Nanometric tin-containing metal oxide particle and dispersion, and preparation method and application thereof

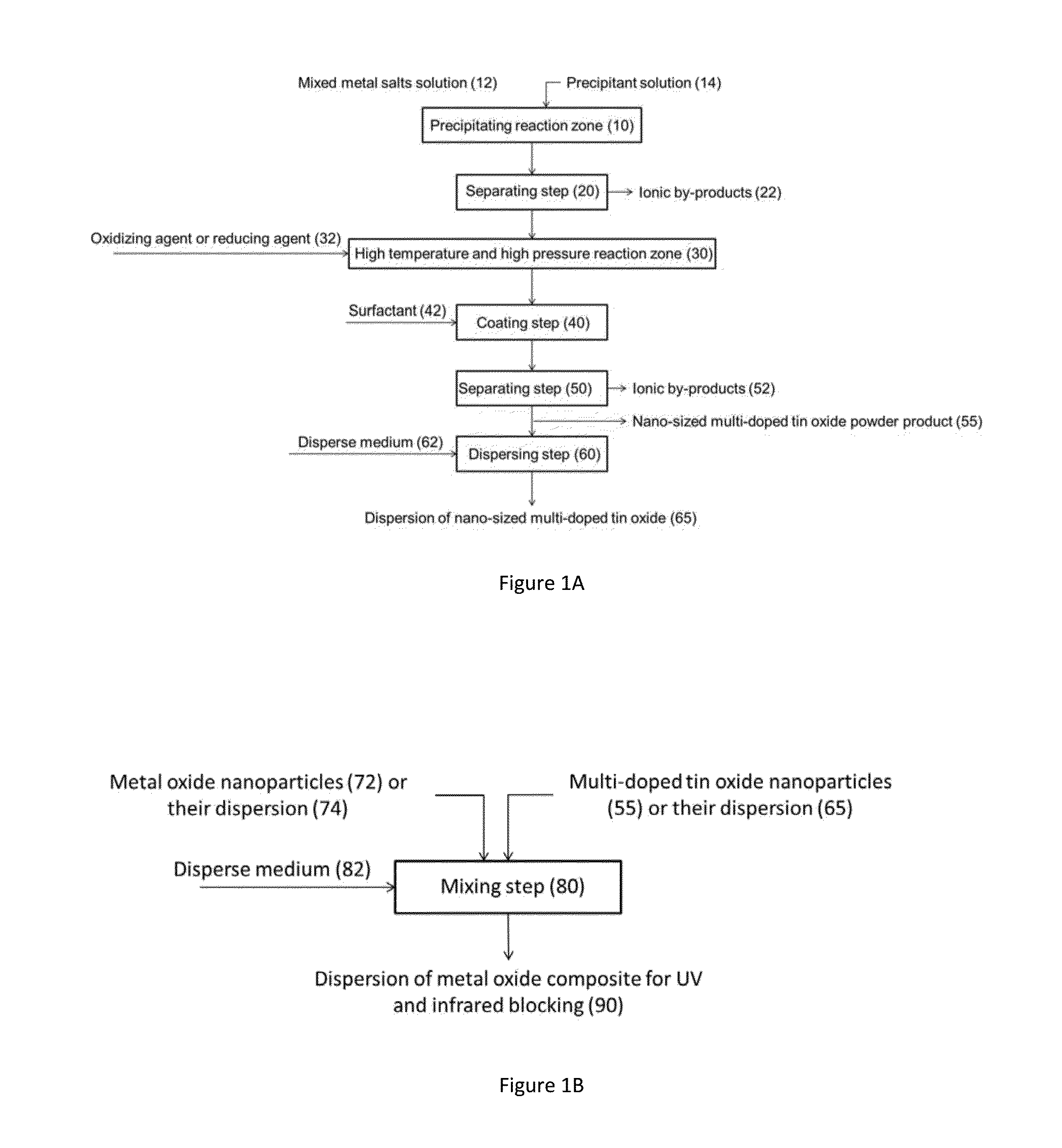

a technology of metal oxide nanoparticles and nanoparticles, which is applied in the field of nanometric tin-containing metal oxide nanoparticles and their di, can solve the problems of high equipment price by using the above method, high energy consumption within the building, and harmful to the surface paint of furniture and human bodies. high, high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

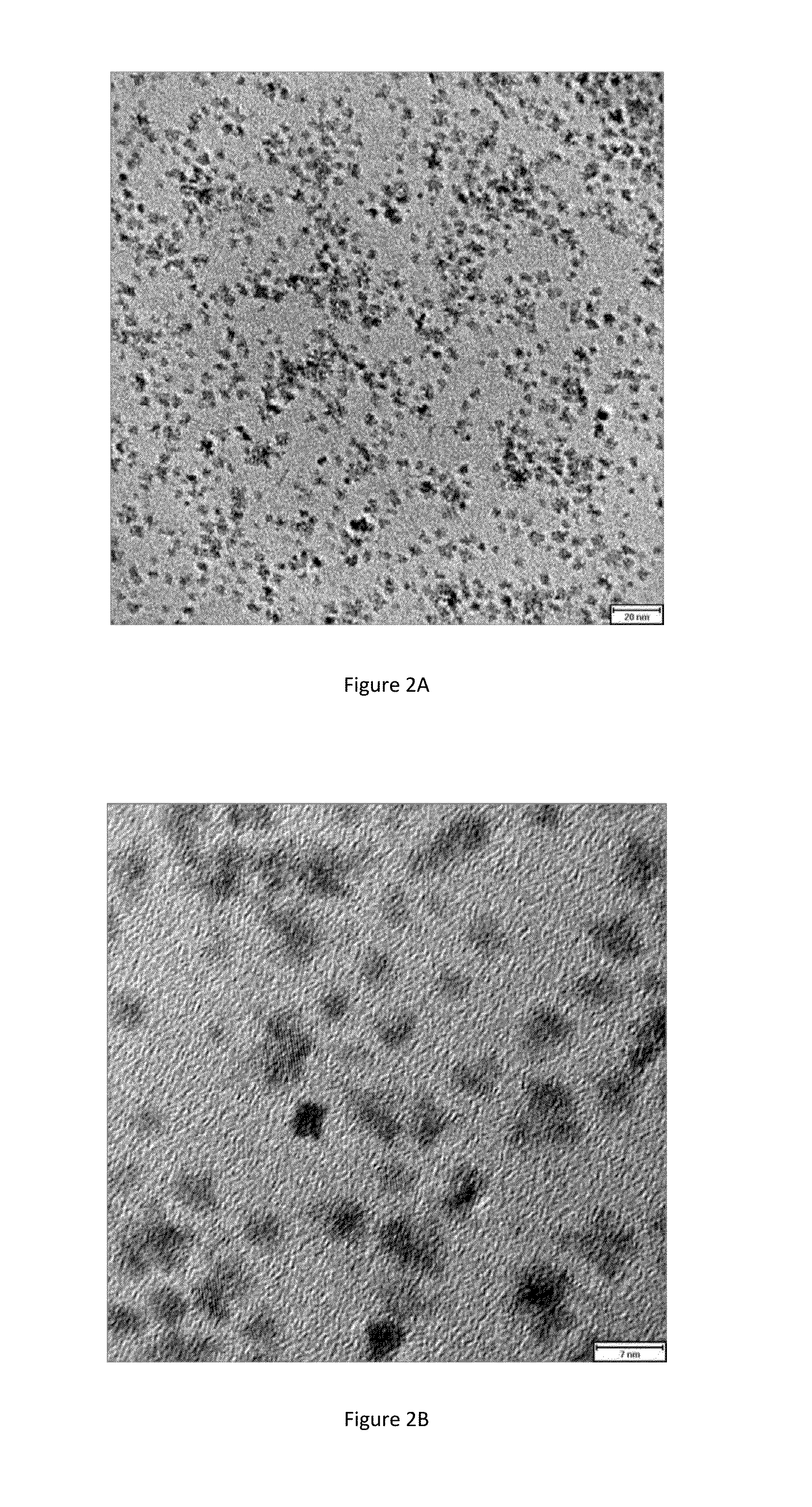

example 1

[0171]350.8 g of tin tetrachloride pentahydrate dissolved in 1 L of 2.5M diluted hydrochloric acid, and then 22.8 g of antimony trichloride was added under vigorous stirring to a solution of tin tetrachloride, maintaining the vigorous stirring to form a uniform suspension.

[0172]During the vigorous stirring, 1 L of 6M aqueous ammonia was added to the suspension, then keep at 60° C. for 20 min. The resulting pale yellow slurry was centrifuged and re-dispersed into 1.5 L of water, then centrifuged again, and repeated the above procedure until nearly no ionic impurities.

[0173]The resulted filter cake was re-dispersed in around 1 L of water, and transferred to a hydrothermal reactor with adding 100 ml of hydrogen peroxide. The slurry was heated to 250° C., and held for 8 hours.

[0174]When the hydrothermal reactor was cooled to room temperature, the dark blue slurry was centrifuged and washed by water, then centrifuged to obtain a cake.

[0175]The cake was re-dispersed to about 600 mL of wat...

example 2

[0186]Steps before the hydrothermal treatment and hydrothermal treatment conditions and procedures were the same to described in Example 1.

[0187]When hydrothermal reactor cooling down to room temperature, blue slurry was collected and centrifuged, then washed and dispersed in water, centrifuged again to obtain a cake.

[0188]The cake was re-dispersed to 1 L of methanol with 2.5 g of tetramethyl ammonium hydroxide and 500 mL of methanol containing 44.5 g of Titanate coupling agent (product name: NDZ-311) and stirred for 10 min. The slurry was centrifuged and sufficiently dispersed into 1 L of methanol and centrifuged again. The sediment was redispersed into 600 mL of butyl acetate, together with 7.5 g of another titanate coupling agent (product name: NDZ-109). The suspension was evaporated to dryness under reduced pressure to collect the dark blue powder.

[0189]The powder was re-dispersed into the butyl acetate to the solid content of ATO nano-particles (based on the weight of the dispe...

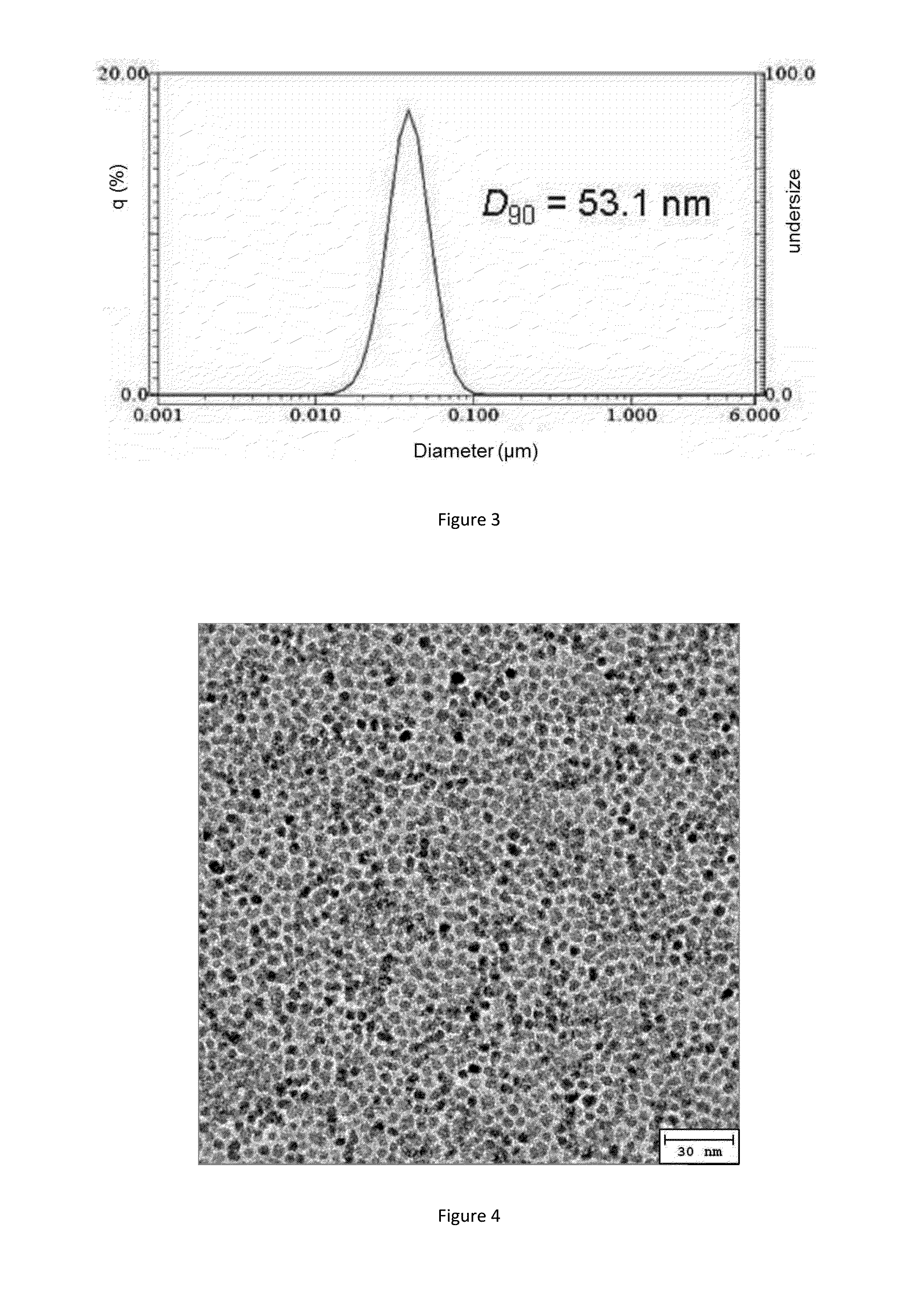

example 3

[0191]350.8 g of tin tetrachloride pentahydrate was dissolved in 1.5 L of methanol, then adding 22.8 g of antimony trichloride with stirring to a clear solution.

[0192]During the stirring, 1 L of 6M aqueous ammonia was added to the solution and maintained at 60° C. for 30 min.

[0193]The resulted pale yellow slurry was centrifuged and re-dispersed into 1.5 L of water, centrifuged again, repeated the above procedure until nearly no ionic impurities.

[0194]The resulted cake was re-dispersed into 1 L of water and transferred to hydrothermal reactor, with adding 100 mL of hydrogen peroxide. The slurry was heated to 290° C. and maintained for 8 hours.

[0195]When hydrothermal reactor cooling down to room temperature, the blue slurry was collected and centrifuged, then washed and dispersed with water, and centrifuged to obtain a dark blue cake.

[0196]The cake was re-dispersed into 600 mL of water, with 7.5 g of tetramethyl ammonium hydroxide and 300 mL of methanol solution containing 22.5 g of c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com