A znsb for a lithium-ion battery 2 o 6 Negative electrode material and preparation method thereof

A lithium-ion battery and negative electrode material technology, which is applied in battery electrodes, secondary batteries, nanotechnology for materials and surface science, etc., can solve unsatisfactory cycle performance and rate performance, large volume changes of lithium-ion batteries, Poor cycle performance and other issues, to achieve the effect of improving electrochemical performance, excellent rate performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

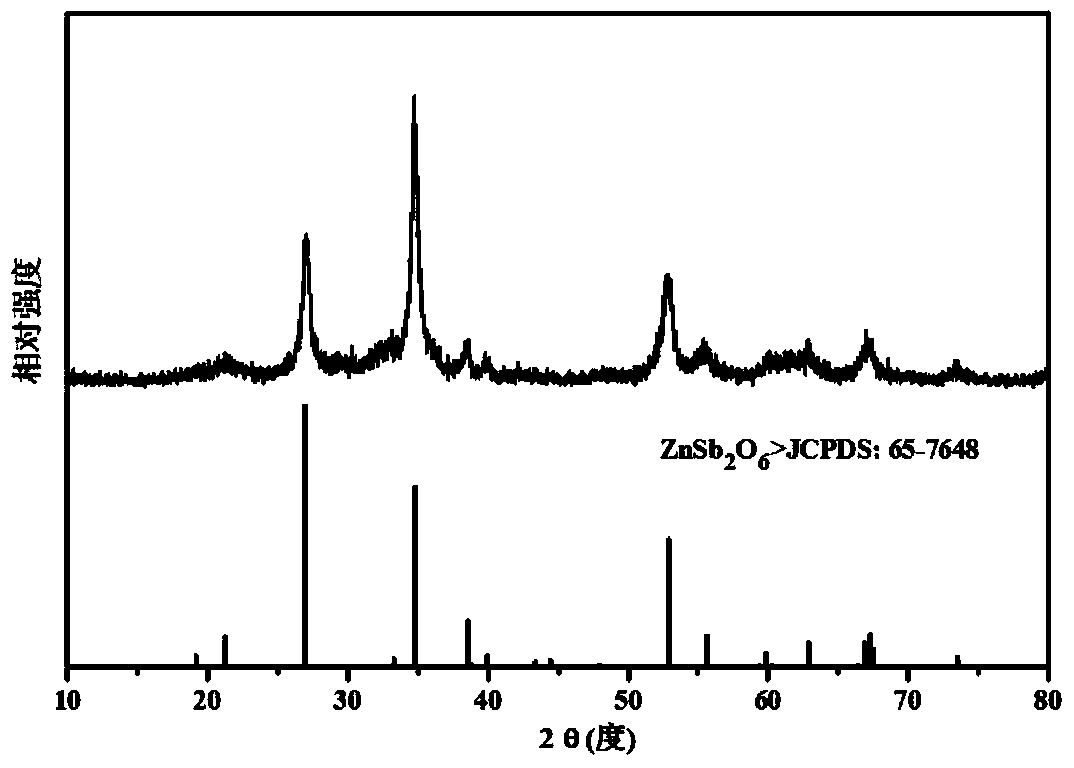

[0027] 10mmol zinc sulfate heptahydrate is dissolved in 100ml deionized water to form solution A, 20mmol antimony potassium tartrate is dissolved in 100ml deionized water to form solution B, after the two solutions are mixed, add 6ml of hydrazine hydrate (80wt.%), at 30 Stir magnetically for 12 hours at ℃, centrifuge after stirring, wash with deionized water and ethanol several times in sequence, and dry at 80 ℃ to obtain a white powder.

[0028] The dried white powder was calcined in the air atmosphere for 2h, the calcination temperature was 800°C, and the heating rate was 5°C / min to obtain ZnSb 2 o 6 particles.

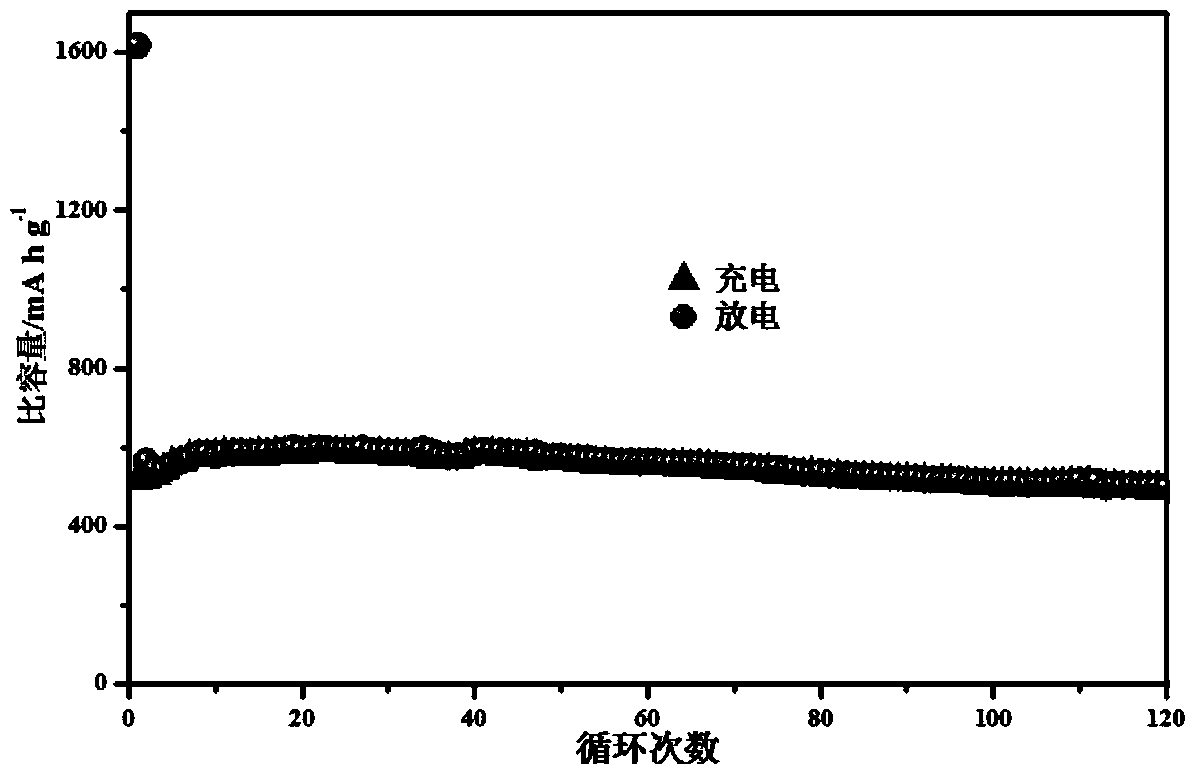

[0029] Mix the material obtained in Example 1, conductive carbon black, and sodium alginate uniformly according to the mass ratio of 7:1.5:1.5, add a small amount of water, grind and mix thoroughly to form a uniform paste, and coat it on the copper foil substrate as a test The electrodes were vacuum-dried at 60°C to obtain pole pieces. A 2025-type half-battery wa...

Embodiment 2

[0035] Dissolve 20mmol zinc sulfate heptahydrate in a mixed solvent of 50ml deionized water + 50ml absolute alcohol to form solution A, dissolve 40mmol antimony potassium tartrate in 200ml deionized water to form solution B, mix the two solutions and add 10ml of hydration Hydrazine (80wt.%) was magnetically stirred at 30°C for 16h, centrifuged after stirring, washed with deionized water and ethanol several times in sequence, and dried at 80°C to obtain a white powder.

[0036] The dried white powder was calcined in the air atmosphere for 4 hours, the calcination temperature was 800°C, and the heating rate was 5°C / min, and ZnSb with a size of 80-90nm was obtained. 2 o 6 particles.

[0037] The ZnSb prepared in this embodiment 2 o 6 Nanoparticles were used as working electrodes, and lithium sheets were used as counter electrodes to assemble 2025-type button batteries. The reversible capacity was maintained at 500mA h / g after 120 cycles at a current density of 100mA / g.

Embodiment 3

[0039] Dissolve 20mmol zinc chloride in 100ml deionized water to form solution A, dissolve 40mmol sodium antimony tartrate in 200ml deionized water to form solution B, mix the two solutions, add 20mmol sodium borohydride, and stir magnetically at 50°C for 12h , centrifuged after stirring, washed with deionized water and ethanol several times in sequence, and dried at 80°C to obtain a white powder.

[0040] The dried white powder was calcined in the air atmosphere for 4h, the calcination temperature was 600°C, and the heating rate was 5°C / min to obtain ZnSb 2 o 6 particles.

[0041] The ZnSb prepared in this embodiment 2 o 6 Nanoparticles were made into working electrodes, and lithium sheets were used as counter electrodes to assemble 2025-type button batteries. The reversible capacity was maintained at 450mA h / g after 120 cycles at a current density of 100mA / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com