Method for separating arsenic and alkali in arsenic and alkali residues based on superfine ferric hydroxide colloid

A technology for ferric hydroxide and arsenic-alkali residue, which is applied in the field of comprehensive utilization of resources, can solve the problems of low efficiency, high cost, and difficult disposal of arsenic-removing waste residue, and achieves the effects of low energy consumption, low cost, and improved arsenic-alkali separation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

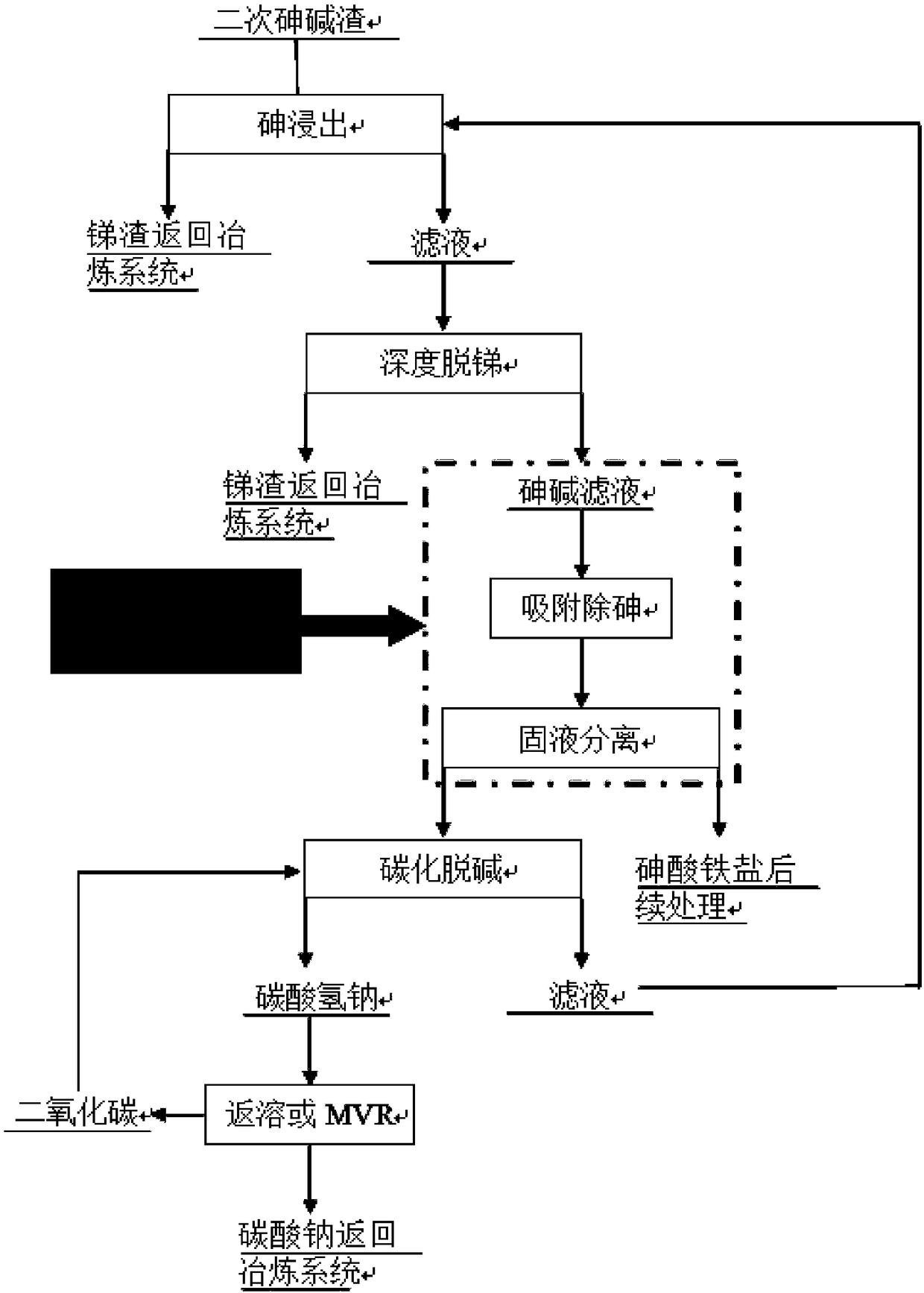

Image

Examples

Embodiment 1

[0047] Preparation of ferric hydroxide colloid: configuring Fe 3+ A solution with a concentration of 20g / L (pH3+ Quickly add a neutralizing agent to the solution, and stir at a high speed to adjust the pH to about 5. After reacting for 10 minutes, continue to add the neutralizing agent to adjust the pH to 8-9 to obtain highly active ultrafine Fe(OH) 3 colloid;

[0048] Preparation of ferric arsenate crystal nuclei: configure 5g / L ferrous sulfate solution, add 10g / L sodium arsenite to it, control the reaction temperature at 85°C, slowly add oxidant to convert ferrous ions into ferric ions, ferrous ions Arsenate is transformed into arsenate, and sodium hydroxide is used as a neutralizing agent to adjust the pH to 5-6 to obtain iron arsenate crystal nuclei with good crystallization properties;

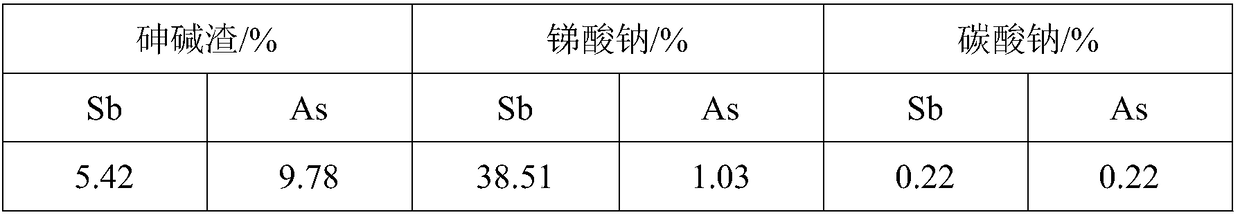

[0049] Using this process to treat the secondary arsenic-alkali slag of an antimony smelter in Hunan, the As content of the polluted acid is as high as 9.78g / L, the Sb content is 5.42g / L...

Embodiment 2

[0053] The preparation of ferric hydroxide colloid and ferric arsenate crystal nucleus is as in Example 1.

[0054] Using this process to treat the secondary arsenic-alkali slag of an antimony smelter in Hunan, the As content of the polluted acid is as high as 15.56g / L, the Sb content is 3.12g / L, and the sodium carbonate content is 50.23g / L. Take 50g of arsenic-alkali slag, grind it for 10 minutes, and ensure that -200 mesh accounts for 86%, add 250mL of water, stir at high speed, the leaching temperature is 80-85°C, and the leaching time is 60 minutes. The filtrate obtained by filtering is sodium carbonate, sodium arsenate and The mixed solution of sodium antimonate and the leach slag are returned to the antimony smelting system. Add 0.06g ultra-fine pyrrhotite catalyst to the filtrate, then add sodium hypochlorite, react for 30min, magnetic separation (magnetic field strength 1000GS) separate pyrrhotite and recycle, non-magnetic components are filtered to obtain sodium arsen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com