A preparation method for reducing the particle size of sodium pyroantimonate

A technology of sodium pyroantimonate and particle size, which is applied in the field of flame retardant materials, can solve the problem of excessive grain size of sodium pyroantimonate, and achieve the effects of no three wastes pollution, high yield and good comprehensive recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

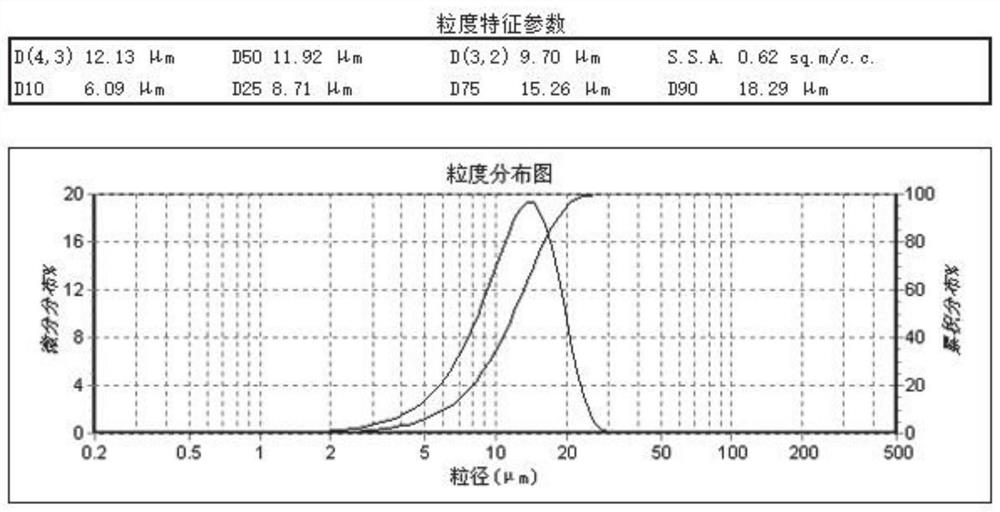

Embodiment 1

[0058] Step (1): Pre-reaction:

[0059] Add 50kg antimony trioxide and 100L pure water into a 500L reaction kettle, stir and mix well, then add 105L (potassium hydroxide solution, concentration is 4mol / L) potassium hydroxide (potassium hydroxide is 0.5% of the mass of antimony trioxide) times), stir evenly, heat up to 70°C and react at a constant temperature for 0.5 hours;

[0060] Step (2): Oxidation reaction:

[0061] Step (1) After the reaction is completed, the temperature is raised to 90 ° C, and (30%) hydrogen peroxide (0.8 times the mass of antimony trioxide) is added while stirring, and the reaction is carried out at a constant temperature for 0.5 hours;

[0062] Step (3): precipitation reaction: (precipitation temperature 90°C)

[0063] In the reaction system of step (2), add tartaric acid 50Kg (and the mass ratio of antimony trioxide is 1: 1, and the concentration of tartaric acid in the system is 100g / L) and sodium chloride 80Kg (and the quality of antimony trioxi...

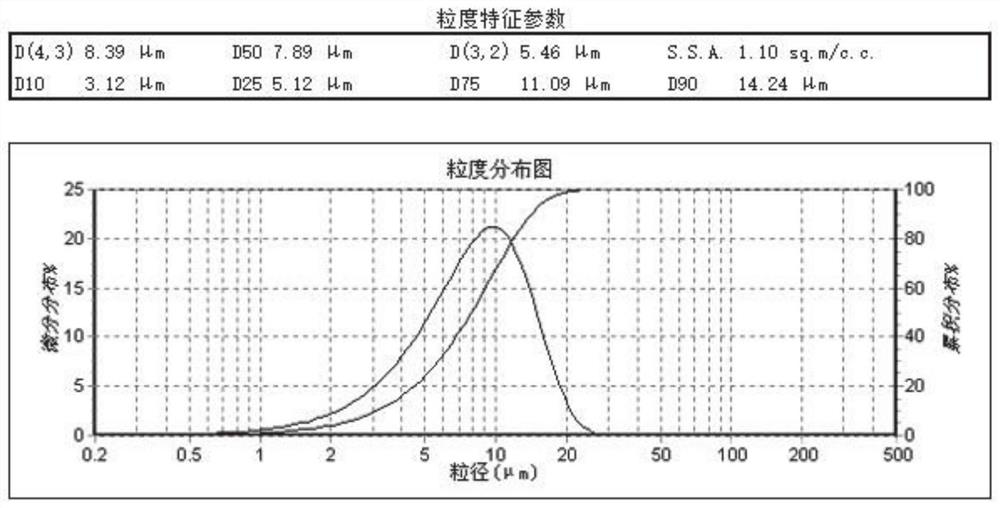

Embodiment 2

[0066] Step (1): Pre-reaction:

[0067] Add 50kg antimony trioxide and 100L pure water into a 500L reaction kettle, stir and mix well, then add 105L (potassium hydroxide solution, concentration is 4mol / L) potassium hydroxide (potassium hydroxide is 0.5% of the mass of antimony trioxide) times), stir evenly, heat up to 70°C and react at a constant temperature for 0.5 hours;

[0068] Step (2): Oxidation reaction:

[0069] Step (1) After the reaction is completed, the temperature is raised to 90°C, and 30% hydrogen peroxide (0.8 times that of antimony trioxide) is added while stirring, and the reaction is carried out at constant temperature for 0.5 hours;

[0070] Step (3): Precipitation reaction: (temperature 90°C)

[0071] In the reaction system of step (2), add tartaric acid 100Kg (and the mass ratio of antimony trioxide is 2: 1, and the concentration of tartaric acid in the system is 200g / L) and sodium chloride 80Kg (and the quality of antimony trioxide The ratio is 1.6:1,...

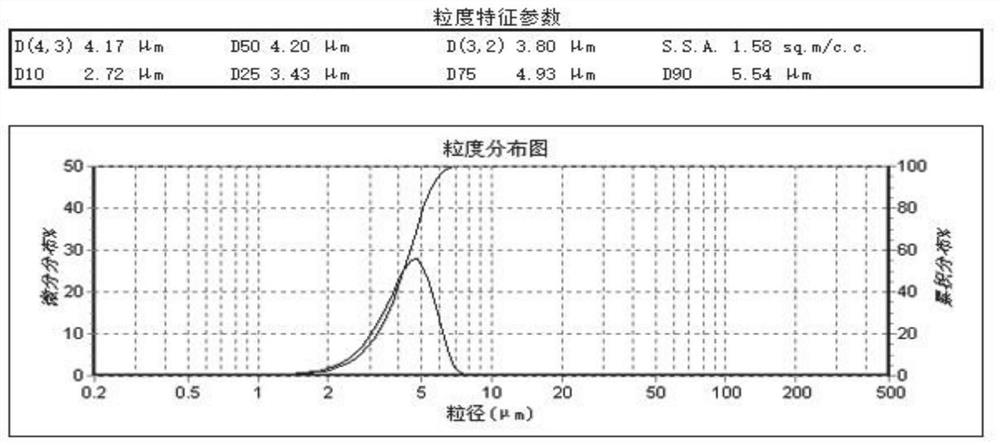

Embodiment 3

[0074] Step (1): Pre-reaction:

[0075] Add 50kg antimony trioxide and 100L pure water into a 500L reactor, stir and mix well, then add 105L potassium hydroxide (potassium hydroxide solution, concentration is 4mol / L) (potassium hydroxide is 0.5% of the mass of antimony trioxide times), stir evenly, heat up to 70°C and react at a constant temperature for 0.5 hours;

[0076] Step (2): Oxidation reaction:

[0077] Step (1) After the reaction is completed, the temperature is raised to 90°C, and 30% hydrogen peroxide (potassium hydroxide is 0.8 times the mass of antimony trioxide) is added while stirring, and the reaction is carried out at constant temperature for 0.5 hours;

[0078] Step (3): Precipitation reaction: (temperature 90°C)

[0079] In the reaction system of step (2), add tartaric acid 200Kg (the mass ratio of tartaric acid and antimony trioxide is 4: 1, and concentration is 400g / L) and sodium chloride 80Kg (and the mass ratio of antimony trioxide is 1.6: 1. The conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com