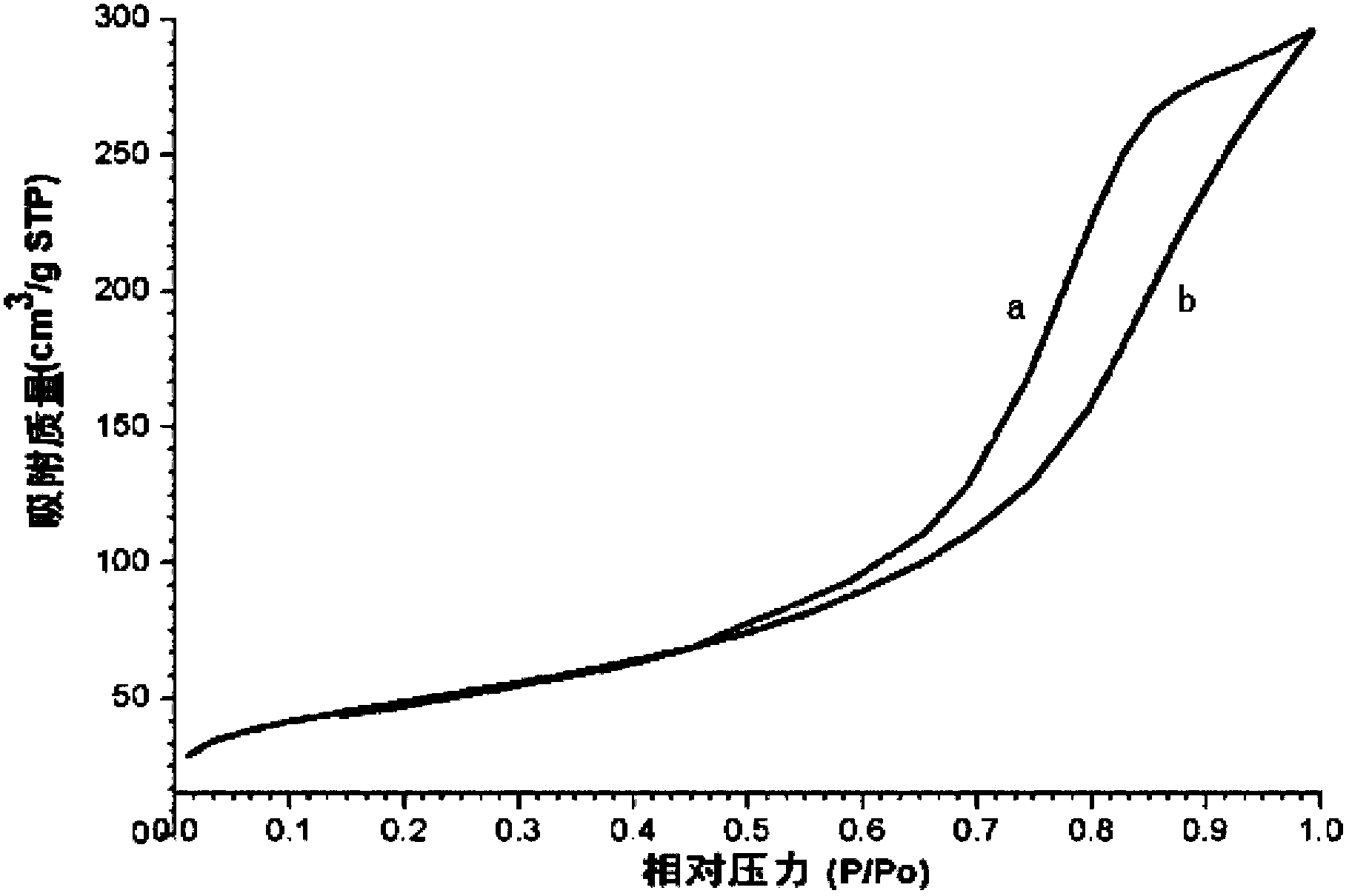

Method for preparing high-purity silica packing through sol-gel process

A technology of chromatographic column packing and silica gel chromatographic column, which is applied in the field of preparation of high-purity silica gel, can solve the problems of unsuitability for high-purity products, long time, influence on product purity, etc., and achieve great application value, strong separation ability and monodispersity Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

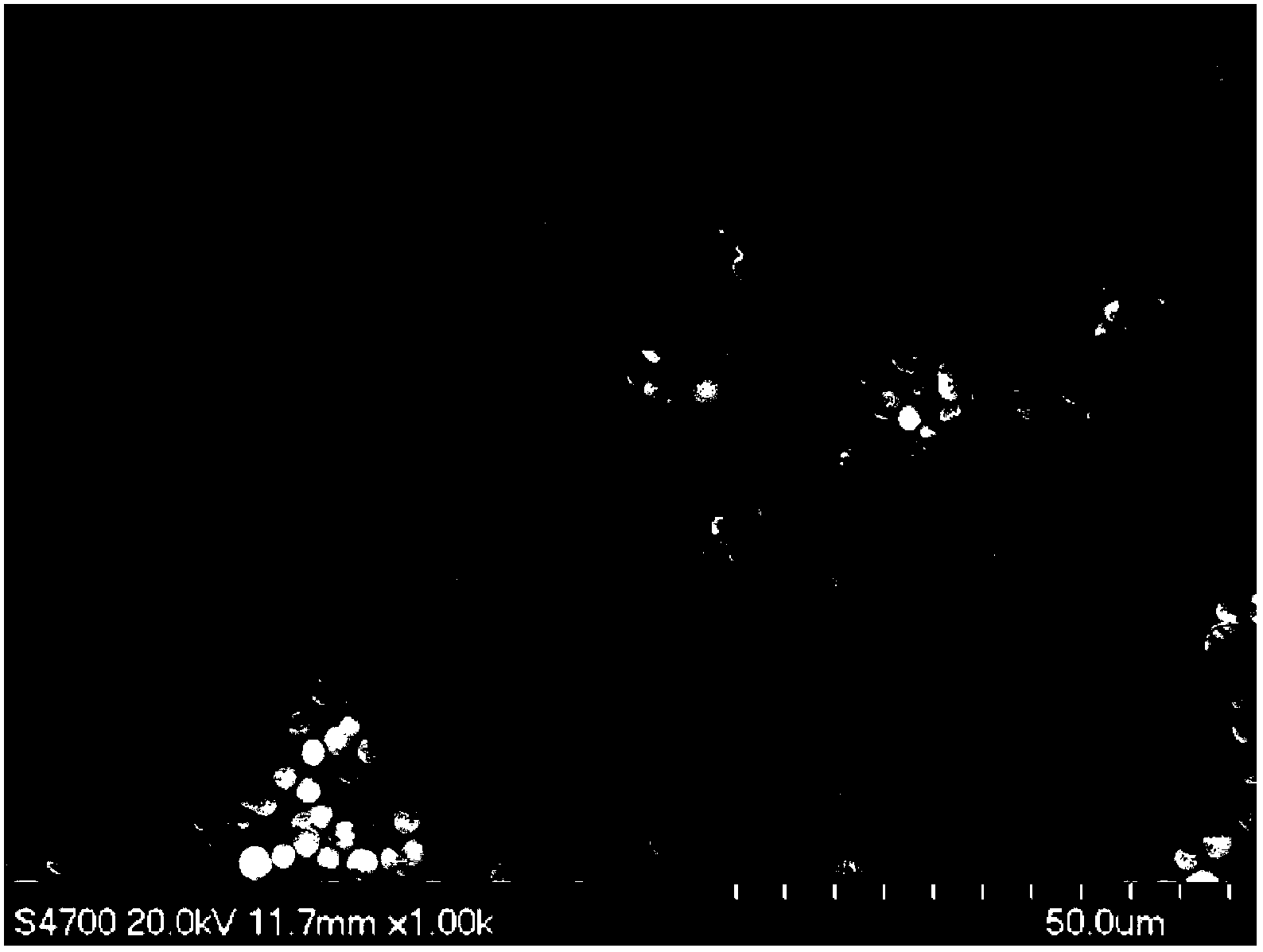

[0026] Add 160mL of analytically pure ammonia water with a concentration of 25-28% in a 500mL three-necked bottle equipped with a reflux device, raise the temperature of the water bath to 70°C, and mechanically stir at a speed of 800rpm, add 16.0g of monocrystalline silicon powder (99.99%, 70μm), and continue to heat up When the temperature reaches 75°C, add 100 mL of ammonia water dropwise into the reaction vessel at a rate of 10 mL for half an hour. During the reaction process, ammonia gas was introduced to keep the pH value of the reaction solution not less than 11, and the reaction was terminated after 6 hours to obtain a silica hydrosol with a solid content of about 30.3%.

[0027]Take 5g of the silica aqueous sol prepared above in a beaker, add 0.1g of sodium dodecylbenzenesulfonate, oscillate ultrasonically for 15min, transfer to a three-necked flask equipped with a stirrer, thermometer and water separator, add 50mL For n-heptane, heat and stir, keep the temperature whe...

Embodiment 2

[0031] Add 160mL of analytically pure ammonia water with a concentration of 25-28% in a 500mL three-necked bottle equipped with a reflux device, raise the temperature of the water bath to 70°C, and mechanically stir at a speed of 900rpm, add 12.0g of monocrystalline silicon powder (99.99%, 70μm), and continue to heat up When the temperature reaches 80°C, add 140 mL of ammonia water to the reaction vessel at a rate of 10 mL for half an hour. Ammonia gas was introduced to keep the pH value of the reaction solution not less than 11, and the reaction was terminated after 7 hours to obtain a silica hydrosol whose solid content was determined to be about 31.2%.

[0032] Take 5g of the above-prepared silica aqueous sol in a beaker, add 0.3g of dedecyltrimethylammonium bromide, ultrasonically vibrate for 15min, transfer to a three-necked flask equipped with a stirrer, a thermometer and a water separator, add 70mL of n-heptane, heat and stir, keep the temperature when the temperature r...

Embodiment 3

[0036] Add 160mL of analytically pure ammonia water with a concentration of 25%-28% into a 500mL three-necked flask equipped with a reflux device, raise the temperature of the water bath to 70°C, and stir at a speed of 1000rpm, add 14.0g of monocrystalline silicon powder (99.99%, 60~100μm), When the temperature continued to rise to 90°C, 120 mL of ammonia water was added to the reaction vessel at a rate of 10 mL for half an hour. Ammonia gas was introduced to keep the pH value of the reaction solution not less than 11, and the reaction was terminated after 8 hours to obtain a silica hydrosol whose solid content was determined to be about 33.4%.

[0037] Take 5g of the above-prepared silica aqueous sol in a beaker, add 0.5g of polyglycol, ultrasonically vibrate for 15min, transfer to a three-necked flask equipped with a stirrer, a thermometer and a water separator, add 80mL of n-heptane, and heat Stir, keep the temperature when the temperature reaches 80°C, react until no water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com