Blue organic electroluminous material and its preparation method and application

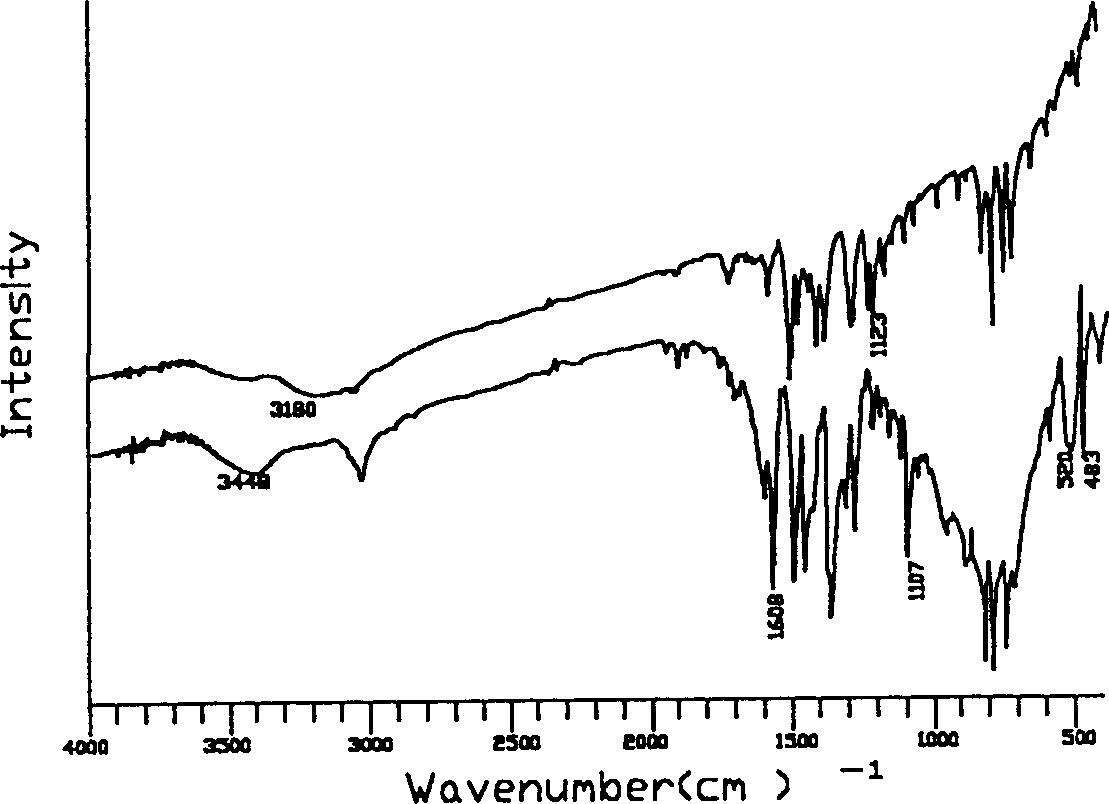

A milky white, hydroxyquinoline technology, applied in the direction of luminescent materials, chemical instruments and methods, etc., to achieve the effects of high color purity, high purity, high yield and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

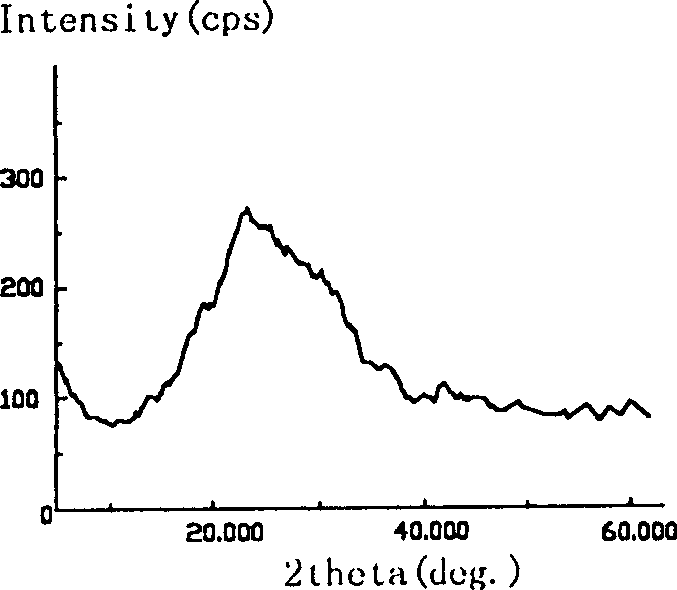

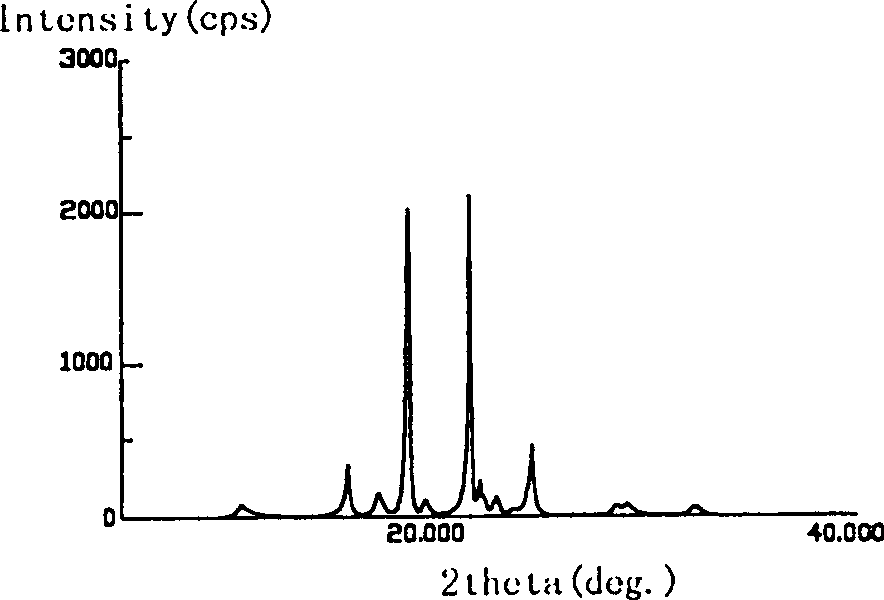

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: the acetone solution of 40ml, 0.5M 8-hydroxyquinoline is added in the there-necked flask, then slowly drip into 4.2ml triethylamine, then slowly drip into 0.5M, 30ml lithium sulfate aqueous solution, temperature keeps Stir at about 70°C for 2 hours and let stand for 24 hours to obtain milky white needle-like crystals, wash with deionized water, ethanol or acetone several times, filter, and dry at 80°C to obtain Liq. Yield 67.1%.

Embodiment 2

[0024] Embodiment 2: the acetone solution of 40ml, 0.5M 8-hydroxyquinoline is added in the there-necked flask, then slowly drip into 7ml triethylamine, then slowly drip into 0.5M, 30ml lithium sulfate aqueous solution, the temperature is maintained at Stir at about 70°C for 2 hours and let stand for 24 hours to obtain milky white needle-like crystals, wash with deionized water, ethanol or acetone several times, filter, and dry at 80°C to obtain Liq. Yield 71.2%.

Embodiment 3

[0025] Embodiment 3: the ethanol solution of 40ml, 0.5M 8-hydroxyquinoline is added in the there-necked flask, then slowly drip into 7ml triethylamine, then slowly drip into 0.5M, 30ml lithium sulfate aqueous solution, the temperature is maintained at Stir at about 70°C for 2 hours and let stand for 24 hours to obtain milky white needle-like crystals, wash with deionized water, ethanol or acetone several times, filter, and dry at 80°C to obtain Liq. Yield 44.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com