Patents

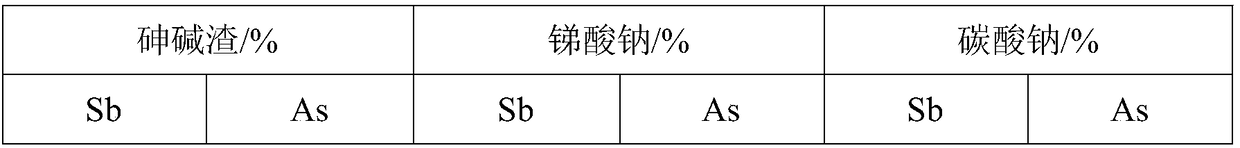

Literature

80results about "Antimonates/antimonites" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Synthesis of cathode active materials

Owner:LITHIUM WERKS TECH BV +1

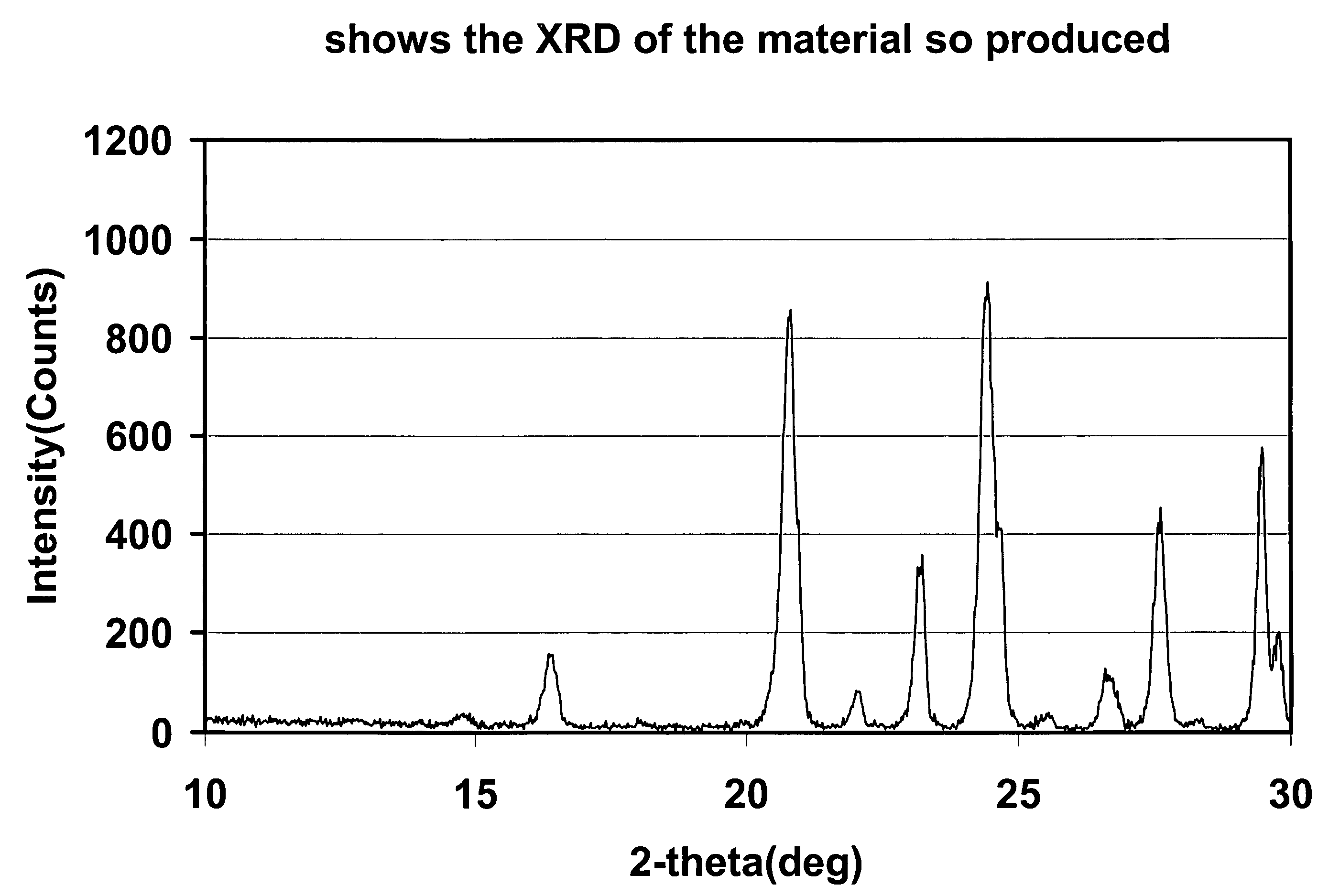

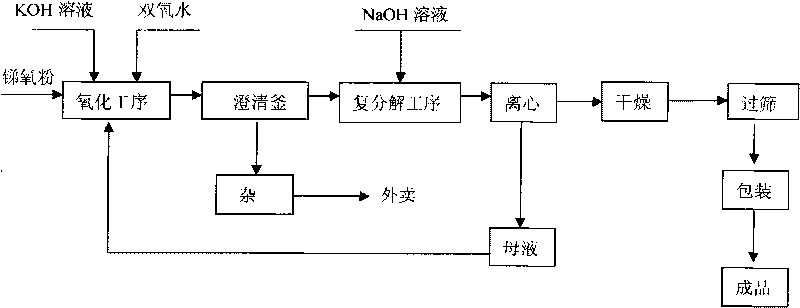

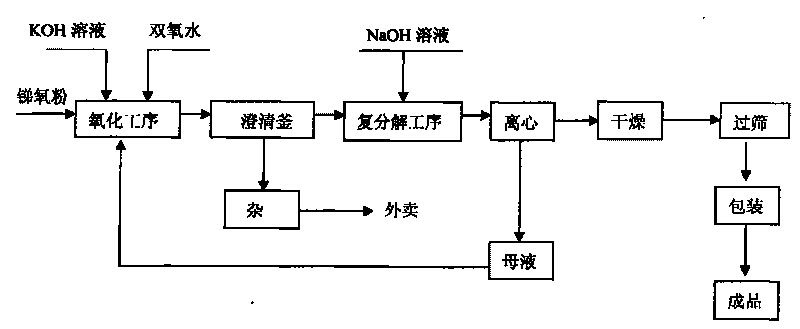

Production process for preparing ultra-white nanometer sodium pyroantimonate

InactiveCN101693553AHigh whitenessLower requirementAntimonates/antimonitesDominant whiteDecomposition

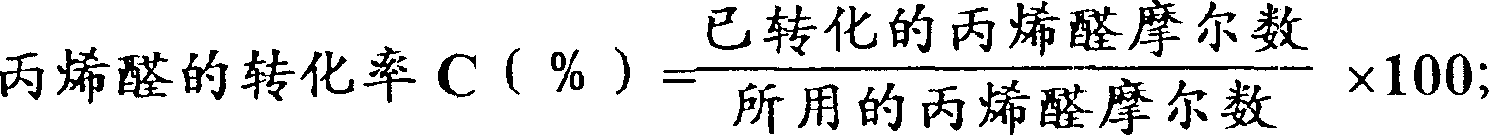

The invention relates to a production process for preparing ultra-white nanometer sodium pyroantimonate. The process comprises the following steps: adopting low-quality antimonious oxide powder and adding 27.5 percent hydrogen peroxide for reacting at 60-120 DEG C for 1-2 h by using a potassium hydroxide solution as a leaching agent, wherein the solid-liquid ratio of the antimonious oxide powder and the potassium hydroxide solution is 1:5-20; clarifying the reaction liquid for more than half an hour, pumping the supernate into a double decomposition kettle and adding a sodium hydroxide solution into the double decomposition kettle for reaction under normal pressure to convert potassium antimonate into sodium antimonate; separating the sediment by centrifugation, drying and screening to obtain the ultra-white nanometer sodium pyroantimonate product with the whiteness of more than 93 percent; and leaching and oxidizing the double decomposition mother liquor for recycling. The obtained product has the whiteness of more than 93 percent and can be used as a clarifying defoaming agent and a flame retardant agent in solar power generation and dominant white glass.

Owner:ZHUZHOU ANTE ANTIMONY CHEM IND

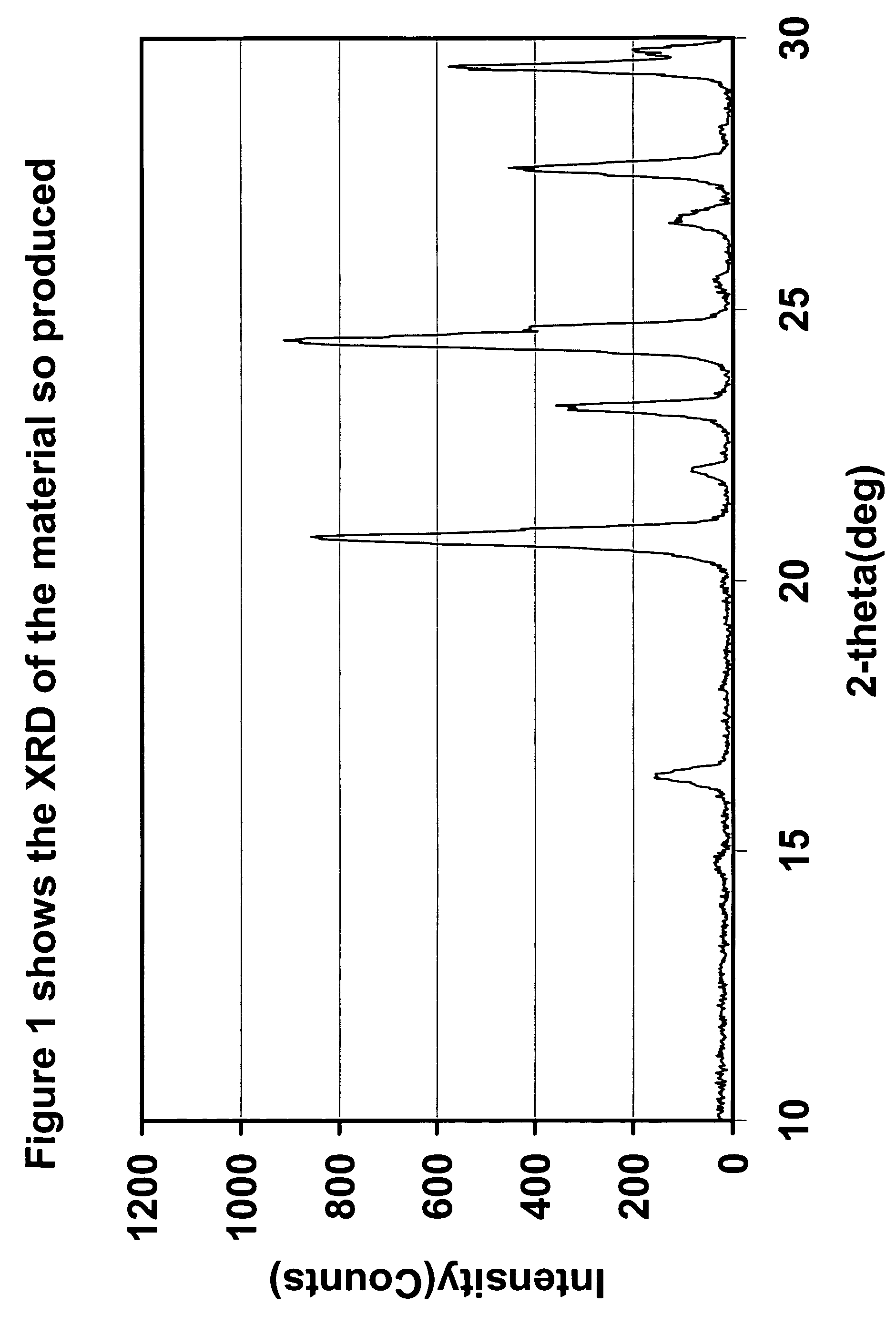

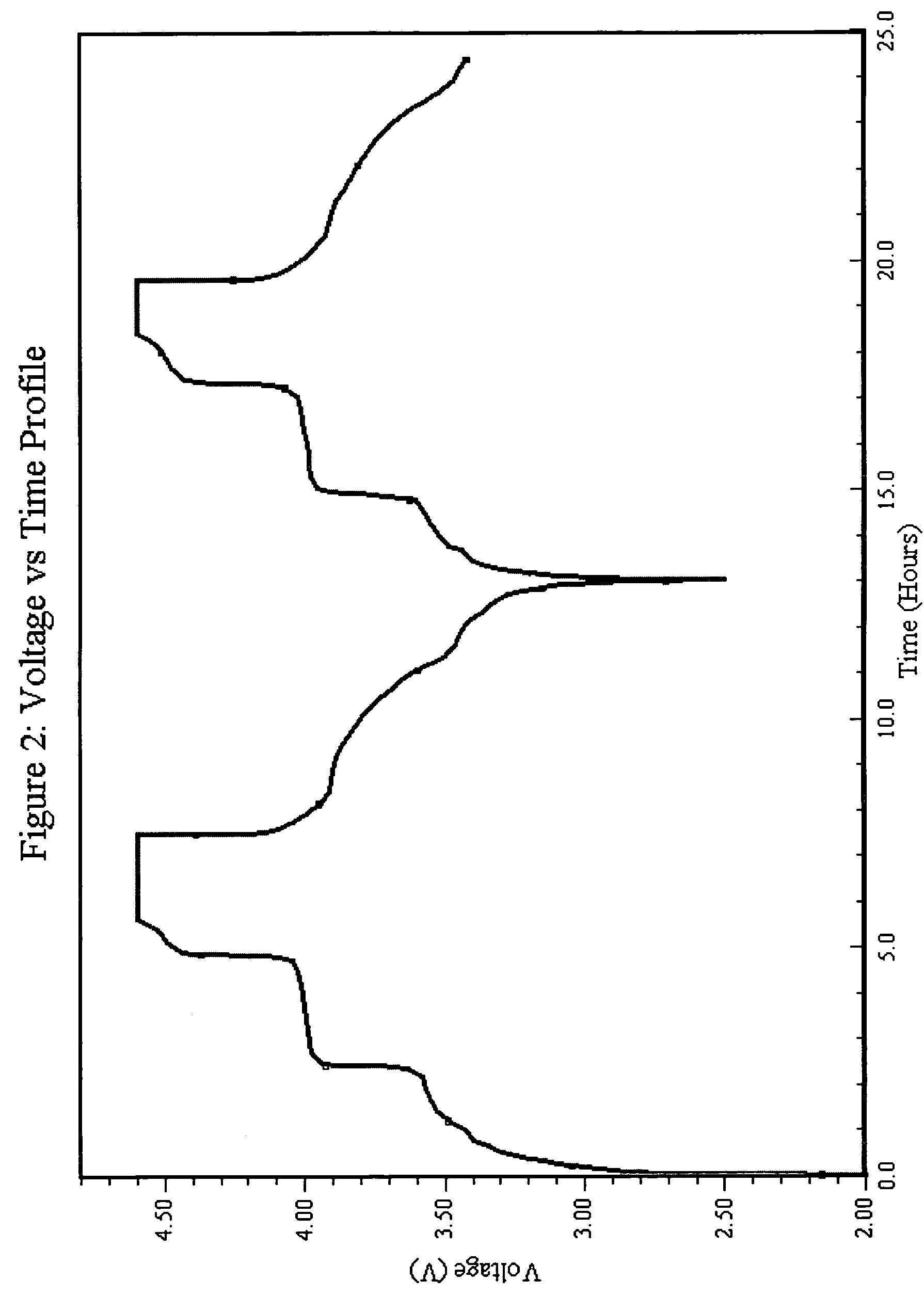

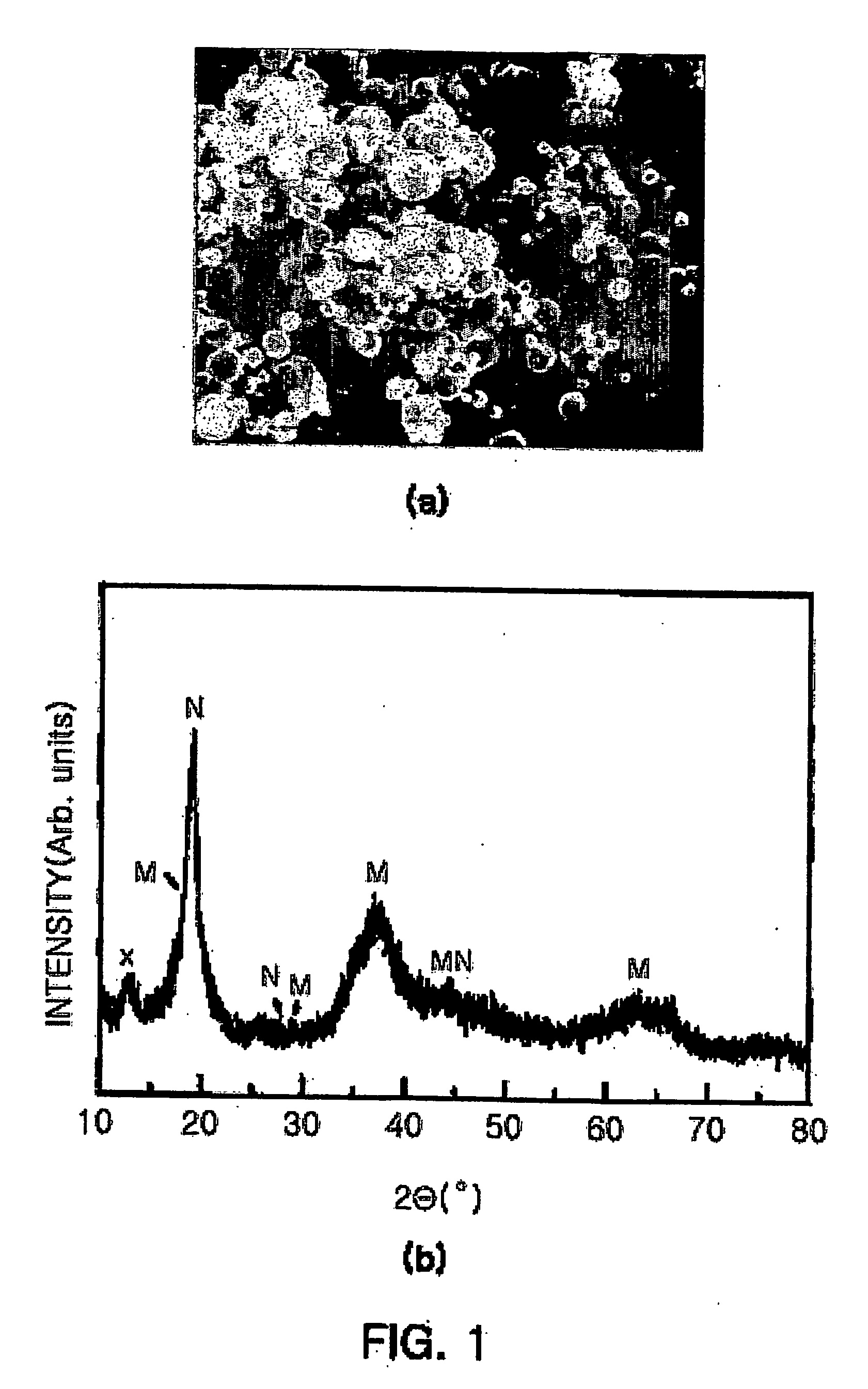

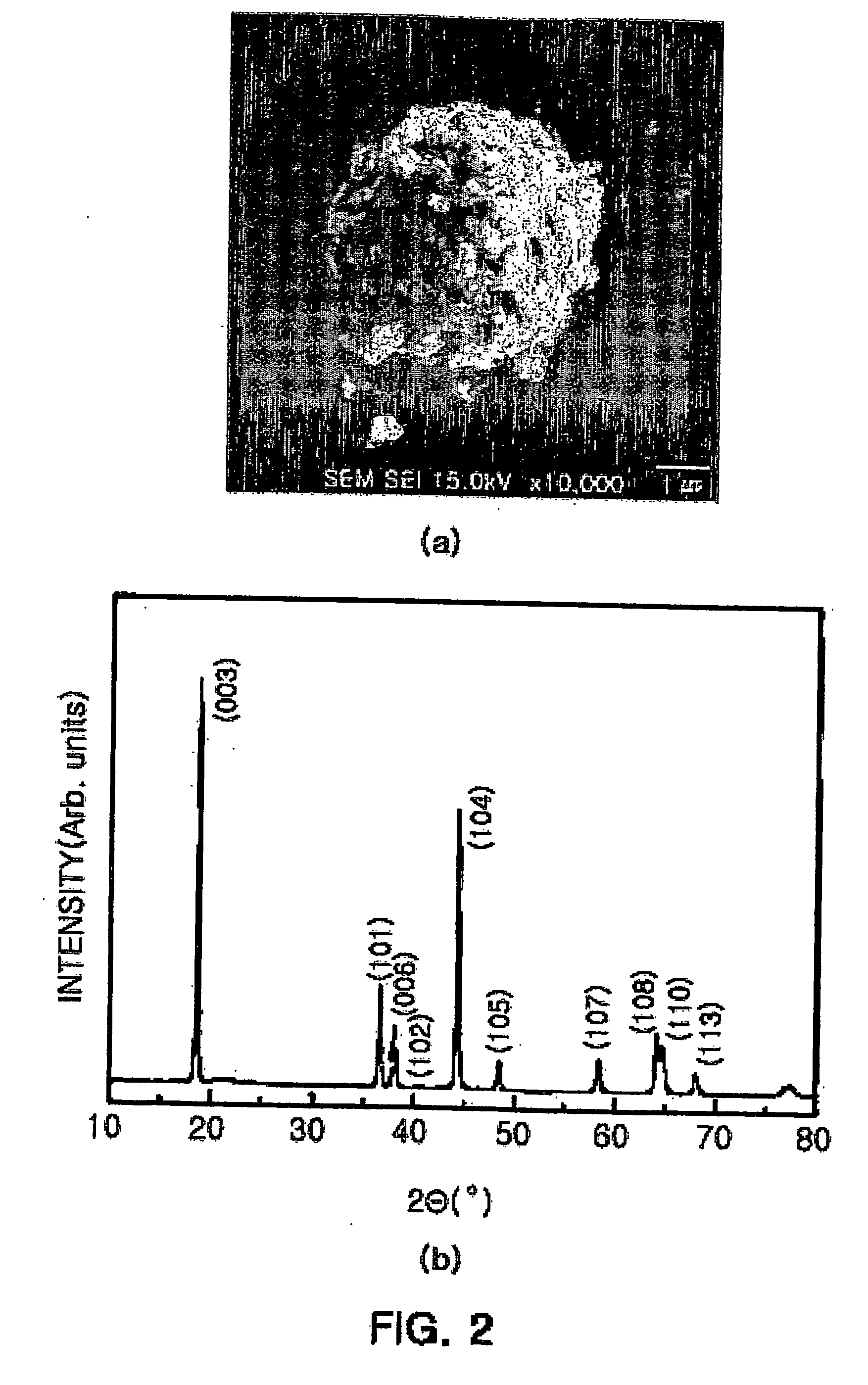

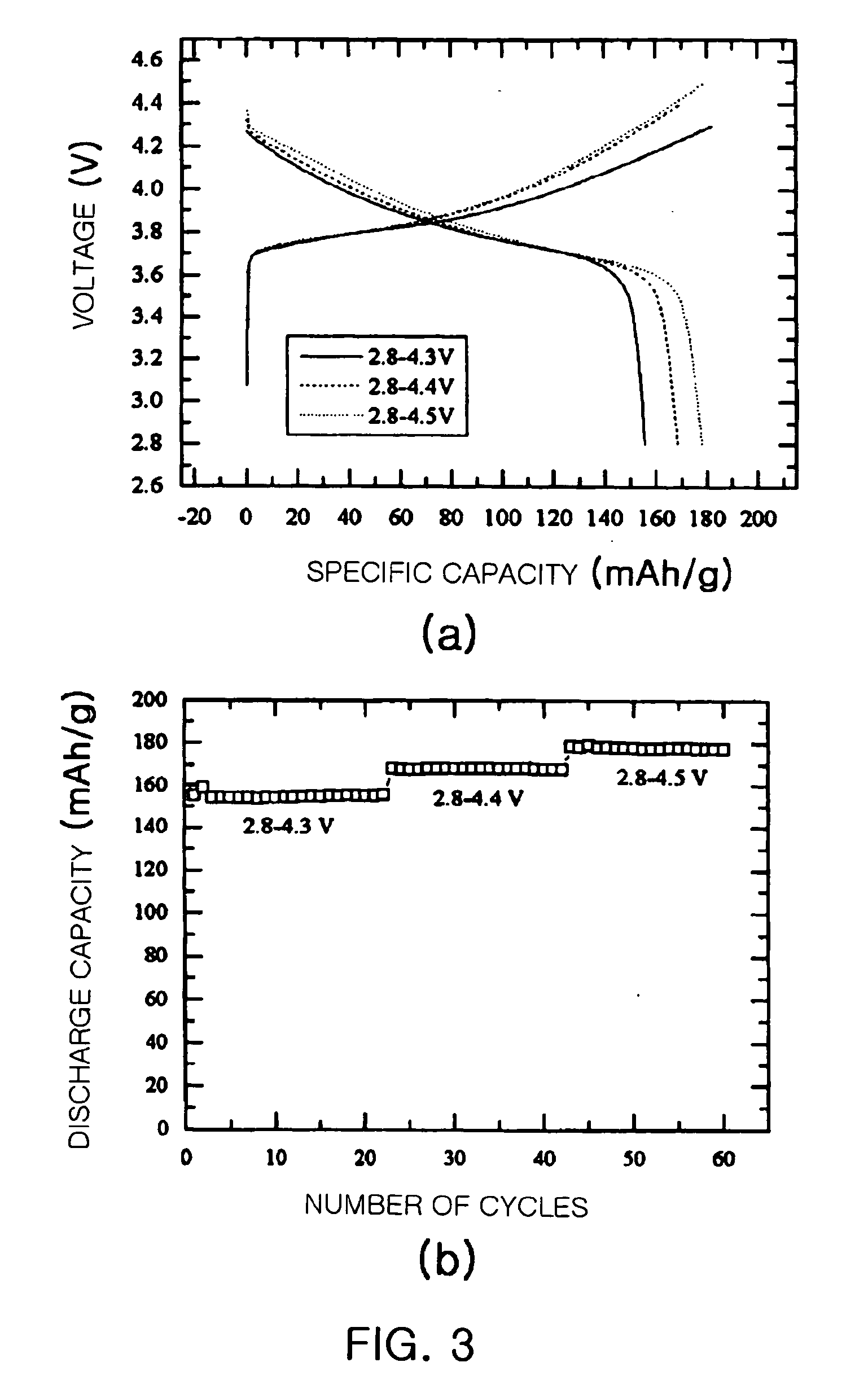

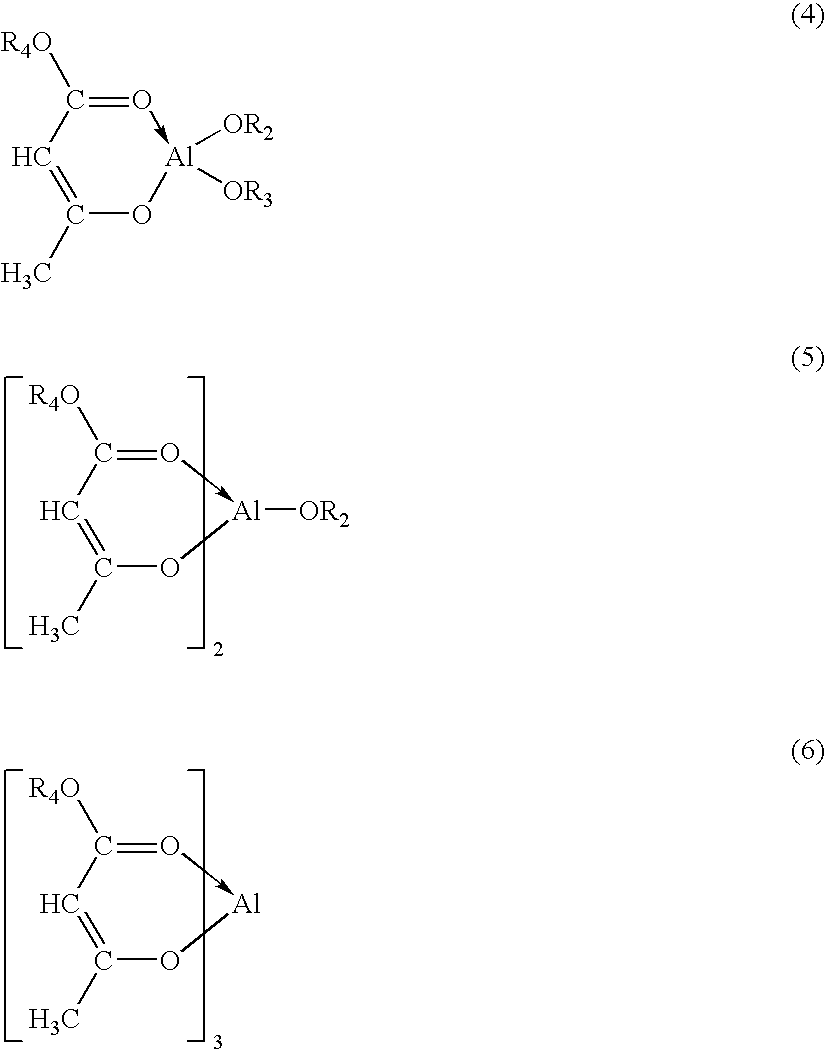

Method for producing lithium composite oxide for use as positive electrode active material for lithium secondary batteries

InactiveUS20060222947A1Excellent charge-discharge cycle characteristicExcellent characteristic capacity maintenanceAluminium compoundsElectrode manufacturing processesOrganic acidPhysical chemistry

Disclosed herein is a method for producing a lithium composite oxide for use as a positive electrode active material for lithium secondary batteries by a spray pyrolysis process. The method comprises the steps of: subjecting an organic acid salt solution of metal elements constituting a final composite oxide other than lithium to a spray pyrolysis process to obtain an intermediate composite oxide powder; and solid state-mixing the intermediate composite oxide powder and an organic acid salt of lithium, followed by thermally treating the mixture.

Owner:IUCF HYU (IND UNIV COOP FOUNDATION HANYANG UNIV)

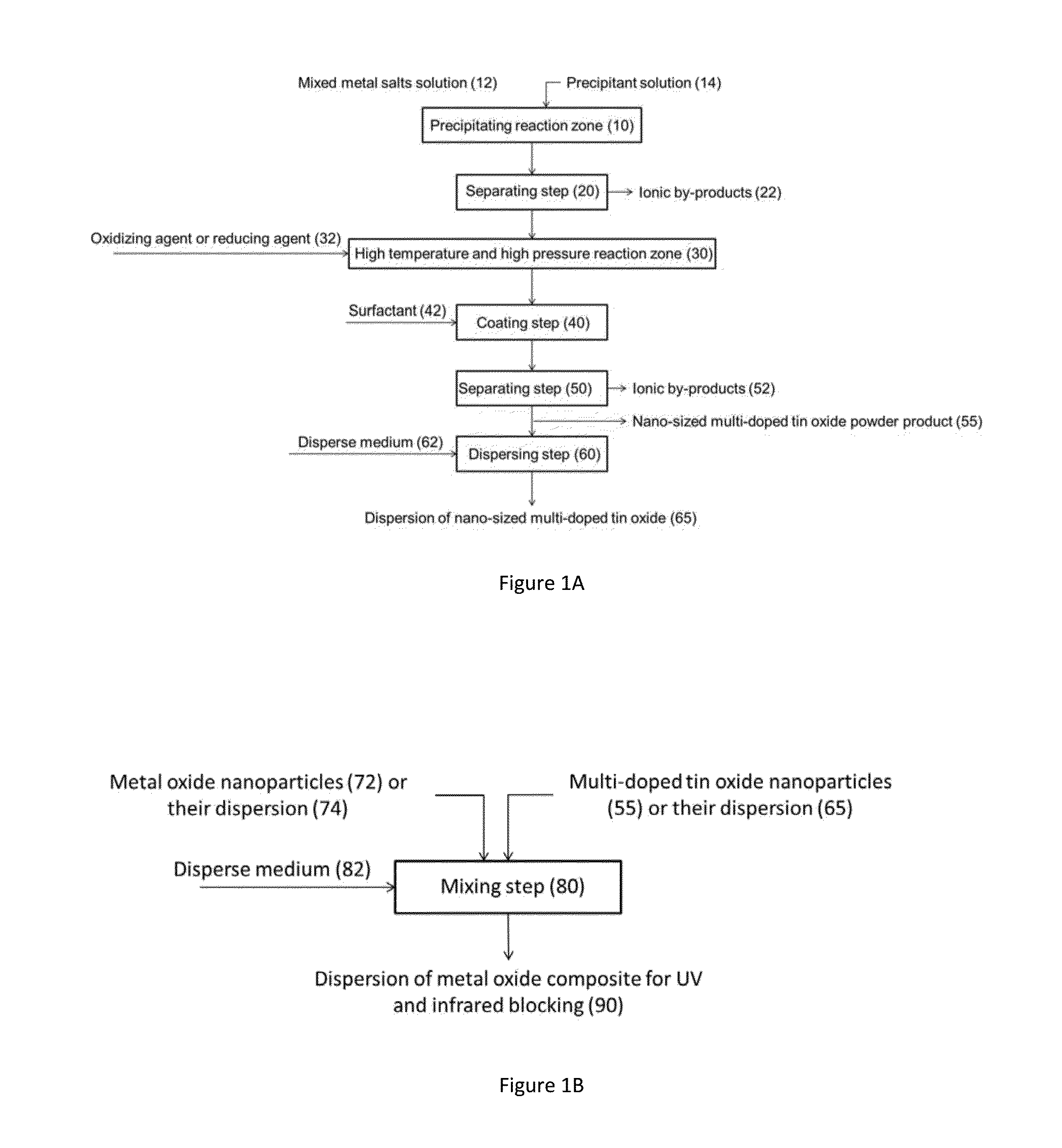

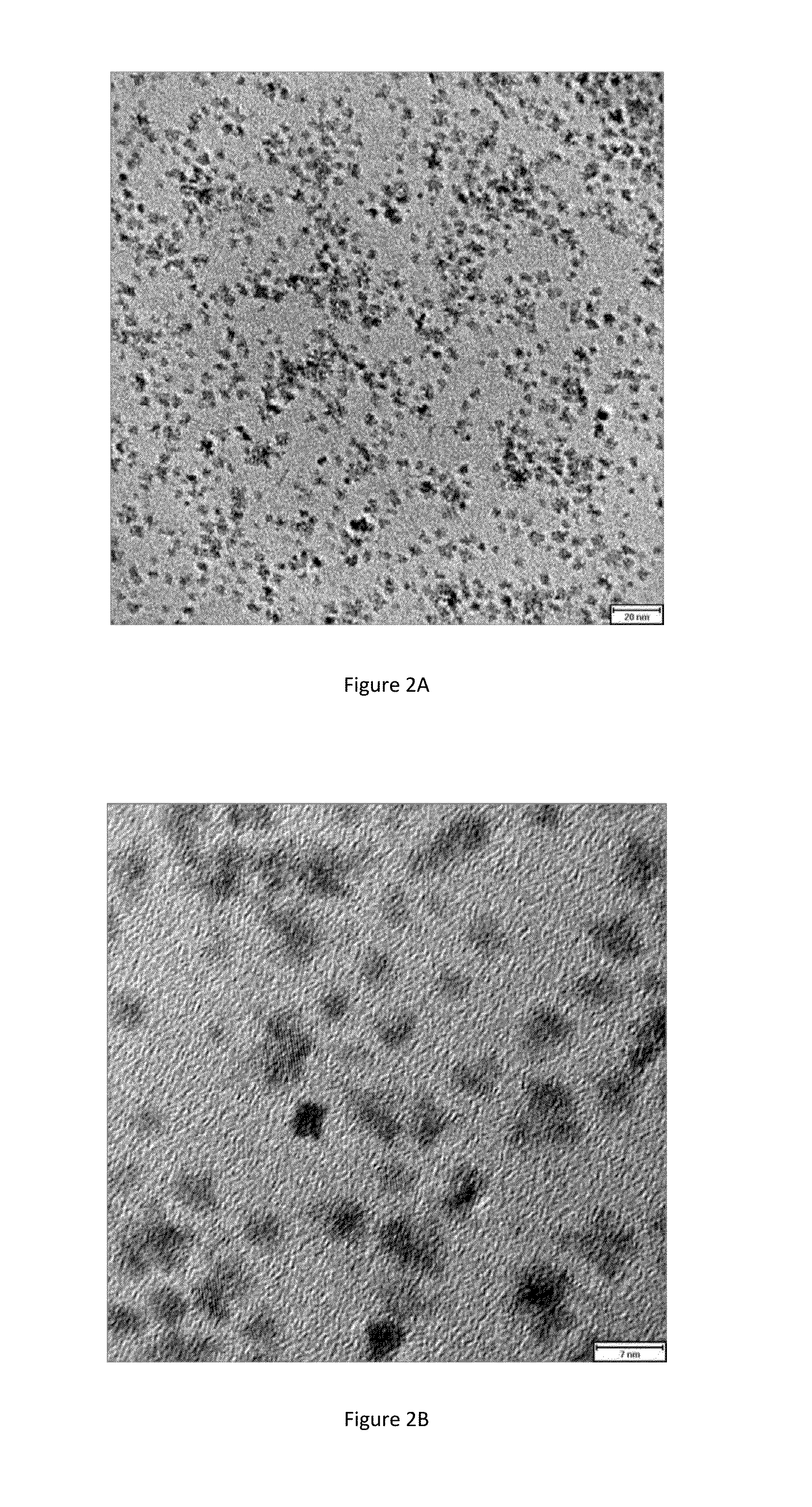

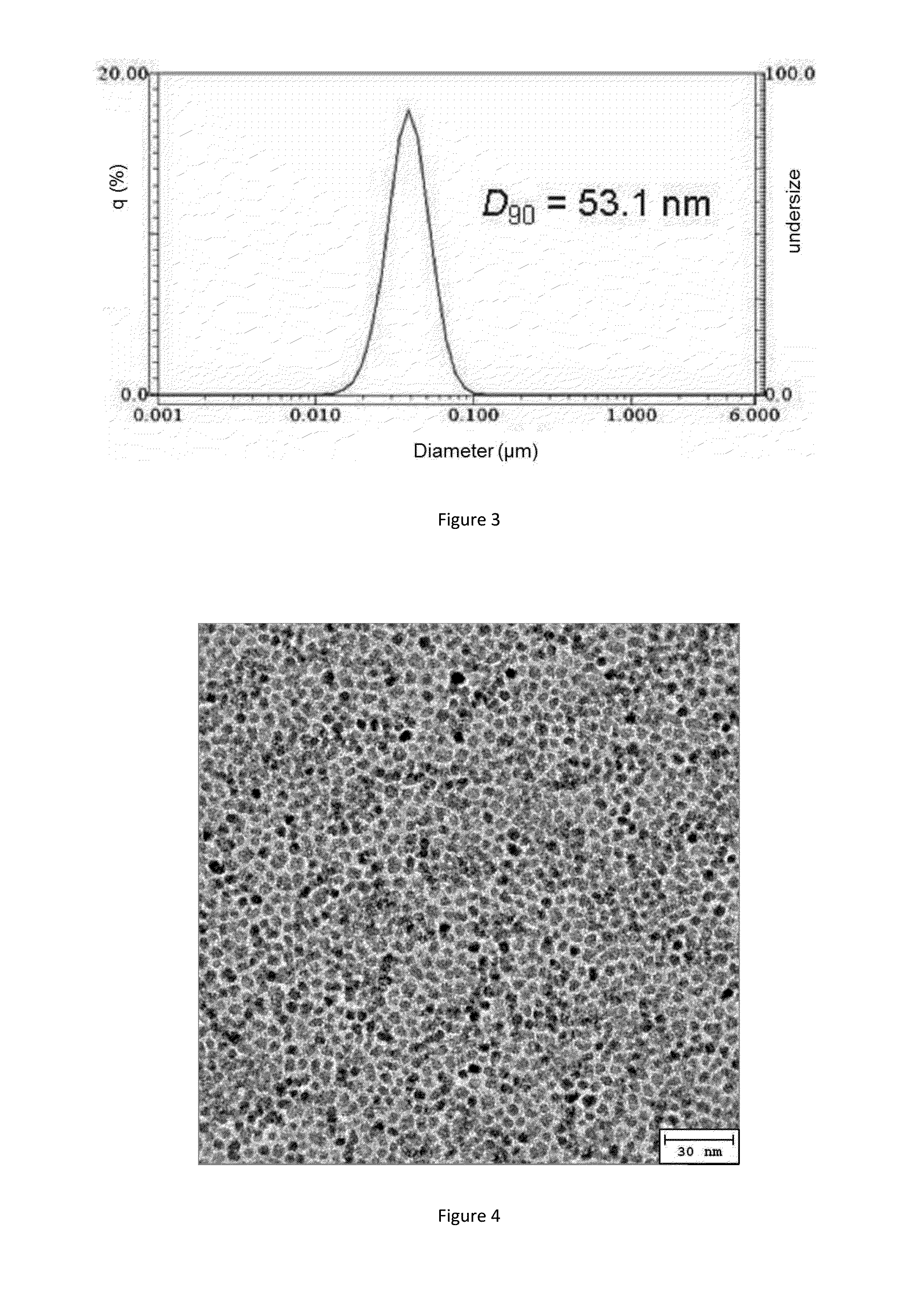

Nanometric tin-containing metal oxide particle and dispersion, and preparation method and application thereof

InactiveUS20150160379A1High transparencyLow costMaterial nanotechnologyGermanium dioxideMetal oxide nanoparticlesThermal radiation

There is disclosed a tin-containing metal oxide nanoparticle, which has an index of dispersion degree less than 7 and a narrow particle size distribution which is defined as steepness ratio less than 3. There is disclosed dispersion, paint, shielding film and their glass products which comprise the said nanoparticles. Besides, there are also disclosed processes of making the tin-containing metal oxide nanoparticle and their dispersion. The tin-containing metal oxide nanoparticles and their dispersion disclosed herein may be applied on the window glass of houses, buildings, vehicles, ships, etc. There is provided an excellent function of infrared blocking with highly transparent, and to achieve sunlight controlling and thermal radiation controlling.

Owner:XIAMEN NANOTECH +1

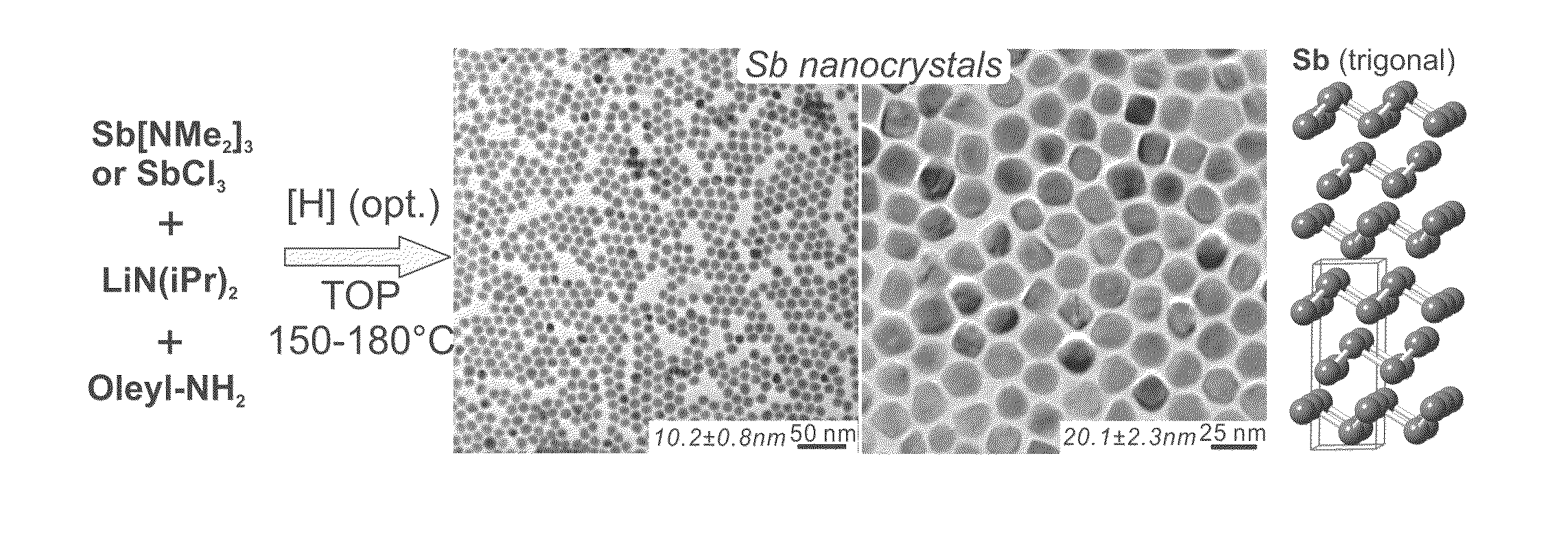

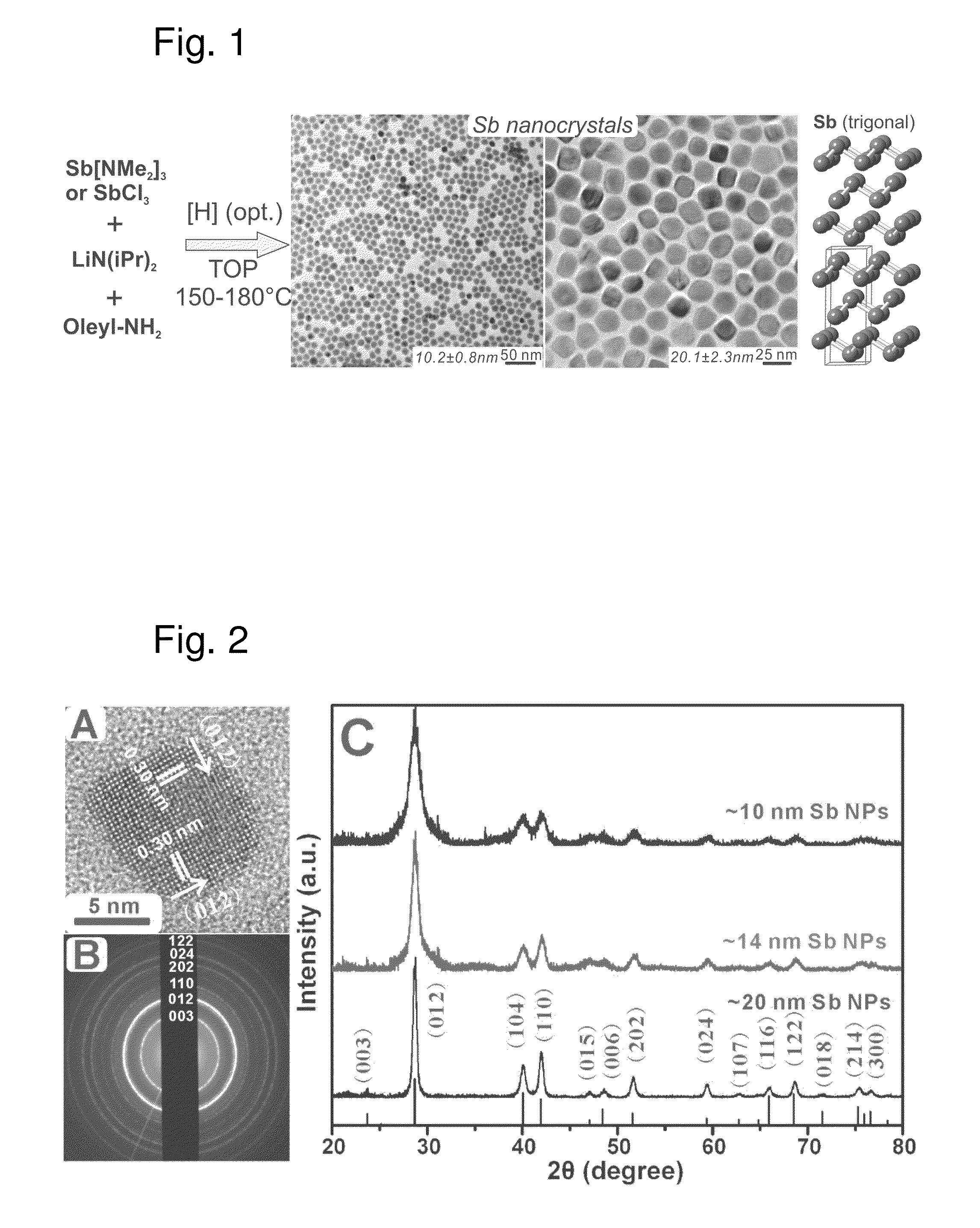

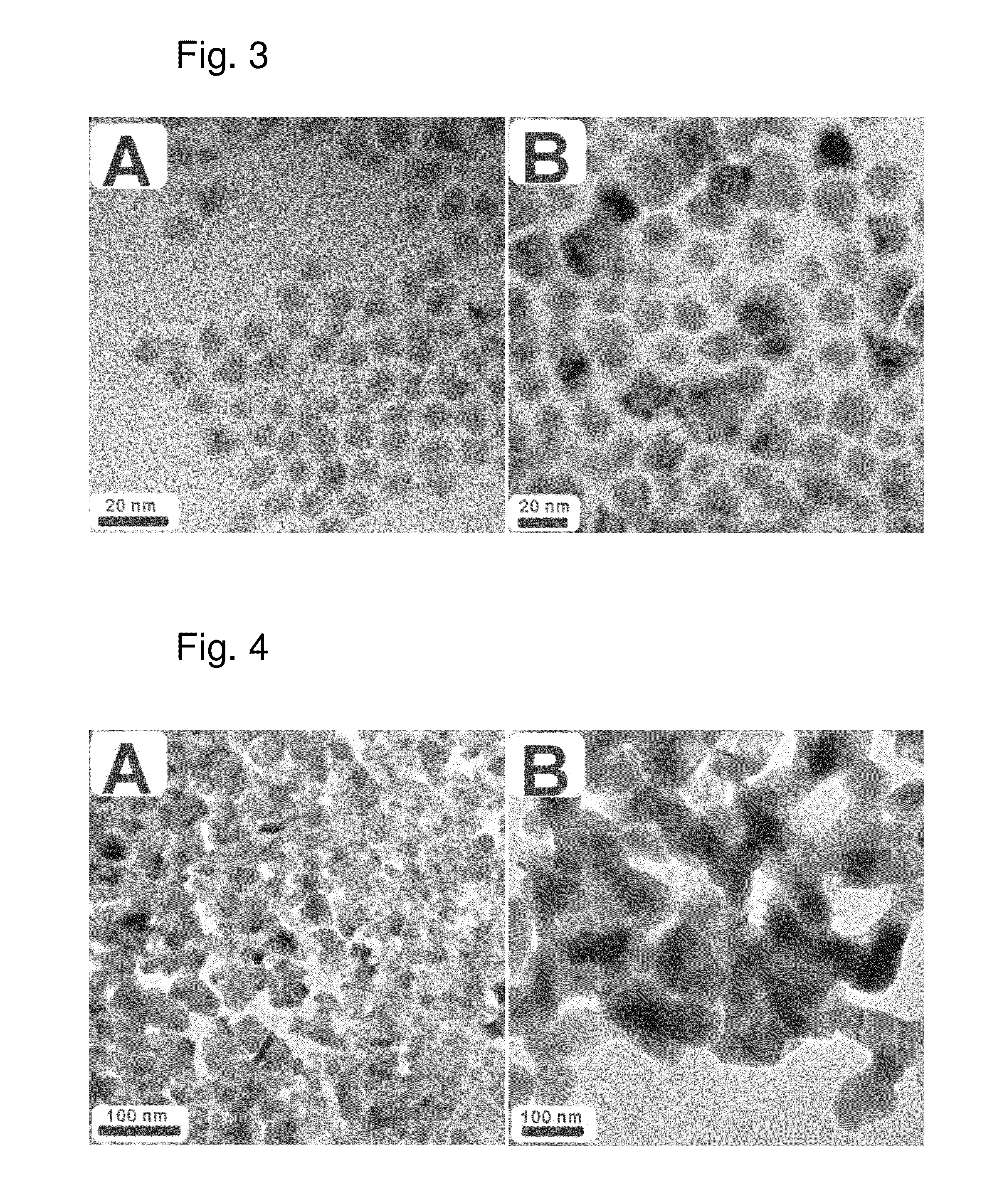

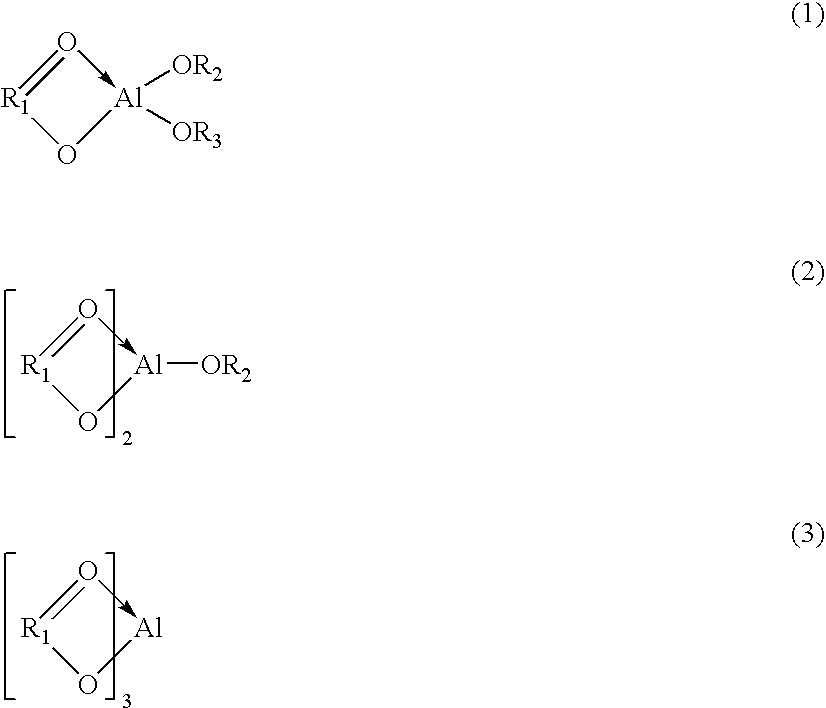

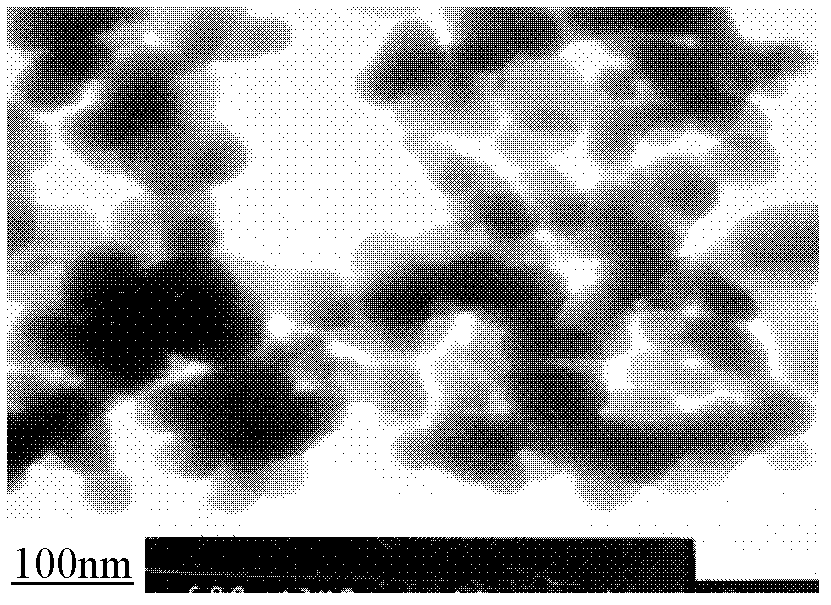

Antimony based anode material for rechargeable batteries and preparation method

ActiveUS20150147650A1Narrow size distributionConvenient amountMaterial nanotechnologyFinal product manufactureRechargeable cellSolvent

An antimony based anode material for a rechargeable battery comprises nanoparticles of composition SbMxOy where M is a further element selected from the group consisting of Sn, Ni, Cu, In, Al, Ge, Pb, Bi, Fe, Co, Ga, with 0≦x<2 and 0≦y≦2.5+2x. The nanoparticles form a substantially monodisperse ensemble with an average size not exceeding a value of 30 nm and by a size deviation not exceeding 15%. A method for preparing the antimony based anode material is carried out in situ in a non-aqueous solvent and starts by reacting an antimony salt and an organometallic amide reactant and oleylamine.

Owner:BELENOS CLEAN POWER HLDG

Anhydrous zinc antimonate sol and process for producing same

There is provided a sol in which surface-modified colloidal particles are dispersed in a liquid, wherein the surface-modified colloidal particles are obtained by using anhydrous zinc antimonate colloidal particles, metal oxides comprising tin atom, zinc atom, antimony atom and oxygen atom, or tin oxide-doped anhydrous zinc antimonate colloidal particles as nuclei, and by coating the surface of the nuclei with an aluminum-containing substance (e.g., an aluminum chelating agent), a polymer type surfactant (e.g., a polycarboxylic acid ester or polyethylene glycol monoaliphatic acid ester surfactant) or both of them. The anhydrous zinc antimonate sol is used for several purposes such as transparent antistatic materials in the form of resin, plastic, glass, paper, magnetic tape or the like, transparent UV absorbers, transparent heat radiation absorbers, high refractive index hard coating agent, anti-reflective agent and the like.

Owner:NISSAN CHEM IND LTD

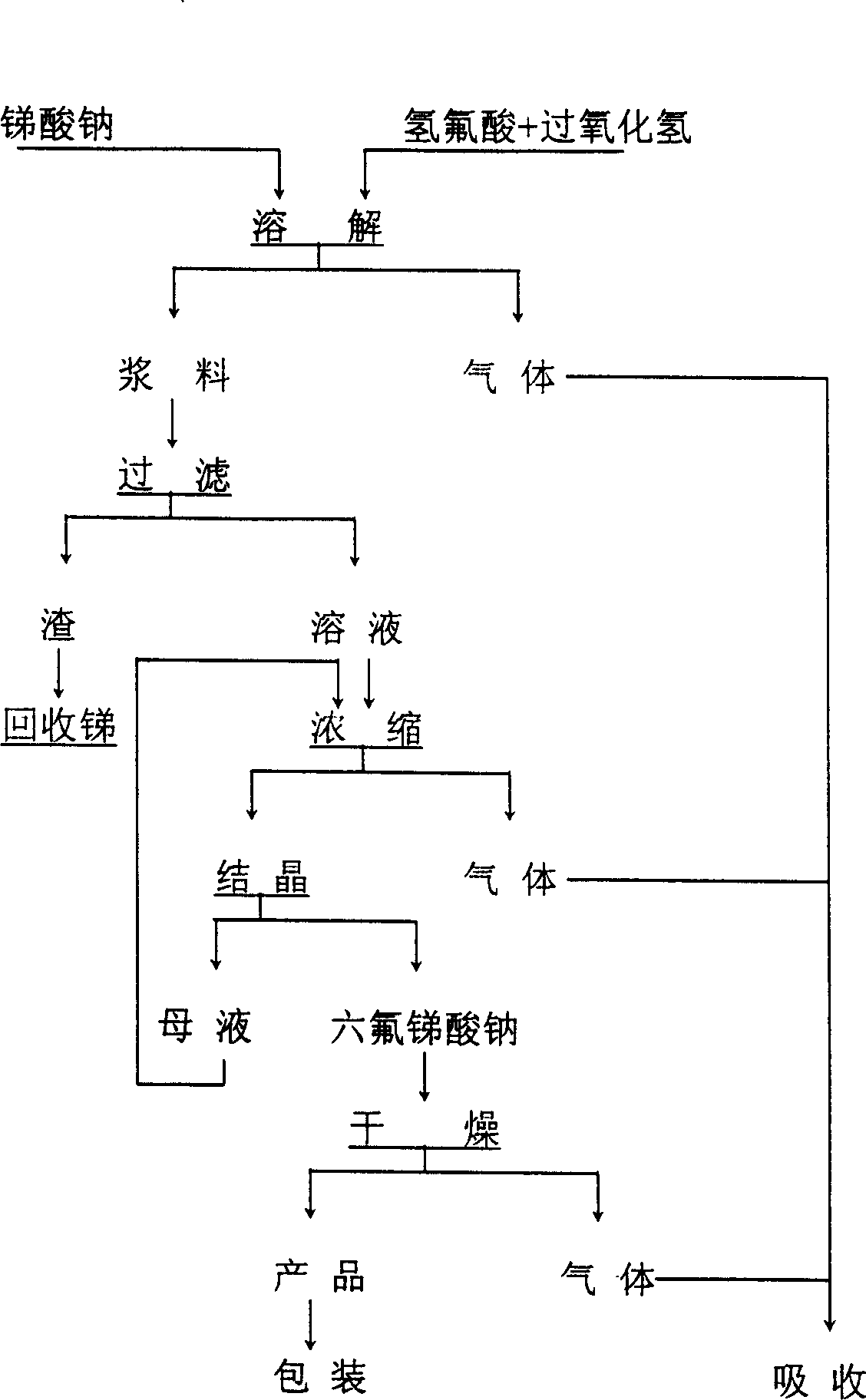

Method for preparing sodium hexafluoroantimonate

InactiveCN1743273AReduce productionEasy to control stoichiometryAntimonates/antimonitesChemical industryHydrofluoric acid

This method relates to the preparation of fine chemicals in chemical industry, especially the method for the preparation of sodium hexafluoroantimonate(Na3SbF6) with sodium antimonate(Na3SbO4) as raw material, which is as follow: first, after reaction between Na3SbO4 and fluohydric acid in proportion of 1: 6.6~9.5 under 50-100 degree C, filtrate to remove insoluble residue and condense the filter liquor under 95~136 deg.c; then cool, crystallization and centrifugal separation to obtain the product Na3SbF6, then the mother liquor is returned for recondensation. Advantages: directly product Na3SbF6 to save the preparation if the intermediate product of H3SbF6 or SbF5, easy and accurate control to stoichiometry of sodium and antimony; lower comprehensive cost.

Owner:CENT SOUTH UNIV

Method for preparing nanometer sulfo antimony acid antimony

ActiveCN102583534AEasy to recycleGood compatibilityNanotechnologyAntimonates/antimonitesPerformance indexLubrication

The invention discloses a method for preparing nanometer sulfo antimony acid antimony via the uniform precipitation method, comprising the following steps: employing leukonin and antimony white as the raw materials; utilizing sodium sulfide to leach leukonin, thus to obtain a pentavalent antimony solution; employing the sodium chloride solution of the hydrochloric acid to leach antimony white forpreparing a trivalent antimony solution; slowly adding the two solutions into a buffer system containing a surfactant; and employing supersonic wave stirring for homogeneous precipitation. The generated precipitation, after receiving the treatment of aging, dispersing, rinsing, and drying in a tartrate solution, is turned into the nanometer sulfo antimony acid antimony product. The method features simple process and high yield, causes no pollution to the environment, and is easy to operate and put into industrial production. The color of the produced product is umber, with granularity being 93nm, and is compatible with the grease. The produced nanometer sulfo antimony acid antimony is an excellent extreme pressure-antiwear additive and solid lubricant of the lubrication grease. As an additive, the performance index of the product far exceeds the national standards about the extreme pressure lubrication grease.

Owner:YIYANG SHENGLI CHEM IND

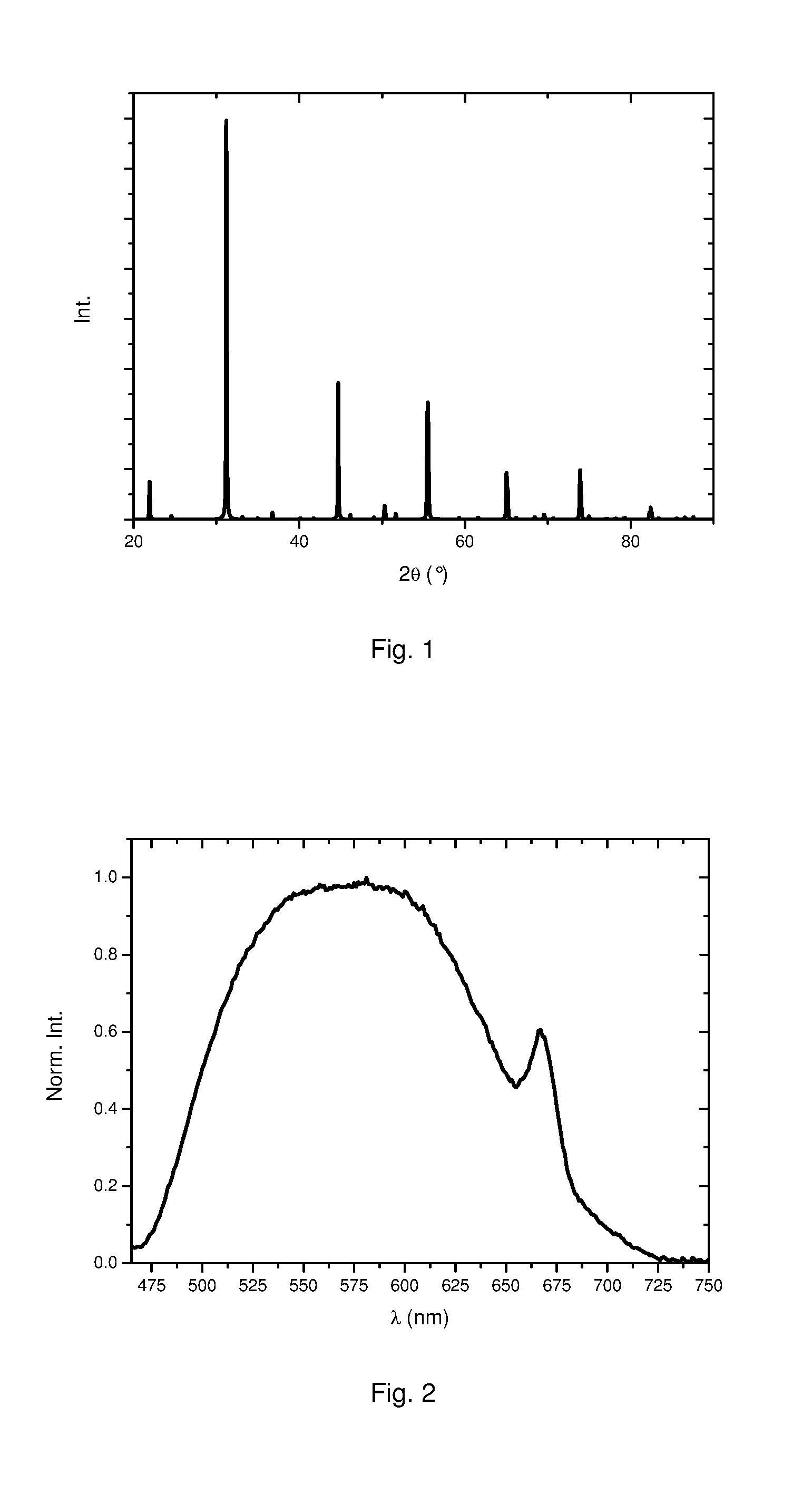

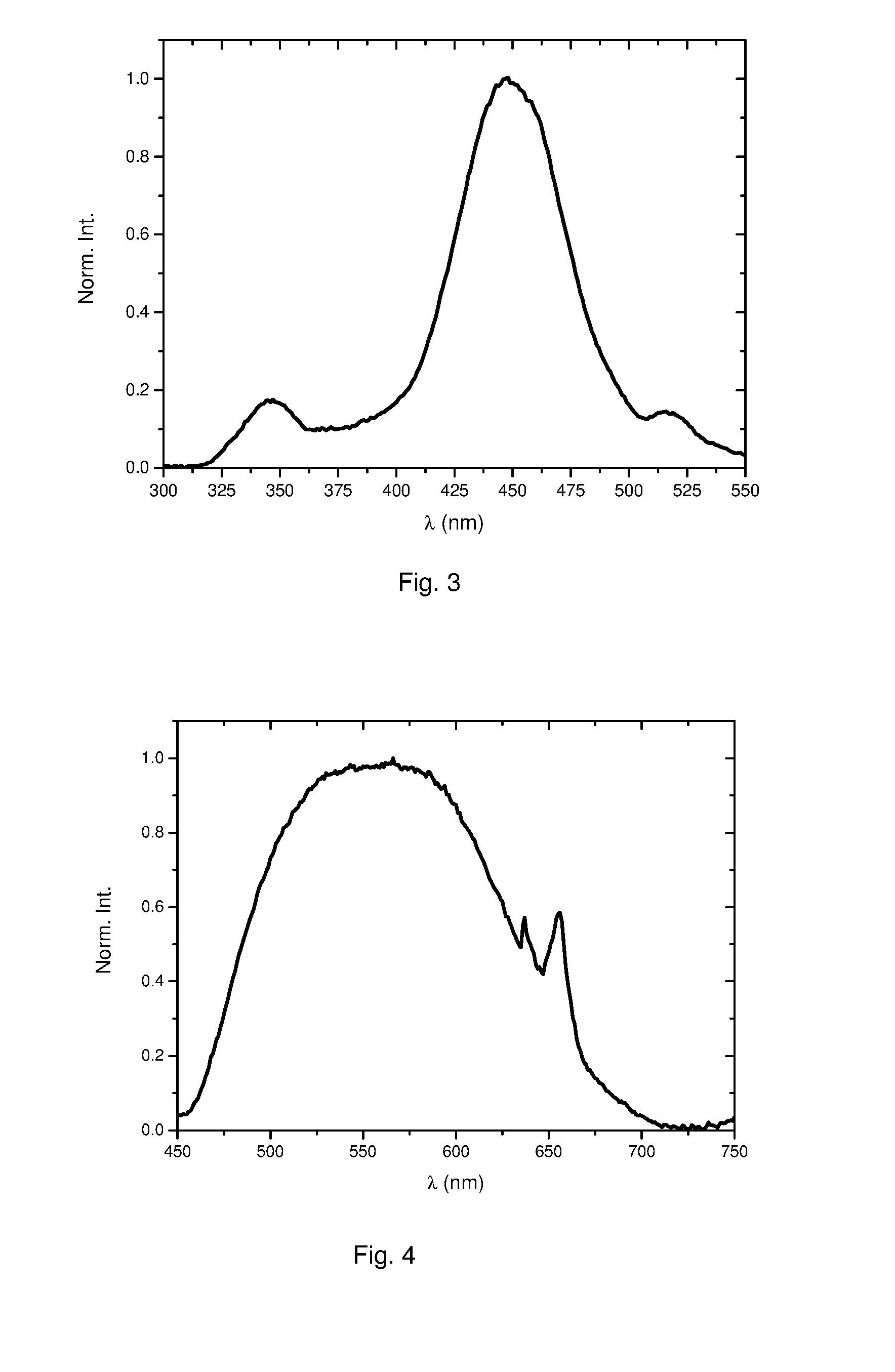

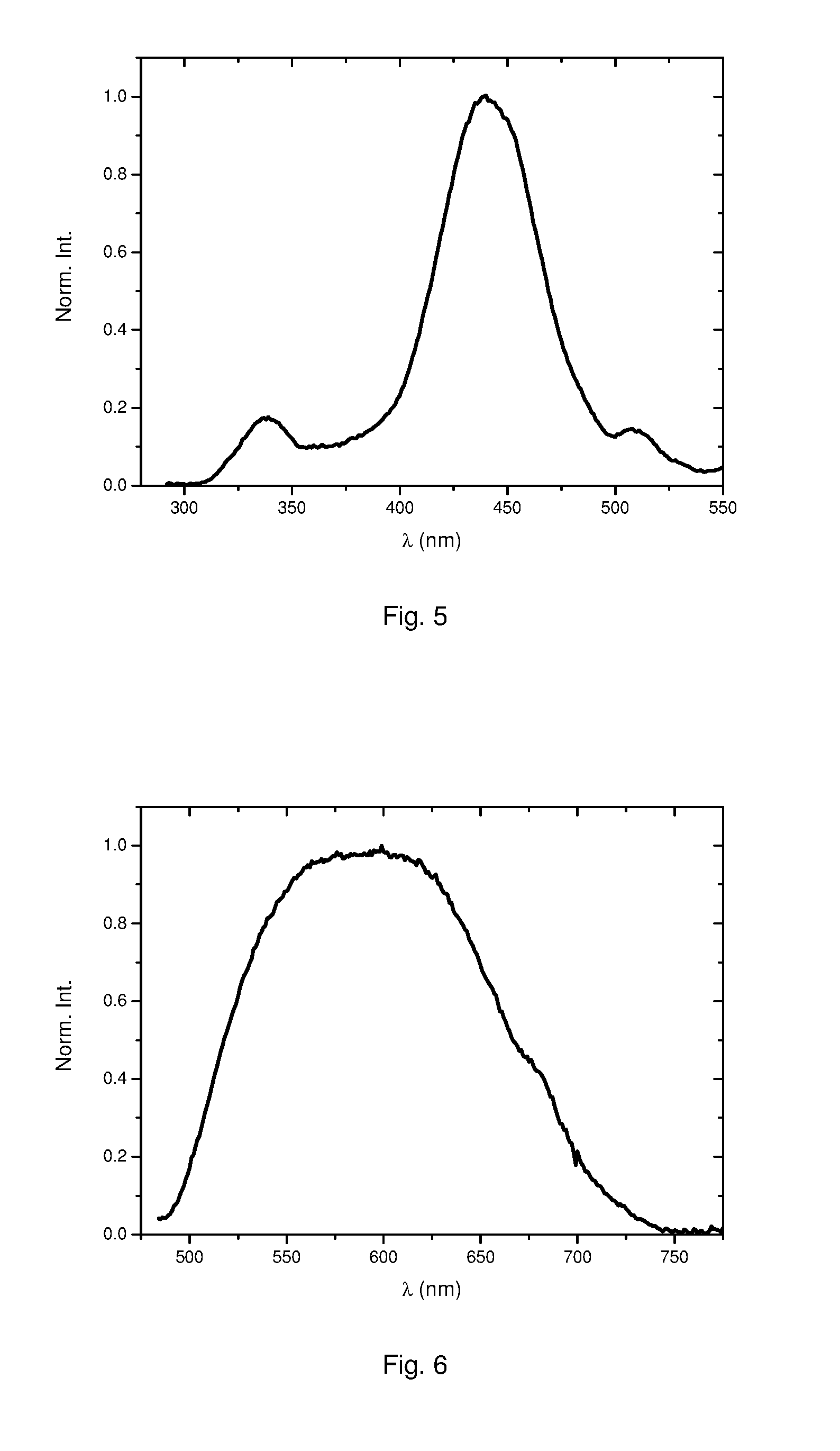

Eu2+-activated phosphors

InactiveUS20160304779A1Low thermal quenching resistivityGood colorTantalum compoundsElectroluminescent light sourcesPhosphorSolar cell

The invention relates to Eu2+-activated phosphors, to a process of its preparation, the use of these phosphors in electronic and electro optical devices, such as light emitting diodes (LEDs) and solar cells and especially to illumination units comprising said magnesium alumosilicate-based phosphors.

Owner:MERCK PATENT GMBH

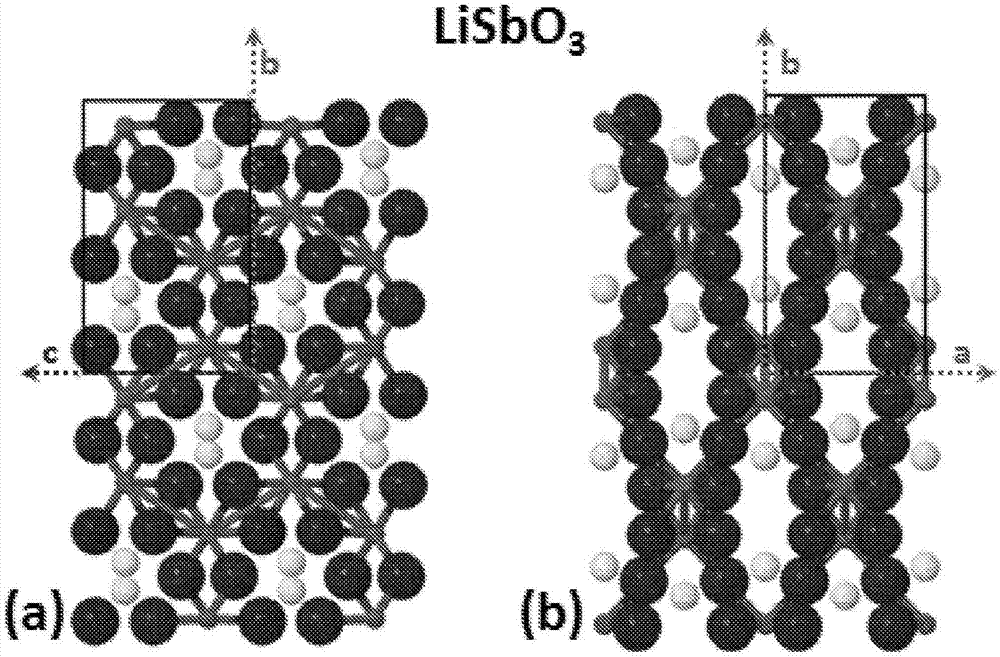

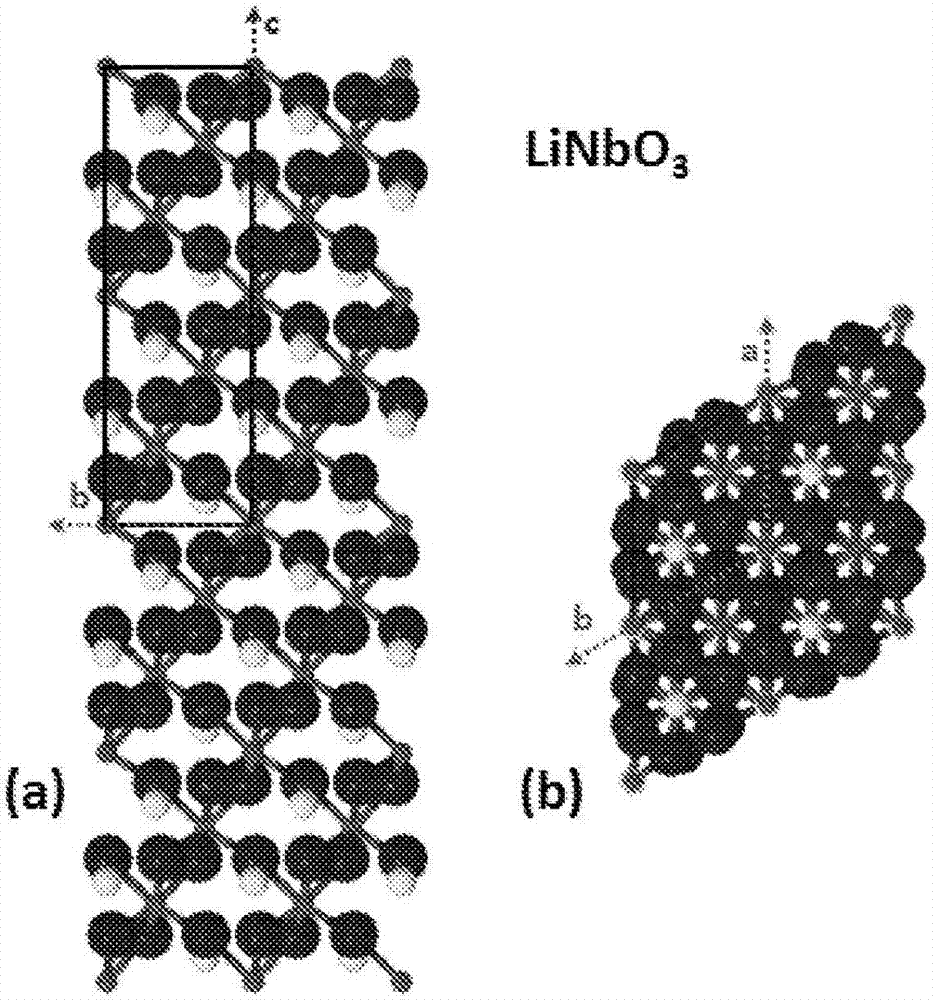

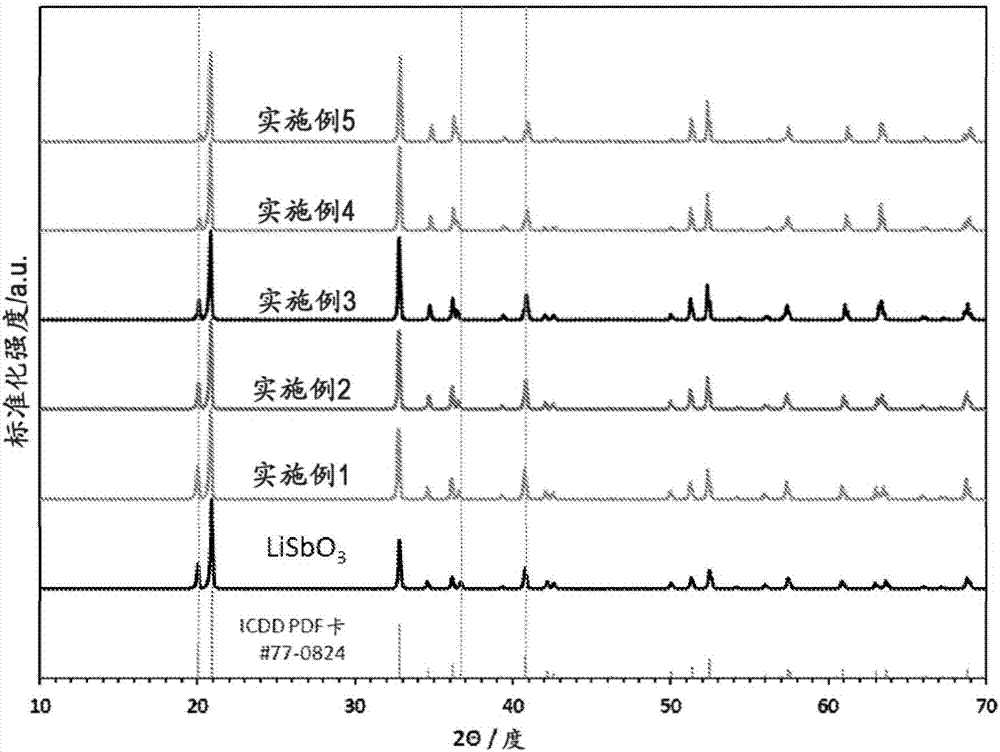

PIGMENTS BASED ON LiSbO3 AND LiNbO3 RELATED STRUCTURES

The present invention involves pigments derived from compounds with the LiSbO3-type or LiNbO3-type structures. These compounds possess the following formulations M1M5Z3, M1M2M4M5Z6, M1M32M5Z6, M1M2M3M6Z6, M12M4M6Z6, M1M5M6Z6, or a combination thereof. The cation M1 represents an element with a valence of +1 or a mixture thereof, the cation M2 represents an element with a valence of +2 or a mixture thereof, the cation M3 represents an element with a valence of +3 or a mixture thereof, the cation M4 represents an element with a valence of +4 or a mixture thereof, the cation M5 represents an element with a valence of +5 or a mixture thereof, and the cation M6 represents an element with a valence of +6 or a mixture thereof. The cation M is selected from H, Li, Na, K, Rb, Cs, Mg, Ca, Sr, Ba, Sc, Y, La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, Ti, Zr, Hf, V, Nb, Ta, Cr, Mo, W, Mn, Fe, Ru, Co, Ni, Cu, Ag, Zn, B, Al, Ga, In, Si, Ge, Sn, P, Sb, or Te. The anion Z is selected from N, O, S, Se, Cl, F, hydroxide ion or a mixture thereof. Along with the elements mentioned above vacancies may also reside on the M or Z sites of the above formulations such that the structural type is retained. The above formula may also include M dopant additions below 20 atomic %, where the dopant is selected from H, Li, Na, K, Rb, Cs, Mg, Ca, Sr, Ba, Sc, Y, La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, Ti, Zr, Hf, V, Nb, Ta, Cr, Mo, W, Mn, Fe, Ru, Co, Ni, Cu, Ag, Zn, B, Al, Ga, In, Si, Ge, Sn, P, Sb, Bi, Te, or mixtures thereof.

Owner:SHEPHERD COLOR COMPANY

Preparation method of guaranteed-reagent sodium antimonate

InactiveCN105314676ASimple preparation processControllableAntimonates/antimonitesFiltrationDistilled water

The invention relates to a preparation method of guaranteed-reagent sodium antimonate, which includes the following steps: 1) oxidization of antimonous oxide: placing the antimonous oxide and sodium hydroxide into a stainless steel barrel, adding distilled water with continuous stirring to dissolve the raw materials, heating the solution at 60 DEG C, and adding slowly a hydrogen peroxide solution with continuous stirring to obtain sodium antimonate precipitate, and spin-drying the precipitate to obtain a substance A; and (2) synthesis to prepare the guaranteed-reagent sodium antimonate: adding the substance A in the step 1) to a 37 wt% hydrochloride acid solution with continuous stirring to dissolve the substance A, regulating the pH to 2, performing filtration to obtain a solution B, adding sodium hydroxide to the solution B with continuous stirring to neutralize the solution until pH=6, separating out the precipitate and cooling the precipitate, washing the precipitate with distilled water, spin-drying the precipitate and drying the precipitate in a drier at 110 DEG C for 3 h to obtain the guaranteed-reagent sodium antimonate. In the method, under effects of the oxidizing agent hydrogen peroxide, the sodium antimonate is generated by oxidizing the antimonous oxide and carrying out a reaction to the oxidized antimonous oxide and sodium hydroxide.

Owner:TIANJIN CHEM REAGENT RES INST

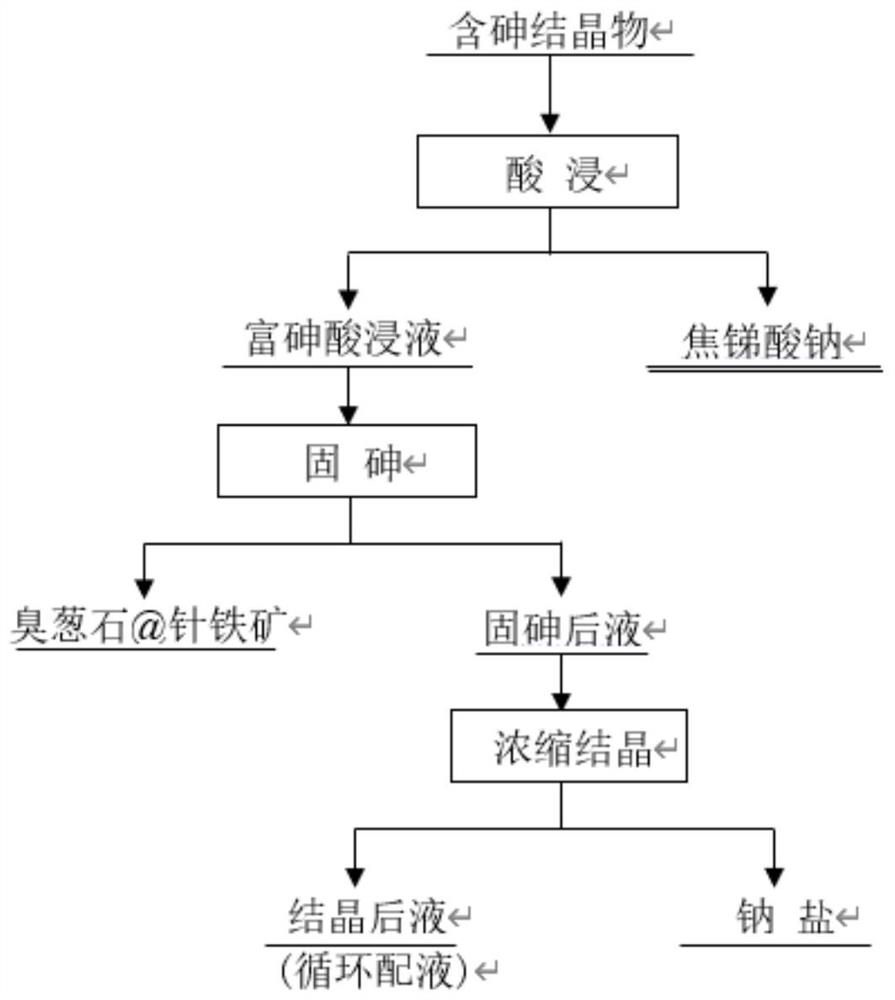

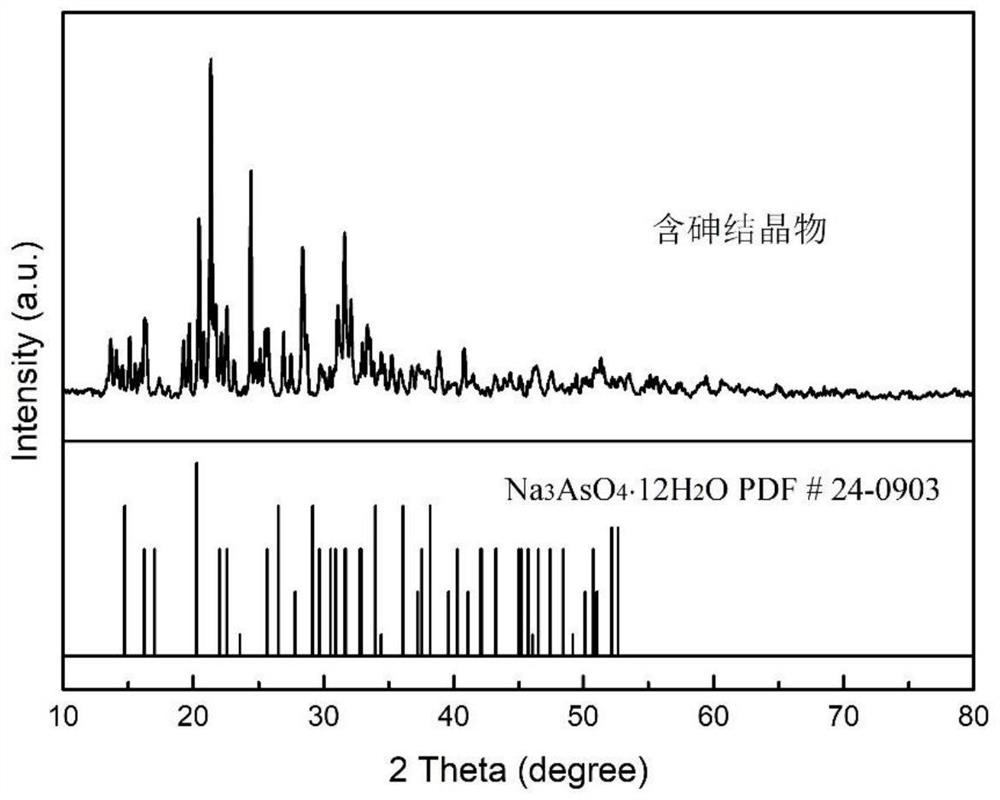

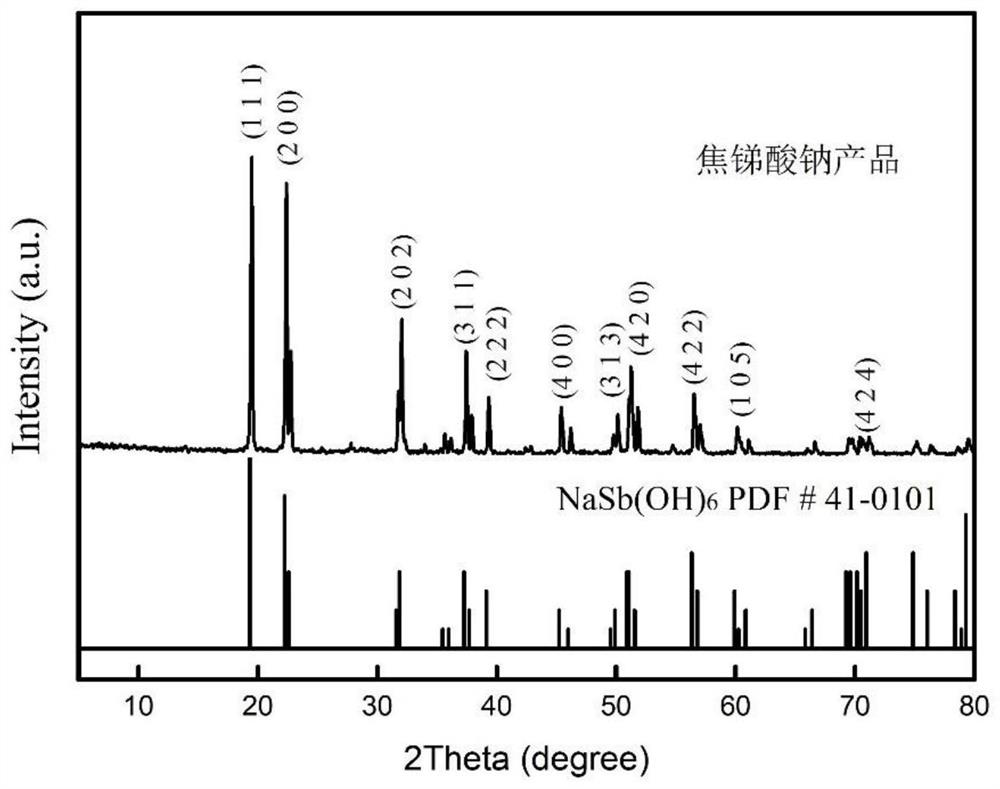

Method for recovering antimony and solid arsenic from arsenic-containing crystal substance

ActiveCN114561558ARealize closed loopClosed loop to eliminateArsenites/arsenatesIron oxides/hydroxidesNonferrous metalPhysical chemistry

The invention discloses a method for recycling antimony through acid leaching of arsenic-containing crystal substances, fixing arsenic in arsenic-rich pickle liquor and recycling sodium salt through concentration and crystallization of liquor after arsenic fixing, and relates to the field of resource utilization of by-products in production of non-ferrous metal chemicals. According to the method, arsenic-containing crystal substances in sodium pyroantimonate production are leached through dilute sulphuric acid to obtain cubic crystal sodium pyroantimonate which meets the first-grade product of the Chinese nonferrous metal industry standard (YS / T 22-2010), and the technical problem of recycling antimony in the arsenic-containing crystal substances is solved. Ferrite is added into the arsenic-rich acid leaching solution, oxygen is introduced into the arsenic-rich acid leaching solution to synthesize the high-stability scorodite and goethite core-shell structure, the arsenic concentration in TCLP is lower than the specified value 5 mg / L of the national standard (GB5085.3-2007), and non-toxic and harmless arsenic in arsenic-containing non-ferrous metal resource utilization is achieved. And concentrating and crystallizing the arsenic-fixing liquid to recover the sodium salt, thereby completing the purification and regeneration of the solution and achieving the purpose of closed-loop cyclic utilization of the solution. The method has the advantages of simple operation, stable product components, high stability of the arsenic fixing material, good solution cycle performance and the like.

Owner:CENT SOUTH UNIV

Antimony sulantimonate and production method thereof

The invention discloses antimony thioantimonate and a method for preparing the same, which are characterized by using sodium pyroantimonate and antimony trioxide powder as raw materials, producing a solution of quinquevalent antimony (Sb) by impregnating the sodium pyroantimonate with a sodium sulphide solution, producing a solution of trivalent antimony by impregnating the antimony trioxide powder with hydrochloric acid, pouring the two solutions into a buffer system for synthesis, adjusting the pH value of the mixed solution with hydrochloric acid and sodium hydroxide respectively to keep the pH value between 2.0 and 2.5, and settling, bleaching, drying, crushing and screening precipitations to obtain the antimony thioantimonate product. The method has the advantages of simple process, stable reaction system, good comprehensive recycling, high-quality products, no 'three wastes' pollution and so on. The product of the method is mainly used as an extreme-pressure wear-resistant additive for lubricant grease and a solid lubricating agent.

Owner:YIYANG SHENGLI CHEM IND

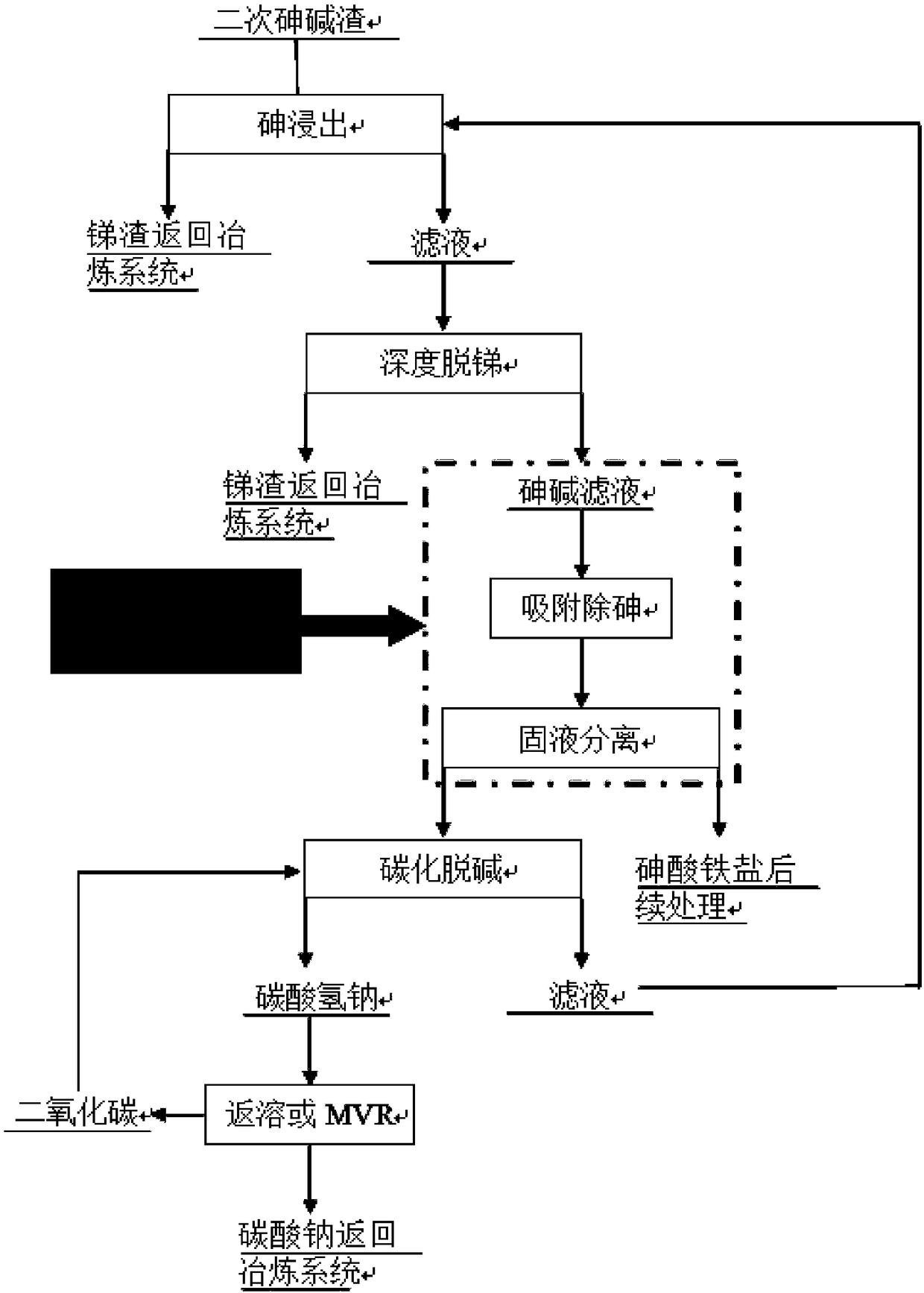

Method for separating arsenic and alkali in arsenic and alkali residues based on superfine ferric hydroxide colloid

ActiveCN108585057AReduce energy consumptionLow costIron oxides/hydroxidesAlkali metal carbonates shape formationSolubilityFerric hydroxide

The invention discloses a method for separating arsenic and alkali in arsenic and alkali residues based on a superfine ferric hydroxide colloid. The method includes the steps: leaching the arsenic andalkali residues by water, and performing antimony removal on leaching solution through oxidation to obtain solution containing sodium carbonate and sodium arsenate; adding iron arsenate crystal nucleus and the superfine ferric hydroxide colloid to perform reaction to obtain iron arsenate crystals, and performing solid-liquid separation to obtain solution containing sodium carbonate and an iron arsenate product; leading carbon dioxide into the solution containing the sodium carbonate to perform reaction to separate out sodium hydrogen carbonate crystals, and performing thermal decomposition onthe sodium hydrogen carbonate crystals to obtain a sodium carbonate product. According to the method, arsenate in arsenic and alkali residue leaching solution is adsorbed and converted by the superfine Fe (OH)3 colloid with high activity to generate stable iron arsenate precipitation with low solubility and good crystal property, arsenic and alkali in arsenic and alkali residue leaching solutionare effectively separated, and the method overcomes the shortcomings of low iron salt arsenic removal utilization efficiency, incomplete purification and the like under the strong alkaline condition,is simple in process and convenient to operate and meets industrial production.

Owner:CENT SOUTH UNIV

Method for preparing antimony thioantimonate based on stable reaction system

ActiveCN103214035AAvoid decompositionAvoid hydrolysisAntimonates/antimonitesHigh concentrationChemical products

The invention provides a method for preparing antimony thioantimonate based on a stable reaction system, belonging to the technical field of preparation for chemical products. The method comprises the following steps of: preparing a high-concentration Sb<3+> ion conjugate solution, which is not hydrolyzed under acidic, alkali and neutral conditions, by using antimony white as a raw material through acidification and conjugation; preparing sodium thioantimonate under alkali conditions; and then reacting the Sb<3+> ion conjugate solution and a sodium thioantimonate solution to prepare antimony thioantimonate. By using the method, the problems that antimony halide is hydrolyzed under alkali conditions and sodium thioantimonate is decomposed when being in contact with acid are solved; and the obtained antimony thioantimonate is high in purity and good in performance, and can be used as an extreme pressure antiwear additive for lubricating grease and a solid lubricant. The preparation process is simple, clean and stable, no side reaction occurs in the preparation course, the yield is high, the product is pure, the performance is good, and the method is suitable for industrial production.

Owner:湖南益阳生力材料科技有限公司 +1

Preparation method of nano antimony thioantimonate

InactiveCN108163890AImprove leaching rateIncrease profitMaterial nanotechnologyAdditivesSulfurPotassium sodium tartrate

The invention discloses a preparation method of nano antimony thioantimonate, wherein the preparation method comprises the steps: adding a sodium thioantimonate solution into a complex solution of trivalent antimony, dispersing with ultrasonic waves, controlling the temperature of the reaction system at 20-35 DEG C, adjusting the pH value of the reaction system to 6.3-7.8 with hydrochloric acid, after completion of addition of the sodium thioantimonate solution, continuing to disperse for 10-15 min by ultrasonic waves, filtering to take a filter residue, washing the filter residue with a potassium sodium tartrate solution and purified water, and grinding for 3-5 h by a ball mill, and thus obtaining the product. The content of sulfur in antimony thioantimonate obtained by the preparation method provided by the invention is low, the product is stable and pure, the yield is high, the properties are good, the particles are in nanoscale, and the nano antimony thioantimonate has the advantages of good compatibility with lubricating grease, good extreme pressure wear resistance and good lubrication performance; as an additive, the nano antimony thioantimonate has various properties far beyond the requirements of the national standards on extreme pressure lubricating grease, can be industrially produced and has a good application prospect.

Owner:广西生富锑业科技股份有限公司

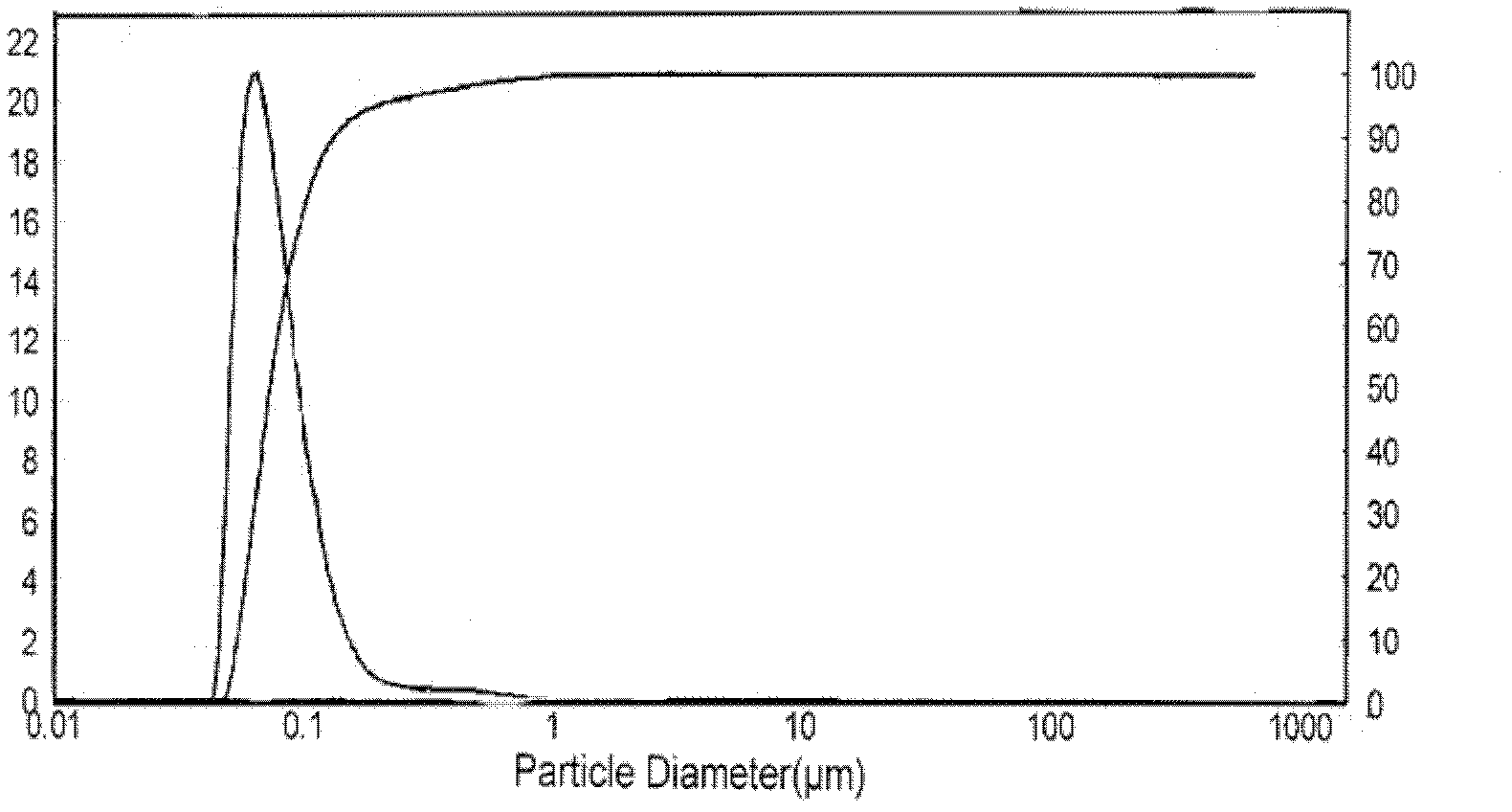

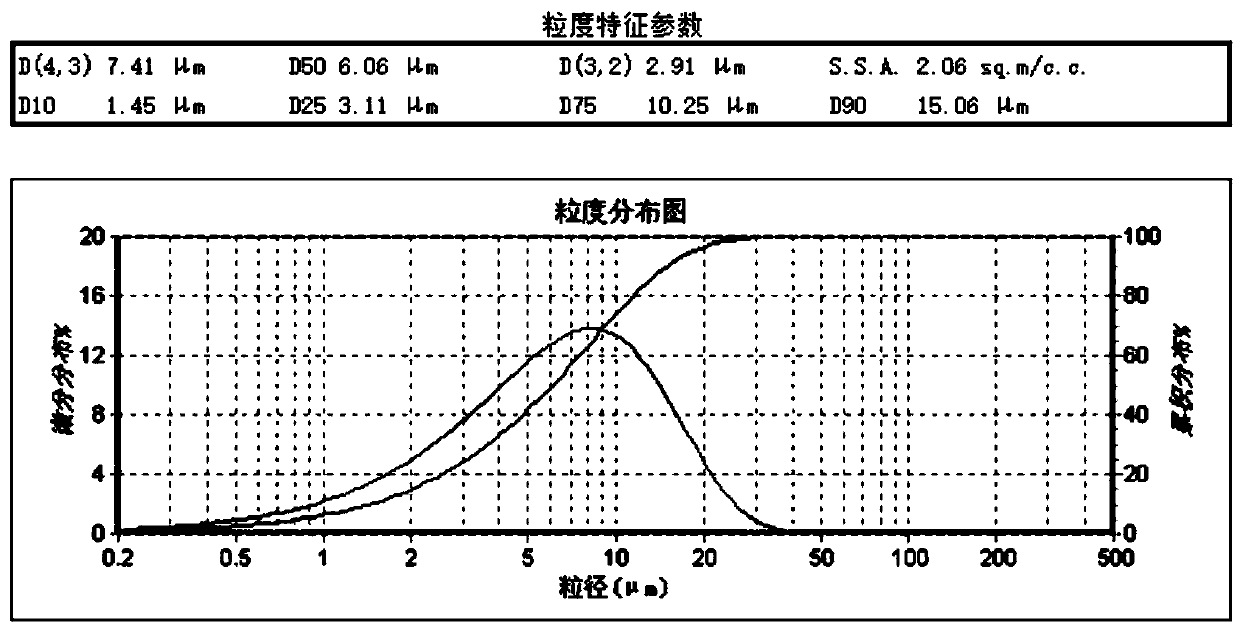

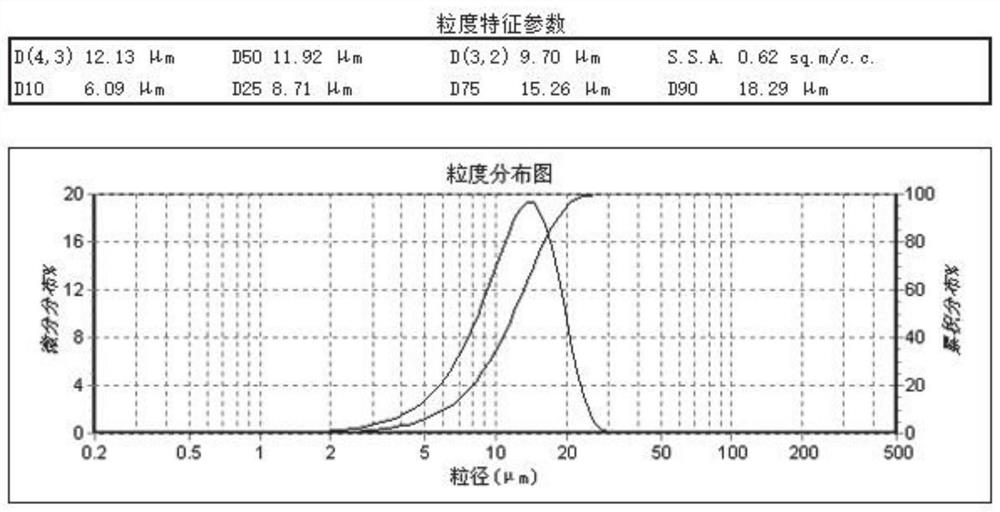

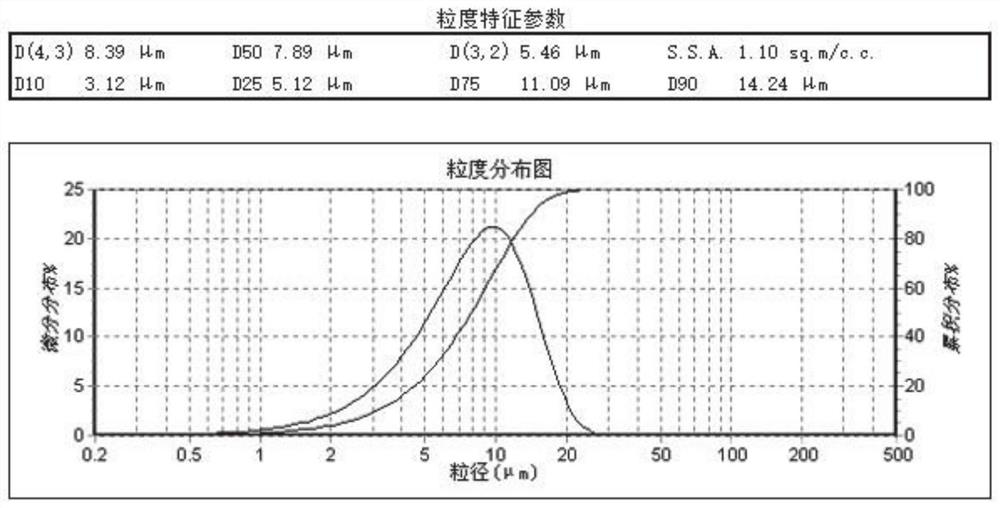

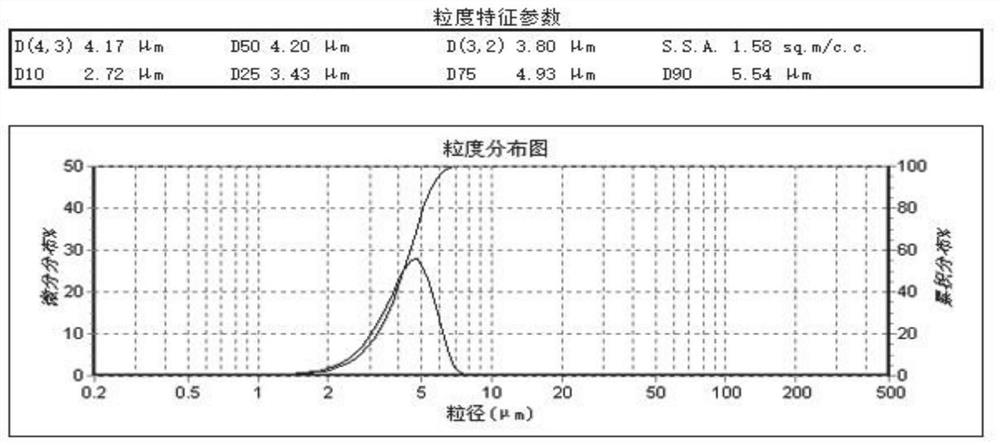

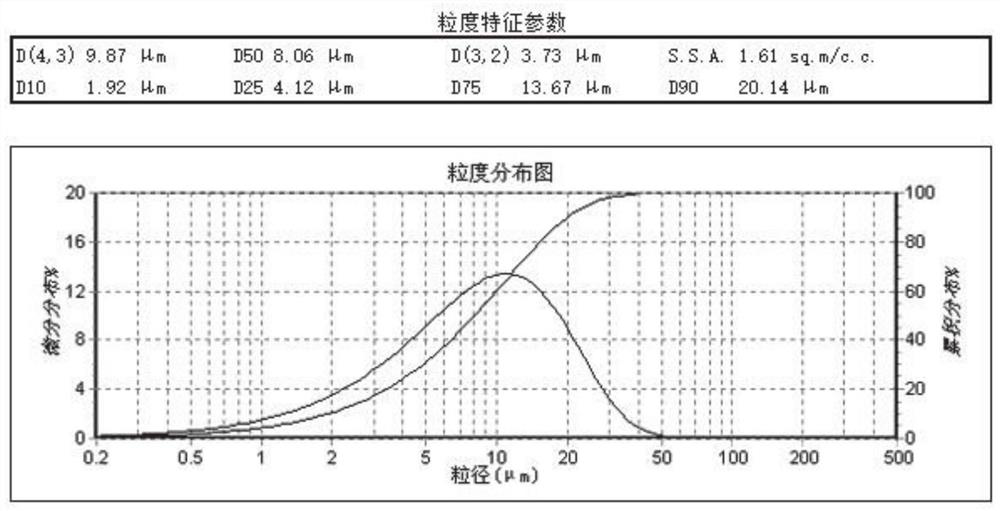

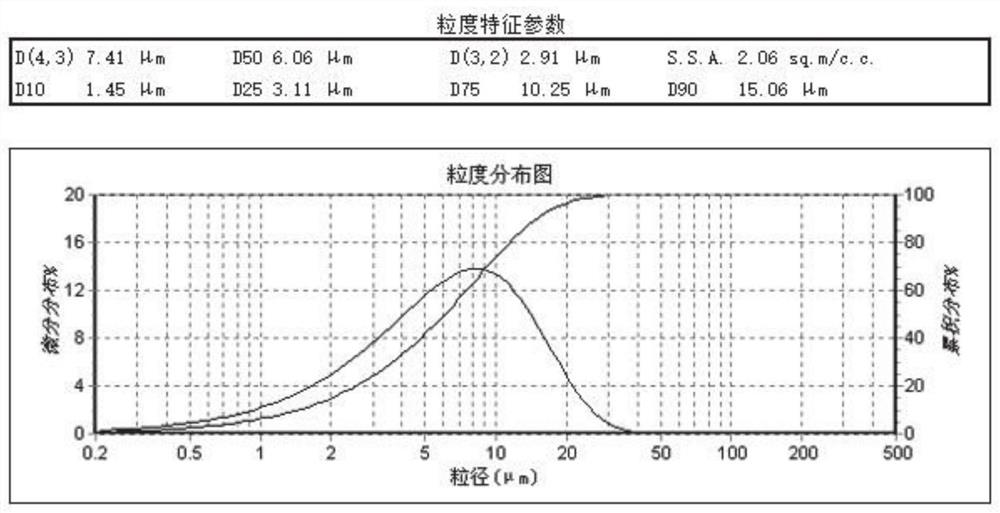

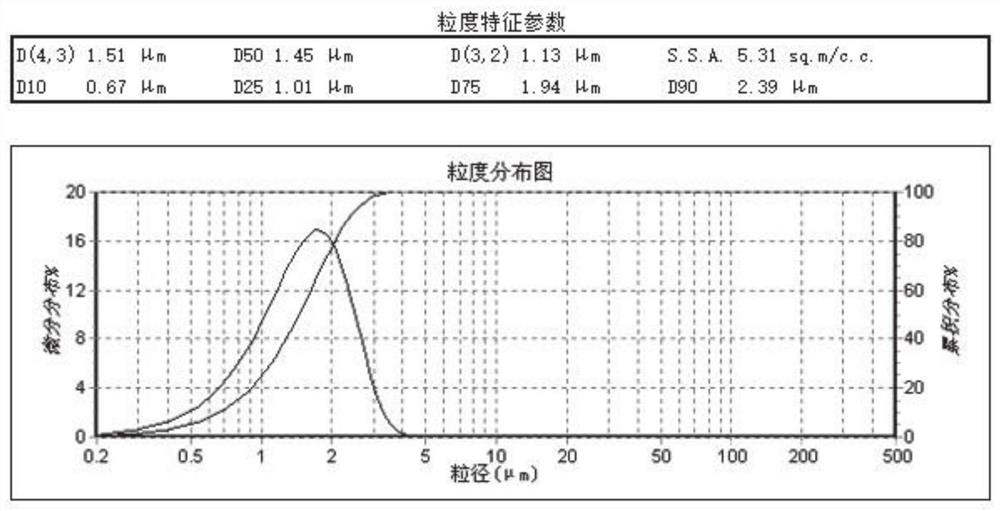

Preparation method of sodium pyroantimonate with reduced grain size

ActiveCN110015688ASolve the technical problem of excessive particle sizeSolve the technical problem of excessive granularityAntimonates/antimonitesCALCIUM HYDROXIDE SOLUTIONAntimony trioxide

The invention discloses a preparation method of sodium pyroantimonate with a reduced grain size. The preparation method comprises the following steps: step (1), subjecting antimony trioxide and hydrogen peroxide to oxidation in advance; and step (2), after the reaction in the step (1) is finished, adding a surfactant and sodium hydroxide to the reaction system for precipitation reaction, and carrying out solid-liquid separation, washing and drying treatment after the precipitation reaction is finished, so as to obtain sodium pyroantimonate with a fine grain size. According to the preparation method of sodium pyroantimonate with a reduced grain size, antimony trioxide, as a raw material, is fully oxidized with hydrogen peroxide, the surfactant is added to promote the grain refinement, and then a sodium hydroxide solution is added for sufficient reaction so as to generate a precipitate, and the precipitate is washed, so that the final product superfine sodium pyroantimonate is obtained.Compared with a traditional process, the preparation method of sodium pyroantimonate with a reduced grain size adopts steps of firstly adding hydrogen peroxide for oxidization and then adding sodium hydroxide for reaction, while the traditional process adopts steps of firstly adding sodium hydroxide and then adding hydrogen peroxide. Sodium pyroantimonate obtained by the traditional process generally has a grain size of about 40 micron, while the sodium pyroantimonate obtained by the preparation method disclosed in the invention is significantly improved in grain size.

Owner:YIYANG SHENGLI CHEM IND +1

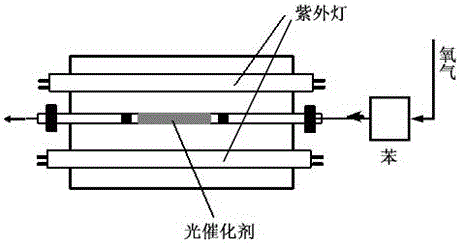

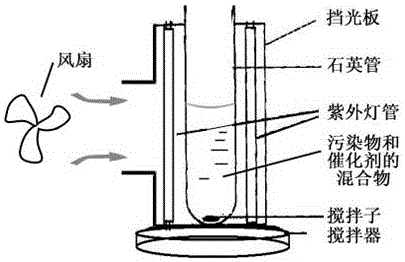

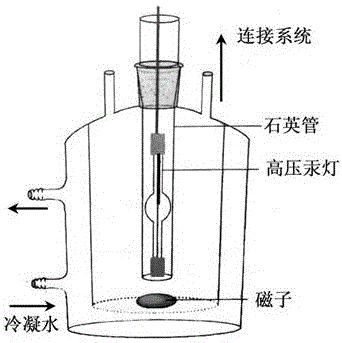

Strontium antimonate photocatalyst and preparation and application thereof

InactiveCN106390984AImprove conversion rateImprove quantum efficiencyGas treatmentWater/sewage treatment by irradiationQuantum efficiencyUltraviolet lights

Owner:FUZHOU UNIV

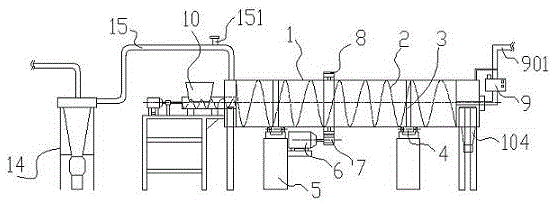

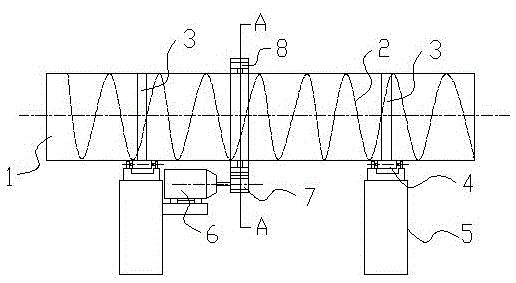

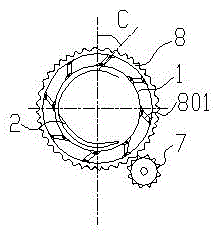

High-temperature reaction furnace for producing sodium antimonate by sodium pyroantimonate dehydration

ActiveCN105540665AIncrease productivityShorten the production cycleChemical industryAntimonates/antimonitesSodium antimonateDehydration

The invention discloses a high-temperature reaction furnace for producing sodium antimonate by sodium pyroantimonate dehydration, which comprises a furnace body capable of rotating horizontally, a feeder and a tail gas treatment device which are arranged on one side of the furnace body, and an igniter arranged on the other side of the furnace body, wherein the furnace body is arranged on a furnace stage through a roller ring on the periphery, and forms a rolling contact with support rollers on the furnace stage; the inner wall of the furnace body is provided with an inner screw conveyer; and the periphery of the furnace body is provided with a power gear ring which meshes with a driving gear, which is fixed to the furnace stage and connected with a rolling motor. The invention aims to provide a high-temperature reaction furnace for producing sodium antimonate by sodium pyroantimonate dehydration, which shortens the production cycle, implements circulating production and has the advantages of high production efficiency, energy saving, environment friendliness and labor saving.

Owner:ZHUZHOU ANTE NEW MATERIAL TECH CO LTD

Method for resource utilization of arsenic alkali slag by extraction and separation

ActiveCN110282640ASimple processLess investmentArsenites/arsenatesSolid solvent extractionSlagResource utilization

The invention relates to a method for resource utilization of arsenic alkali slag by extraction and separation. The method comprises the following steps: adding glycerin into arsenic alkali slag subjected to crushing and grinding or placing slurry obtained through grinding of the arsenic alkali slag and the glycerin in a leaching tank for leaching and extraction, and performing solid-liquid separation to obtain antimony-enriched slag and a glycerin phase solution, wherein the obtained glycerin phase solution is a mixed solution containing arsenate and soda ash, the glycerin phase solution is subjected to cooling crystallization or freezing crystallization separation to obtain a mixture of arsenate crystals and soda ash crystals, and glycerin separated through cooling crystallization or freezing crystallization separation is recycled for the leaching and extraction of the arsenic alkali slag; the obtained antimony-enriched slag is a solid mixture containing antimonate and aluminosilicate minerals, and is used for returning antimony to refine or process antimony or antimony oxide and antimonate. The method has the advantages that the flow is short, the investment is relatively low, no waste water pollutants are generated in a separation process, the arsenic alkali slag is extracted and separated by a safe solvent, and the solvent can be recycled.

Owner:长沙紫宸科技开发有限公司

Hydrophobic-organic-solvent dispersion of surface-modified colloidal particles of anhydrous zinc antimonate, coating composition containing the same, and coated member

InactiveUS20130143035A1Good dispersibilityConducive to preservationMaterial nanotechnologyPigmenting treatmentOrganic solventPhosphoric acid

There is provided a hydrophobic-organic-solvent dispersion containing colloidal particles of anhydrous zinc antimonate having high transparency which has not been attained hitherto, a coating composition containing the hydrophobic-organic-solvent dispersion and a member coated with the coating composition. A hydrophobic-organic-solvent dispersion comprising colloidal particles of anhydrous zinc antimonate having a primary particle diameter of 5 to 500 nm, which are surface-modified with azi alkylamine and a surfactant having an acid group is used. The surfactant has a carboxylic acid group, a sulfonic acid group, or a phosphoric acid group.

Owner:NISSAN CHEM IND LTD

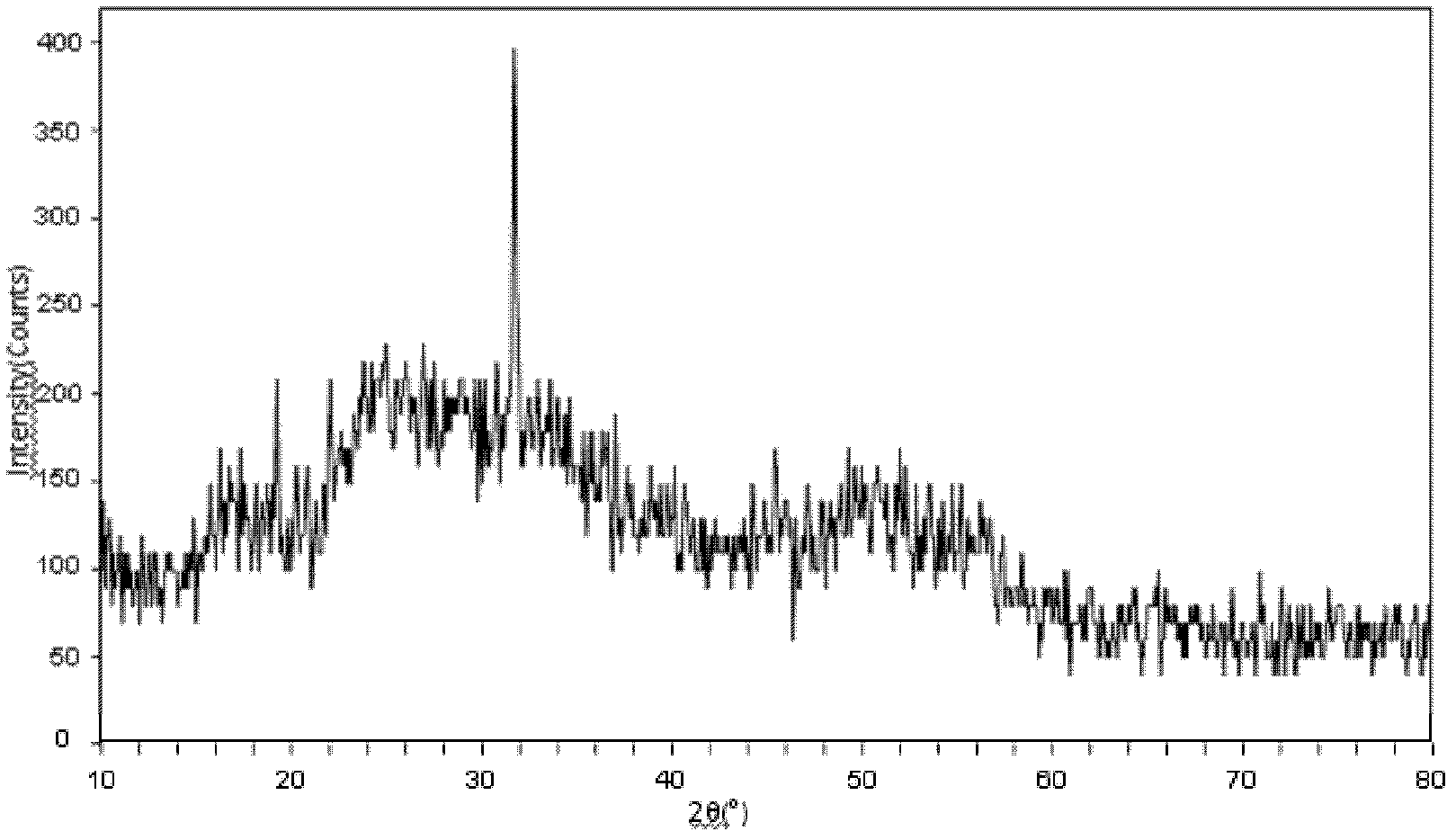

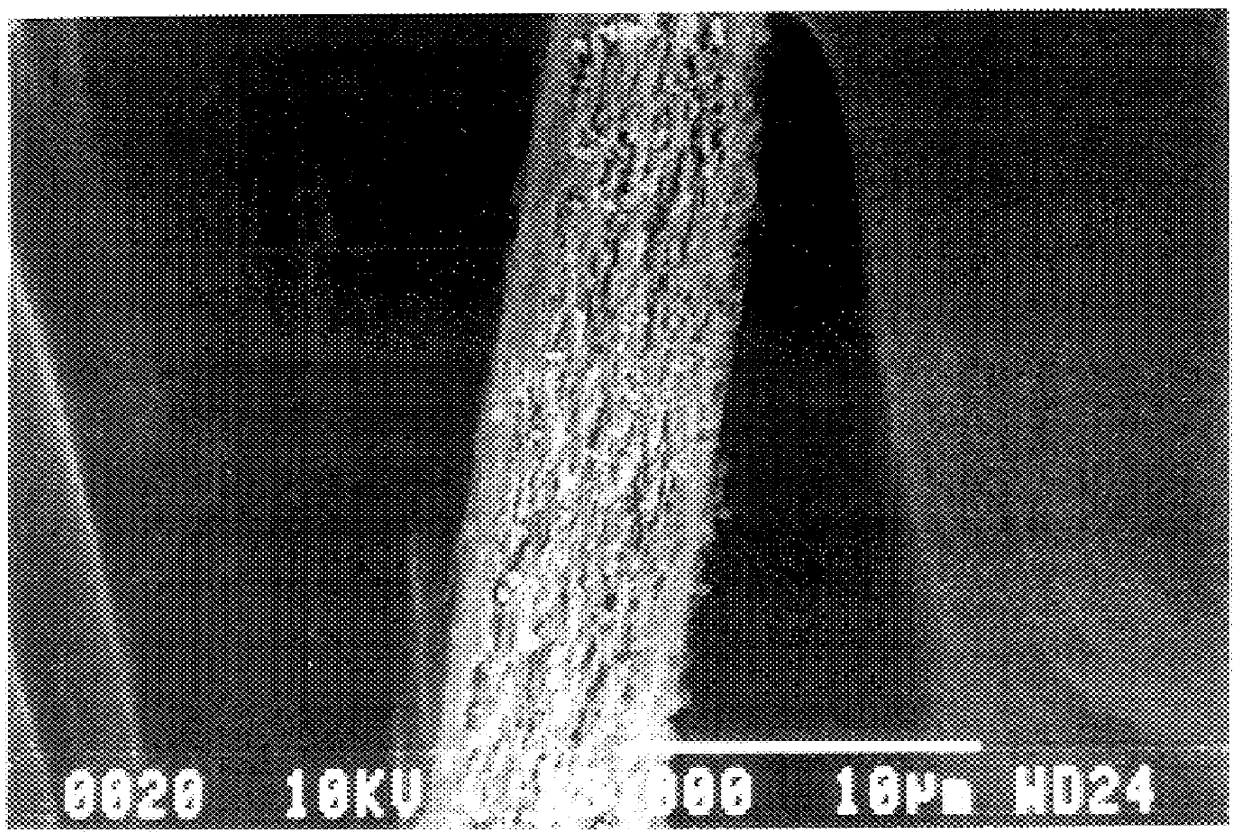

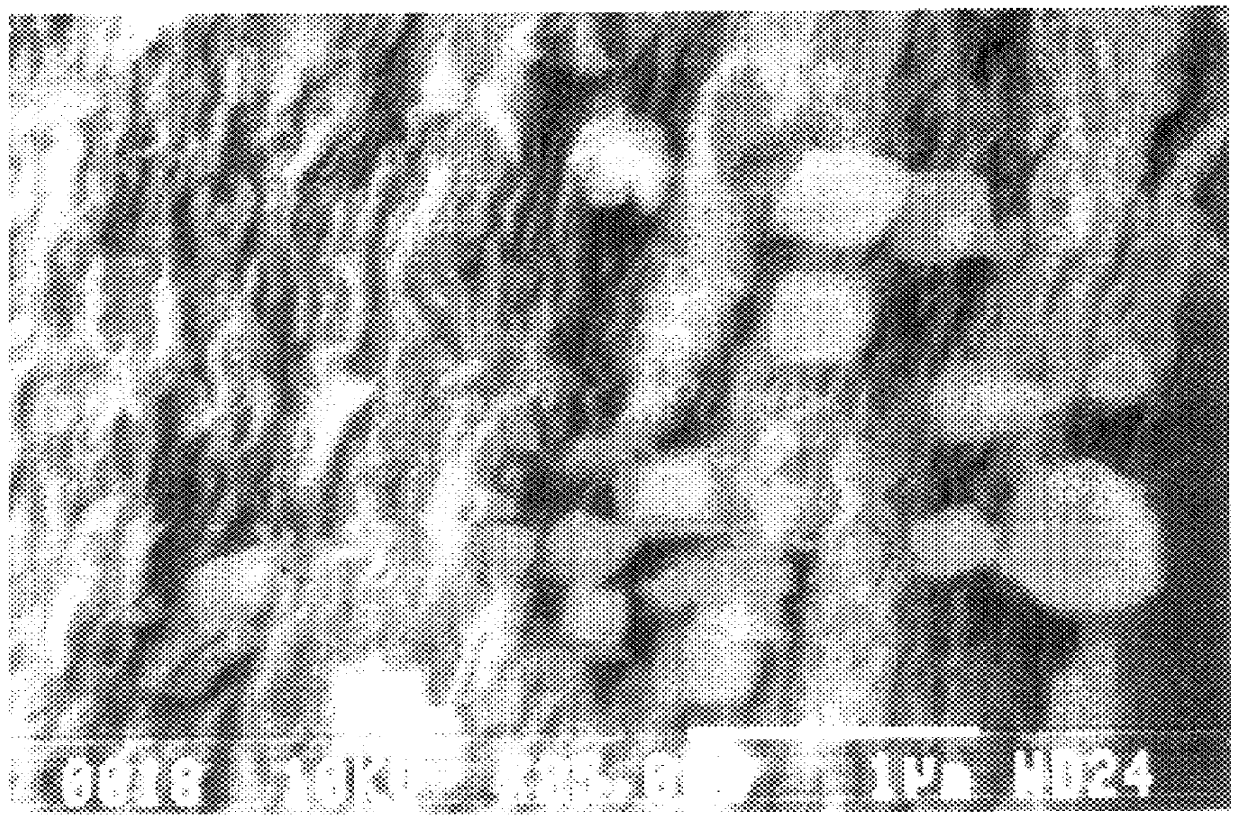

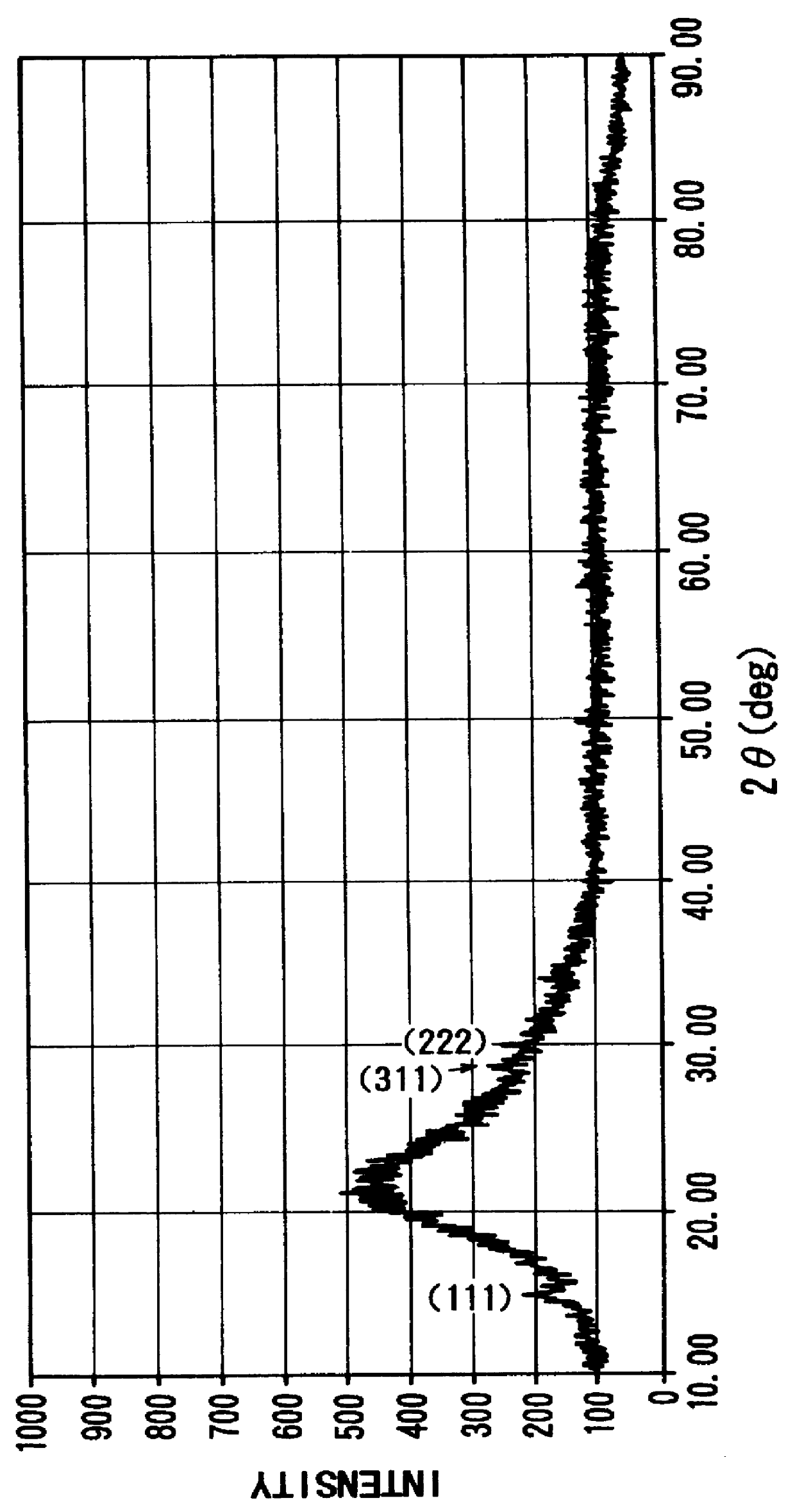

High-proton-conductive antimonic acid film

To provide an antimonic acid film having an excellent conductivity and a high response to humidity, and useful as a high-performance humidity sensor, a hydrogen gas sensor or a hydrogen fuel cell, the present invention provides an antimonic acid film comprising single crystals of cubic antimonic acid dispersed in amorphous antimonic acid by causing metallic antimony or an oxygen-containing compound thereof to react with hydrogen peroxide using the resultant reaction solution as the raw material, and forming a film on an insulated substrate.

Owner:NATIONAL RESEARCH INSTITUTE FOR METALS SCIENCE AND TECHNOLOGY AGENCY

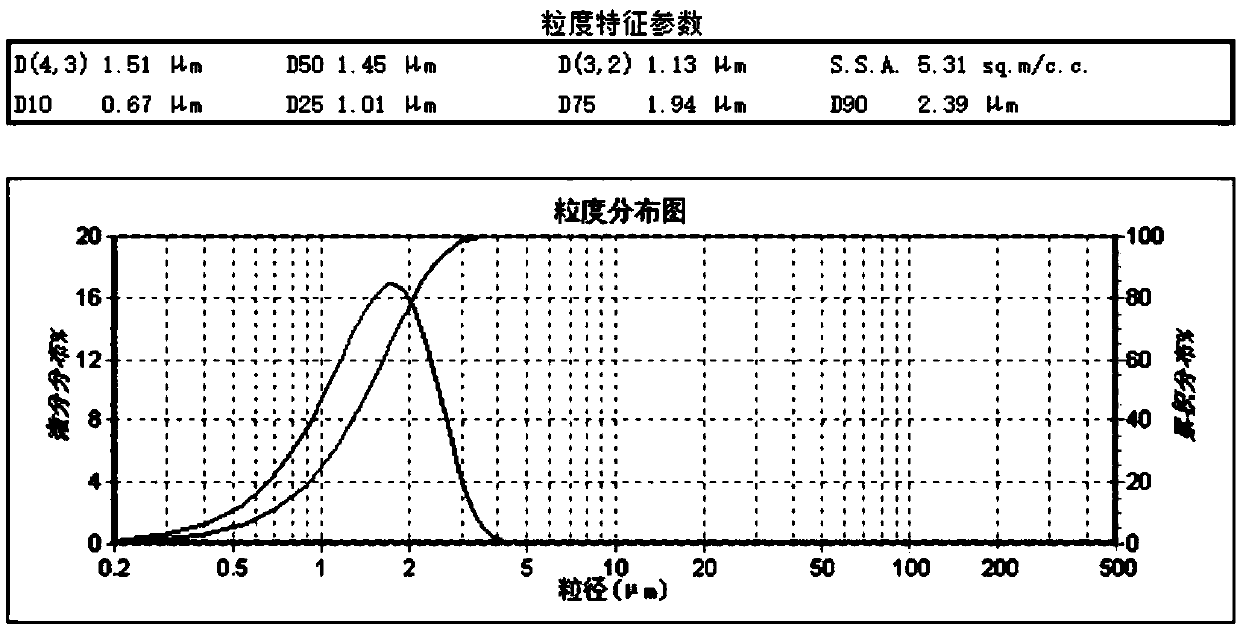

Preparation method of ultrafine granular sodium antimonate

A preparation method of ultrafine granular sodium antimonate comprises the following steps: (1) stirring and mixing antimony trioxide and potassium hydroxide with water, dissolving, heating, then adding an aqueous solution of hydrogen peroxide, and oxidizing to obtain a potassium citrate solution; (2) slowly adding the potassium citrate solution obtained by the reaction in the step 1) into a high-concentration sodium hydroxide solution of 600-800 g / L, and stirring at a high speed at 80-95 DEG C and reacting to obtain sodium antimonate having a particle diameter of less than or equal to 3.0 microns, and cooling; (3) carrying out solid-liquid separation on the reaction liquid in the step (2), carrying out slurry washing on the sodium antimonate solid with water for 2 to 3 times, spin-dryingafter washing and drying through a dryer so as to obtain the finished product ultrafine granular sodium antimonate. The ultrafine granular sodium antimonate prepared by the above preparation method has uniform particle size which is less than or equal to 3 microns, and is mainly used as a flame retardant in fabrics such as fibers and a clarifying agent for glass shells of color kinescopes and high-grade glass. The preparation process is simple; requirements on preparation equipment are low; energy consumption is low; and the product purity is high.

Owner:CHANGSHA YEXING ANTIMONY IND

Method for preparing metal oxidizing acid salt and said salt

The invention relates to multi-metal oxide compounds with a 2-component structure, containing molybdenum, vanadium, antimony, one or more of the elements W, Nb, Ta, Cr and Ce and one or more of the elements Cu, Zn, Co, Fe, Cd, Mn, Mg, Ca, Sr and Ba. The invention also relates to the use of said compounds for producing acrylic acid by means of a gas phase catalytic oxidation process.

Owner:BASF AG

Sulfo sodium antimonite nano material preparation method

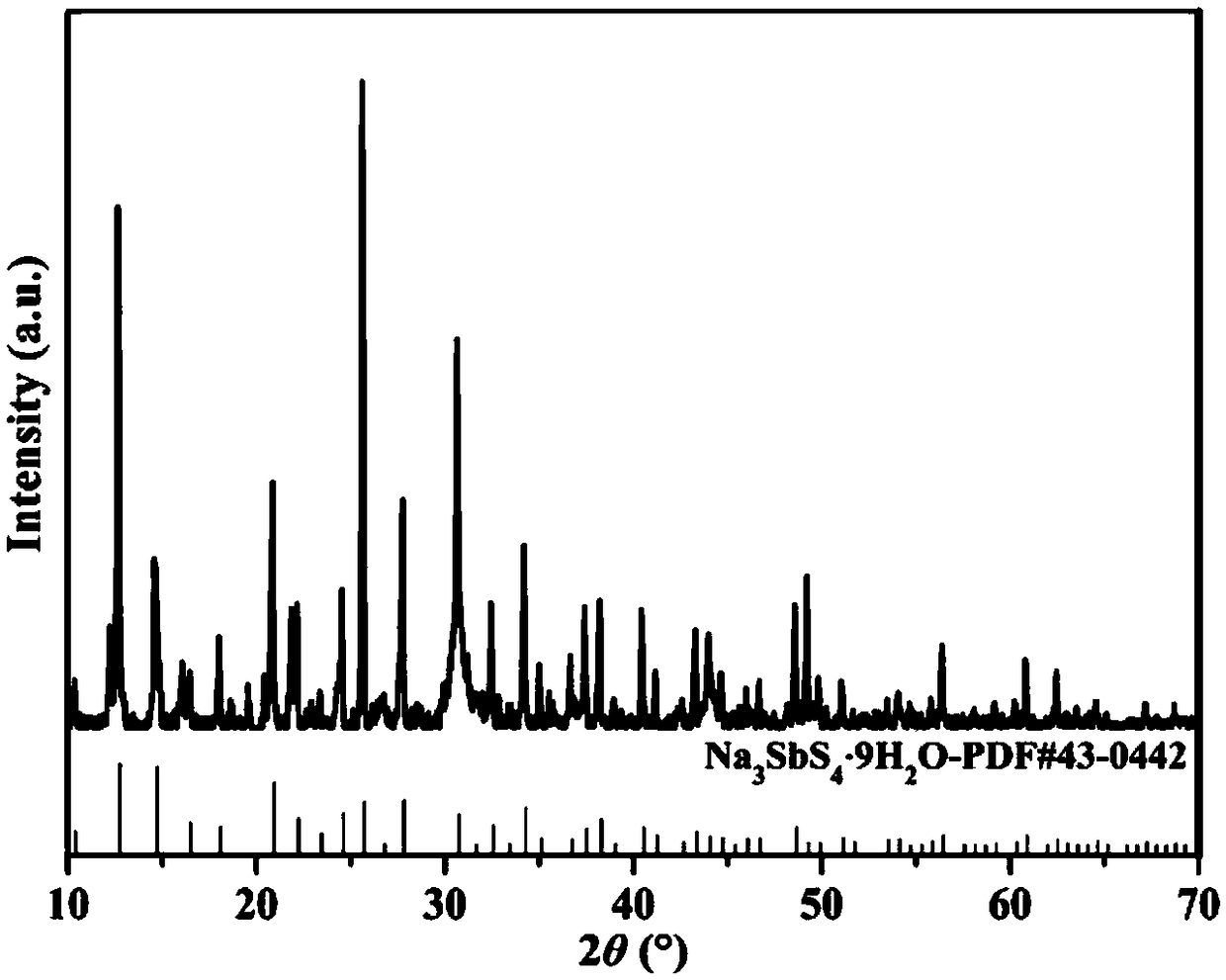

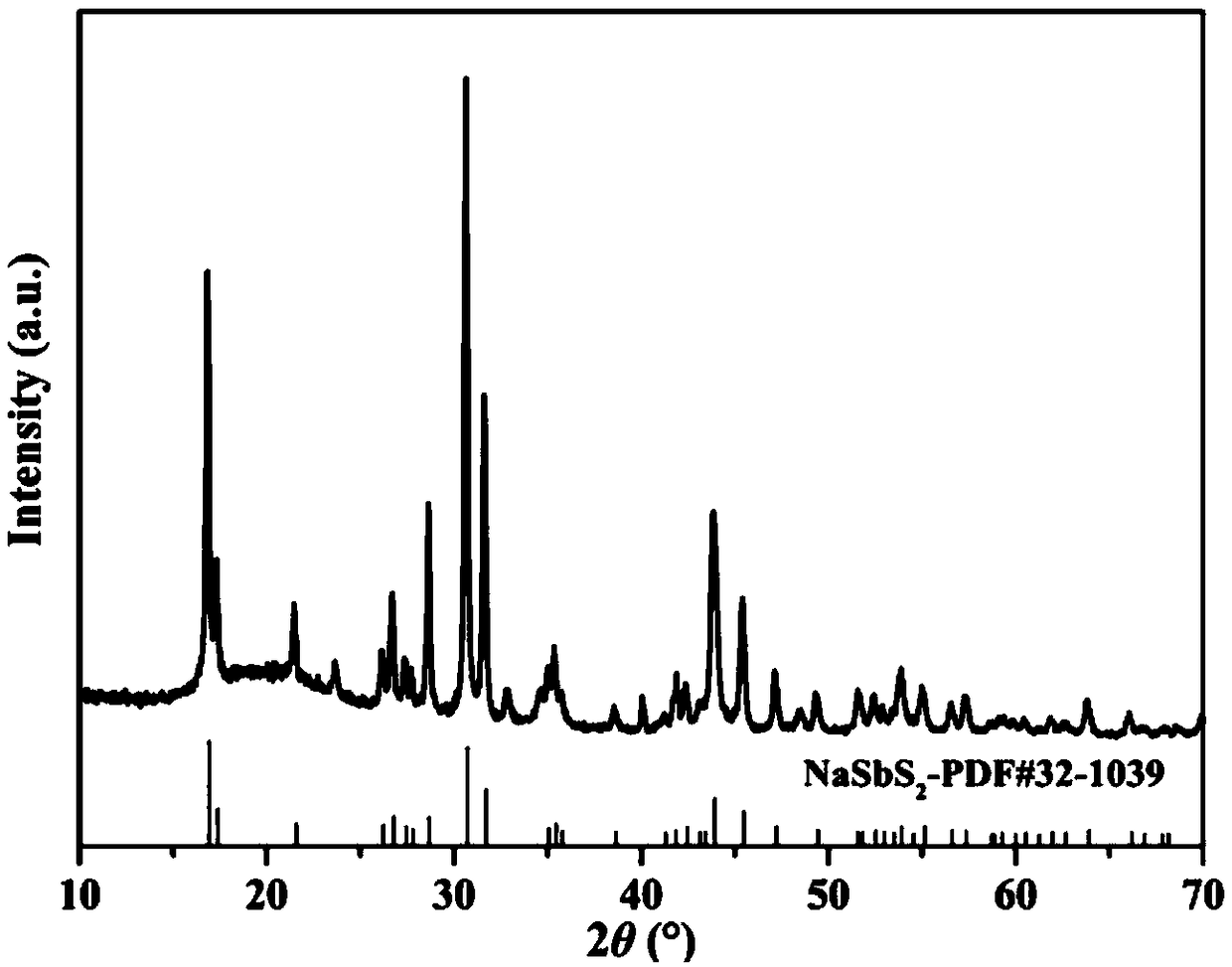

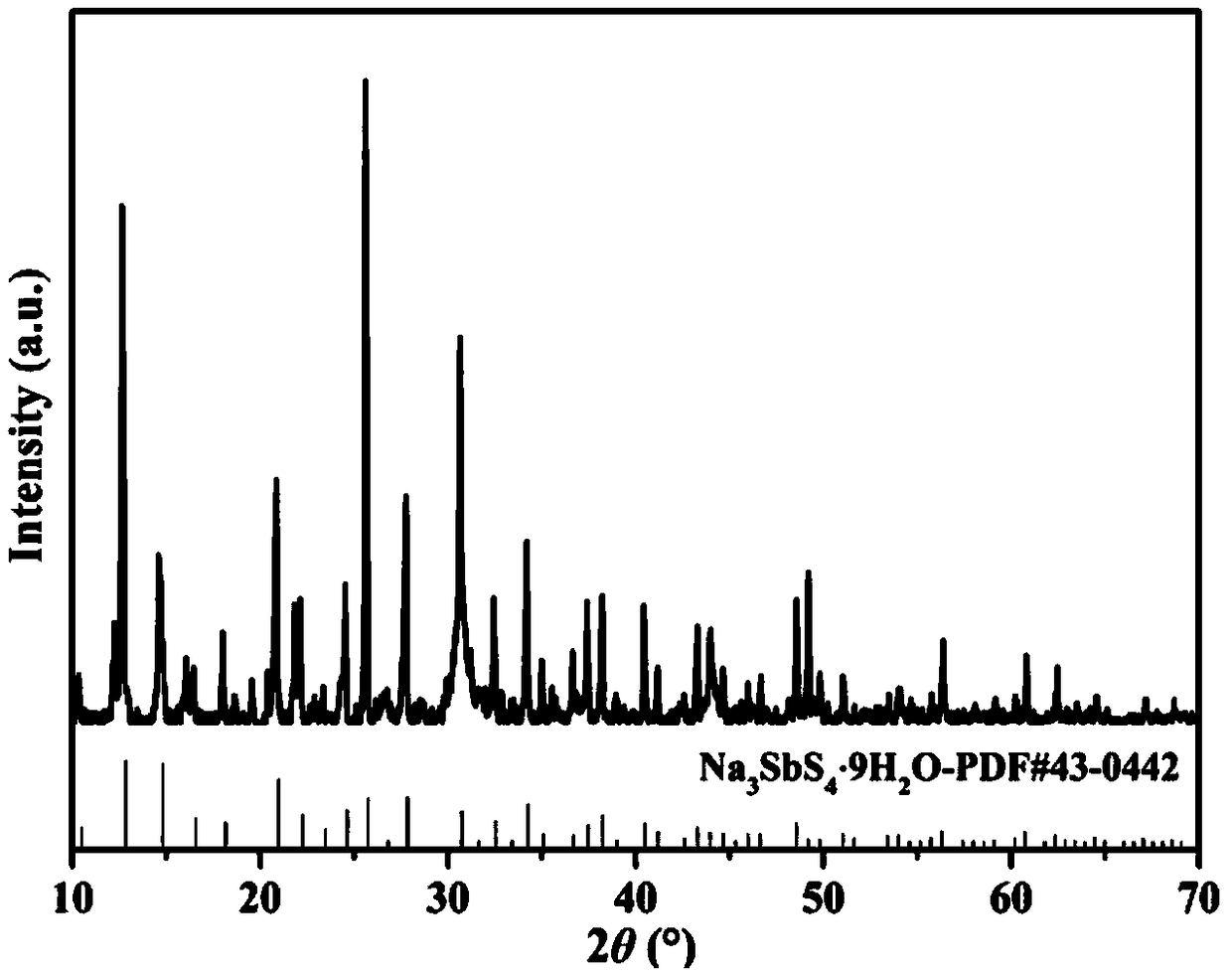

ActiveCN109437298AStrong purityInfluence of purity, strong feasibilityAntimonates/antimonitesWater bathsArgon atmosphere

The invention discloses a NaSbS2 nano material preparation method and belongs to the technical field of nano material preparation. Na3SbS4.9H2O prepared by a water bath method is utilized as a precursor material; water is utilized as a solvent, so that safety hazards caused by heat evaporation of an organic solvent and effects on the sample purity are avoided, and feasibility is strong; a reactionprocess is performed in a container with an opening, an expensive high-pressure reaction kettle has no need to be used, and limit of the reaction container volume is avoided; the technological conditions have the advantages of moderate conditions, environmental friendliness, simpleness and low cost; a NaSbS2 nanoparticle material can be prepared under a low temperature through heat treatment in the argon atmosphere; the NaSbS2 nanoparticle material has the advantages of good crystallinity, high purity, even dispersion and even morphology. According to the NaSbS2 nano material preparation method disclosed by the invention, the reaction raw materials are easy to obtain, the cost is low, processing equipment is simple, and energy consumption is low; furthermore, the precursor is prepared under the normal pressure, so that safety is good, and feasibility is strong; thus, the NaSbS2 nano material preparation method has the advantages of economic property, practicability and very good industrialization prospect.

Owner:CENT SOUTH UNIV

Additive for YAG laser marking

InactiveCN1827530APigmenting treatmentAntimony oxides/hydroxides/oxyacidsMixed oxideMaterials science

Owner:ENGELHARD CORP

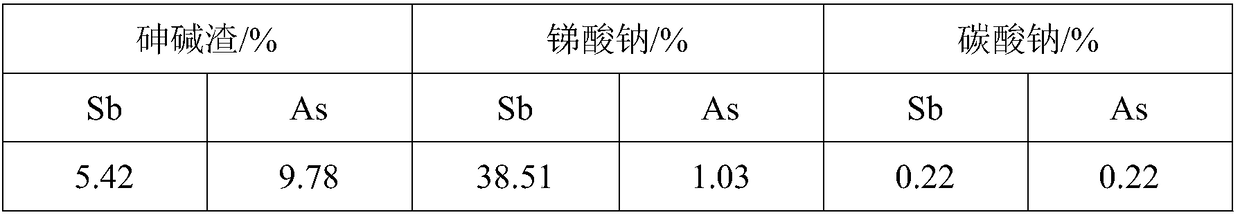

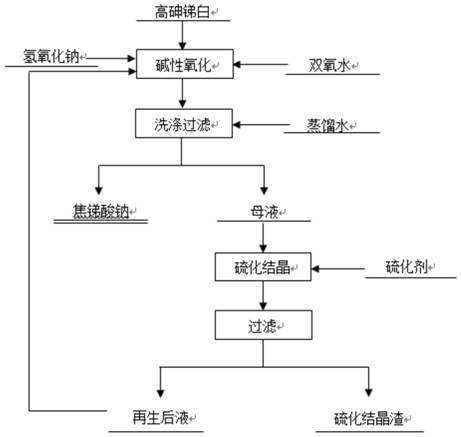

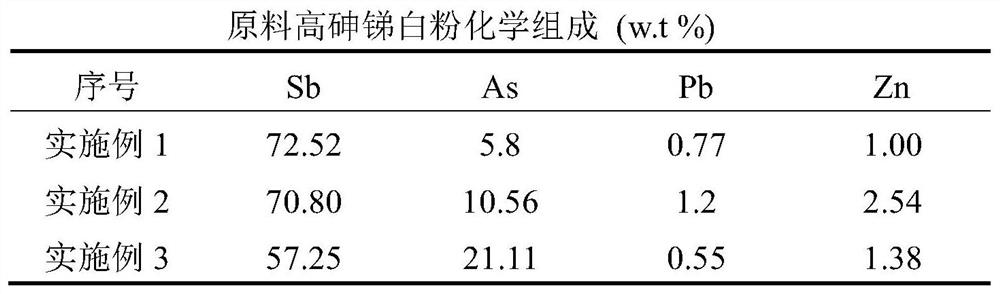

Method for preparing sodium pyroantimonate and regenerating and recycling mother liquor

ActiveCN113371757AIncrease crystallization rateIncrease profitProcess efficiency improvementAntimonates/antimonitesZinc ionPhysical chemistry

The invention discloses a method for preparing a sodium pyroantimonate product from high-arsenic antimony white and vulcanizing, crystallizing, regenerating and recycling mother liquor, and relates to the field of antimony fine chemicals. According to the method, the low-cost-value high-arsenic antimony white is subjected to alkaline oxidation to prepare the sodium pyroantimonate product with the high additional value, the mother liquor containing impurities such as arsenic, lead and zinc is subjected to sulfuration crystallization to achieve cooling crystallization of sodium arsenate and sulfuration precipitation of lead and zinc ions, and the purified and regenerated mother liquor is continuously used for preparing the sodium pyroantimonate. The sodium pyroantimonate product meets the second-grade product requirement of the Chinese nonferrous metal industry standard (YS / T 22-2010), and the problem of separation of impurities such as antimony, arsenic, lead and zinc during preparation of sodium pyroantimonate from high-arsenic antimony white with complex components is solved. Meanwhile, the mother liquor is efficiently regenerated through vulcanization and crystallization, the problems that arsenic and alkali are difficult to separate and energy consumption is high after evaporation, concentration and crystallization are carried out are solved, and finally, the regenerated mother liquor is used for preparing sodium pyroantimonate, and efficient preparation of a product and recycling of the mother liquor are achieved; technical innovation is provided for high-valued utilization of low-price high-arsenic antimony white and purification and regeneration of mother liquor. The method has the advantages of convenience in operation, stable product components, high mother liquor purification efficiency and the like.

Owner:CENT SOUTH UNIV

A preparation method for reducing the particle size of sodium pyroantimonate

ActiveCN110713209BSmall particle sizeImprove the preparation effectAntimonates/antimonitesPhysical chemistryPotassium hydroxide

The invention discloses a method for preparing superfine sodium pyroantimonate by adding potassium hydroxide, comprising the following steps: step (1): antimony trioxide and potassium hydroxide are pre-reacted; Add oxidant to the pre-reaction system to carry out oxidation reaction; step (3): add complexing agent and sodium hydroxide to the oxidation reaction system of step (2) to carry out precipitation reaction; Sodium pyroantimonate was obtained. In the method of the present invention, antimony trioxide is used as raw material, potassium hydroxide is used for pre-reaction, and then oxidation reaction is carried out to oxidize Sb(III) into Sb(V), and finally a complexing agent and compounding agent are innovatively added to the oxidation reaction system. Sodium hydroxide, carry out precipitation reaction under the coordination action of described complexing agent, can obviously reduce the grain size of sodium pyroantimonate like this.

Owner:YIYANG SHENGLI CHEM IND +1

A preparation method for reducing the particle size of sodium pyroantimonate

ActiveCN110015688BSolve the technical problem of excessive particle sizeSmall particle sizeAntimonates/antimonitesActive agentPhysical chemistry

The invention discloses a preparation method for reducing the particle size of sodium pyroantimonate, which comprises the following steps: step (1): antimony trioxide and hydrogen peroxide are pre-oxidized; step (2): after the reaction in step (1), the A surfactant and sodium hydroxide are added to the reaction system to carry out a precipitation reaction; after the precipitation reaction is completed, solid-liquid separation, washing and drying are performed to obtain sodium pyroantimonate with a fine particle size. The present invention uses antimony trioxide as a raw material, fully oxidizes antimony trioxide with hydrogen peroxide, and adds a surfactant to promote the refinement of crystal grains, and then adds sodium hydroxide solution for full reaction, and the resulting precipitate is washed to obtain the final The product is ultrafine sodium pyroantimonate. Compared with the traditional process, the present invention uses hydrogen peroxide to oxidize first, and then sodium hydroxide to react; while the traditional process is to add sodium hydroxide first, and then hydrogen peroxide. The particle size of sodium pyroantimonate obtained by the traditional process is generally about 40um, but the present invention has a very large improvement in the particle size.

Owner:YIYANG SHENGLI CHEM IND +1

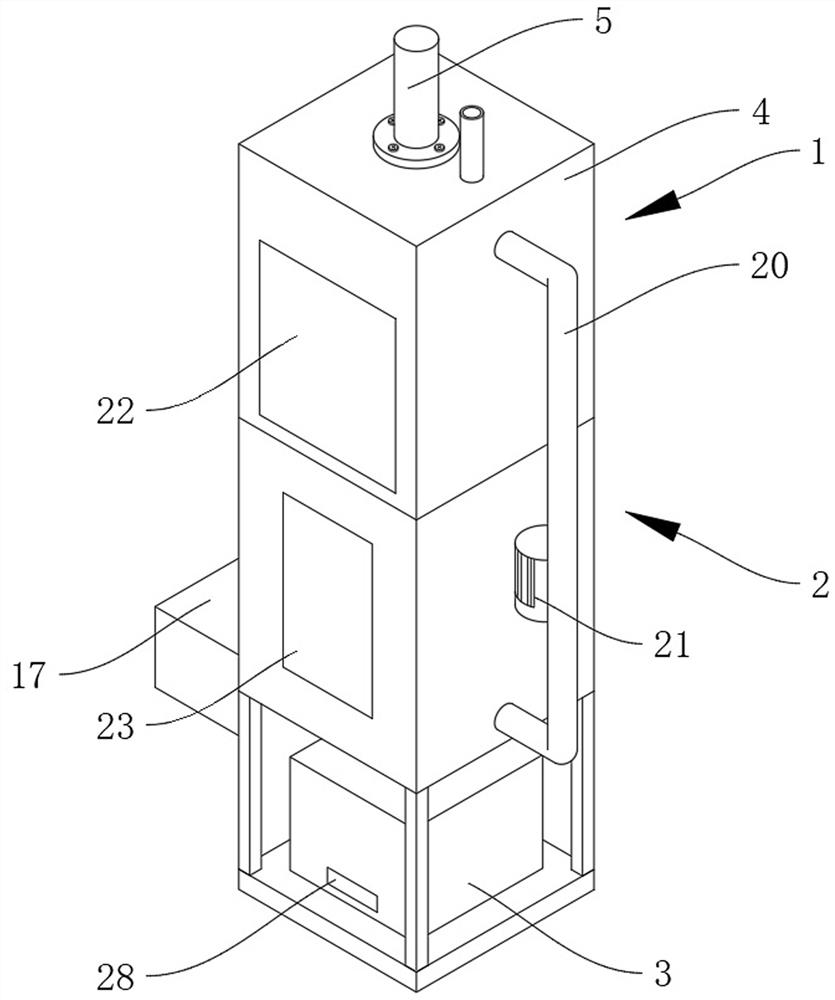

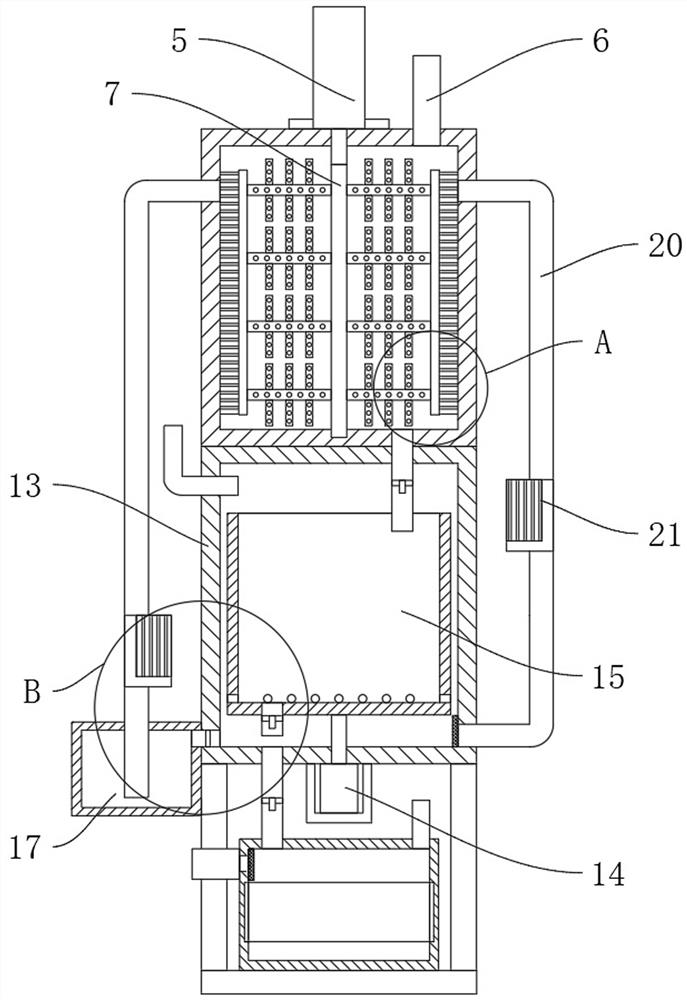

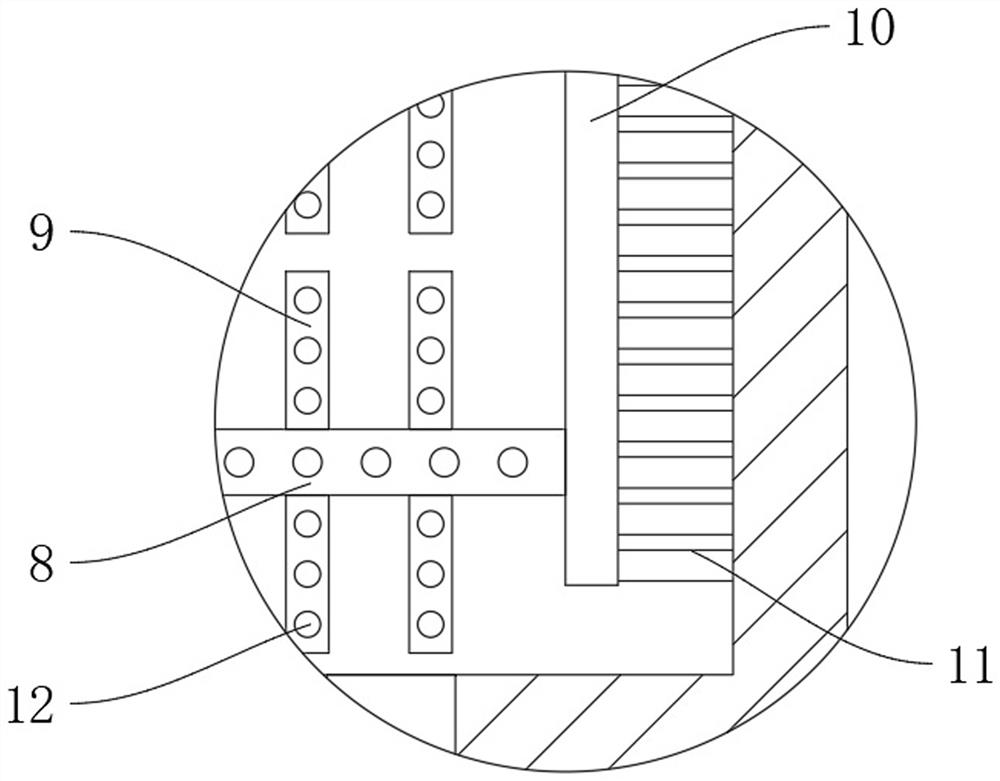

Equipment and method for producing sodium pyroantimonate by pure oxygen oxidation method

InactiveCN114516659AImprove reaction efficiencyIncrease profitChemical/physical/physico-chemical stationary reactorsAntimonates/antimonitesElectric machineryEngineering

The invention discloses equipment and method for producing sodium pyroantimonate through a pure oxygen oxidation method, and belongs to the technical field of sodium pyroantimonate production.The equipment comprises a reaction kettle mechanism, a centrifugal mechanism and a drying mechanism which are sequentially installed from top to bottom; the reaction kettle mechanism comprises a reaction kettle shell, a feeding pipe inserted into one side of the top of the reaction kettle shell and a transmission motor mounted in the center of the top of the reaction kettle shell, the output end of the transmission motor penetrates through the top of the reaction kettle shell and is coaxially connected with a rotating rod, and a plurality of stirring plates are uniformly connected to the side wall of the rotating rod; the top and the bottom of each stirring plate are evenly connected with a plurality of auxiliary plates, and a connecting plate is connected between the sides, away from the rotating rod, of the multiple stirring plates. According to the equipment for producing the sodium pyroantimonate through the pure oxygen oxidation method, the reaction efficiency in the reaction kettle shell is higher, the utilization rate of raw materials is higher, the occupied area is smaller, and more space is saved.

Owner:LUOYANG HAIHUI NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com