Method for preparing metal oxidizing acid salt and said salt

A technology of antimony trioxide and hydrogen peroxide, applied in the field of multi-metal oxide materials of formula, can solve the problems such as incomplete selectivity of active acrylic acid and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

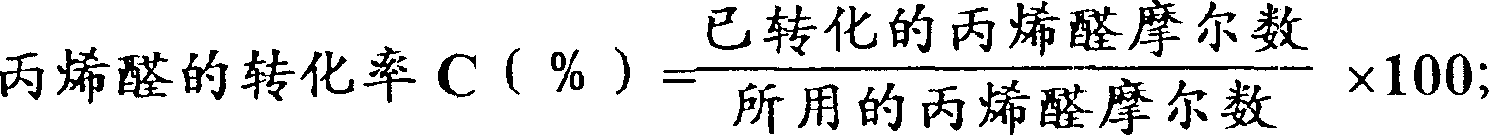

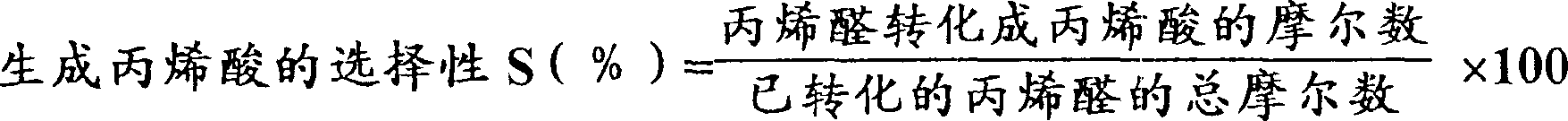

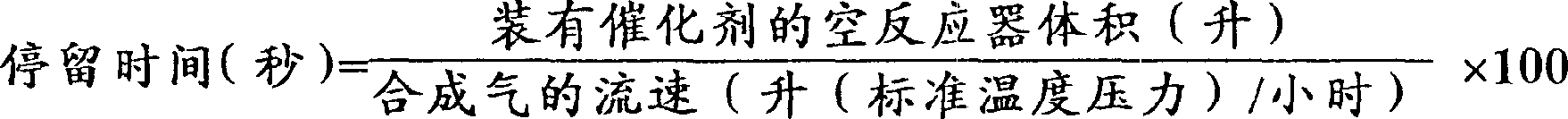

Method used

Image

Examples

Embodiment

[0049] I. Preparation of Catalyst

[0050] Example

[0051] a) Preparation of raw material 1

[0052] 946.0 grams of Sb with a Sb content of 83.0% (by weight) were mixed under stirring 2 o 3 Suspended in 4 liters of water. At room temperature (25°C), 822.4 grams of 30% (by weight) H 2 o 2 Aqueous solution was added. Thereafter, the suspension was heated to 100° C. within 1 hour, stirred further, and refluxed at this temperature for 5 hours. Then 595.6 grams of Cu(CH) with a Cu content of 32.0% by weight 3 COO) 2 ·H 2 A solution of O in 4 liters of water was added to the aqueous suspension at 100°C within 30 minutes and the temperature of the entire aqueous mixture dropped to 60°C. 407.9 g of a 25% strength by weight aqueous ammonia solution are then added at this temperature. Thereafter, the aqueous suspension was stirred for a further 2 hours at 80° C. and then cooled to room temperature (25° C.). Finally, the aqueous suspension was spray-dried (inlet temperature:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com