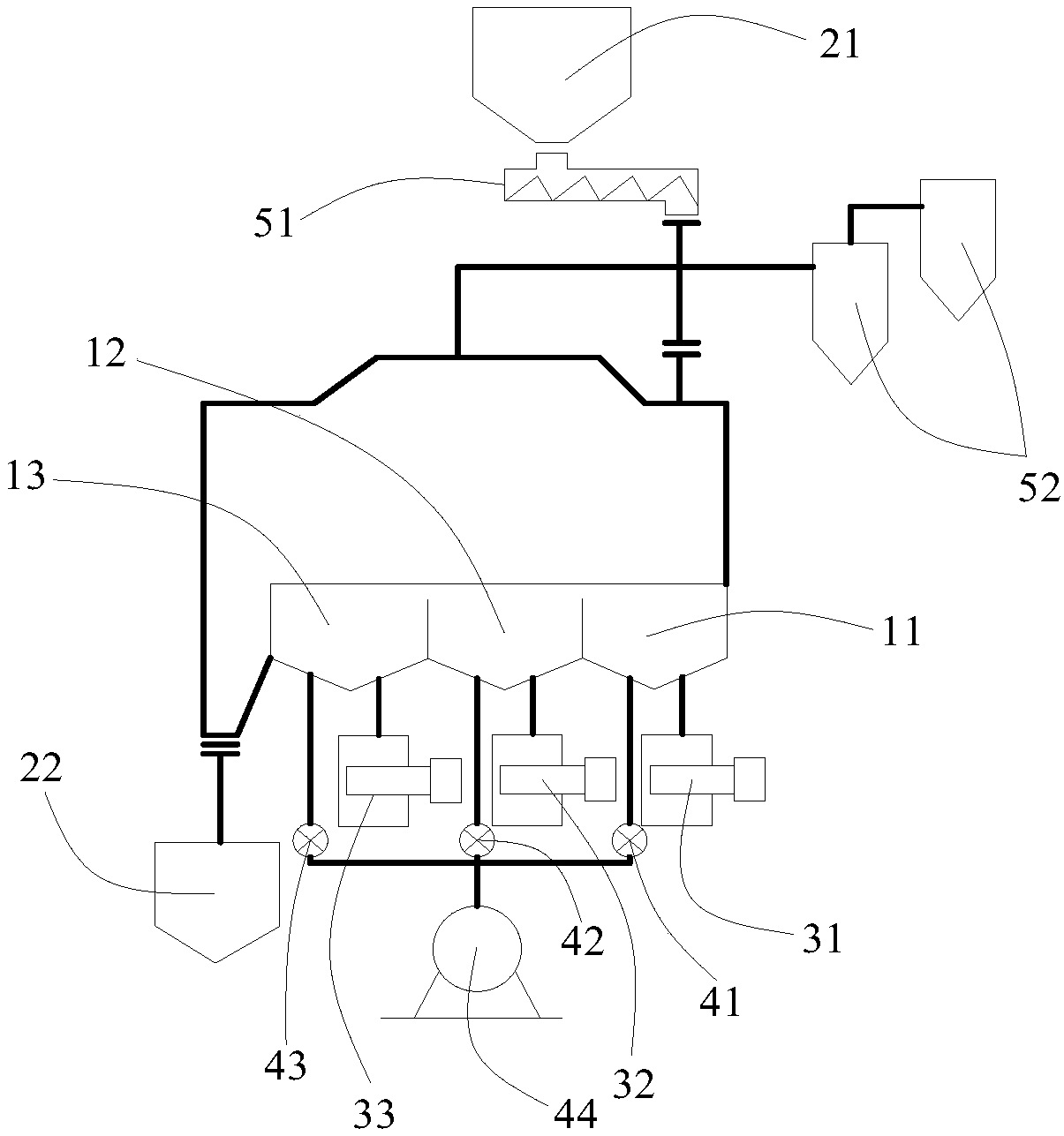

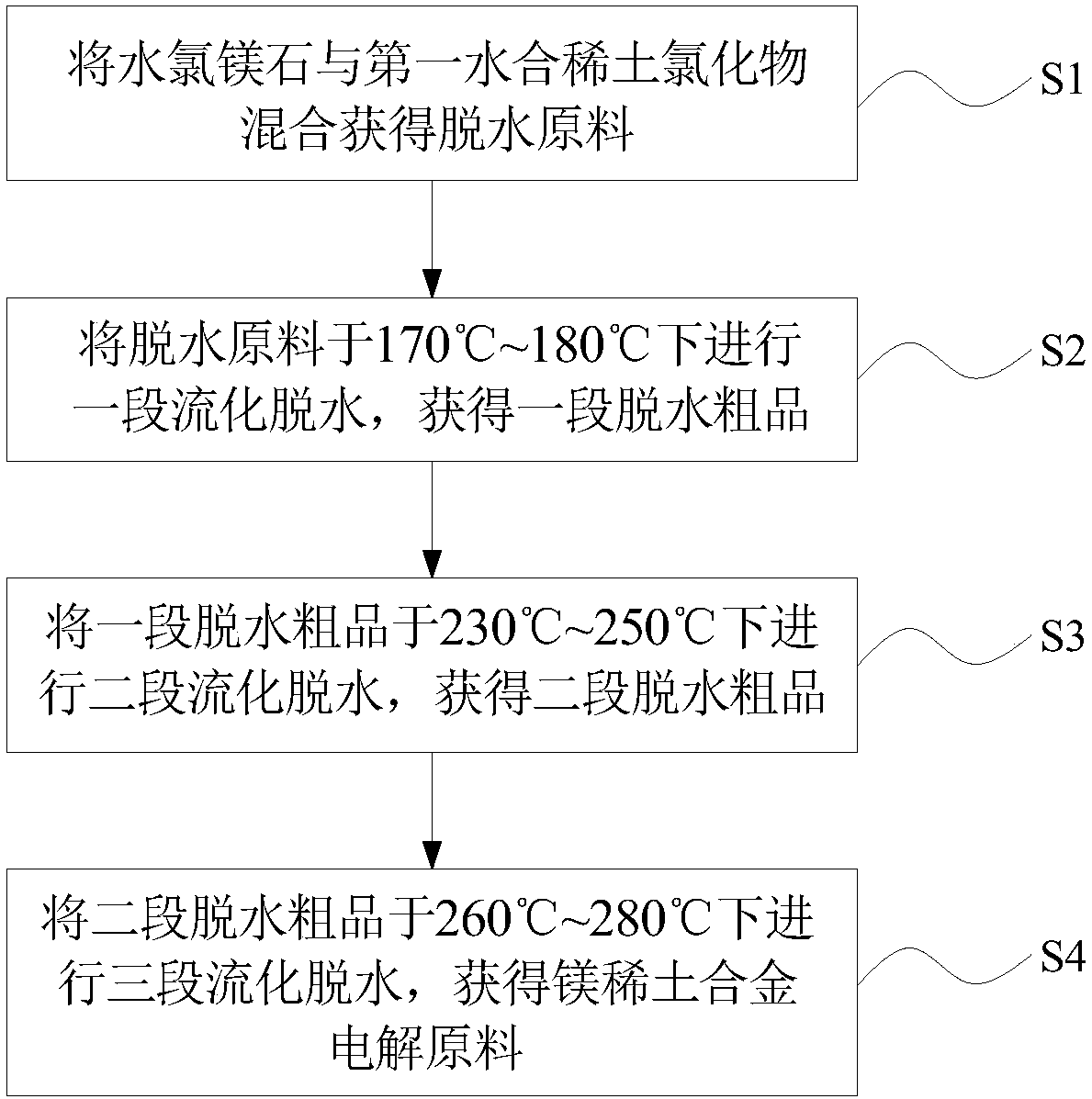

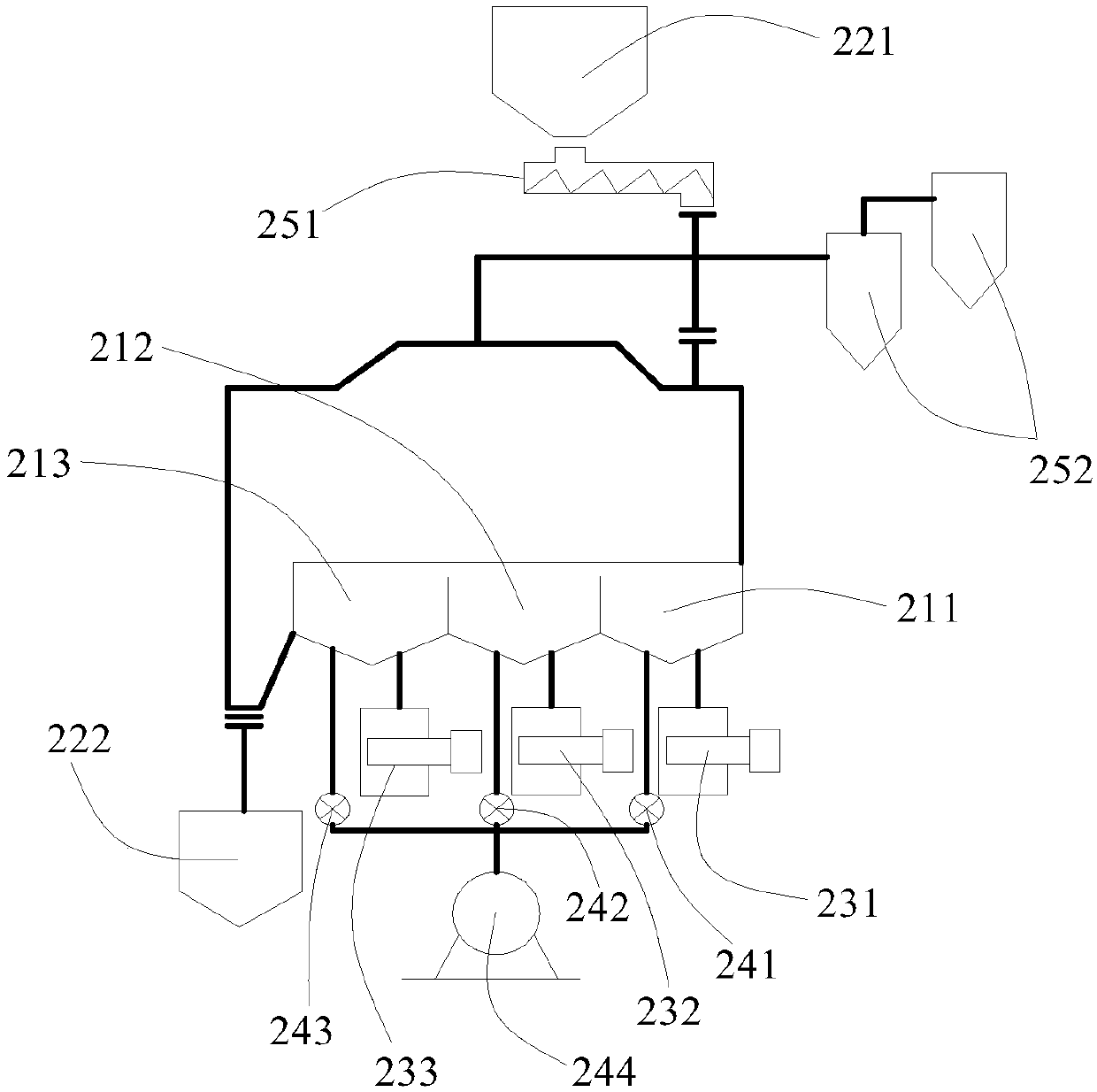

Preparation method of magnesium-rare earth alloy electrolysis raw material

The invention discloses a preparation method of magnesium-rare earth alloy electrolysis raw material. The preparation method comprises the following steps: S1, bischofite and first hydrated rare-earthchloride are mixed, and then dehydrated raw material is obtained; S2, first-stage fluidization dehydration is carried out on the dehydrated raw material at the temperature of 170-180 DEG C, and thena first-stage dehydrated crude product is obtained; S3, second-stage fluidization dehydration is carried out on the first-stage dehydrated crude product at the temperature of 230-250 DEG C, and then asecond-stage dehydrated crude product is obtained; and S4, third-stage fluidization dehydration is carried out on the second-stage dehydrated crude product at the temperature of 260-280 DEG C and inthe hydrogen chloride gas atmosphere, so that the magnesium-rare earth alloy electrolysis raw material is obtained. According to the preparation method of the magnesium-rare earth alloy electrolysis raw material, staged fluidization dehydration on the bischofite and the hydrated rare-earth chloride is carried out, the hydrogen chloride protective gas atmosphere is provided, so that a hydrolysis effect is effectively inhibited in the process that an intermediate product is dehydrated to form the magnesium-rare earth alloy electrolysis raw material, and product purity is greatly improved; and the preparation method is low in dehydration temperature, low in preparation cost and good in dehydration effect.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

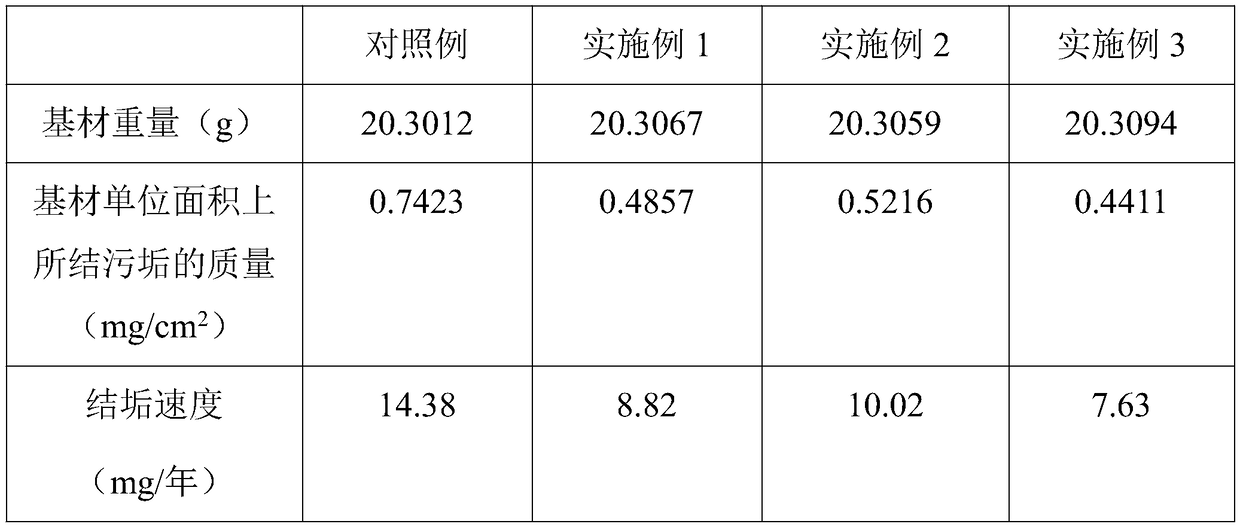

Composite slow-release scale inhibitor

InactiveCN108862639AStrong alkali resistanceGood anti-scaling effectSpecific water treatment objectivesScale removal and water softeningALLYL SUCROSEHydrolysis

The invention provides a composite slow-release scale inhibitor. The composite slow-release scale inhibitor is prepared from the following raw materials in parts by weight: 20-25 parts of polyepoxysuccinic acid, 12-16 parts of polyacrylic acid, 6-10 parts of hydrolyzed maleic anhydride, 10-15 parts of modified chitosan, 3-6 parts of sodium gluconate, 1-3 parts of surfactants and 25-30 parts of water; the modified chitosan is mainly obtained through reaction between the chitosan and dimethylaminoethyl acrylate, and the substitution degree of the modified chitosan is 60-85%. By the scale inhibitor with high hydrolysis resistance, the problems of high consumption speed and poor scale inhibition effect of conventional metal orthophosphate scale inhibitors are solved.

Owner:芜湖市颂晖商贸有限公司

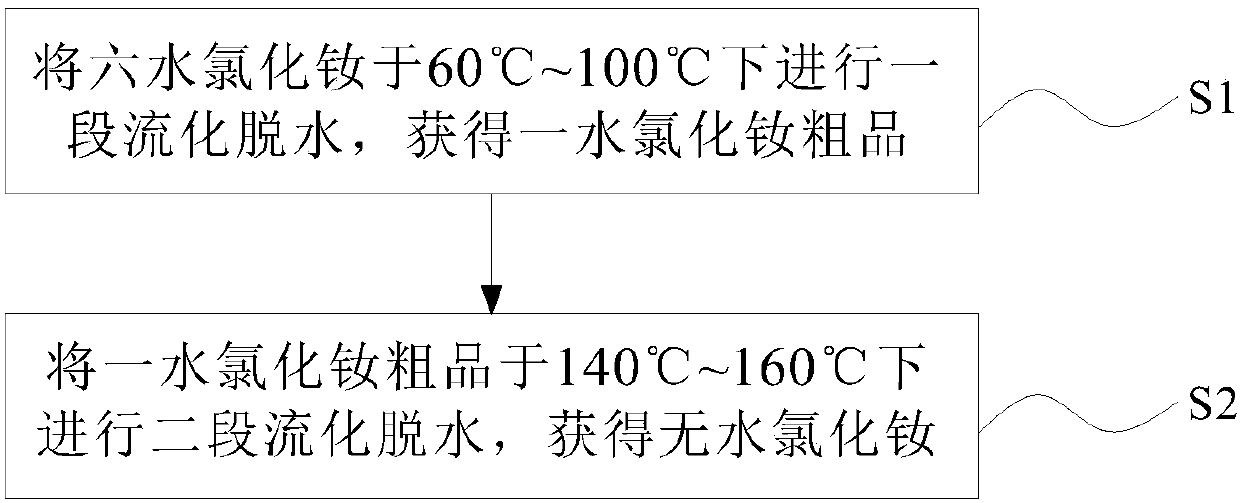

Preparation method of absolute neodymium chloride

InactiveCN107601544AInhibition of hydrolysisReduce pollutionRare earth metal compoundsCalcium Chloride HexahydrateNeodymium chloride

The invention discloses a preparation method of absolute neodymium chloride. The method comprises the following steps: S1) performing primary fluidization and dehydration on neodymium chloride hexahydrate at the temperature of 60-100 DEG C to obtain a neodymium chloride monohydrate crude product; and S2) performing secondary fluidization and dehydration on the neodymium chloride monohydrate crudeproduct at the temperature of 140-160 DEG C to obtain absolute neodymium chloride; wherein, the step of secondary fluidization and dehydration is carried out under hydrogen chloride gas atmosphere. According to the preparation method of absolute neodymium chloride, the neodymium chloride hexahydrate is subjected to segment fluidization and dehydration, hydrogen chloride protective gas atmosphere is provided, the hydrolysis of an intermediate product neodymium chloride monohydrate in a dehydration process to absolute neodymium chloride is effectively inhibited, product purity is greatly increased, the dehydration temperature in the preparation method of the absolute neodymium chloride is low, the preparation cost is low, and the dehydration effect is good.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Encapsulation composition for a solar cell and preparing method of encapsulation sheet

InactiveCN103849064AImprove insulation performanceStable maintenance structureFinal product manufactureCoatingsElectrical batteryCarvacryl acetate

The invention relates to an encapsulation composition for a solar cell and a preparing method of an encapsulation sheet. The encapsulation composition can prevent the performance reduction, of a module, being caused by electric leakage, the encapsulation composition is provided with good insulating property, and can make the solar cell keep stable for a long time. The encapsulation composition comprises an ethylene-vinyl acetate copolymer resin as a main material, on the basis of the weight of the resin, the encapsulation composition also comprises 0.1-5 parts by mass of a peroxide added as a key additive, and 0.01-5 parts by mass of a metal ion catching agent.

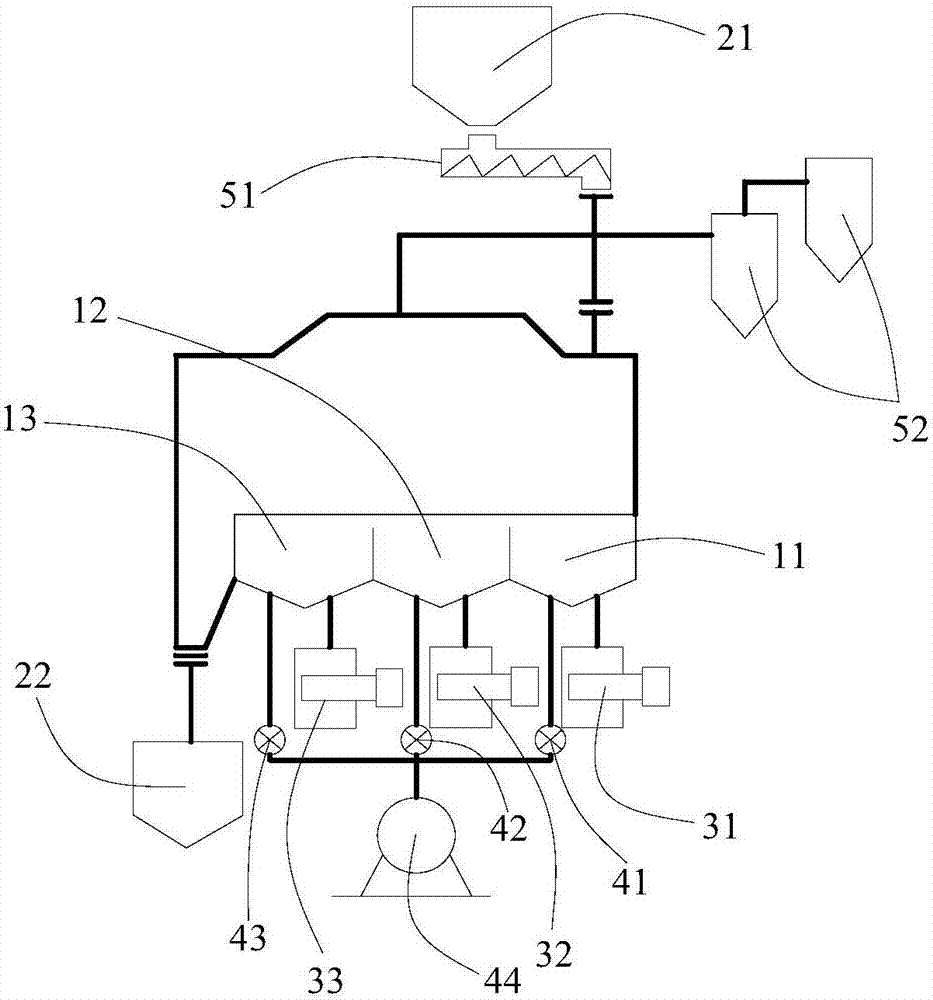

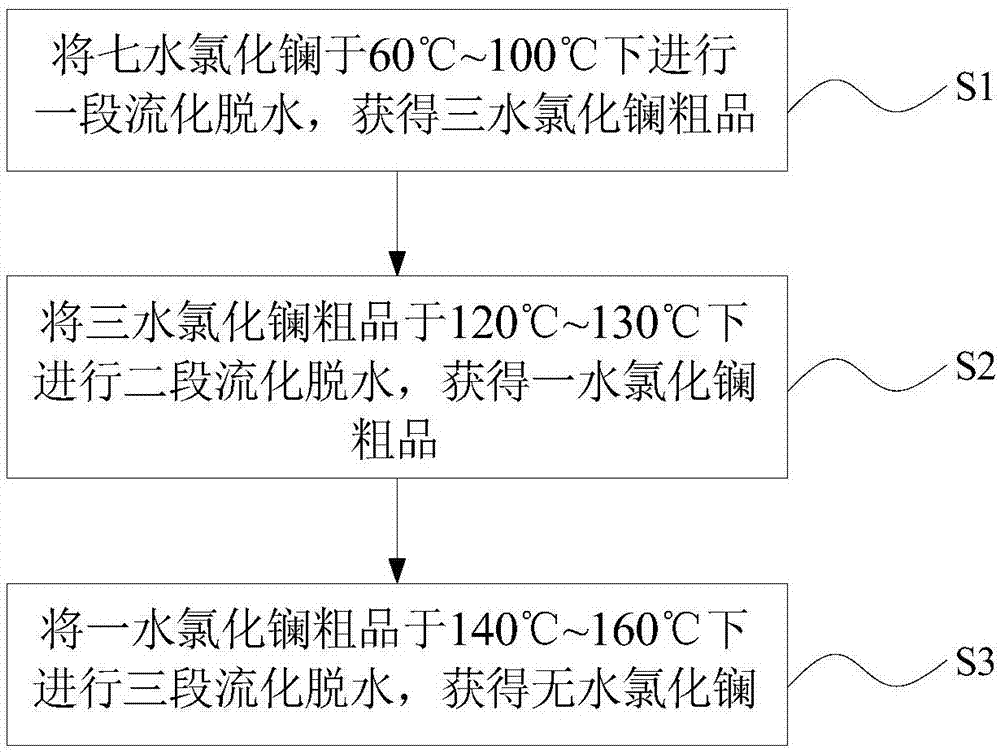

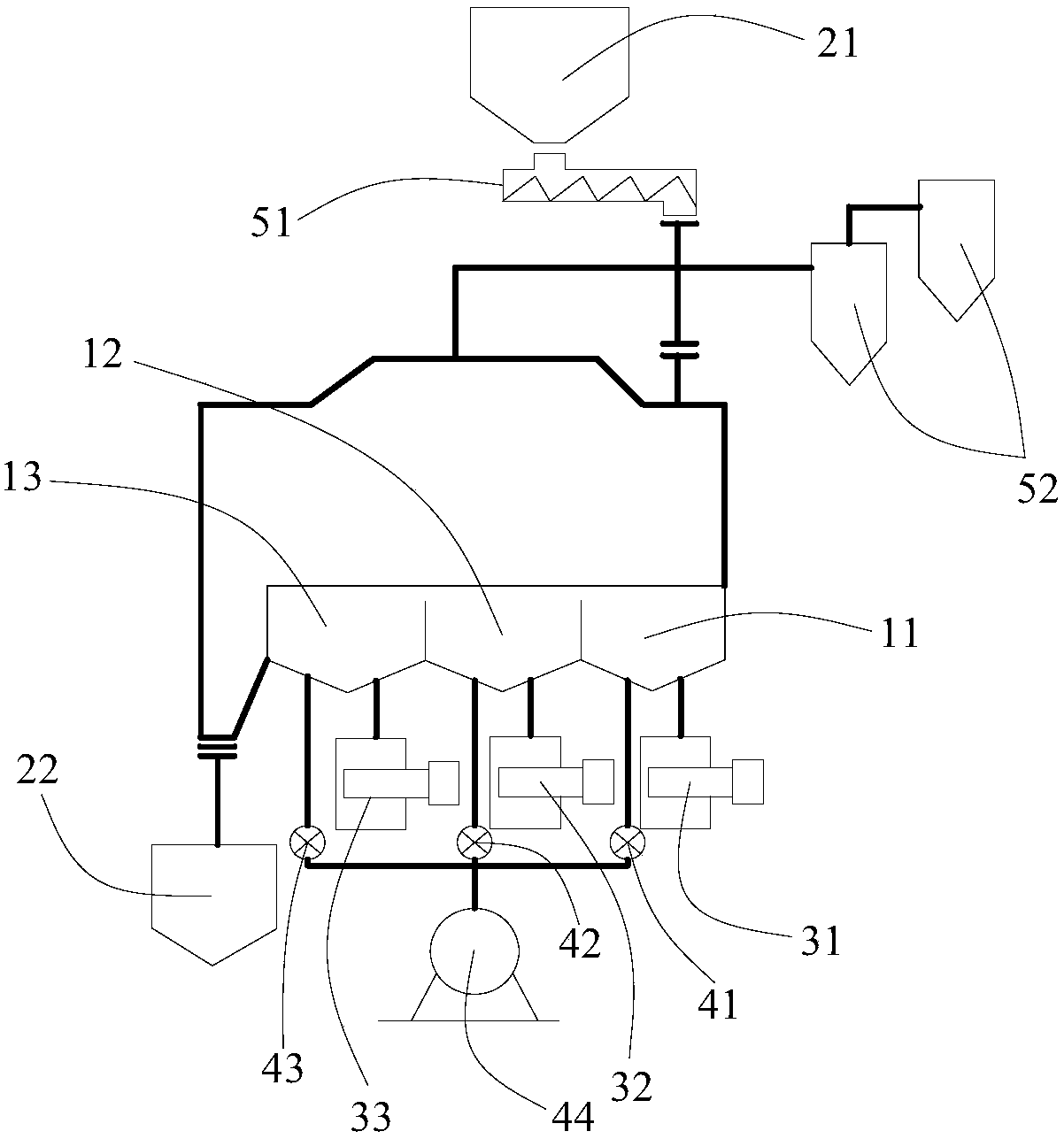

Preparation method of anhydrous lanthanum chloride

InactiveCN107500334AInhibition of hydrolysisReduce pollutionRare earth metal chloridesChlorideLanthanum

The invention discloses a preparation method of anhydrous lanthanum chloride. The preparation method comprises the following steps: S1, carrying out first-section fluidization dehydration on lanthanum chloride heptahydrate at 60 DEG C to 100 DEG C to obtain a lanthanum chloride trihydrate crude product; S2, carrying out second-section fluidization dehydration on the lanthanum chloride trihydrate crude product at 120 DEG C to 130 DEG C to obtain a lanthanum chloride monohydrate crude product; S3, carrying out third-section fluidization dehydration on the lanthanum chloride monohydrate crude product at 140 DEG C to 160 DEG C to obtain the anhydrous lanthanum chloride, wherein the three sections of fluidization dehydration are carried out in a hydrogen chloride gas atmosphere. According to the preparation method of the anhydrous lanthanum chloride, disclosed by the invention, the lanthanum chloride heptahydrate is subjected to sectioned fluidization dehydration and a hydrogen chloride protection gas atmosphere is provided, so that a hydrolysis effect in a process of dehydrating an intermediate product lanthanum chloride monohydrate into the anhydrous lanthanum chloride is effectively inhibited and the purity of a product is greatly improved; the preparation method of the anhydrous lanthanum chloride has the advantages of low dehydration temperature, low preparation cost and good dehydration effect.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

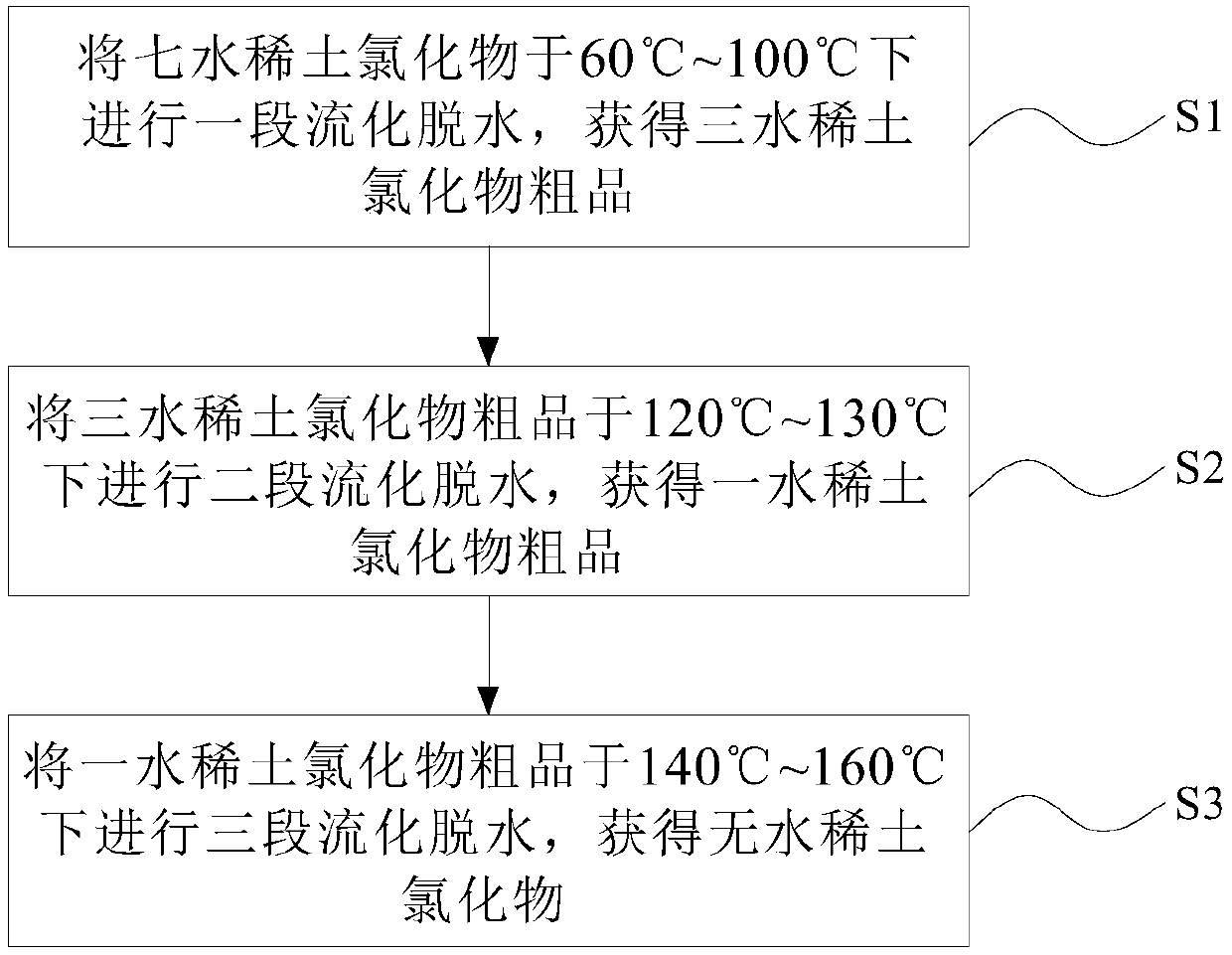

Preparation method for anhydrous rare earth chloride

InactiveCN107827140AInhibition of hydrolysisReduce pollutionRare earth metal chloridesHydrogen chlorideChloride

The invention discloses a preparation method for an anhydrous rare earth chloride. The method comprises the following steps: step 1, performing first-stage fluidization dehydration on a rare earth chloride heptahydrate under the temperature of 60 DEG C-100 DEG C to obtain a crude product of a rare earth chloride trihydrate; step 2, performing second-stage fluidization dehydration on the crude product of the rare earth chloride trihydrate under the temperature of 120 DEG C-130 DEG C to obtain a crude product of a rare earth chloride monohydrate; and step 3, performing third-stage fluidization dehydration on the crude product of the rare earth chloride monohydrate under the temperature of 140 DEG C-160 DEG C to obtain the anhydrous rare earth chloride, wherein the third-stage fluidization dehydration is carried out in a hydrogen chloride gas atmosphere. According to the preparation method for the anhydrous rare earth chloride provided by the invention, the rare earth chloride heptahydrate is subjected to staged fluidization dehydration, and the hydrogen chloride protection gas atmosphere is provided, so that hydrolysis in the process of dehydration of the intermediate product rare earth chloride monohydrate to the anhydrous rare earth chloride is effectively inhibited, and the product purity is greatly improved; and the preparation method for the anhydrous rare earth chloride hasthe advantages of a low dehydration temperature, low preparation costs and good dehydration effects.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

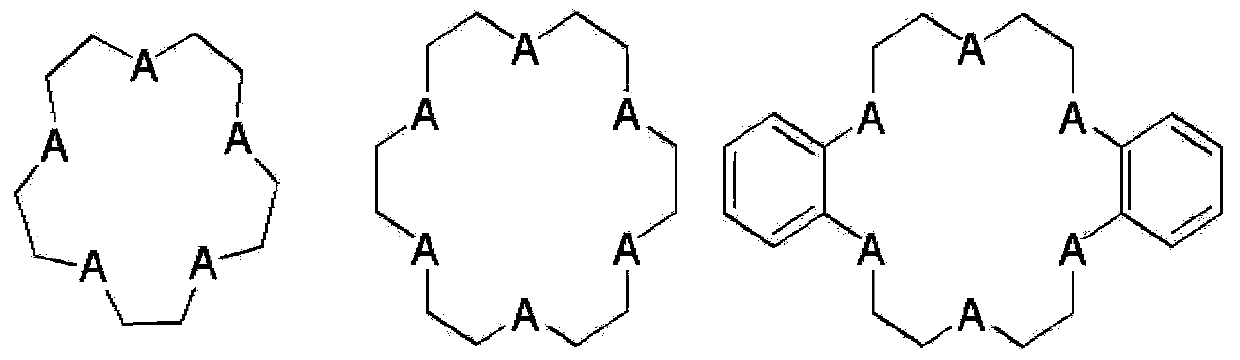

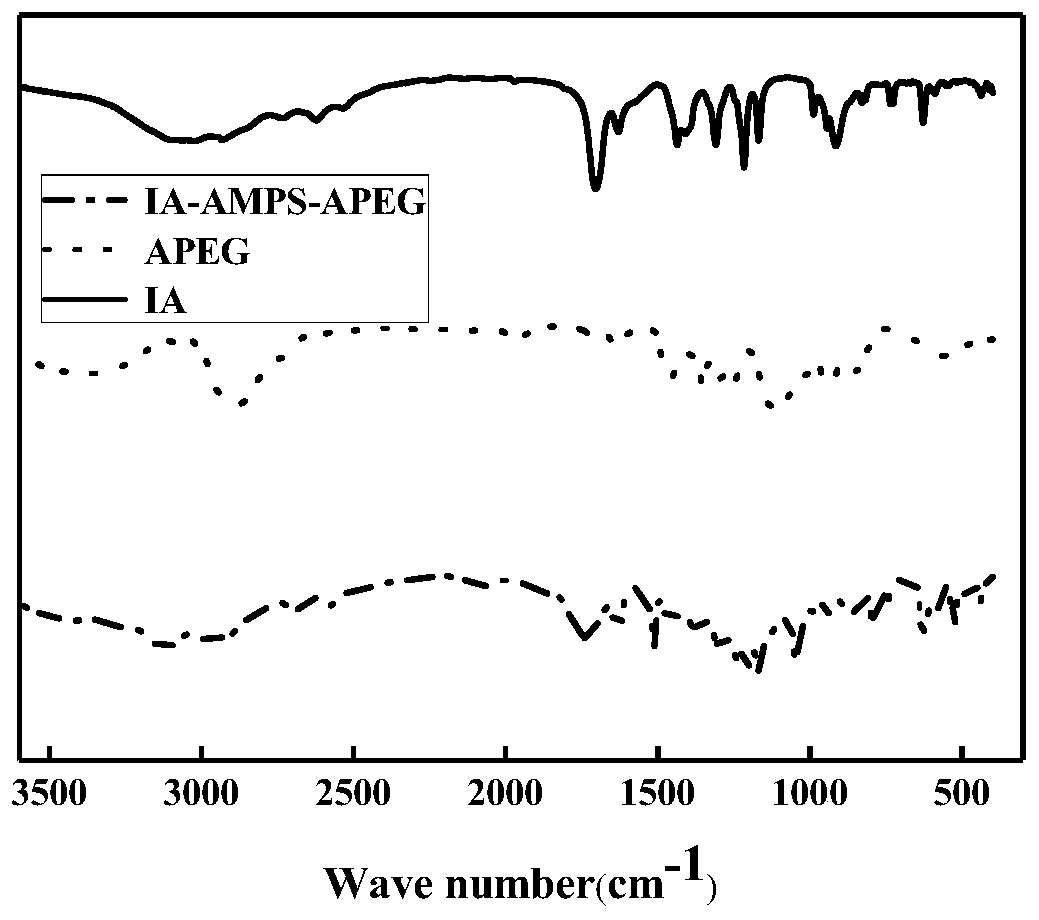

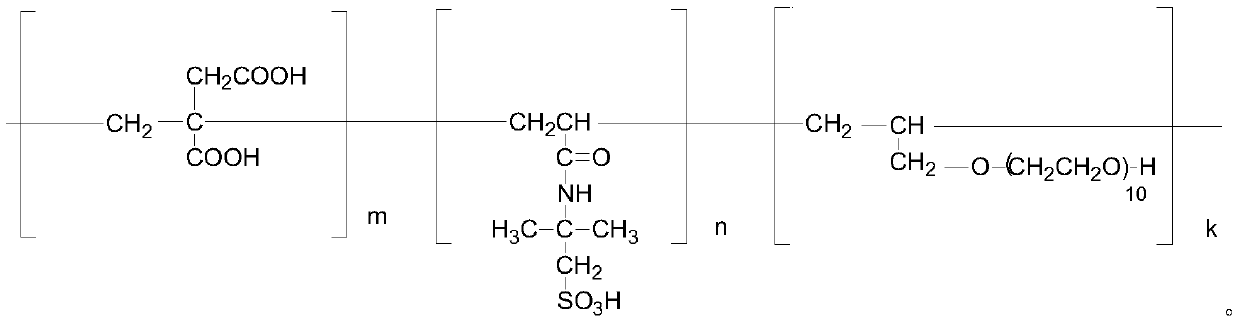

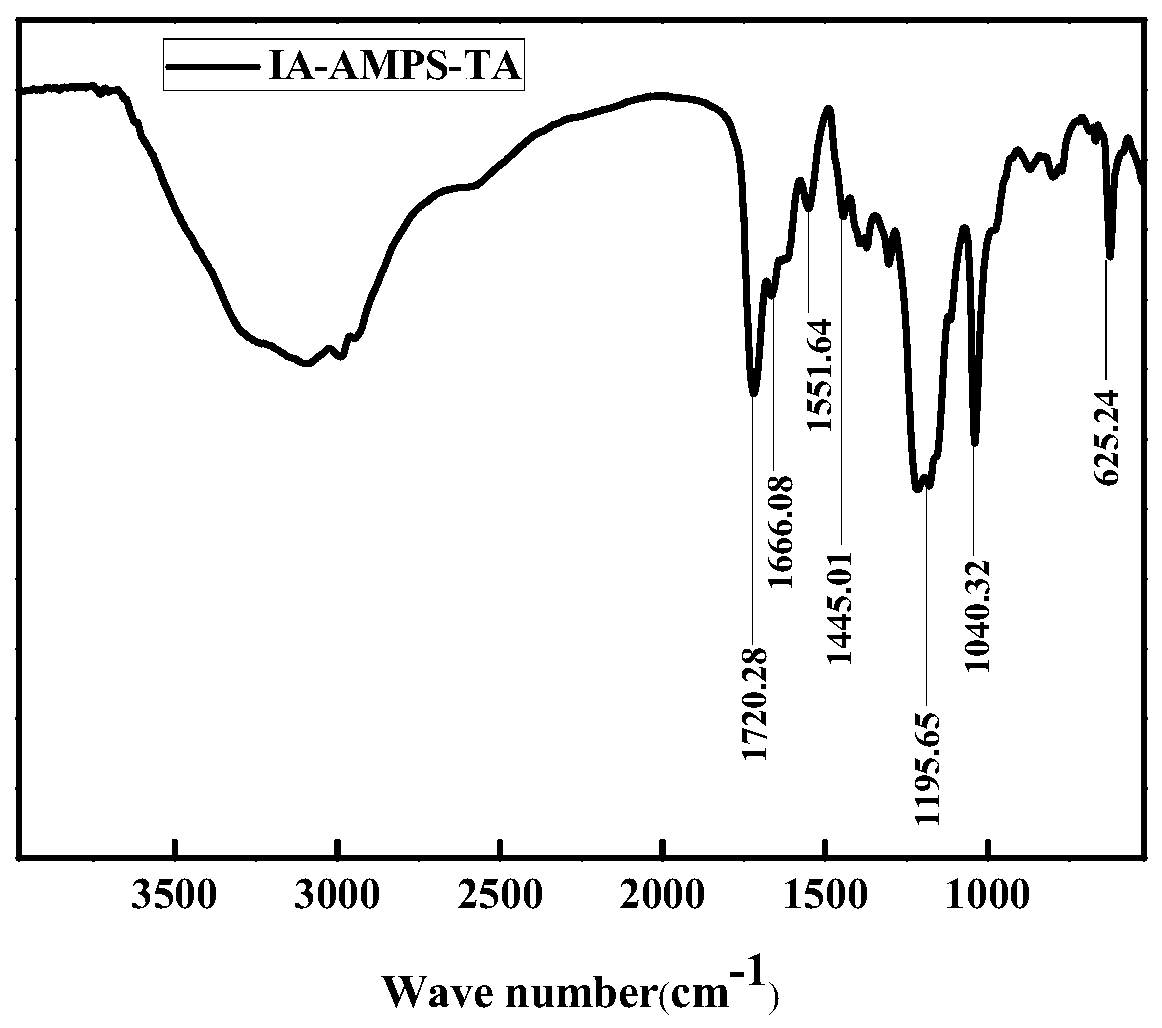

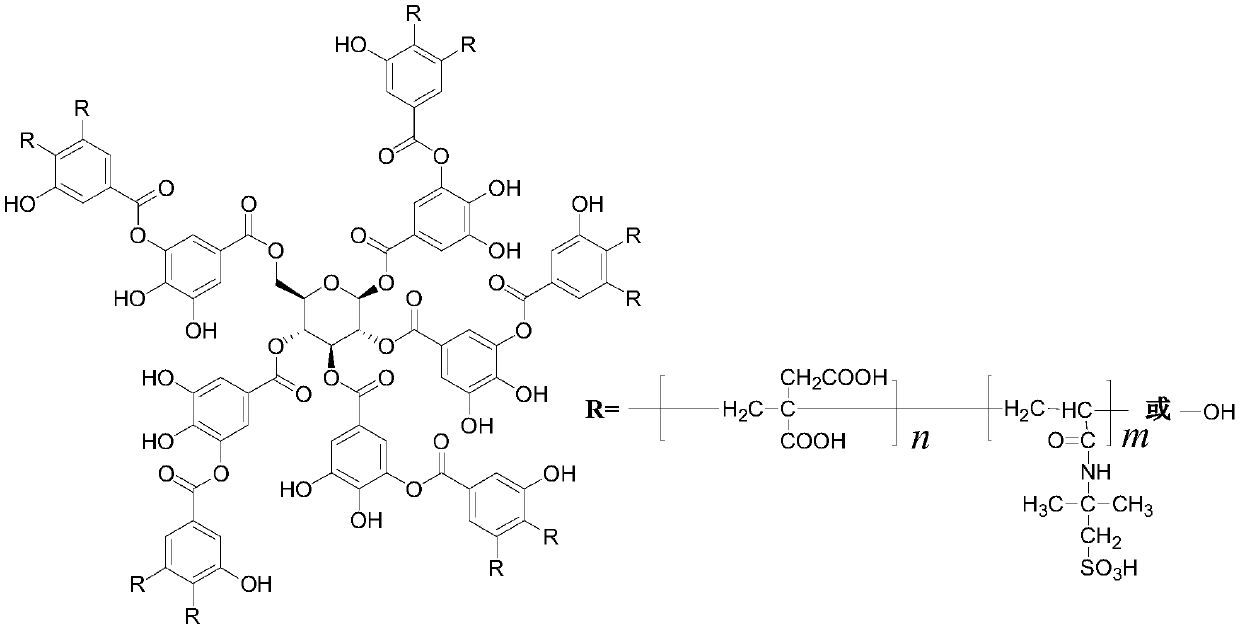

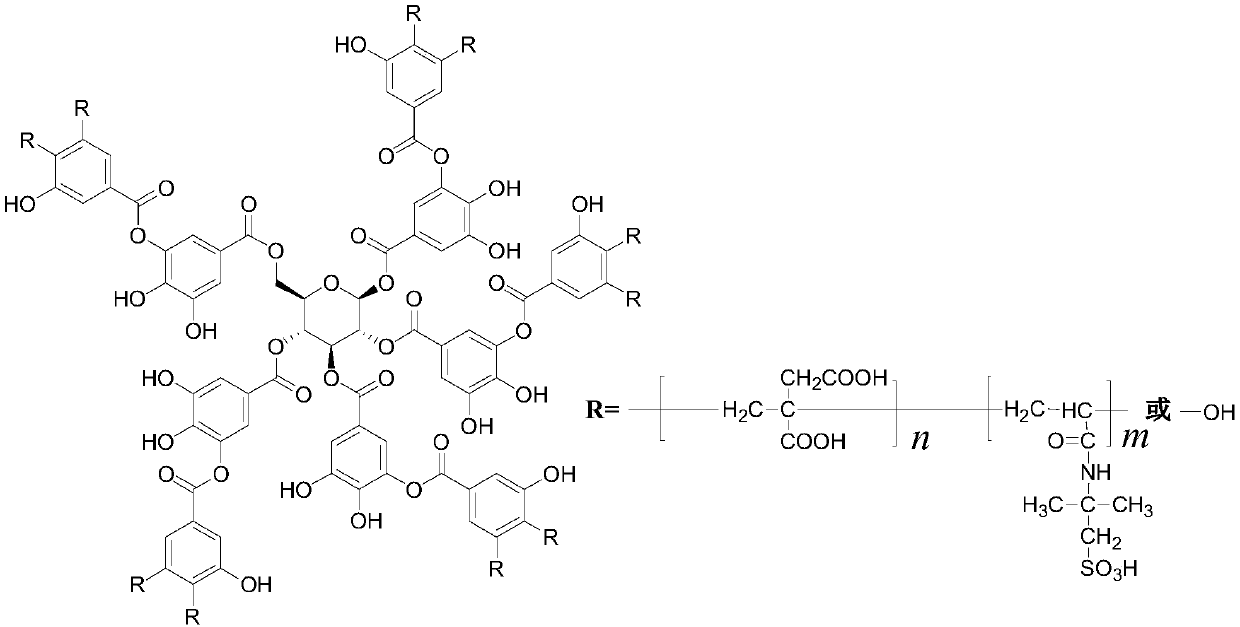

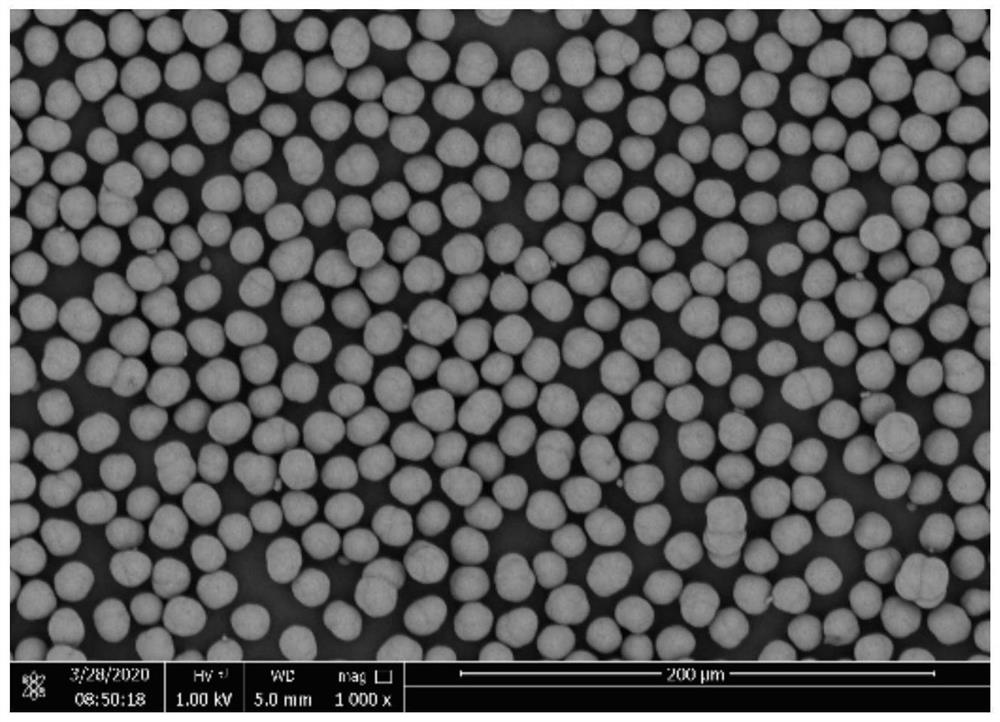

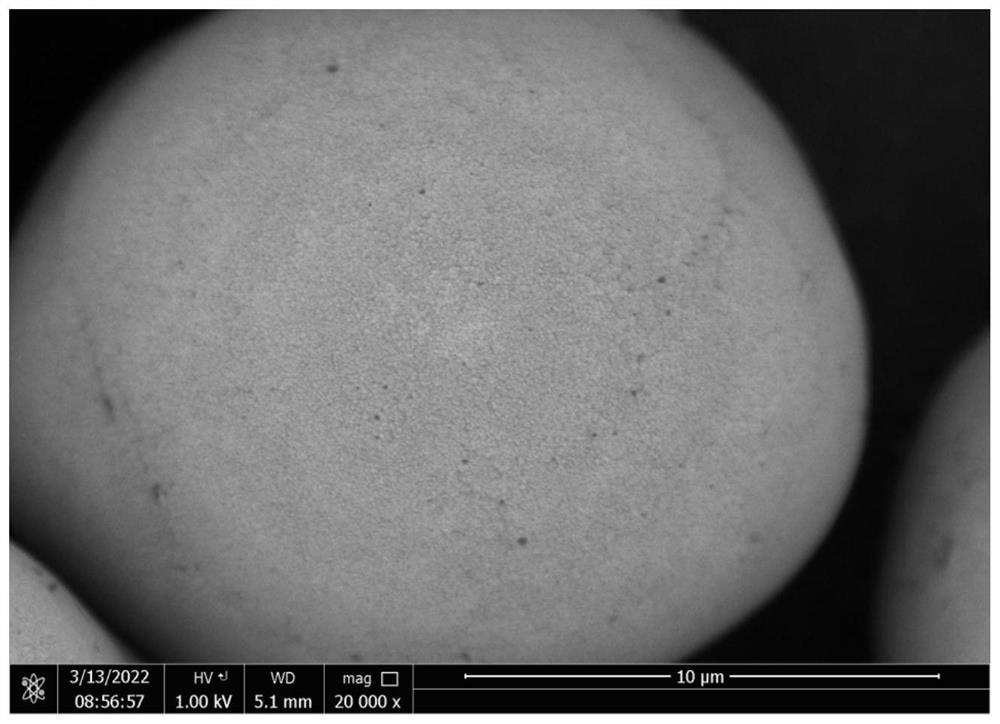

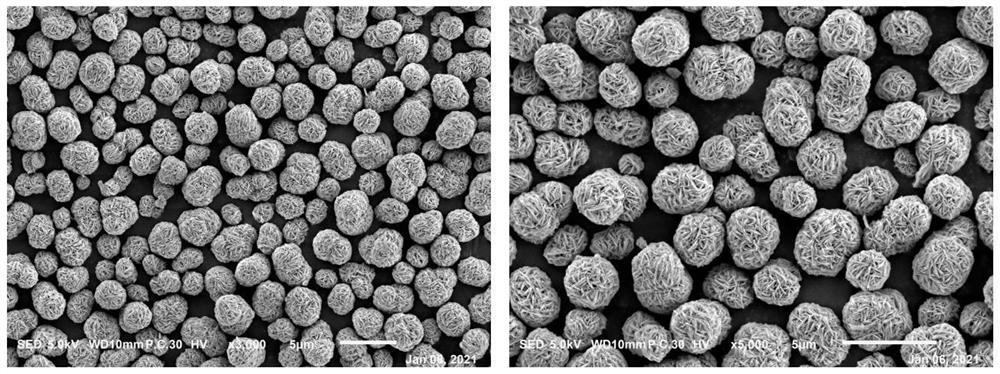

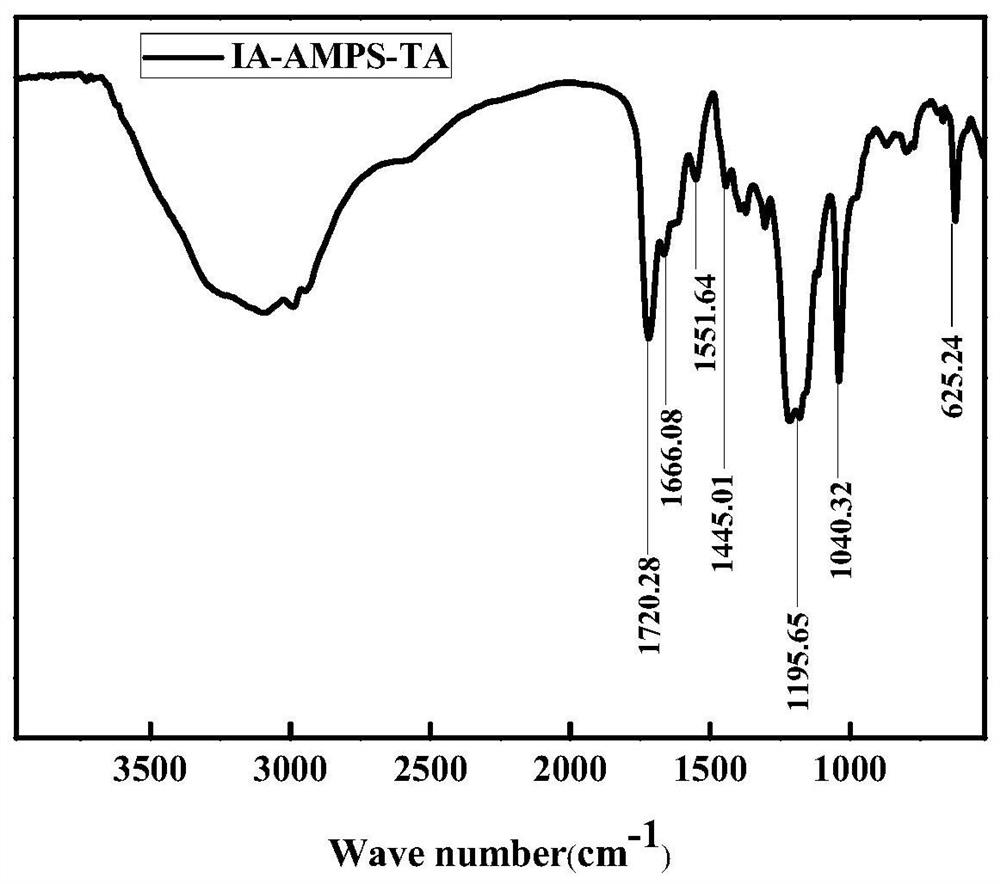

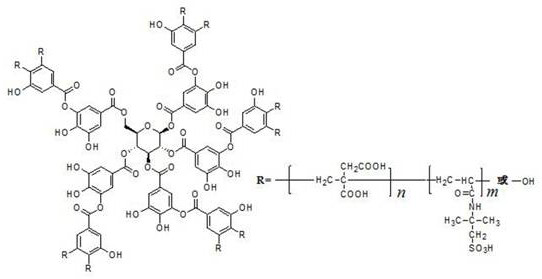

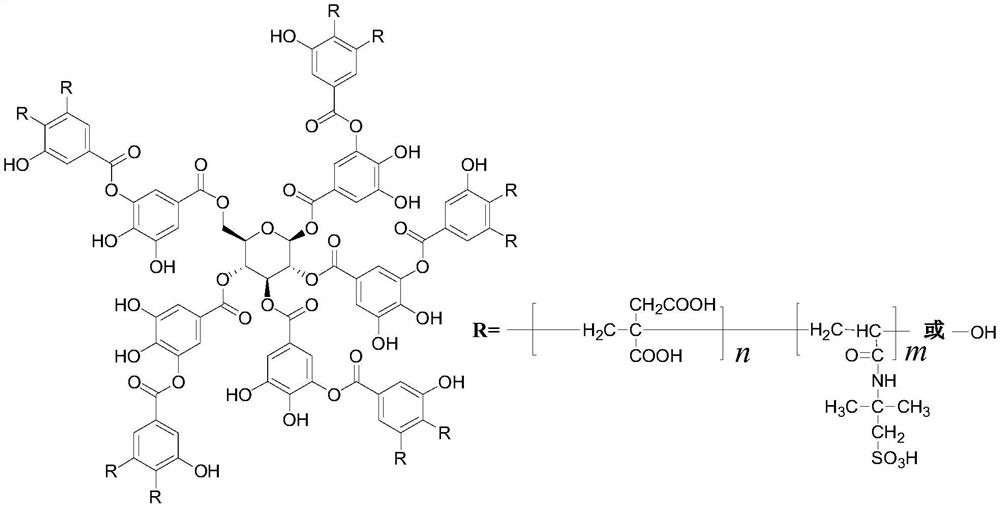

Ternary grafted copolymer and preparing method and application thereof

InactiveCN109776722AGood dispersion performanceGood slurry fluidityScale removal and water softeningLiquid carbonaceous fuelsCoal waterItaconic acid

The invention relates to a polymer compound and particularly relates to a ternary grafted copolymer and a preparing method and application thereof. The copolymer is prepared from itaconic acid, 2-acrylamido-2-methyl-1-propanesulfonic acid and allyl polyoxyethylene ether through a grafting copolymerization reaction, and has a structure shown in the specification. The copolymer has excellent dispersibility, enables good slurry mobility as a coal water slurry additive, is suitable for a wide range of coal varieties and can be compounded with various dispersants. The copolymer has excellent scaleinhibition performance and can effectively prevent deposition of inorganic calcium scales. The invention also provides the preparing method of the copolymer. The whole production process is free of ''three waste" emission, and a product is non-phosphorus and free of toxic substance, thus meeting the national environment protection requirements of China. The invention further provides application of the copolymer, with the dosage being saved and the efficiency being high.

Owner:SHANDONG UNIV OF TECH

Hydrolyzation tolerant sulfonated polyimide proton exchange membrane and preparation thereof

InactiveCN101340002BGood chemical stabilityImprove hydrophobicitySemi-permeable membranesCell component detailsImideBenzene

The invention discloses a hydrolysis-resistant sulfonated polyimide proton exchange membrane and a preparation method thereof; the hydrolysis-resistant sulfonated polyimide proton exchange membrane is provided with the following constitutional repeating units. In the invention, a sulfonic acid group and a terminal amino group are respectively connected with different benzene rings by a condensation reaction, and a perfluoro group is introduced to a benzene ring with an amino group, thus strengthening the hydrophobicity of the terminal amino group part, inhibiting ring opening and degradation of the imide bond resulting from the strong hydrophilic sulfonic acid group in a molecular structure of the proton exchange membrane and improving the chemical stability of the proton exchange membrane.

Owner:SHANGHAI INST OF TECH

Antistatic plastic composite material for electric power fitting and preparation method of antistatic plastic composite material

The invention discloses an antistatic plastic composite material for an electric power fitting. The antistatic plastic composite material is prepared from the following raw materials in parts by weight: 100 parts of junked and abandoned nylon 66 plastic, 2.5 to 2.8 parts of polybutadiene epoxy resin, 23 to 27 parts of glass fiber, 9 to 10 parts of aluminum nitride, 1.7 to 1.9 parts of nano calcium carbonate, 6 to 8 parts of dimethyl formamide, 2.6 to 2.9 parts of triethylene glycol diisooctoate, 7 to 9 parts of silane coupling agent KH560, 11 to 13 parts of sericite powder, 1.4 to 1.7 parts of secondary-alkyl sulfonate and 4 to 6 parts of polyethylene wax. Nylon is modified into a matrix through the epoxy resin; the modified glass fiber is used as a reinforcing material; the nano calcium carbonate is added into the material after being subjected to graft modification treatment through the dimethyl formamide; afterwards, the composite material prepared by matching with other effective components is used for better solving the problems of magnetic hysteresis loss and eddy current loss, avoids electric energy loss, and has the advantages of being antistatic, resistant to wear and high in mechanical strength, and the like.

Owner:马鞍山市华能电力线路器材有限责任公司

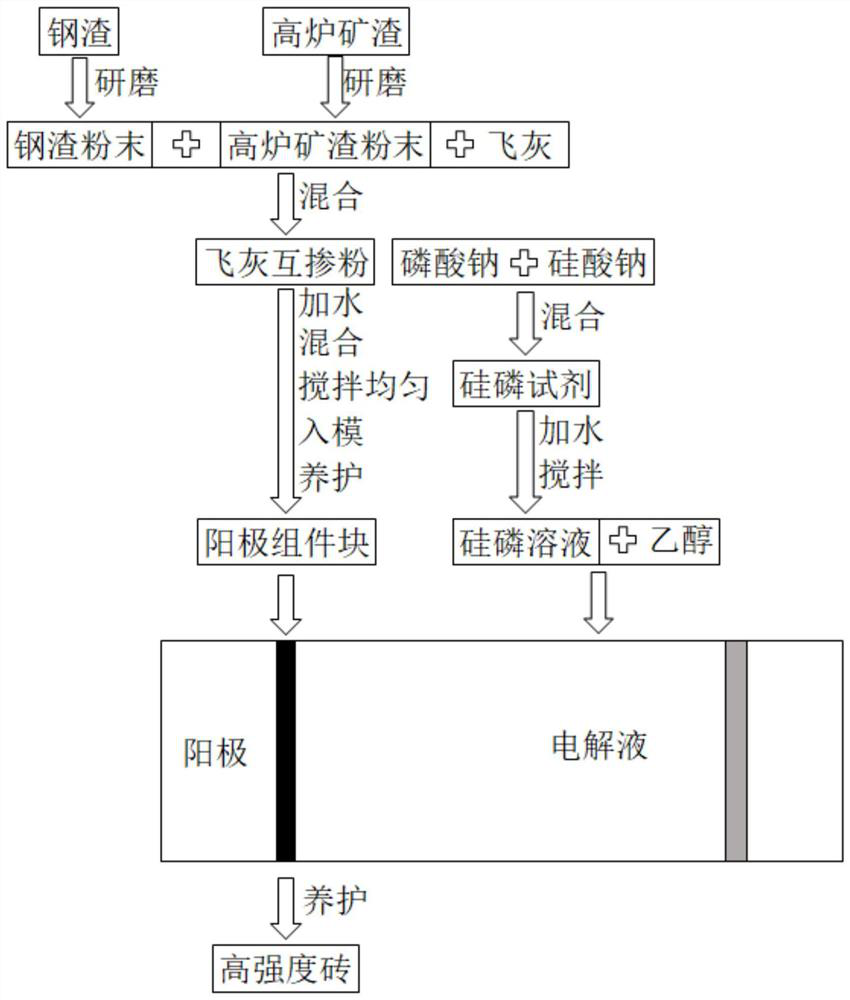

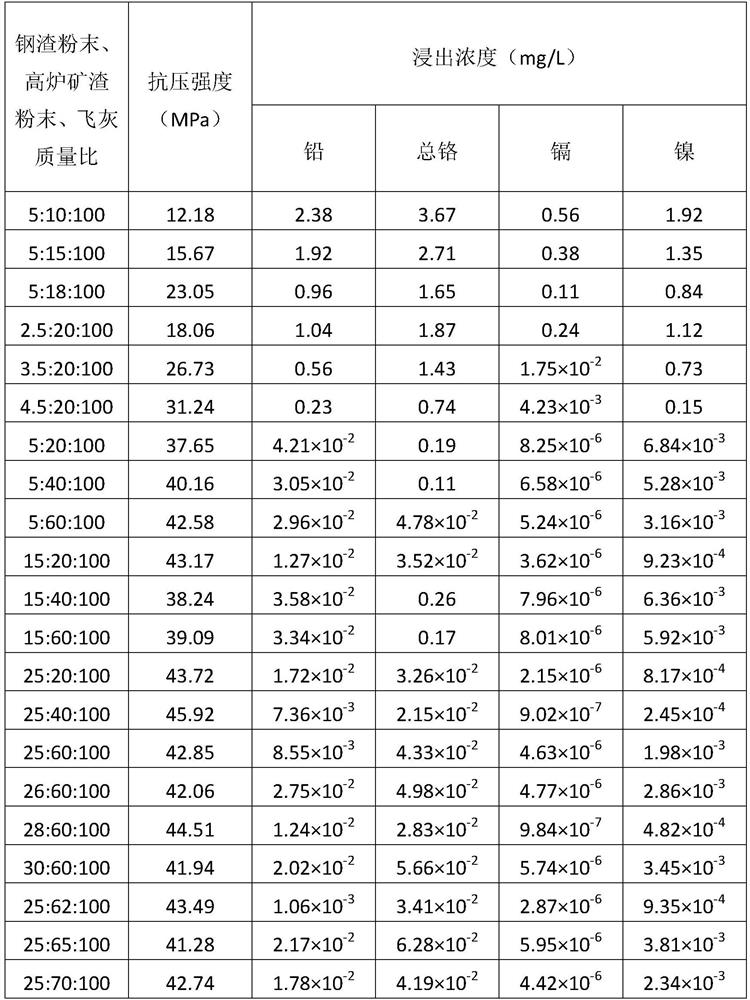

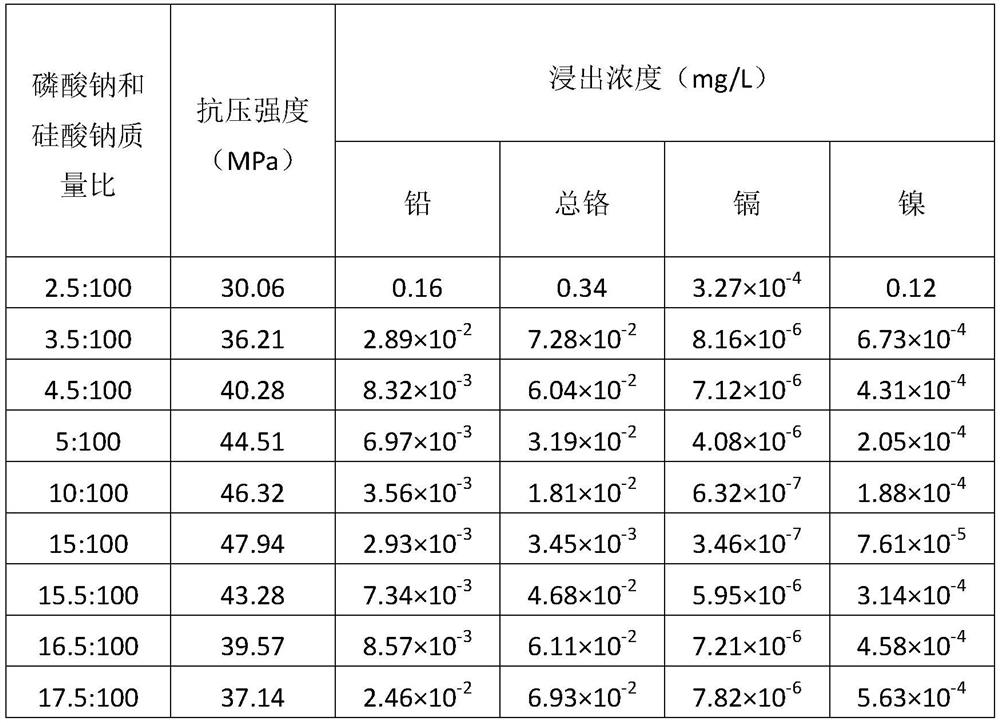

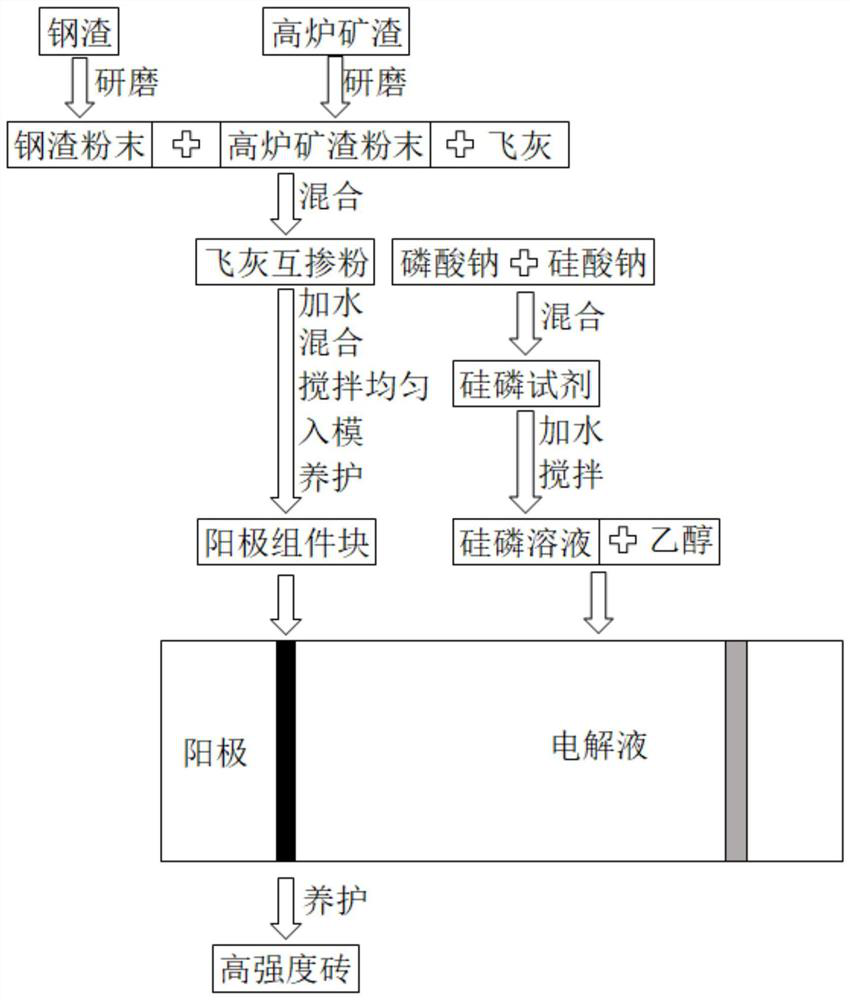

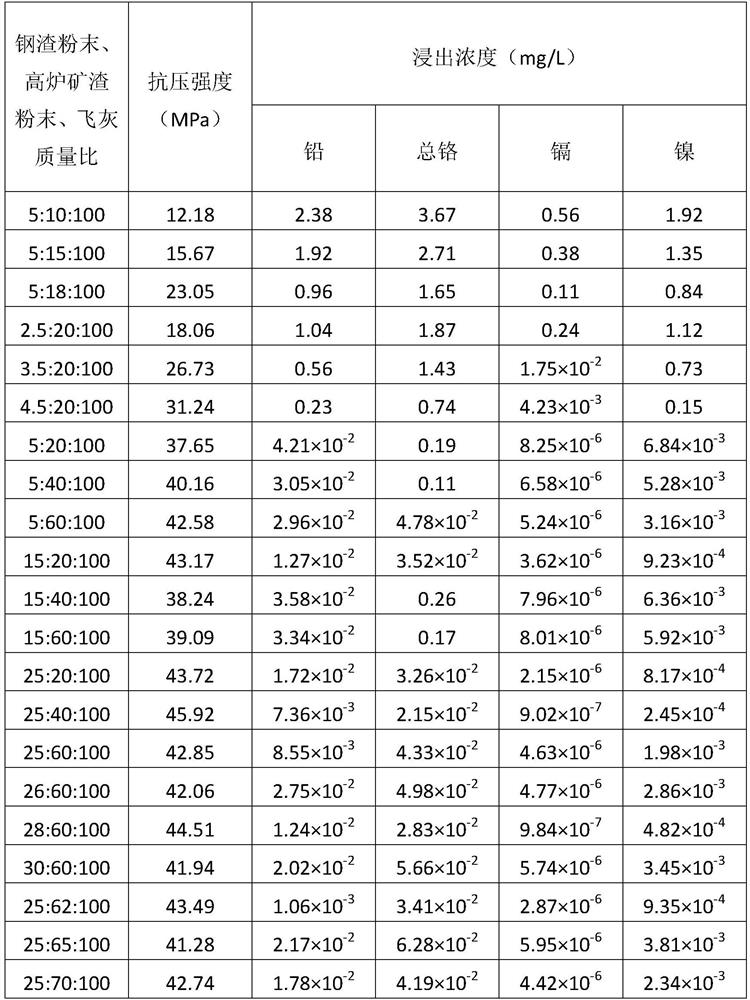

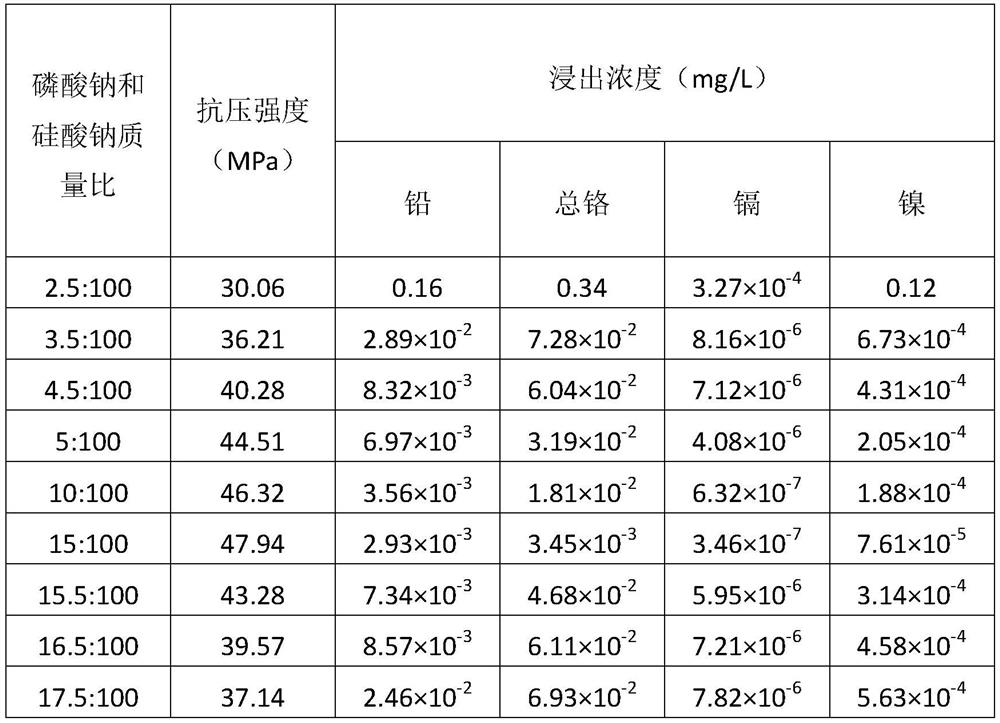

Method for preparing high-strength brick by synergistically utilizing waste incineration fly ash and steel slag

ActiveCN113501679AInhibition of hydrolysisSimple processElectrolysis componentsSolid waste managementSlagSodium silicate

The invention discloses a method for preparing a high-strength brick by synergistically utilizing waste incineration fly ash and steel slag, the method comprises the following steps: (1) grinding the steel slag to obtain steel slag powder; (2) grinding blast furnace slag to obtain blast furnace slag powder; (3) mixing the steel slag powder, the blast furnace slag powder and the fly ash to obtain fly ash mixed powder; (4) mixing water and the fly ash mutual doping powder, uniformly stirring, putting into a mold, and curing to obtain an anode assembly block; (5) mixing sodium phosphate and sodium silicate to obtain a silicon phosphorus reagent; (6) mixing a silicon-phosphorus reagent with water, and stirring until sodium phosphate and sodium silicate are completely dissolved to obtain a silicon-phosphorus solution; (7) adding ethanol into the silicon-phosphorus solution to obtain an electrolyte; and (8) connecting the anode assembly block to an anode, soaking the anode assembly block in the electrolyte, connecting a direct-current power supply, activating, taking down the anode assembly block, and maintaining to obtain the high-strength brick. The process is simple, and the waste incineration fly ash can be converted into the high-strength bricks through operation in a normal-temperature environment.

Owner:浙江中陶环保科技集团有限公司

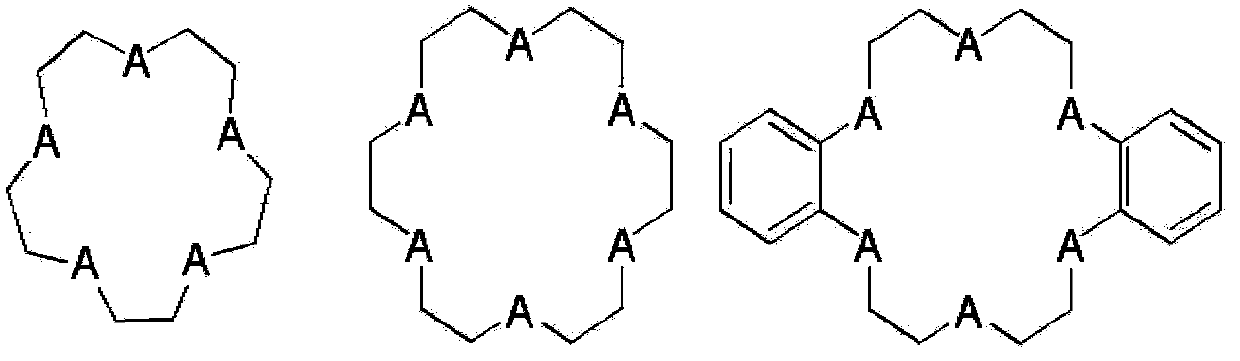

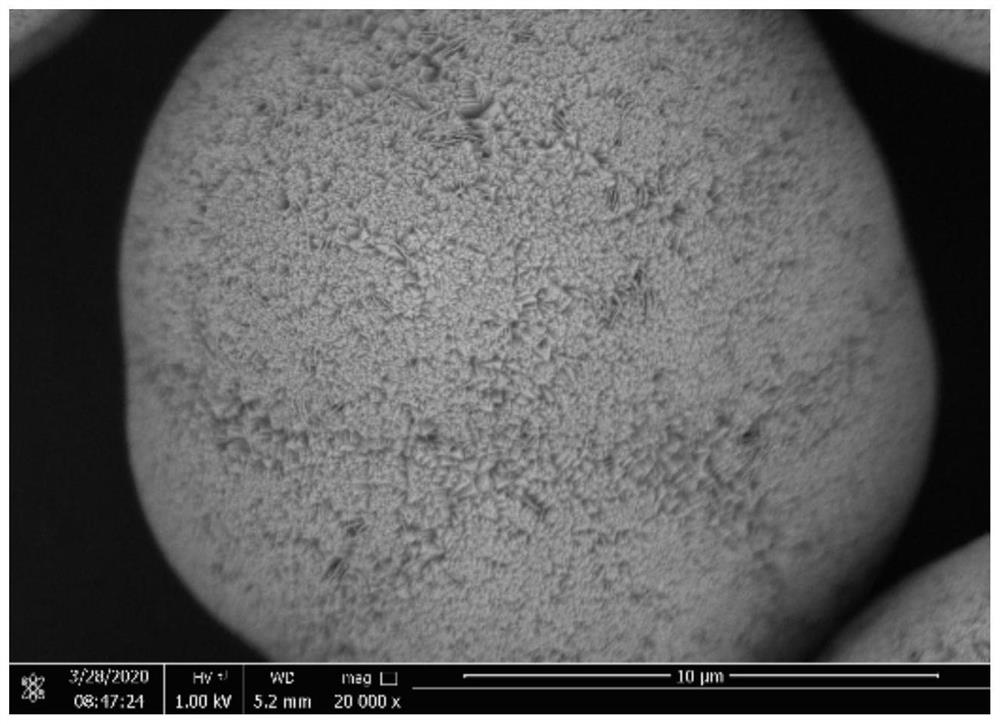

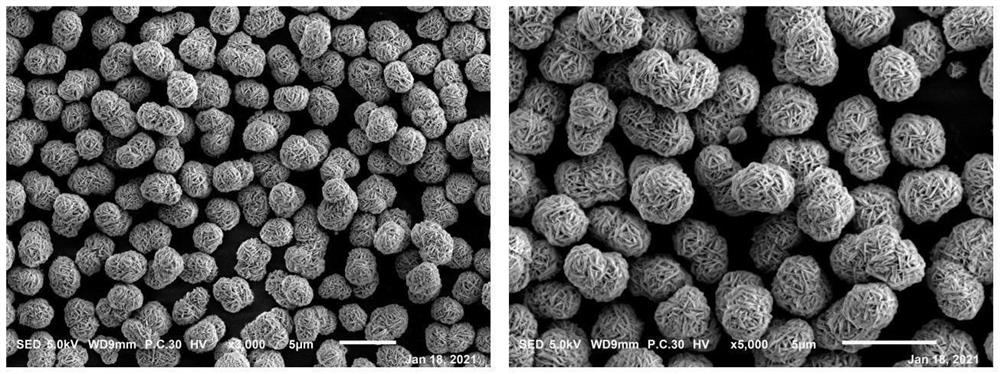

Multifunctional polymer and preparation method and application thereof

ActiveCN109897135AGood anti-scaling effectIncrease concentrationScale removal and water softeningLiquid carbonaceous fuelsHigh concentrationPolymer science

The invention relates to a high molecular compound, in particular to a multifunctional polymer and a preparation method and application thereof. The multifunctional polymer is prepared by subjecting itaconic acid, 2-acrylamido-2-methylpropanesulfonic acid and tannic acid to oxidation and carrying out free radical polymerization. The multifunctional polymer has a structural formula shown in the description and has a molecular weight of four magnitudes. Through molecular design, massive hydroxyl groups are provided; coordinative aggregation of the various functional groups, such as carboxyl group, amido group, sulfo group, hydroxyl group and aromatic rings, is achieved; coaction of the groups gives rise to high hydrophilicity, adsorbing performance and scale-inhibiting performance; as a scale inhibitor, the multifunctional polymer helps effectively remove CaCO3 and CaSO4 scale and plays an important role of reducing operating cost of a reverse osmosis system and extending the life of equipment; the multifunctional polymer has excellent viscosity-reducing and dispersing properties; as a water-coal-slurry additive, the multifunctional polymer provides high concentration, low viscosityand good stability for the prepared water coal slurry. The invention also provides the preparation method and application of the multifunctional polymer.

Owner:SHANDONG UNIV OF TECH

Impact-resistant plastic electric power fitting composite material and making method thereof

The invention discloses an impact-resistant plastic electric power fitting composite material. The composite material is made from, by weight, 100 parts of waste nylon 66 plastic, 2.1-2.4 parts of o-cresol formaldehyde epoxy resin, 20-21 parts of glass fibers, 1.1-1.4 parts of nanometer magnesium oxide, 18-20 parts of carbon black, 6-8 parts of a silane coupling agent KH550, 3-5 parts of chlorinated paraffin, 6-8 parts of a polyurethane emulsion and 4-6 parts of wheat straw fiber micro-powder. Nylon is modified with the epoxy resin to form a matrix, modified glass fibers are adopted as a reinforcement material, the nanometer magnesium oxide grafted and modified with the polyurethane emulsion is added to a material, and other effective components are adopted to prepare the composite material, so the composite material has the advantages of solving of hysteresis loss and eddy current loss, no electric energy loss, high impact resistance, high mechanical strength and long ageing resistance.

Owner:马鞍山市华能电力线路器材有限责任公司

Preparation method and application of magnesium-titanium co-doped cobalt carbonate

PendingCN114702081AInhibition of hydrolysisControllable sedimentation rateCell electrodesSecondary cellsActive agentPhysical chemistry

The invention discloses a preparation method and application of magnesium-titanium co-doped cobalt carbonate, a cobalt-magnesium mixed metal liquid, a precipitator solution and a titanium salt solution are added into a base solution in a parallel flow mode for a reaction, magnesium-titanium co-doped cobalt carbonate slurry is obtained, the precipitator solution is a mixed solution of carbonate and a surfactant, and the titanium salt solution is a mixed solution of magnesium carbonate and titanium carbonate. The titanium salt solution is a mixed solution of an acidic complexing agent and a titanium salt, then carrying out solid-liquid separation on the magnesium-titanium co-doped cobalt carbonate slurry, and washing and drying the obtained solid to obtain the magnesium-titanium co-doped cobalt carbonate. Titanium salt is independently fed into the solution, the acid complexing agent is added into the titanium salt solution, the effects of complexing titanium ions and inhibiting hydrolysis of titanium can be achieved at the same time, the surface active agent and the carbonate solution are mixed, the adsorption capacity of the surfaces of precursor secondary particle balls in the synthesis stage is improved, growth of magnesium-titanium co-doped cobalt carbonate is promoted, and the synthesis efficiency is improved. And the rate capability of the lithium cobalt oxide positive electrode material is remarkably improved by doping magnesium and titanium elements in the bulk phase.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

Slow release scale inhibition agent for circulation cooling water

InactiveCN108862641AStrong alkali resistanceGood synergySpecific water treatment objectivesScale removal and water softeningPolyaspartic acidMercaptobenzothiazole

The invention provides a slow release scale inhibition agent for circulation cooling water. The slow release scale inhibition agent for circulation cooling water is prepared from the following raw materials in parts by weight: 20 to 25 parts of polyepoxysuccinic acid, 12 to 16 parts of polyaspartic acid, 6 to 10 parts of starch, 10 to 15 parts of modified chitosan, 4 to 8 parts of mercaptobenzothiazole, 1 to 3 parts of surfactants and 25 to 30 parts of water, wherein the modified chitosan is mainly prepared from chitosan and DMAEA through reaction, and has the substitution value being 60 to 85percent. The scale inhibition agent solves the environment problem caused by phosphoric chemicals in the existing phosphoric circulation water; the hydrolysis-resistant performance is good.

Owner:芜湖市颂晖商贸有限公司

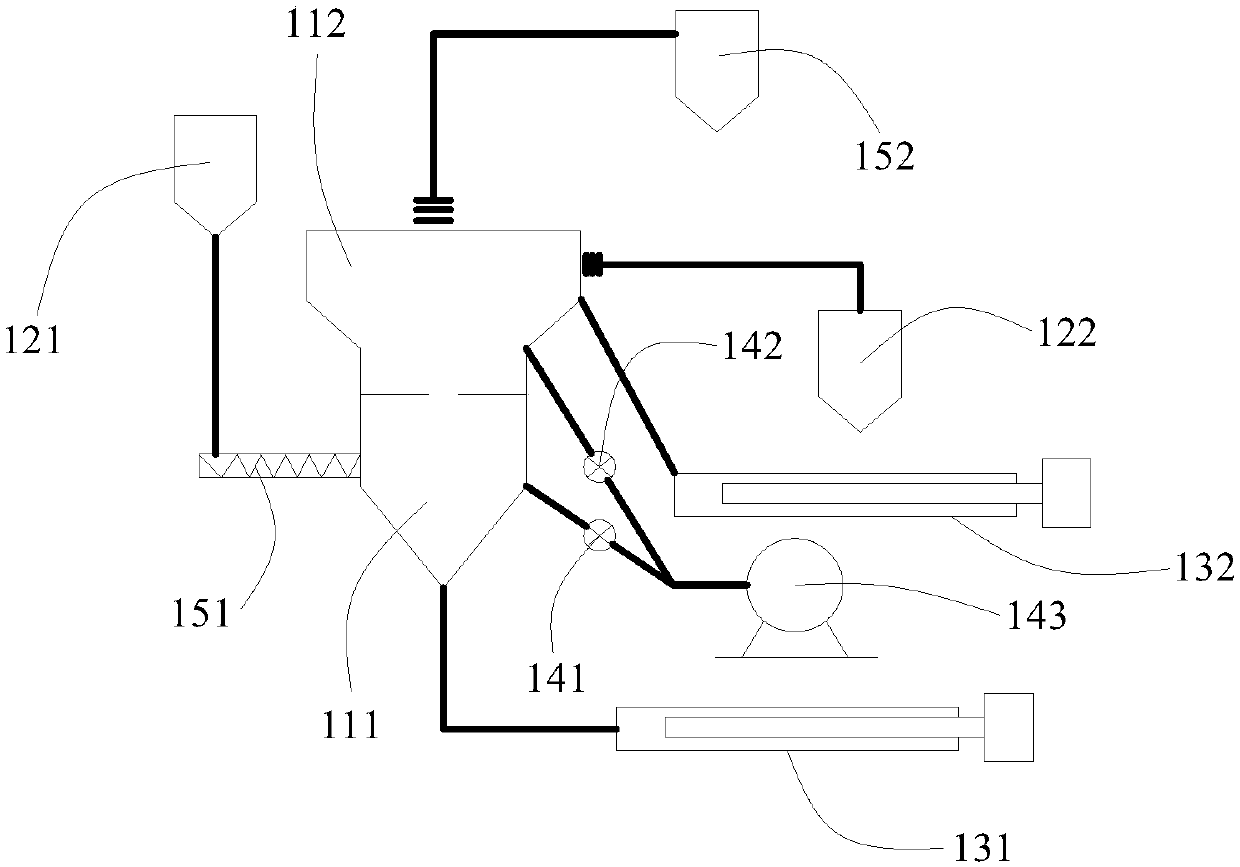

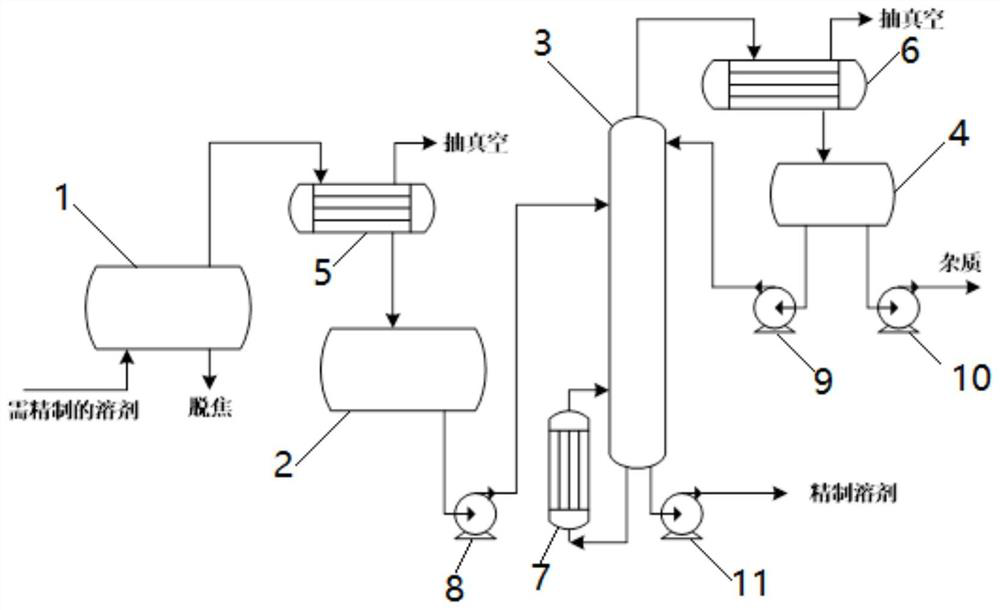

Process system and method for refining dimethyl formamide serving as extraction solvent of C5 separation device

PendingCN114432725AStrengthen the effect of inhibiting hydrolysisInhibition of hydrolysisCarboxylic acid amide separation/purificationVacuum distillation separationPhysical chemistryEngineering

The invention relates to a process system and method for refining an extraction solvent dimethylformamide of a C5 separation device. The process system comprises the following steps: a solvent regeneration kettle carries out decoking treatment on the fed solvent dimethylformamide needing to be refined, and the decoked material is extracted from a gas phase, is condensed by a first condenser and then enters a crude solvent tank; conveying the crude solvent to a solvent refining tower by a crude solvent pump; the solvent refining tower, the second condenser, the reflux tank and the reflux pump of the solvent refining tower form a circulation loop, the solvent refining tower carries out reduced pressure rectification operation on a material subjected to coke removal, the material subjected to reduced pressure rectification is extracted from a gas phase and enters the reflux tank after being condensed by the second condenser, and azeotropic rectification is carried out by taking water as reflux liquid; hydrolysis inhibitor hydrocarbon substances are added into water and intermittently extracted from the tower top through azeotropy, materials subjected to azeotropic rectification are conveyed back to the solvent refining tower through a reflux pump of the solvent refining tower, and after multiple cycles, a tower kettle pump of the solvent refining tower is used for pumping out a refining solvent dimethylformamide, and a tower top extraction pump of the solvent refining tower is used for pumping out impurities.

Owner:CHINA PETROLEUM & CHEM CORP +1

Formula milk powder capable of maintaining bone health and increasing bone mineral substances, and preparation method

The invention discloses a formula milk powder capable of maintaining bone health and increasing bone mineral substances, and a preparation method, and belongs to a dairy product and a preparation technology. The formula milk powder is formed by the compatibility of raw material milk powder, colostrum basic protein and histidine according to parts by weight. Under a condition that a temperature is20-24 DEG C and humidity is 45-65%, the colostrum basic protein and the histidine, which are screened by a sieve of 120 meshes and are sterilized through ultraviolet rays, and 6-10% of the raw material milk powder are subjected to first-level pre-mixing in a three-dimensional mixer for 20-25 min; then, materials subjected to first-level pre-mixing are screened by a sieve of 40 meshes, then, the materials and 90-94% of the residual raw material milk powder are added into a high-speed mixer to be subjected to dry blending under a condition of 35-45 revolution / min for 200-250 S; then, materials subjected to secondary-level dry blending are sent into a packing machine to be vacuumized; and inert gas filling and packaging are carried out to obtain the formula milk powder. According to the formula milk powder, the bone health can be effectively maintained for a long time, effects on supplementing calcium and increasing mineral substances are good, the formula milk powder is safe to eat and has a simple production technology, and nutrient ingredient loss is small.

Owner:白永纯

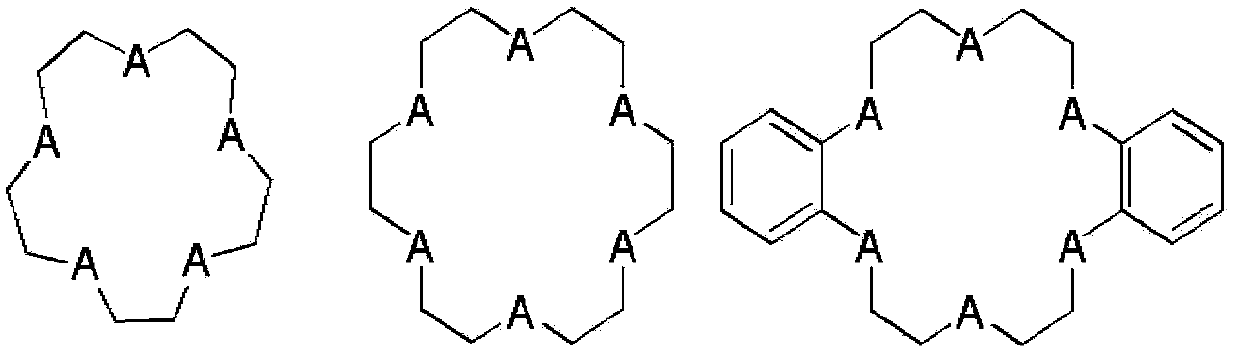

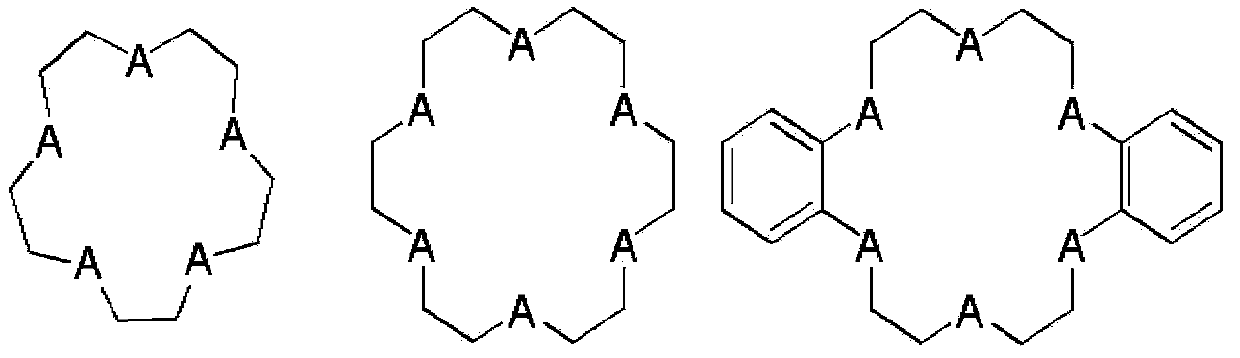

Method for adding ethanol to enhance beta-cyclodextrin yield

InactiveCN101586137BHigh yieldVolatileMacromolecular non-active ingredientsFermentationOrganic solventSolvent

A method for adding ethanol to enhance the beta-cyclodextrin yield belongs to the cyclodextrin production technology field. The invention utilizes the cyclodextrin glycosyltransferase to catalyze the starch to transform and produce the beta-cyclodextrin, adds the ethanol in the reaction liquid to improve the beta-cyclodextrin yield. The method comprises: blending the starch milk with the mass concentration of 15-30%; stirring for 30-120 minutes at 80-90 DEG C, regulating the temperature to 50-60 DEG C, adding the cyclodextrin glycosyltransferase based on the concentration of 3-8 U in 1g starchand adding ethanol; completely reacting for 8-12 hours after the ethanol adding quantity achieves 0.1mL-0.5mL in 1g starch, regulating pH value to 6-9 in the transforming process, filtering, crystallizing and obtaining the beta-cyclodextrin products. The method has no process for recovering the organic solvent and greatly enhances the beta-cyclodextrin yield. The product beta-cyclodextrin has noorganic solvent residues.

Owner:JIANGNAN UNIV

Scale inhibitor for circulating cooling water

InactiveCN108821454AStrong alkali resistanceGood synergyScale removal and water softeningPolyaspartic acidBenzotriazole

The invention discloses a scale inhibitor for circulating cooling water, which is prepared from the following raw materials in parts by weight: 20 to 25 parts of polyepoxysuccinic acid, 12 to 16 partsof polyaspartic acid, 6 to 10 parts of beta-cyclodextrin, 10 to 15 parts of modified chitosan, 3 to 6 parts of benzotriazole, 1 to 3 parts of surfactant and 25 to 30 parts of water. The modified chitosan is prepared mainly by performing a reaction on chitosan and dimethylaminoethyl acrylate; a substitution degree of the modified chitosan is 60 to 85%. The scale inhibitor solves the environment problem caused by a phosphorus containing medicament in existing phosphorus containing circulating cooling water, and has good hydrolysis resistance.

Owner:芜湖市颂晖商贸有限公司

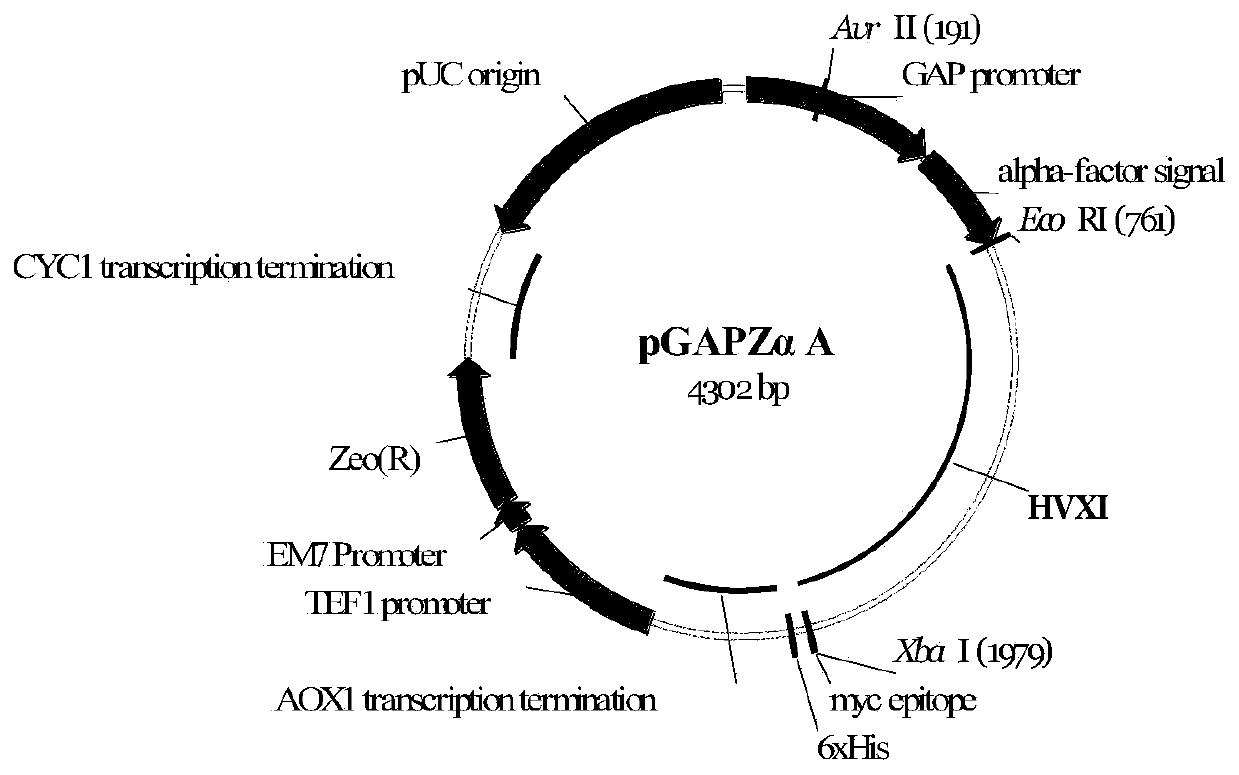

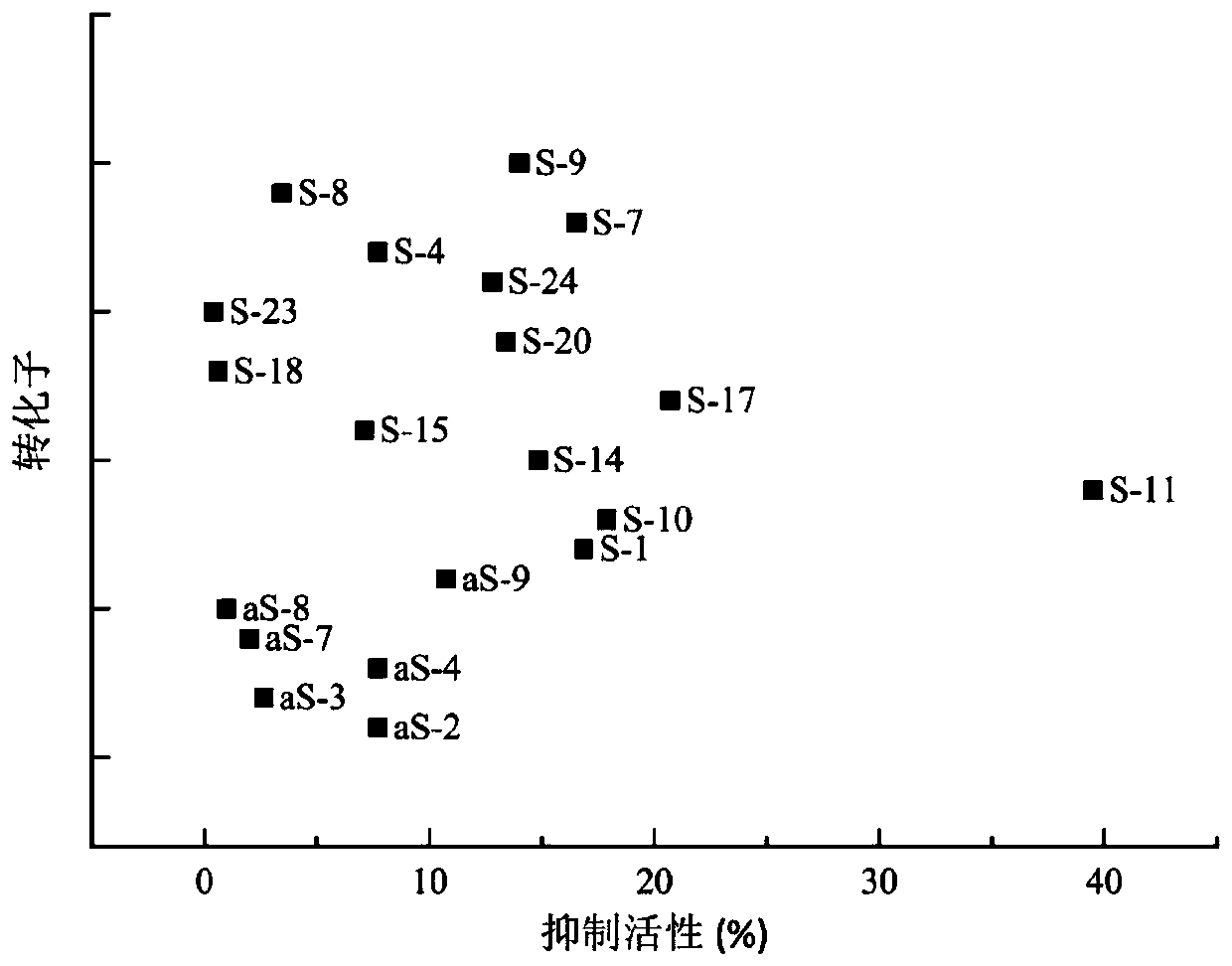

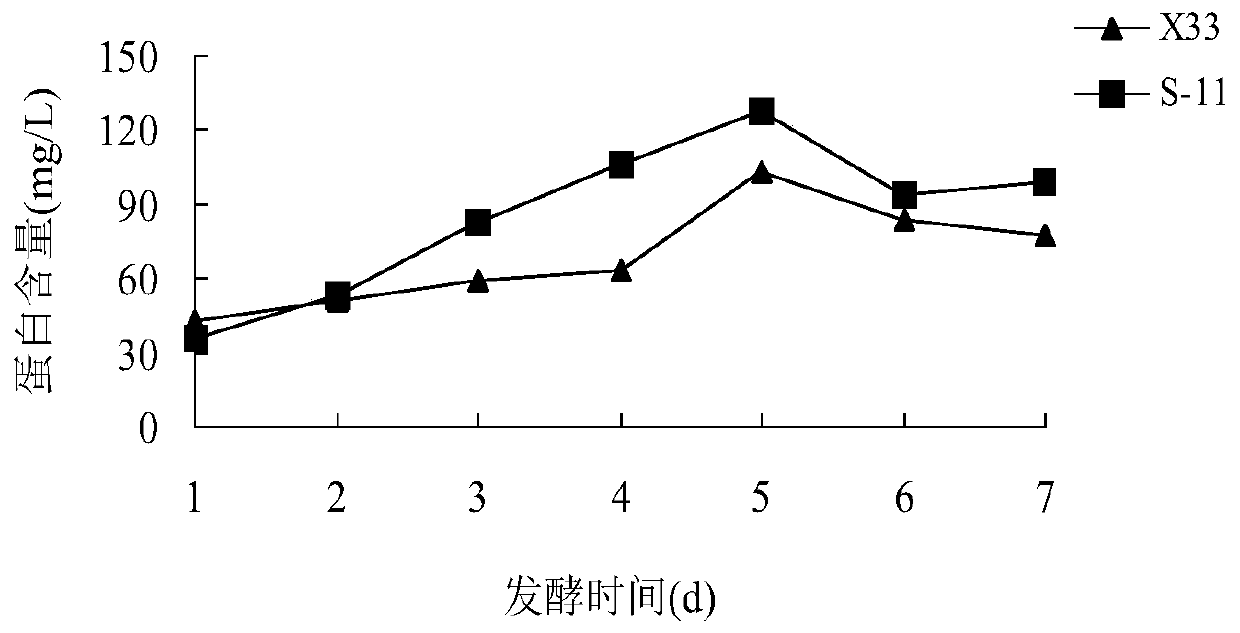

Method for inhibiting production of yeast pre-flocculating factor

InactiveCN110358775AInhibition of hydrolysisInhibitionNucleic acid vectorPeptide preparation methodsPichia pastorisPurification methods

The invention first discloses a codon-optimized gene of a xylanase inhibitor and then discloses an amino acid sequence of the xylanase inhibitor and an expression vector of the xylanase inhibitor. Anexpressing method of the xylanse inhibitor is also disclosed, a separation and purification method of the xylanase inhibitor is further disclosed, and finally a method for inhibiting the production ofa yeast pre-flocculating factor by using the xylanase inhibitor is disclosed. An HVXI gene is expressed in pichia pastoris X33 through a GAP promoter, a transformant having the highest activity is screened by inhibiting the endo-xylanase activity, preliminary separation and purification conditions are determined, the application in a saccharification process is explored, the inhibitory effect onPYF is studied, and a feasible way is provided for further applying the xylanase inhibitor to field barley or a wheat production process to reduce the production of the PYF in the barley or malt.

Owner:YANCHENG INST OF TECH

Synergistic utilization of waste incineration fly ash and steel slag to prepare high-strength bricks

ActiveCN113501679BHigh activityGuaranteed electrical conductivityElectrolysis componentsSolid waste managementElectrolytic agentBrick

The invention discloses a method for synergistically utilizing waste incineration fly ash and steel slag to prepare high-strength bricks, comprising the following steps: (1) grinding steel slag to obtain steel slag powder; (2) grinding blast furnace slag to obtain blast furnace slag powder; (3) mixing steel slag powder, blast furnace slag powder, and fly ash to obtain fly ash intermixing powder; (4) mixing water and fly ash intermixing powder, stirring evenly, putting into a mold, and curing to obtain an anode assembly block; (5) ) mixing sodium phosphate and sodium silicate to obtain silicon phosphorus reagent; (6) mixing silicon phosphorus reagent with water, stirring until sodium phosphate and sodium silicate are completely dissolved to obtain silicon phosphorus solution; (7) adding ethanol to silicon phosphorus (8) connect the anode assembly block to the anode and soak in the electrolyte solution, connect the DC power supply, activate, remove the anode assembly block, and maintain it to obtain high-strength bricks. The process of the invention is simple, and can be operated under normal temperature environment to realize the conversion of waste incineration fly ash into high-strength bricks.

Owner:浙江中陶环保科技集团有限公司

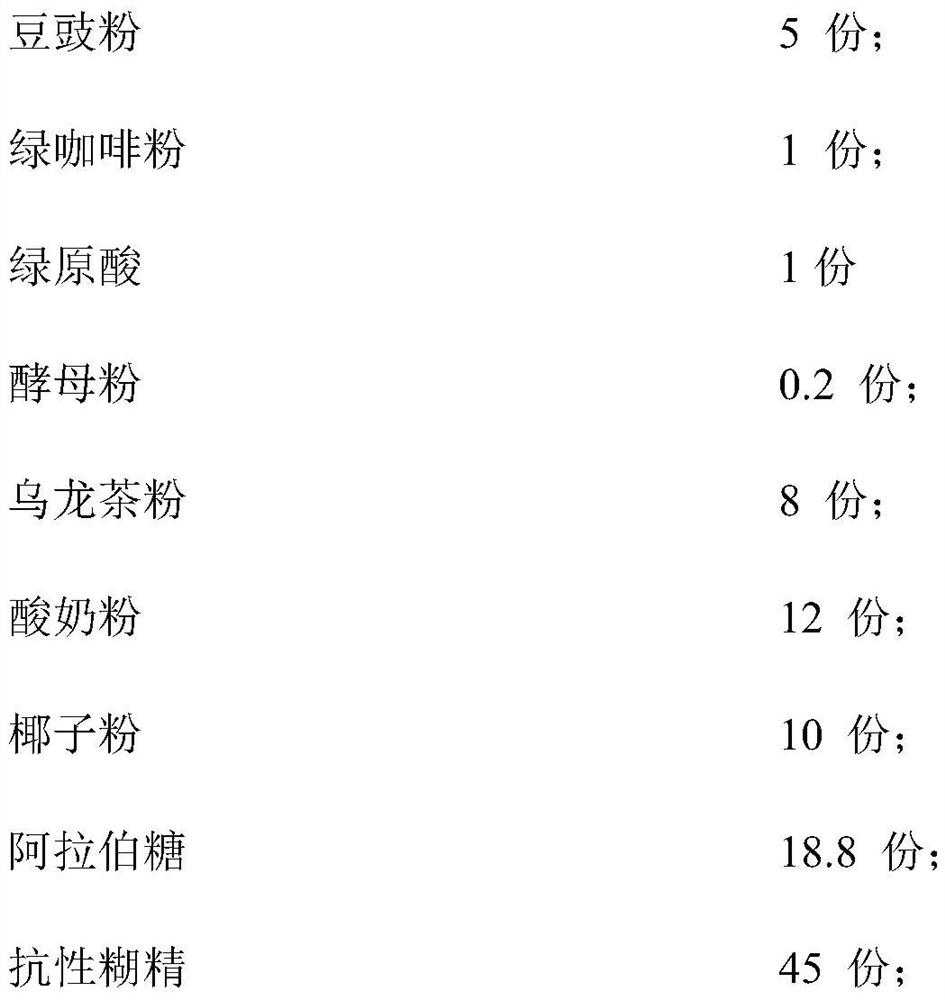

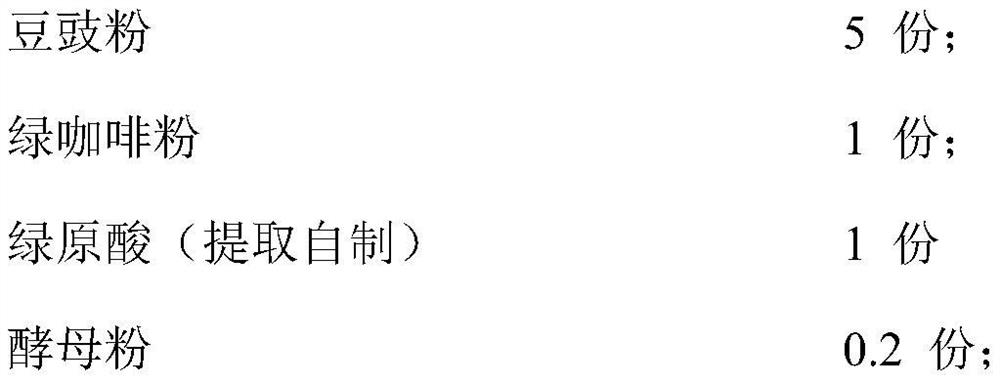

A composition with hypoglycemic effect

ActiveCN111592461BImprove extraction efficiencyHigh extraction purityCarboxylic acid esters separation/purificationFood ingredient functionsBiotechnologyActivated carbon

The present invention relates to the fields of health food and functional food, in particular to a composition with hypoglycemic effect, which comprises the following components: 1-60 parts of tempeh powder, 1-50 parts of green coffee powder, chlorogenic acid 1‑10 parts and 0.01‑10 parts of yeast powder; among them, chlorogenic acid is prepared through the extraction steps of green coffee bean extraction, separation, and activated carbon purification to obtain chlorogenic acid with higher yield and purity. This extraction method can effectively improve green The extraction efficiency of the original acid, the chlorogenic acid has a good effect of lowering blood sugar and blood lipid; and can be well used in products for treating high blood pressure.

Owner:GUANGZHOU NARNIA BIOTECH CO LTD

Solar cell encapsulation material composition and encapsulation sheet manufacturing method

InactiveCN103849064BImprove insulation performanceAvoid accumulationFinal product manufactureCoatingsCarvacryl acetateSolar cell

The invention relates to an encapsulation composition for a solar cell and a preparing method of an encapsulation sheet. The encapsulation composition can prevent the performance reduction, of a module, being caused by electric leakage, the encapsulation composition is provided with good insulating property, and can make the solar cell keep stable for a long time. The encapsulation composition comprises an ethylene-vinyl acetate copolymer resin as a main material, on the basis of the weight of the resin, the encapsulation composition also comprises 0.1-5 parts by mass of a peroxide added as a key additive, and 0.01-5 parts by mass of a metal ion catching agent.

Owner:TORAY ADVANCED MATERIALS KOREA

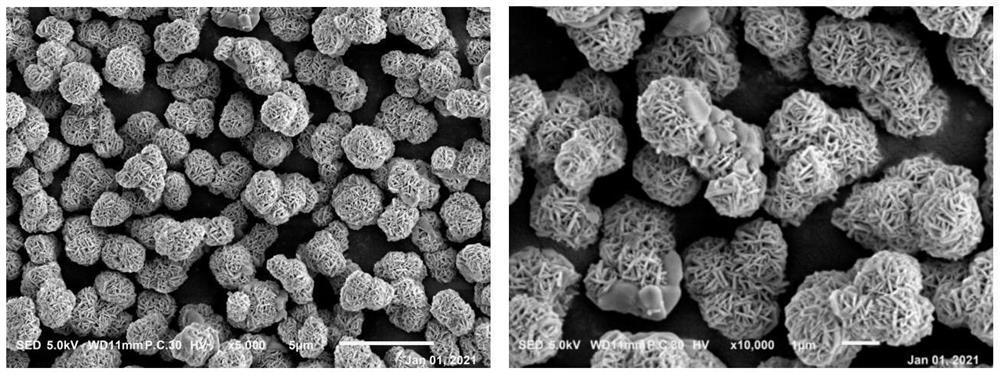

Doped high-rate 5-series single crystal precursor and preparation method thereof

ActiveCN114684874AEnhanced layered structure stabilityStable rate performanceRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsCrystal morphologyHigh rate

The invention discloses a doped high-rate 5-series single crystal precursor and a preparation method thereof, the molecular general formula of the precursor is LiNi0.5 (1-x-y) Co0.2 (1-x-y) Mn0.3 (1-x-y) IrxZry (OH) 2, 3.5 * 10 <-4 > < = x + y < = 3.0 * 10 <-3 >, 4.8 * 10 <-5 > < x < 3.9 * 10 <-4 >, and 3 * 10 <-4 > < y < 3 * 10 <-3 >, the doped high-rate 5-series single crystal precursor is prepared by sequentially preparing a ternary salt solution, a first accompanying liquid and a second accompanying liquid, preparing liquid caustic soda and ammonia water, and preparing a reaction kettle base solution. Carrying out coprecipitation reaction on the main metal ions and the doped element ions, filtering to form a filter cake after the particles reach the target particle size, and washing, drying, screening and demagnetizing the filter cake to obtain the precursor. The precursor prepared by the method is high in layered structure stability and has good sphericity, porosity, primary particle crystal morphology and high rate performance, and the preparation method is beneficial to precision control of the content of final doped elements.

Owner:宜宾光原锂电材料有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com