High-temperature reaction furnace for producing sodium antimonate by sodium pyroantimonate dehydration

A technology of sodium antimonate and high-temperature reaction, which is applied in the direction of antimonate/antimonite, antimony compound, sustainable manufacturing/processing, etc., and can solve problems such as high labor intensity, inconvenient operation, and long production cycle. Achieve the effects of energy saving and environmental protection labor force, shortening production cycle and saving reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

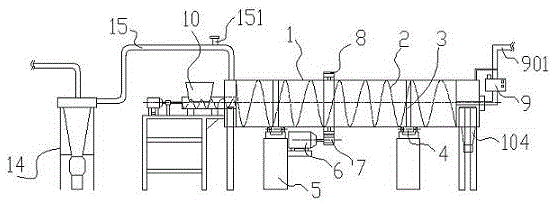

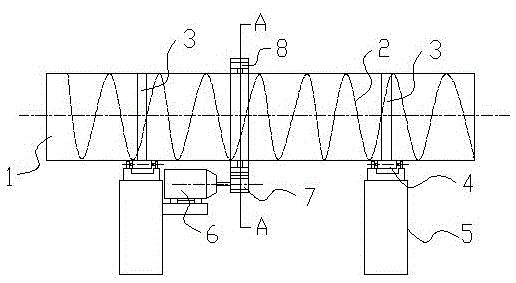

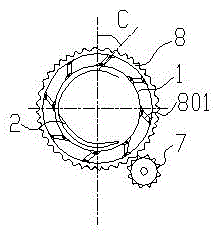

[0033] Such as Figure 1-Figure 6 Shown, the specific structure of the present invention is: a kind of high-temperature reaction furnace that utilizes sodium pyroantimonate dehydration to produce sodium metaantimonate, it comprises the furnace body 1 that can rotate horizontally and the feeding device that one side of furnace body 1 is provided with and tail gas The processing device and the ignition device provided on the other side of the furnace body; the furnace body 1 is erected on the furnace platform 5 through the roller ring 3 arranged on the outer periphery, and is in rolling contact with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com