Method for preparing sodium pyroantimonate and regenerating and recycling mother liquor

A technology of sodium pyroantimonate and mother liquor, applied in chemical instruments and methods, antimonate/antimonite, antimony compounds, etc., can solve the problem of accumulation of impurity ions, limited cycle times, insufficient product quality of sodium pyroantimonate, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

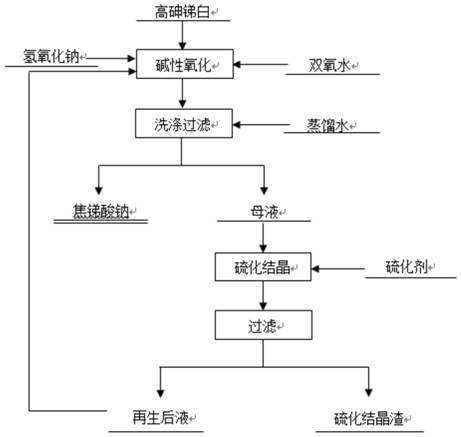

Method used

Image

Examples

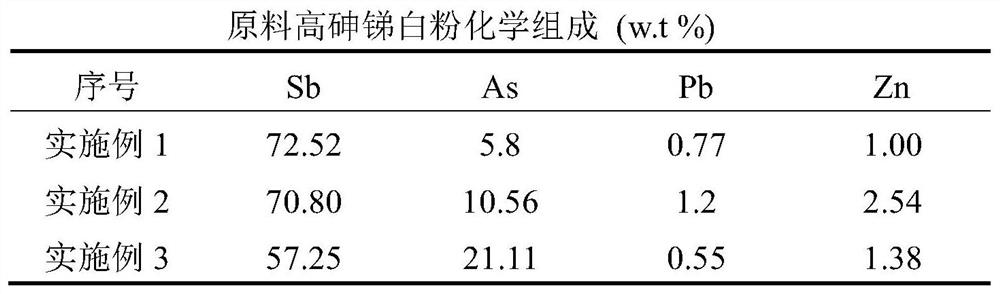

Embodiment 1

[0044] Measure 450mL of distilled water into the reaction kettle, then add 150g of high-arsenic antimony white according to the mass ratio of high-arsenic antimony white to distilled water at 1:3, and add sodium hydroxide at the mass ratio of sodium hydroxide to high-arsenic antimony white at 1:1 After slurrying, turn on the temperature rise switch of the reaction kettle at the same time, after the temperature of the solution in the kettle rises to 75°C, according to the theoretical requirements of the oxidation of As(III) and Sb(III) in high arsenic antimony white to sodium arsenate and sodium pyroantimonate Take hydrogen peroxide that is 1.2 times the amount of hydrogen peroxide and add it at a rate of 3 mL / min, and keep warm for 1 hour after the addition is complete. Then centrifuge and filter while it is hot, and add hot distilled water to wash according to the mass ratio of hot distilled water and high-arsenic antimony white at 1:2. After filtering the sodium pyroantimonat...

Embodiment 2

[0046] Measure 750mL of distilled water into the reaction kettle, then add 150g of high-arsenic antimony white according to the mass ratio of high-arsenic antimony white to distilled water at 1:5, and add sodium hydroxide at the mass ratio of sodium hydroxide to high-arsenic antimony white at 2:1 After slurrying, turn on the temperature rise switch of the reaction kettle at the same time, after the temperature of the solution in the kettle rises to 60°C, start to oxidize As(III) and Sb(III) into sodium arsenate and sodium pyroantimonate according to the theory of high arsenic antimony white Take 1.4 times the amount of hydrogen peroxide required to take hydrogen peroxide and add it at 4mL / min, and keep warm for 2 hours after the addition is complete. Then vacuum filter while it is hot, and add hot distilled water to wash according to the mass ratio of hot distilled water and high-arsenic antimony white at 3:7. After the sodium pyroantimonate product is filtered, transfer it to ...

Embodiment 3

[0048] Measure 900mL of distilled water into the reaction kettle, then add 150g of high-arsenic antimony white according to the mass ratio of high-arsenic antimony white to distilled water at 6:1, and add sodium hydroxide at the mass ratio of sodium hydroxide to high-arsenic antimony white at 3:1 After slurrying, turn on the temperature rise switch of the reaction kettle at the same time, after the temperature of the solution in the kettle rises to 70°C, start to oxidize As(III) and Sb(III) into sodium arsenate and sodium pyroantimonate according to the theory of high arsenic antimony white Take hydrogen peroxide that is twice the amount of hydrogen peroxide required and add it at a rate of 6 mL / min. After the addition is complete, keep warm for 3 hours. Then vacuum filter while it is hot, and add hot distilled water to wash according to the mass ratio of hot distilled water and high-arsenic antimony white at 3:4. After filtering the sodium pyroantimonate product, transfer it t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com