Production process for preparing ultra-white nanometer sodium pyroantimonate

A technology for ultra-white sodium pyroantimonate and production process, which is applied in antimonate/antimonite and other directions, can solve the problems of complex process, high raw material requirements, low production cost, etc., and achieves simple process flow and raw material. The effect of low requirements and extremely low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

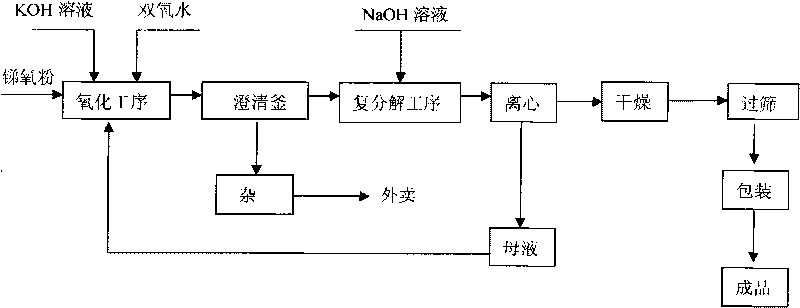

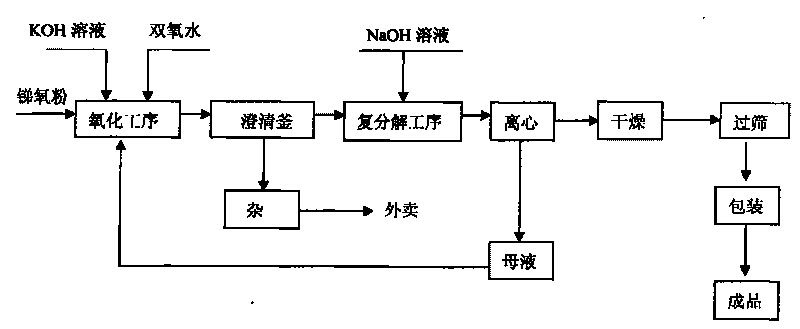

Image

Examples

Embodiment 1

[0015] The preparation concentration is 1200L of potassium hydroxide aqueous solution of 1.12 (specific gravity), 200kg of antimony oxide powder (Sb: 147.6kg) is added in the oxidation reaction kettle respectively, and the temperature is at 60 ℃. The temperature rises to about 120°C, and the antimony trioxide is all converted into potassium antimonate, and the reaction ends without foam in the reaction kettle; Reaction equation: Sb 2 O 3 +2KOH+2H 2 O 2 +3H 2 O→2KSb(OH) 6 ;

[0016] The reaction solution was pumped into the clarification kettle, clarified for more than half an hour, then the clear liquid was pumped into the double decomposition kettle, and 49 kg of NaOH was added to prepare an aqueous solution with a concentration of 1.3 (specific gravity), and the reaction was carried out under normal pressure and at a temperature not greater than 120 ° C. React for more than half an hour to get the precipitate sodium pyroantimonate (reaction equation is: KSb(OH) 0 +NaOH...

Embodiment 2

[0018] The formula is 1500L of potassium hydroxide aqueous solution of 1.20 (specific gravity), 250kg of antimony oxide powder (Sb: 184.5kg) is added to the oxidation reaction kettle respectively, and 220 liters of 27.5% hydrogen peroxide are added at 70 ° C to carry out stirring reaction, and rise to 110 ° C for reaction 2 After 1 hour, the reaction solution was pumped into the clarification kettle, clarified for more than half an hour, and then pumped into the double decomposition kettle, and the aqueous solution prepared by 61 kg of NaOH was added to react, and the reaction was carried out under normal pressure and temperature not higher than 110 ° C for 1 hour, and the precipitate was centrifuged and dried. The sodium pyroantimonate with whiteness ≥93 is obtained by sieving, and the mother liquor is returned to the oxidation process.

[0019] The method firstly converts antimony into water-soluble potassium antimonate, removes other heavy metals and impurities, and then con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com