Doped high-rate 5-series single crystal precursor and preparation method thereof

A high-magnification, precursor technology, applied in chemical instruments and methods, ruthenium/rhodium/palladium/osmium/iridium/platinum compounds, inorganic chemistry, etc., can solve the problem that metal elements cannot co-precipitate with main metal elements and cannot form precipitates etc. to achieve good sphericity, enhanced layered structure stability, and stable rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Using pure water, the ternary salt is made into a ternary salt solution with a concentration of 2mol / L and a Ni:Co:Mn molar ratio of 5:2:3. The Ni, Co, and Mn salts used in the ternary salt solution are NiSO 4 ·6H 2 O, CoSO 4 ·7H 2 O, MnSO 4 ·H 2 O, the main metal concentration of the ternary salt solution is 100 ~ 130g / L; slowly pass 9L of SO 2 To 50L pure water, 50L containing SO 2 After the pure aqueous solution was equally divided, the IrCl 4 ·xH 2 O, ZrOCl 2 ·8H 2 O salt was added three times to two 25L SO containing 2 In the pure aqueous solution of , the element content was detected after each addition, and the first companion feed solution with an Ir salt concentration of 0.6 g / L and a second companion feed solution with a Zr salt concentration of 3 g / L were prepared.

[0048] The NaOH precipitant was prepared into an alkaline solution with a concentration of 10 mol / L with pure water, and then the ammonia water was diluted to a solution of 9.5 mol / L. ...

Embodiment 2

[0061] Further, according to the molar ratio of Ir:Zr=1:5, and according to the proportion of the mass of Ir to the total mass of the precursor of 0.01%, 0.03%, and 0.06%, the precursor was prepared according to the method in Example 1, respectively.

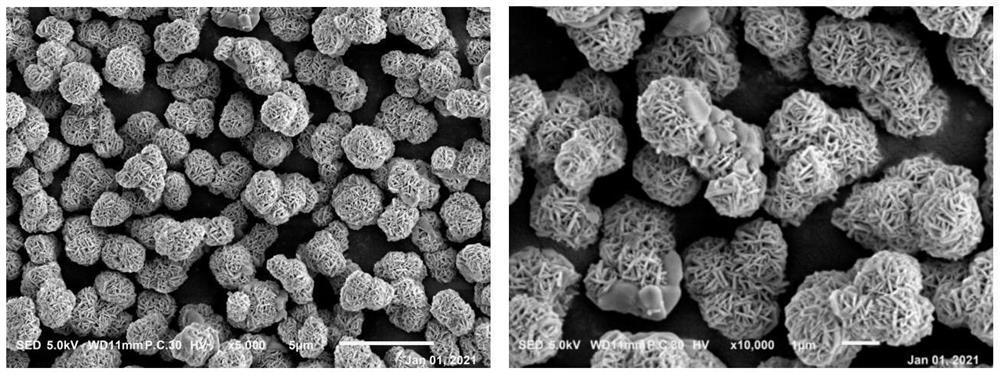

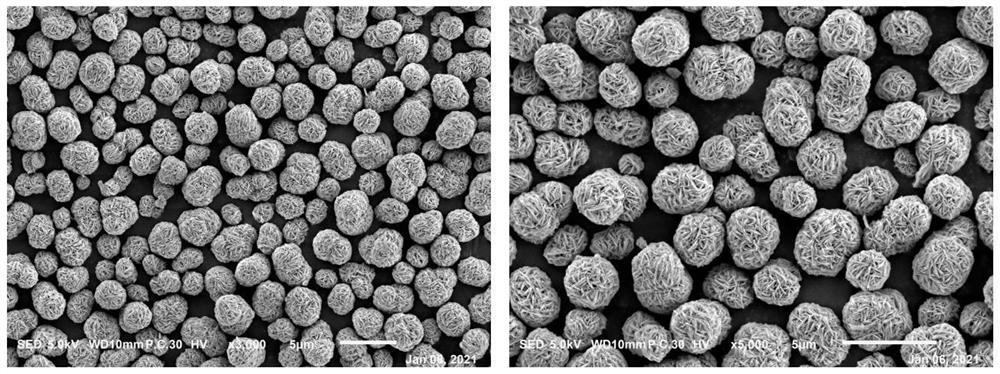

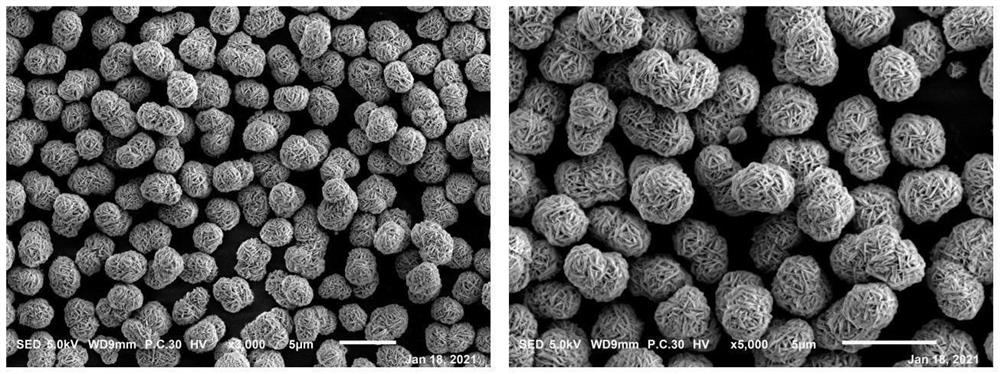

[0062] The three slurries E (Ir0.01%, Zr0.024%), F (Ir0.03%, Zr0.072%), G (Ir0.06%, Zr0.144%) produced by the reaction were put into the The kettle was aged for 4h, then pumped to a centrifuge and dried to be a filter cake, and the filter cake was centrifugally washed with 1 mol / L alkali solution of 8 times the weight, and then centrifugally washed with 6 times the weight of pure water for several times. After the content reaches the standard, it is sent to an oven at 130 ° C for drying; after the moisture is qualified, it is sieved with a 300-mesh sieve tray, and finally demagnetized with a 12000GS iron remover to obtain E, F, G three precursors, the product The shapes are as Figure 5 , Image 6 , Figure 8 . It can be see...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com