Preparation method of sodium pyroantimonate with reduced grain size

A technology of sodium pyroantimonate and particle size, applied in the field of flame retardant materials, can solve the problem of excessive particle size of sodium pyroantimonate, and achieve high yield, no three-waste pollution, and good comprehensive recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Add 50kg of antimony trioxide and 200L of pure water into a 500L reactor, stir and mix evenly, then add 70L of hydrogen peroxide (concentration: 30%), stir evenly, control the pH to 7, and heat up to 70°C for constant temperature reaction (oxidation reaction) 2 Hours, after the reaction is over, the temperature is raised to 90°C, and sodium hydroxide (dosage is 0.6 times that of antimony trioxide) and surfactant sodium lauryl sulfate (0.5Kg) are added while stirring, and the constant temperature reaction (90°C )

[0062] After 1.5 hours, after the reaction, the filter cake was ultrasonically dispersed (in a buffer solution with a pH of 8-9 for 30 minutes), then cooled and crystallized, washed with pure water until the washing liquid was neutral, centrifuged, the liquid was reused, and washed with water The solid product is then dried at 80-90°C to obtain sodium pyroantimonate.

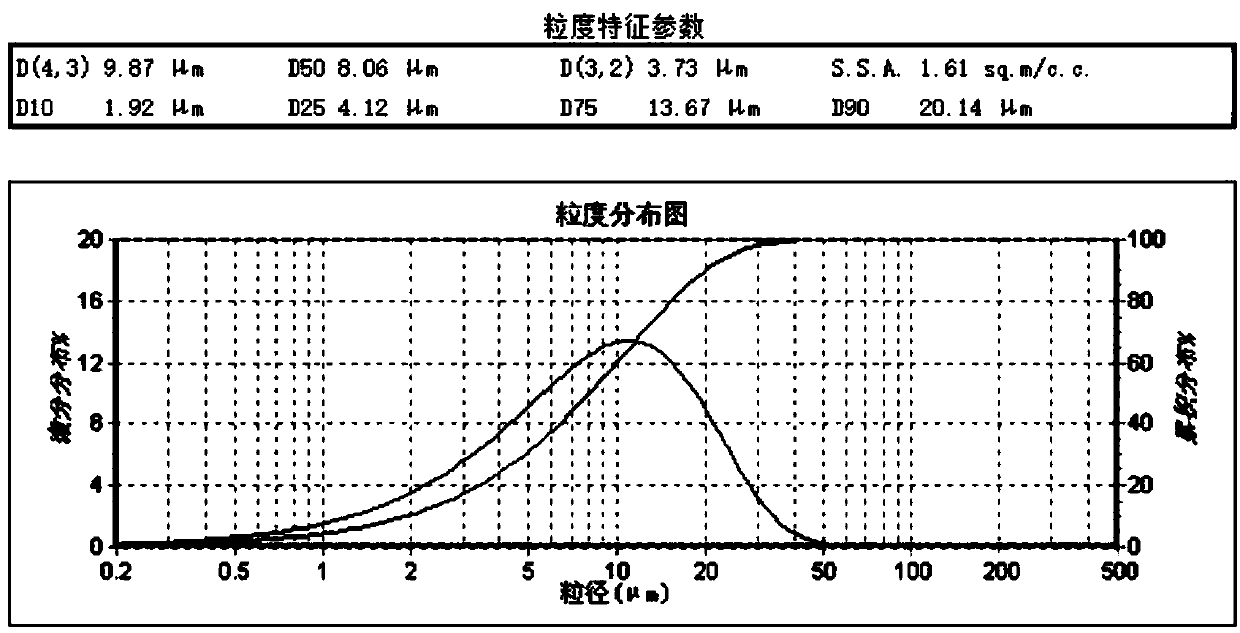

[0063] After testing, see the test results figure 1 , the particle size of sodium pyroanti...

Embodiment 2

[0065] Add 50kg of antimony trioxide and 200L of pure water into a 500L reactor, stir and mix well, then add 70L of hydrogen peroxide, stir well, adjust the pH to 13 with sodium hydroxide, heat up to 70°C and react at a constant temperature for 2 hours, after the reaction Raise the temperature to 90°C, add sodium hydroxide (0.6 times that of antimony trioxide) and surfactant sodium lauryl sulfate (0.5Kg) while stirring, and react at constant temperature for 1.5 hours. After the reaction, the filter cake is ultrasonically Dispersion (ultrasonic dispersion in a buffer solution with a pH of 8.0-9.0), cooling and crystallization, centrifugation, liquid reuse, washing the solid product with water, and drying at 80-90°C to obtain sodium pyroantimonate.

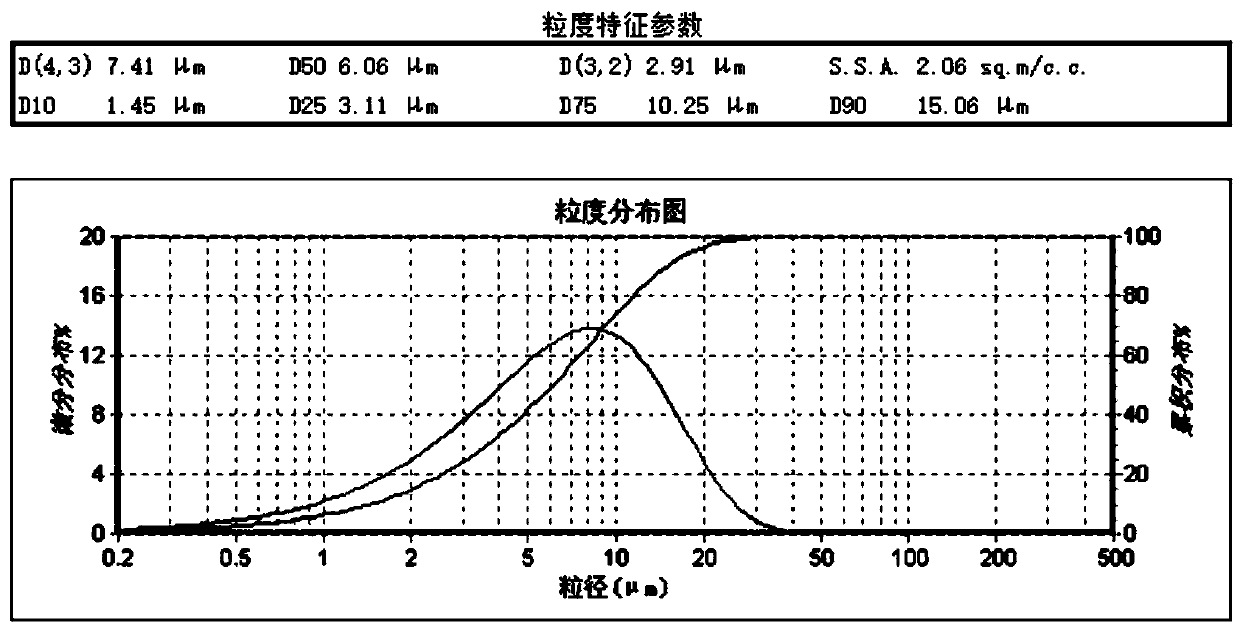

[0066] After testing, see the test results figure 2 , The particle size of sodium pyroantimonate is 6.06um, the whiteness is 78%, and the pH value is 7.32. (Note: The whiteness is tested by a whiteness tester, and the pH value is ...

Embodiment 3

[0068] Add 50kg of antimony trioxide and 200L of pure water into a 500L reactor, stir and mix well, then add 70L of hydrogen peroxide, stir evenly, adjust the pH to 2, raise the temperature to 70°C and react at a constant temperature for 2 hours, and then raise the temperature to 90°C after the reaction. Add sodium hydroxide (addition amount is 0.6 times of antimony trioxide) and surfactant sodium lauryl sulfate (0.5Kg) while stirring, constant temperature reaction 1.5 hours, after reaction finishes filter cake ultrasonic dispersion (in described Dispersed in the buffer solution), then cooled to crystallize, centrifuged, the liquid was reused, the solid product was washed with water and then dried at 80-90°C to obtain sodium pyroantimonate.

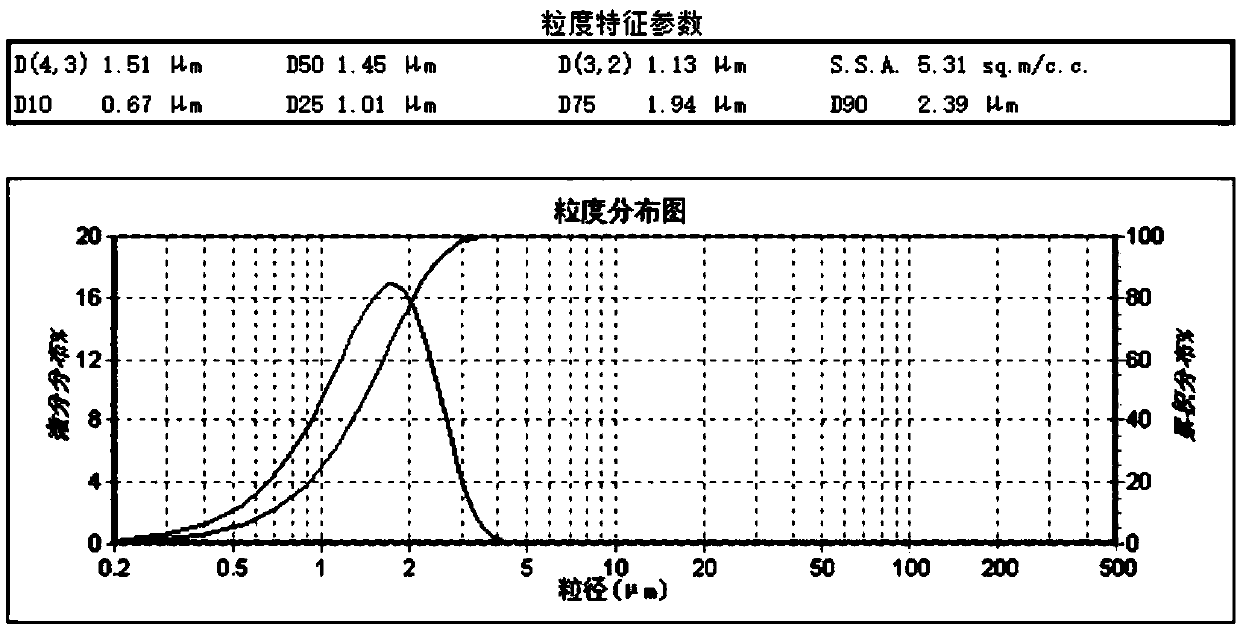

[0069] After testing, see the test results image 3 , the particle size of sodium pyroantimonate is 1.45um, the whiteness is 98%, and the pH value is 7.12. (Note: The whiteness is tested by a whiteness tester, and the pH value is tested ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com