Multifunctional polymer and preparation method and application thereof

A polymer and multi-functional technology, applied in chemical instruments and methods, descaling and water softening, liquid carbon-containing fuels, etc., can solve problems such as poor performance, insufficient raw materials, poor slurry stability, etc., to reduce deposition, run The effect of low cost and low surface viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

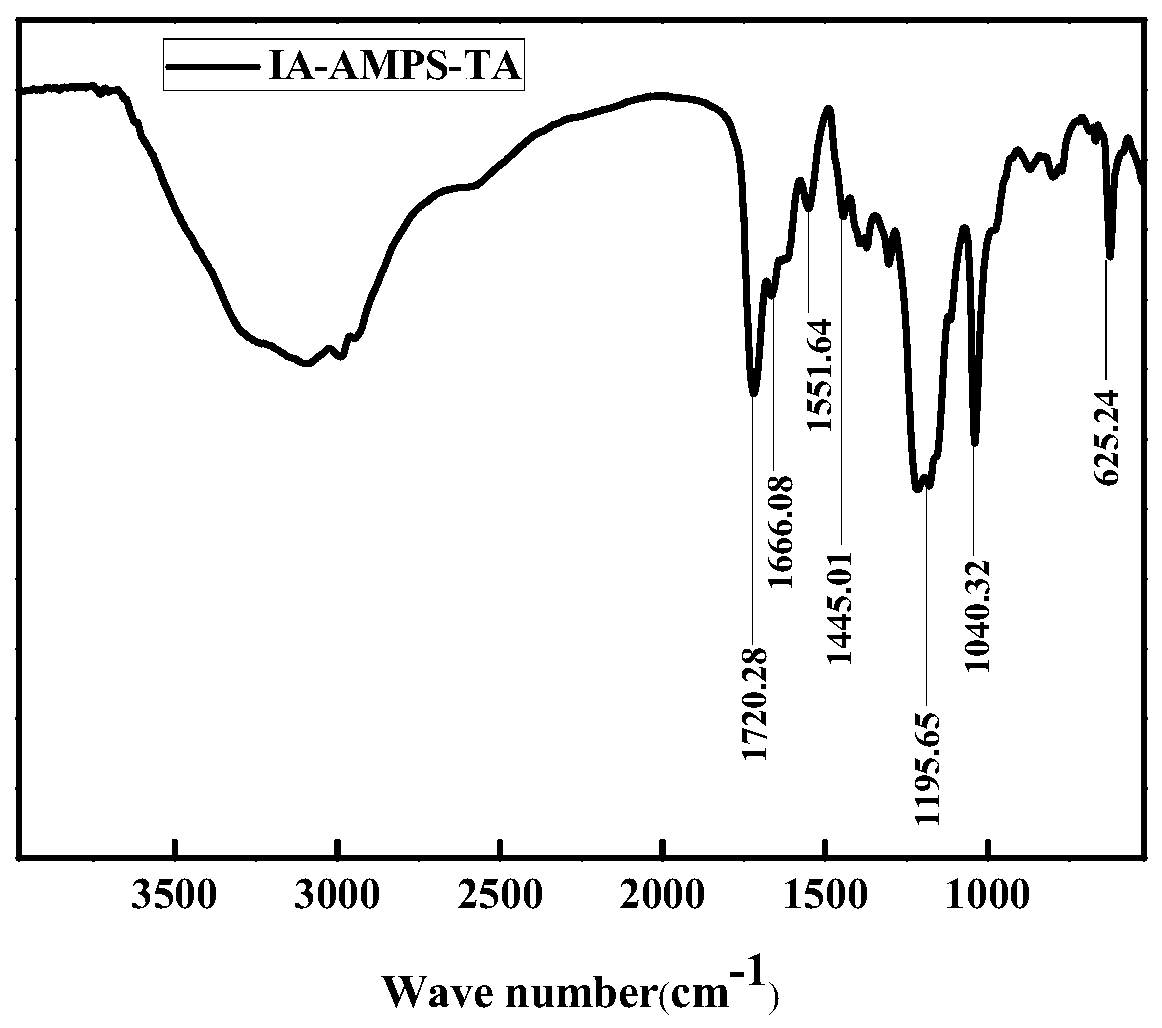

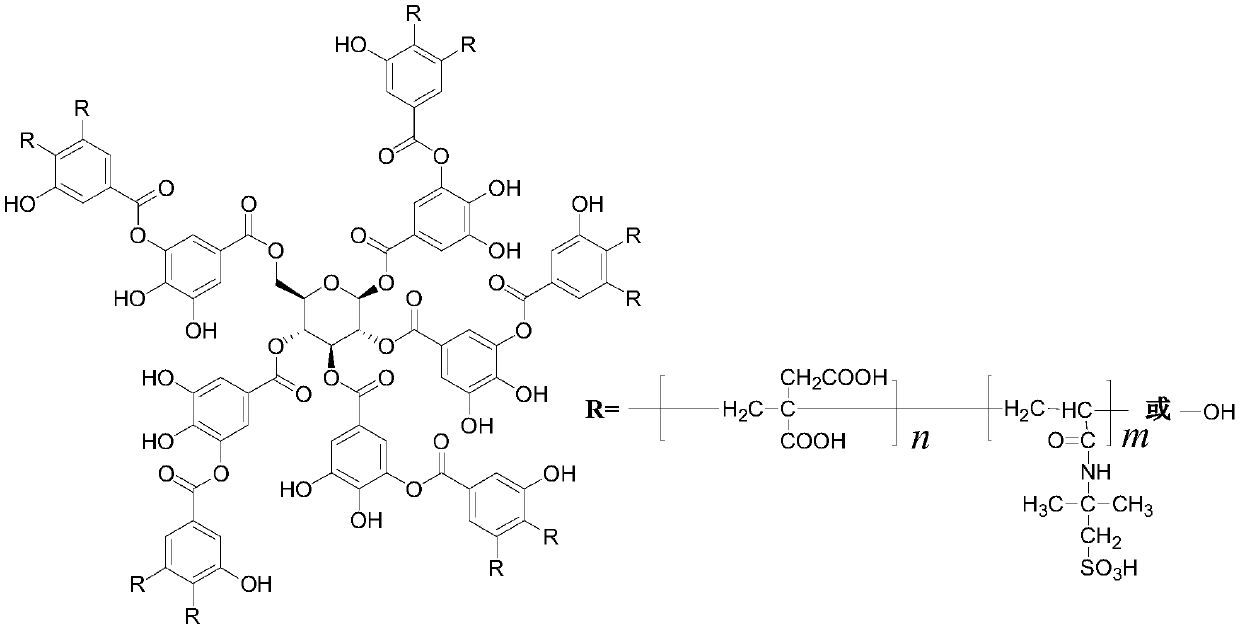

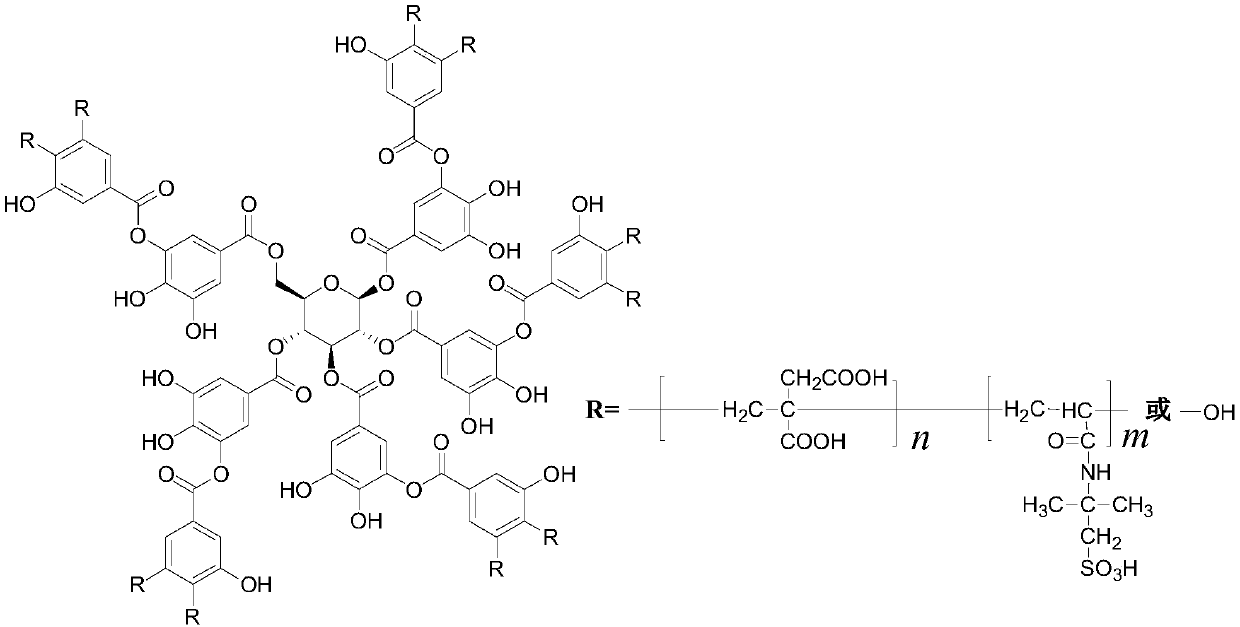

Embodiment 1

[0032] A multifunctional copolymer, used as a scale inhibitor or coal water slurry additive, is composed of the following substances in the following parts by weight:

[0033] 9 parts of itaconic acid (IA), 27 parts of 2-acrylamido-2-methylpropanesulfonic acid (AMPS), 4 parts of tannic acid (TA), 0.6 parts of potassium persulfate, and 69 parts of deionized water.

[0034] Mix tannic acid with deionized water to obtain a tannic acid solution. Add itaconic acid (IA) and 2-acrylamido-2-methylpropanesulfonic acid (AMPS) in proportion to the reaction kettle at 75℃. Add the initiator (potassium persulfate) and the prepared tannic acid solution dropwise at the same time, start the electromagnetic stirrer and stir evenly, the stirring speed is 300 rpm, the stirring time is 3.5h, the reaction temperature is 75 ℃, and the red brown three Meta-graft copolymer, that is, multifunctional copolymer.

[0035] The red-brown ternary graft copolymer prepared in Example 1 was used as a scale inhibitor ...

Embodiment 2

[0039] A multifunctional copolymer, used as a scale inhibitor or coal water slurry additive, is composed of the following substances in the following parts by weight:

[0040] 9 parts of itaconic acid (IA), 27 parts of 2-acrylamido-2-methylpropanesulfonic acid (AMPS), 4 parts of tannic acid (TA), 0.6 parts of potassium persulfate, and 69 parts of deionized water.

[0041] Mix tannic acid with deionized water to obtain a tannic acid solution. Add itaconic acid (IA) and 2-acrylamido-2-methylpropanesulfonic acid (AMPS) in proportion to the reaction kettle at 80℃. Add the initiator (potassium persulfate) and the prepared tannic acid solution dropwise at the same time, start the electromagnetic stirrer and stir evenly, the stirring speed is 300 rpm, the stirring time is 3.5h, the reaction temperature is 80 ℃, and the red-brown three Meta-graft copolymer, that is, multifunctional copolymer.

[0042] The red-brown ternary graft copolymer prepared in Example 2 was used as a scale inhibitor ...

Embodiment 3

[0045] A multifunctional copolymer, used as a scale inhibitor or coal water slurry additive, is composed of the following substances in the following parts by weight:

[0046] 9 parts of itaconic acid (IA), 27 parts of 2-acrylamido-2-methylpropanesulfonic acid (AMPS), 4 parts of tannic acid (TA), 0.6 parts of potassium persulfate, and 69 parts of deionized water.

[0047] Mix tannic acid with deionized water to obtain a tannic acid solution. Add itaconic acid (IA) and 2-acrylamido-2-methylpropanesulfonic acid (AMPS) in proportion to the reaction kettle at 75°C. Add the initiator (potassium persulfate) and the prepared tannic acid solution dropwise at the same time, start the electromagnetic stirrer and stir evenly, the stirring speed is 300 rpm, the stirring time is 3 hours, the reaction temperature is 75 ℃, and the red-brown ternary Graft copolymer, that is, multifunctional copolymer.

[0048] The red-brown ternary graft copolymer prepared in Example 3 was applied as a scale inhibi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com