Preparation method of nano-cu@cuo material and its application in lithium-ion battery

A nano and copper nano technology is applied in the fields of energy materials and electrochemistry to achieve the effects of simple preparation method and equipment, abundant raw materials and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

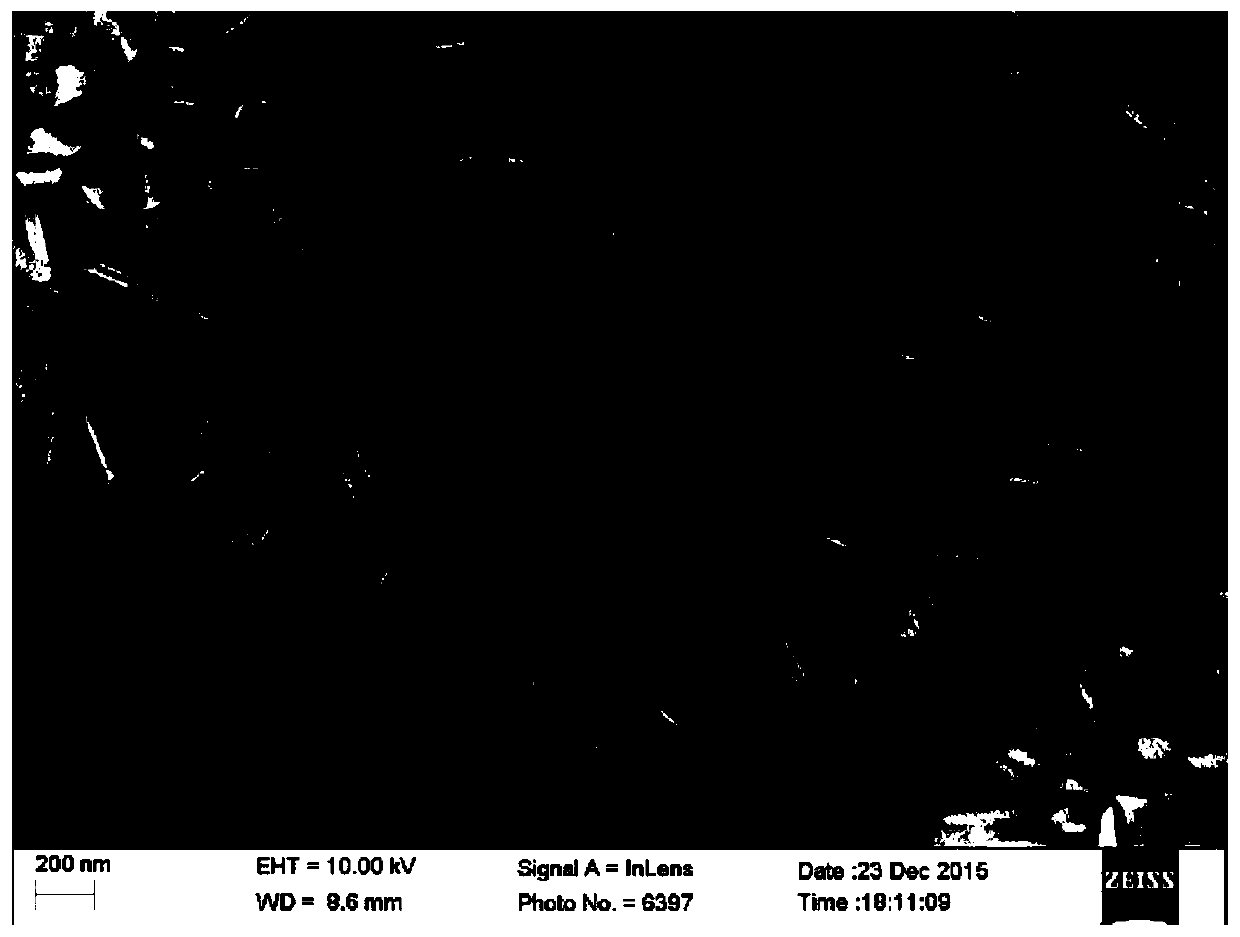

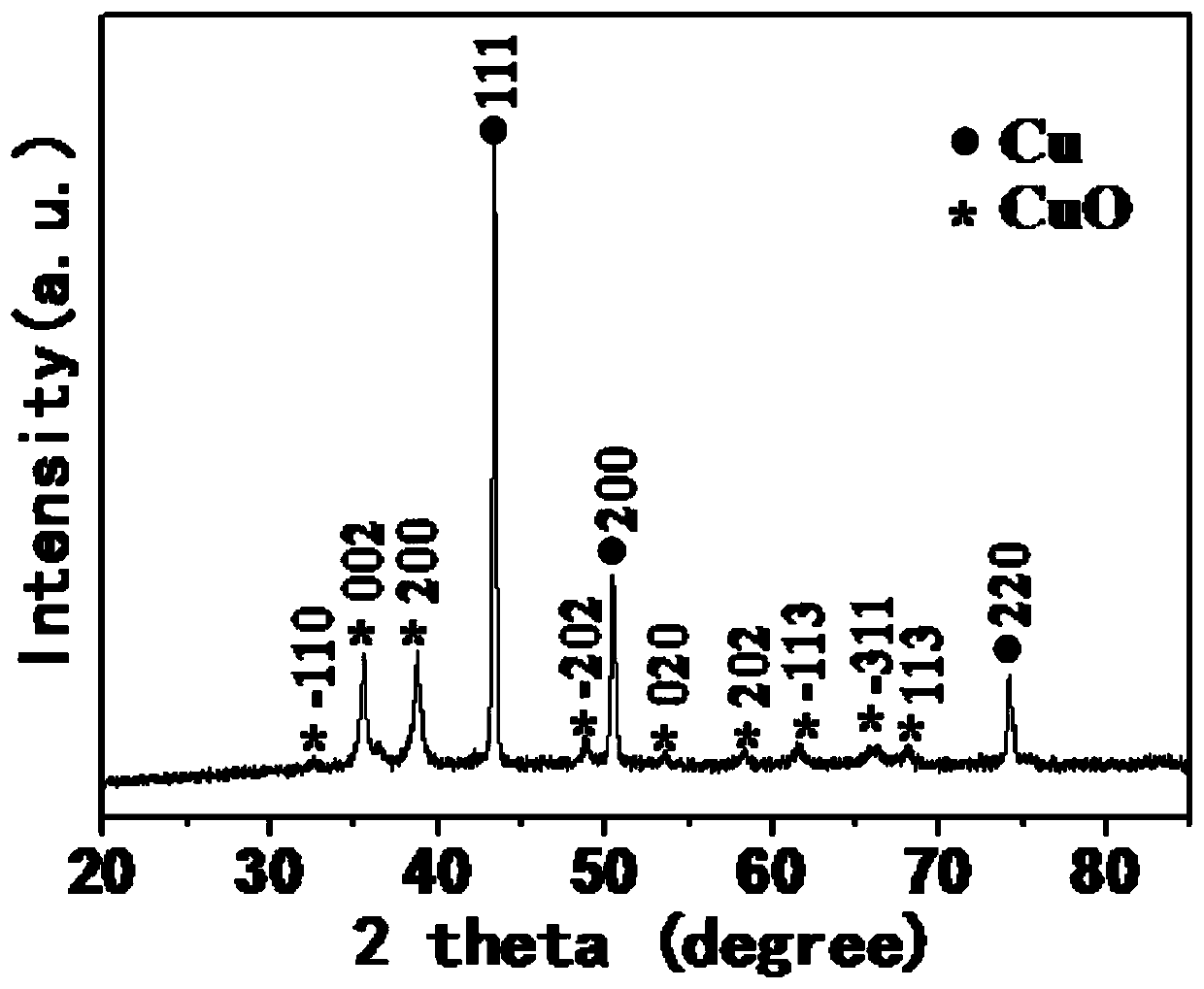

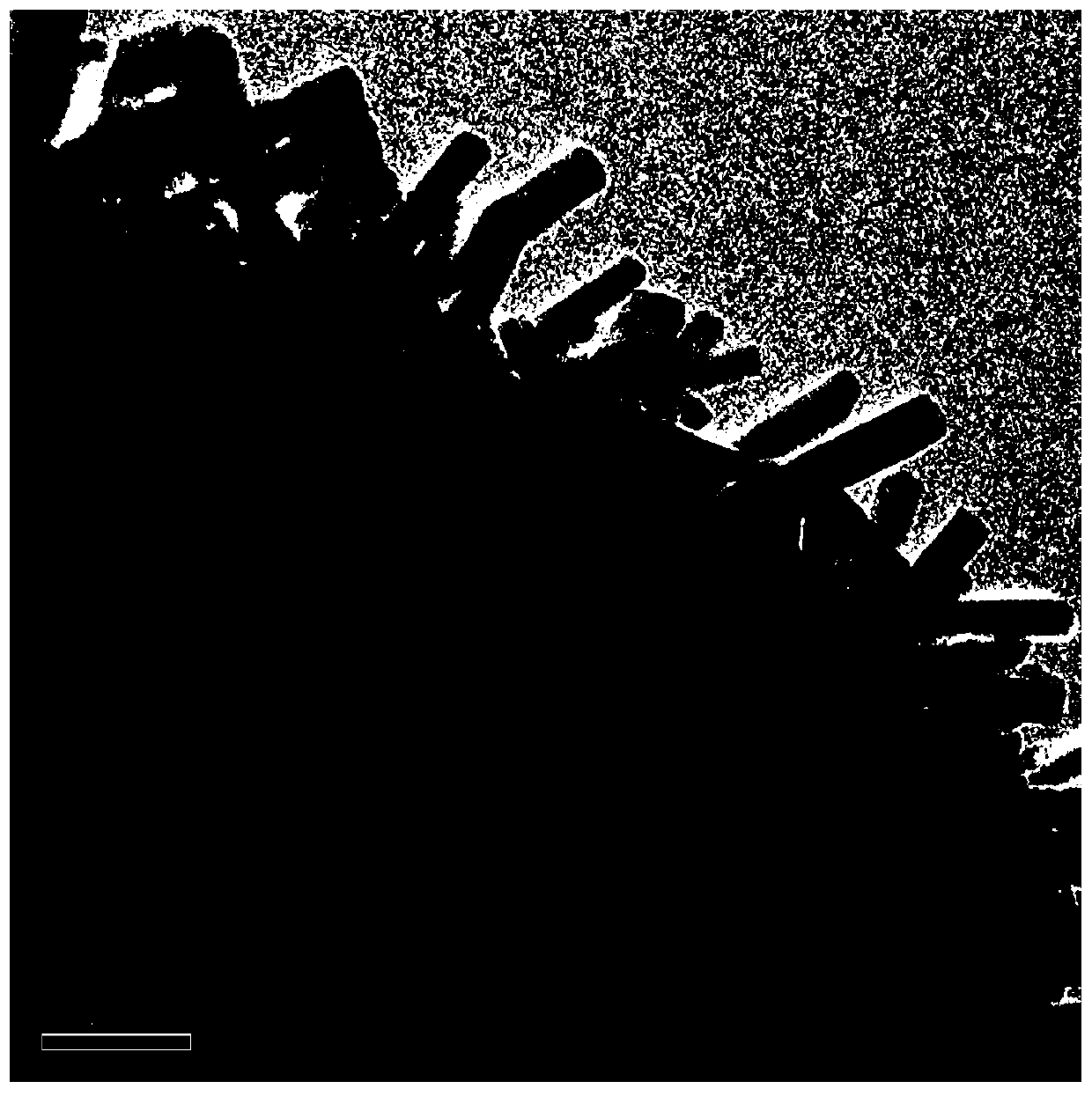

[0028] Stir 0.4 g of glucose, 0.2 g of polyvinylpyrrolidone, and 15 mL of deionized water at room temperature for 4 h to obtain a clear mixture. Add 0.8mmoL of copper sulfate solution to it, stir for 1h, transfer to a hydrothermal reaction kettle and react at 160°C for 4h, centrifuge the product, wash it three times with deionized water and absolute ethanol successively, and put the obtained product in a vacuum drying oven dry to obtain copper nanosheets. 0.025g of copper nanosheets, 10g of water, 0.16g of sodium hydroxide, and 0.16g of 30% hydrogen peroxide were placed in a reaction kettle and stirred for 1min, and kept in an oven at 110°C for 6h. The obtained product was centrifuged, washed with deionized water and absolute ethanol in sequence, and vacuum-dried at 50°C to obtain nano-Cu@CuO material powder.

[0029] The prepared 75 wt.% nano-Cu@CuO material, 15 wt.% acetylene black and 10 wt.% PVDF were mixed evenly to make a slurry, which was evenly coated on the copper fo...

Embodiment 2

[0031] Stir 1 g of glucose, 0.6 g of polyvinylpyrrolidone and 20 mL of deionized water at room temperature for 4 h to obtain a clear mixture. Add 1mmoL of copper sulfate solution to it, stir for 1h, transfer to a hydrothermal reaction kettle and react for 3h at 170°C, centrifuge the product, wash it three times with deionized water and absolute ethanol successively, and put the obtained product in a vacuum drying oven Dry to obtain copper nanosheets. 0.03g of copper nanosheets, 6g of water, 0.2g of sodium hydroxide, and 0.3g of 30% hydrogen peroxide were placed in a reaction kettle and stirred for 1min, and kept in an oven at 110°C for 8h. The obtained product was centrifuged, washed with deionized water and absolute ethanol in sequence, and vacuum-dried at 50°C to obtain nano-Cu@CuO material powder.

[0032] The prepared 75 wt.% nano-Cu@CuO material, 15 wt.% acetylene black and 10 wt.% PVDF were mixed evenly to make a slurry, which was evenly coated on the copper foil, and t...

Embodiment 3

[0034]1.5 g of glucose, 1 g of polyvinylpyrrolidone and 45 mL of deionized water were stirred at room temperature for 4 h to obtain a clear mixture. Add 1.8mmoL of copper sulfate solution to it, stir for 1h, then transfer to a hydrothermal reaction kettle and react for 4.5h at 180°C. The product is centrifuged, washed three times with deionized water and absolute ethanol successively, and the obtained product is dried in vacuum. Dry in an oven to obtain copper nanosheets. 0.04g of copper nanosheets, 10g of water, 0.3g of sodium hydroxide, and 0.5g of 30% hydrogen peroxide were placed in a reaction kettle and stirred for 3 minutes, and kept in an oven at 110°C for 12 hours. The obtained product was centrifuged, washed with deionized water and absolute ethanol in sequence, and vacuum-dried at 60°C to obtain nano-Cu@CuO material powder.

[0035] The prepared 75 wt.% nano-Cu@CuO material, 15 wt.% acetylene black and 10 wt.% PVDF were mixed evenly to make a slurry, which was evenl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com