Sulfo sodium antimonite nano material preparation method

A nanomaterial, sodium sulfide technology, applied in antimonate/antimonite, chemical instruments and methods, antimony compounds, etc., can solve the problem of long reaction period, uneven product size distribution, reaction vessel, etc. of sol-gel method. Volume limitation and other issues, to achieve the effect of low cost, uniform morphology and strong crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

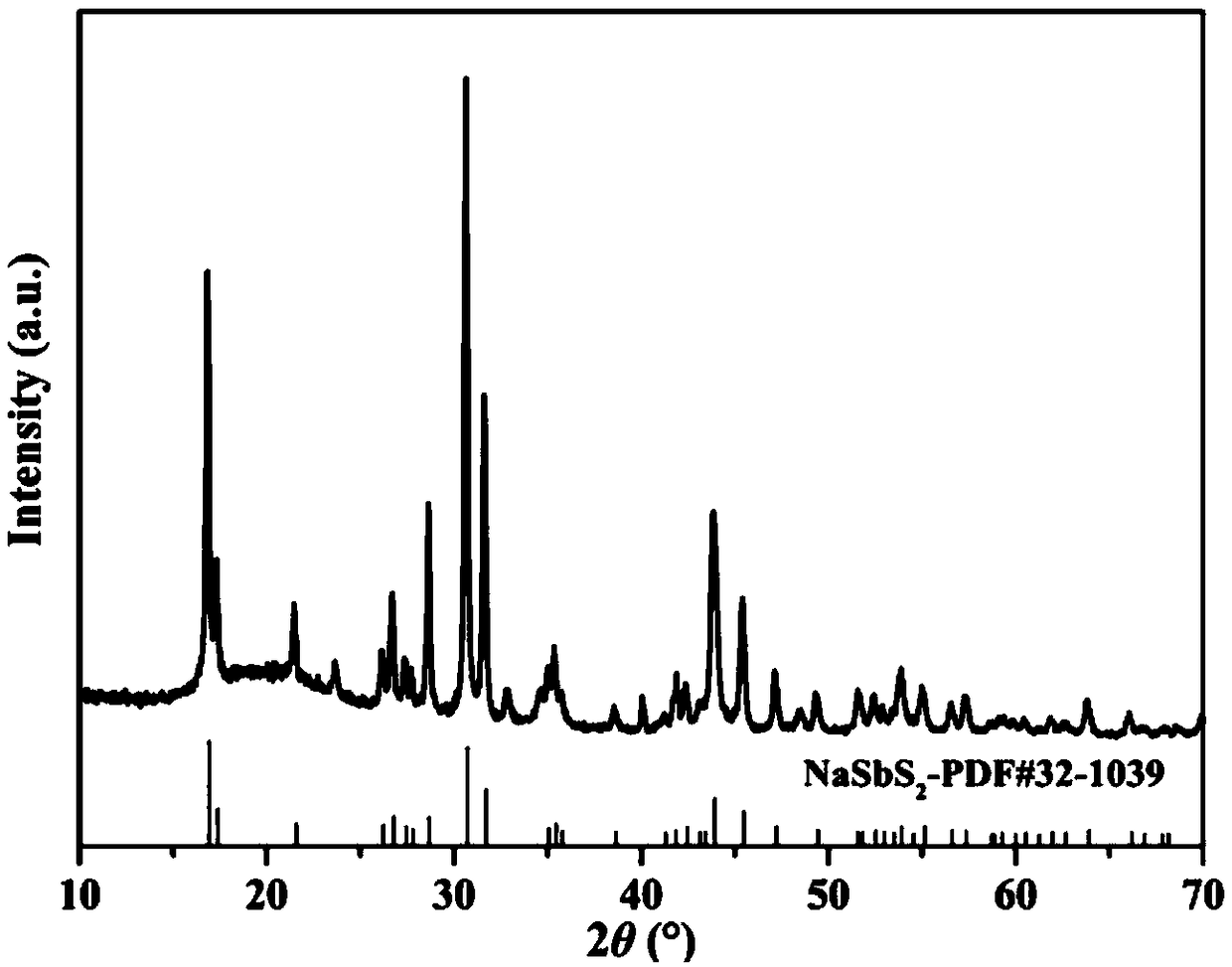

[0031] A kind of NaSbS of the embodiment of the present invention 2 The preparation method of nanometer material, comprises the following steps:

[0032] (1) Na 2 S·9H 2 O was dissolved in an appropriate amount of deionized water to obtain C Na =0.6mol / L sodium sulfide solution;

[0033] (2) press n Na :n S =1:1.2 molar ratio CH 4 N 2 S was added to the sodium sulfide solution and kept stirring until CH 4 N 2 S was completely dissolved to obtain a reddish-brown mixed solution;

[0034] (3) press n Na :n Sb =2.9:1 molar ratio will Sb 2 o 3 Add to the mixed solution obtained in step (2), and mix evenly to obtain a suspension;

[0035] (4) Place the suspension at 70°C and continue to stir for 1 hour to form a reddish-brown suspension solution. Let it stand at room temperature for 8 hours. Centrifuge and wash the standing product several times with absolute ethanol until the centrifugation solution is transparent and clear. Placed in a vacuum oven at 50°C for 8 hour...

Embodiment 2

[0038] A kind of NaSbS of the embodiment of the present invention 2 The preparation method of nanometer material, comprises the following steps:

[0039] (1) Na 2 S·9H 2 O was dissolved in an appropriate amount of deionized water to obtain C Na =0.8mol / L sodium sulfide solution;

[0040] (2) press n Na :n S =1:1.3 molar ratio TAA was added to the sodium sulfide solution, and the stirring was continued until the TAA was completely dissolved to obtain a mixed solution;

[0041] (3) press n Na :n Sb =3.1:1 molar ratio will Sb 2 S 3 Add to the mixed solution obtained in step (2), and mix evenly to obtain a suspension;

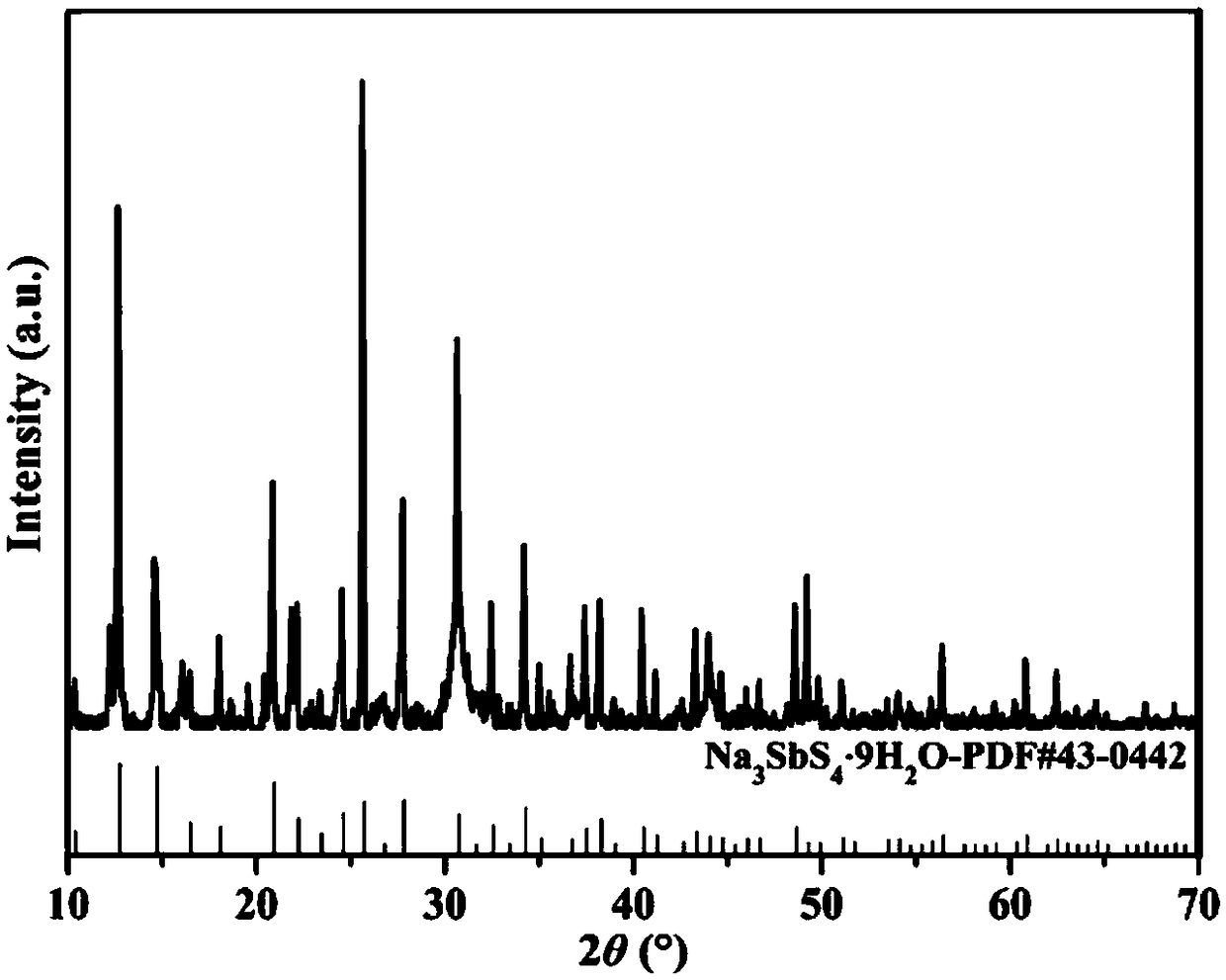

[0042] (4) Place the suspension at 80°C and continue to stir for 3 hours to form a reddish-brown suspension solution. Let it stand at room temperature for 10 hours. Centrifuge and wash the standing product several times with absolute ethanol until the centrifuged liquid is transparent and clear. Placed in a vacuum oven at 70°C for 10 h to obtain Na 3 Sb...

Embodiment 3

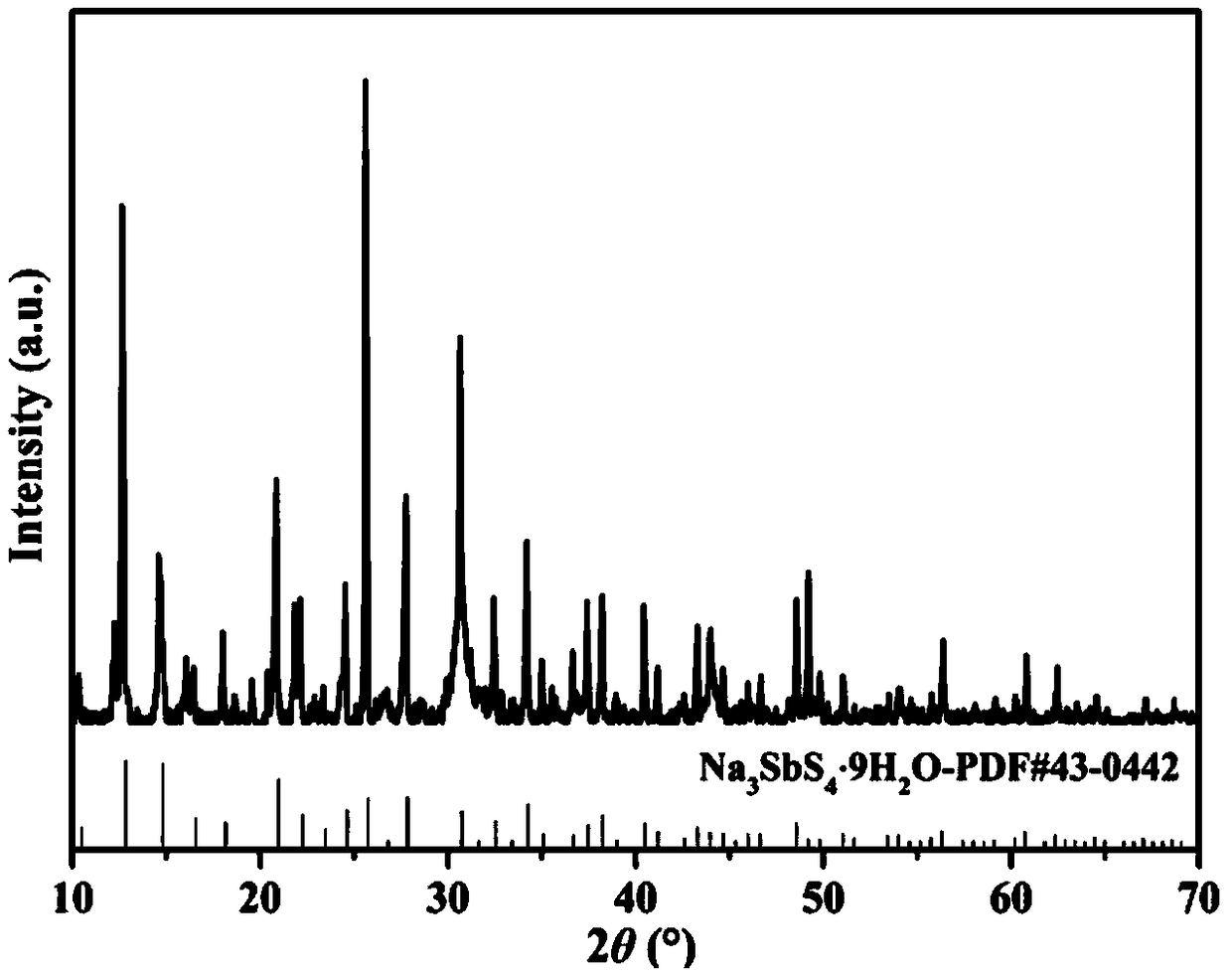

[0045] A kind of NaSbS of the embodiment of the present invention 2 The preparation method of nanometer material, comprises the following steps:

[0046] (1) Na 2 S·9H 2 O was dissolved in an appropriate amount of deionized water to obtain C Na =0.6mol / L sodium sulfide solution;

[0047] (2) press n Na :n S =1:1.1 molar ratio TAA was added to the sodium sulfide solution, and the stirring was continued until the TAA was completely dissolved to obtain a mixed solution;

[0048] (3) press n Na :n Sb =2.9:1 molar ratio: add the Sb powder into the mixed solution obtained in step (2), and mix evenly to obtain a suspension;

[0049] (4) Place the suspension at 70°C and continue to stir for 1 hour to form a reddish-brown suspension solution. Let it stand at room temperature for 8 hours. Centrifuge and wash the standing product several times with absolute ethanol until the centrifugation solution is transparent and clear. Placed in a vacuum oven at 50°C for 8 hours to obtain N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com