Method for recovering antimony and solid arsenic from arsenic-containing crystal substance

A recovery method and crystallization technology, applied in the field of resource utilization of by-products in the production of non-ferrous metal chemicals, to achieve the effects of coarse grains, no pollution, and a simple synthesis process

Active Publication Date: 2022-05-31

CENT SOUTH UNIV

View PDF15 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

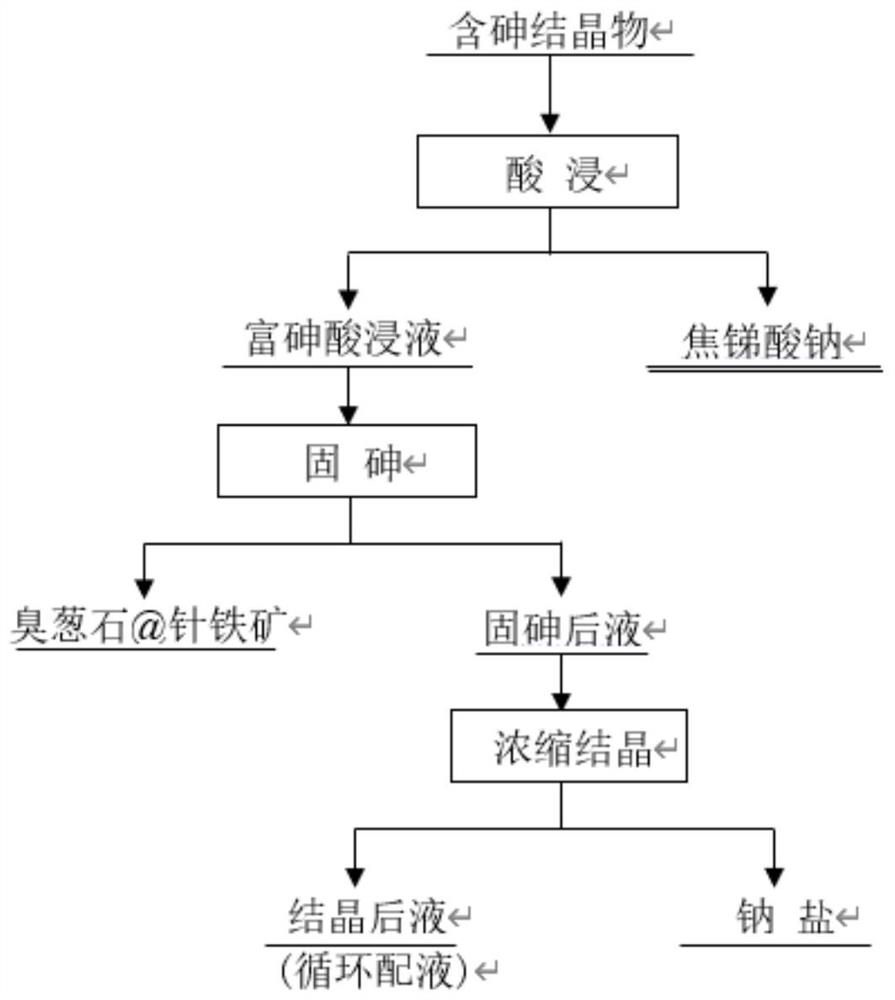

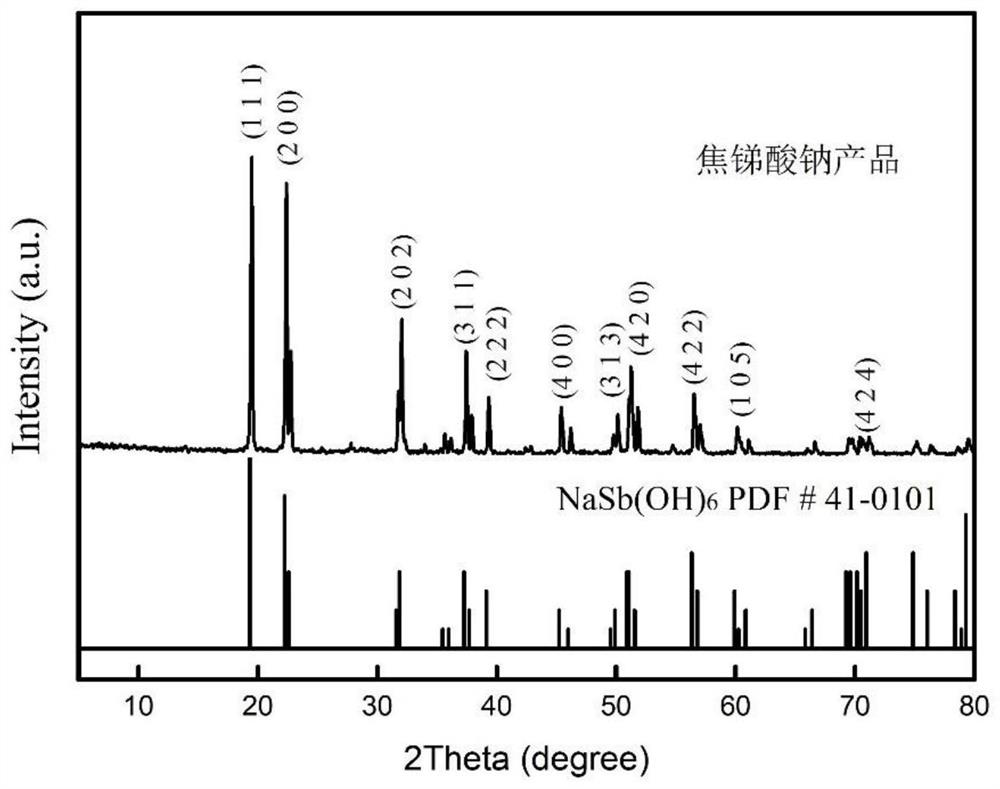

[0006] In order to solve the problems of antimony recovery in the existing arsenic-containing crystals, non-toxic and harmless high-arsenic solution and solution recycling, the first purpose of the present invention is to use dilute sulfuric acid solution to leach arsenic-containing crystals to dissolve sodium arsenate Generate arsenic acid (root) into the solution, and sodium pyroantimonate is insoluble in dilute sulfuric acid and remains in the precipitate to realize antimony recovery

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

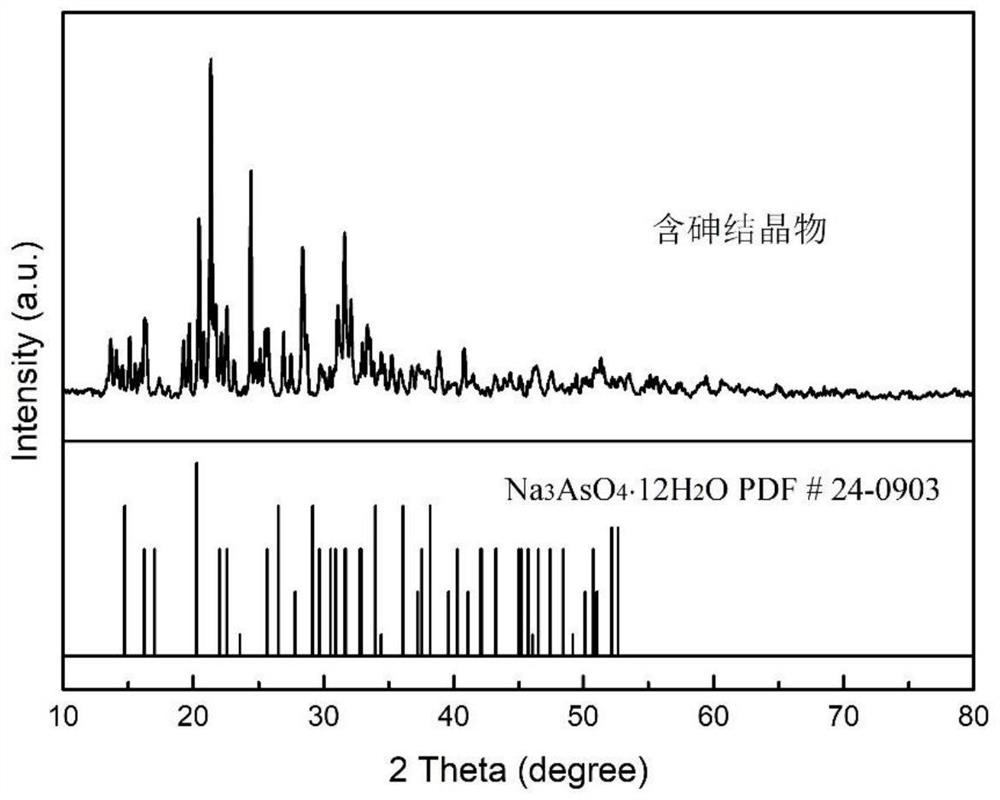

The invention discloses a method for recycling antimony through acid leaching of arsenic-containing crystal substances, fixing arsenic in arsenic-rich pickle liquor and recycling sodium salt through concentration and crystallization of liquor after arsenic fixing, and relates to the field of resource utilization of by-products in production of non-ferrous metal chemicals. According to the method, arsenic-containing crystal substances in sodium pyroantimonate production are leached through dilute sulphuric acid to obtain cubic crystal sodium pyroantimonate which meets the first-grade product of the Chinese nonferrous metal industry standard (YS / T 22-2010), and the technical problem of recycling antimony in the arsenic-containing crystal substances is solved. Ferrite is added into the arsenic-rich acid leaching solution, oxygen is introduced into the arsenic-rich acid leaching solution to synthesize the high-stability scorodite and goethite core-shell structure, the arsenic concentration in TCLP is lower than the specified value 5 mg / L of the national standard (GB5085.3-2007), and non-toxic and harmless arsenic in arsenic-containing non-ferrous metal resource utilization is achieved. And concentrating and crystallizing the arsenic-fixing liquid to recover the sodium salt, thereby completing the purification and regeneration of the solution and achieving the purpose of closed-loop cyclic utilization of the solution. The method has the advantages of simple operation, stable product components, high stability of the arsenic fixing material, good solution cycle performance and the like.

Description

A method for recovering antimony and solid arsenic from arsenic-containing crystals technical field The present invention relates to by-product resource utilization field in non-ferrous metal chemical production, be specifically related to a kind of from arsenic-containing Method for recovering antimony from crystals and synthesizing core-shell solid arsenic products. Background technique [0002] The abundance of arsenic in the earth's crust is 1.5 to 5 mg / kg, and more than 87% of it is associated or symbiotic with non-ferrous metal minerals. During the mining, beneficiation, smelting and product processing of metal mineral resources, the original mineral state is destroyed and released into the environment, causing great damage. ecological pressure. Arsenic enters the product in the smelting process and contains arsenic by-products [Hza B, Gla B, Lz C, et al. al.Strategies for arsenic pollutioncontrol from copper pyrometallurgy based on the study of arsenic source...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22B30/02C22B30/04C01G28/02C01G30/02C01G49/02

CPCC22B30/04C22B30/02C01G30/023C01G28/02C01G49/02C01P2002/72C01P2004/03C01P2004/80Y02P10/20

Inventor 唐攒浪唐新村刘好男肖泽裕

Owner CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com