A kind of deintercalation type vanadium-based negative electrode material and preparation method thereof

A negative electrode material, vanadium-based technology, applied in the field of deintercalated vanadium-based negative electrode materials and its preparation, can solve the problems of lack of lithium resource reserves, high cost of lithium-ion batteries, and inapplicability of large-scale energy storage, etc., to achieve stable cycle The effect of performance, low cost, and good rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

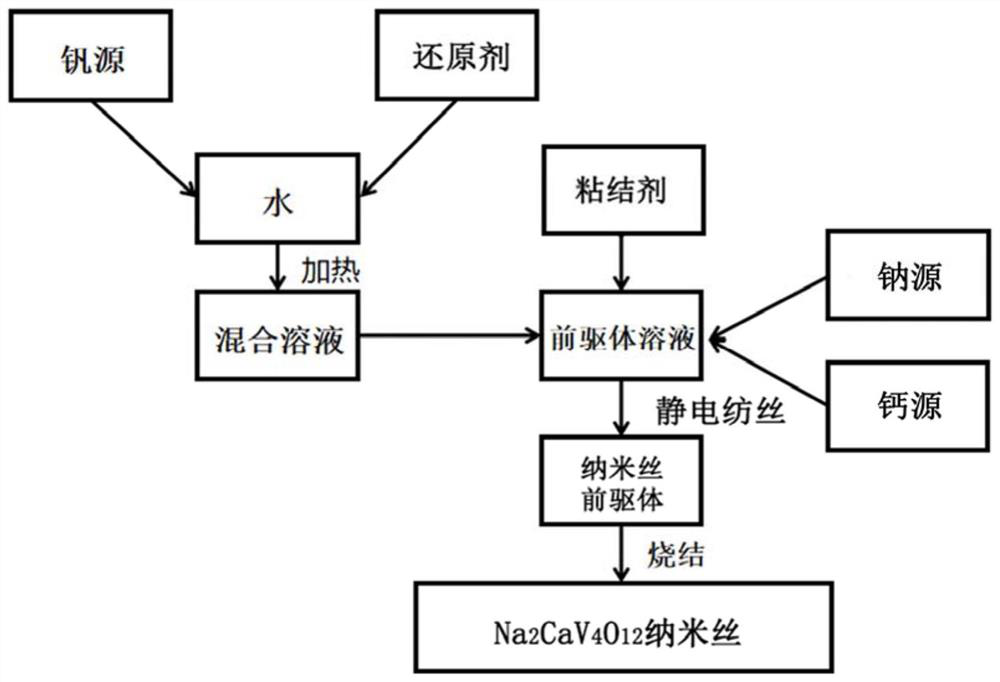

[0053] S1: 0.00125 mol sodium acetate, 0.000625 mol calcium acetate, 0.0025 mol ammonium metavanadate, 0.6 g ascorbic acid, 10 mL water were uniformly mixed and heated to 60°C to form a mixed solution;

[0054] S2: Add 1 g of PVP to the mixed solution obtained in S1, and stir for 30 min to obtain a viscous liquid;

[0055] S3: The viscous liquid obtained in S2 was electrospun under the conditions of a voltage of 20 kV applied to the needle, a distance between the needle and the collector of 15 cm, and a liquid discharge rate of 1.5 mL / h to obtain a nanofilament precursor;

[0056] S4: The nanofilament precursor obtained in S3 was sintered at 430 °C for 6 h to obtain Na 2 CaV 4 o 12 nanowires.

[0057] Electrode materials were prepared by electrospinning, and Examples 2-15 are shown in Table 1.

[0058] Table 1

[0059]

[0060]

Embodiment 16

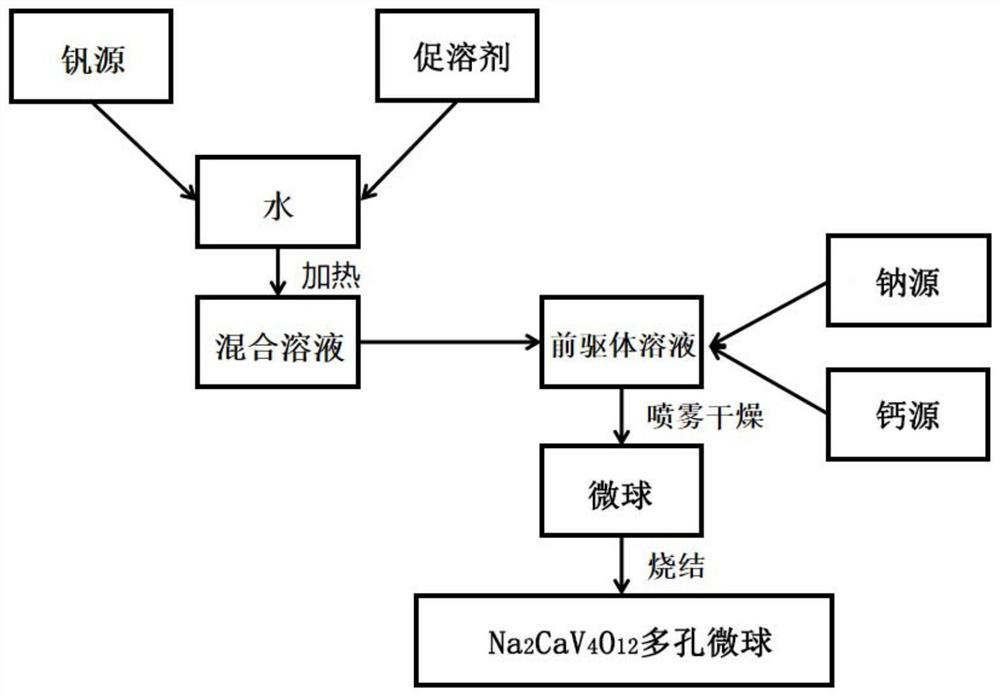

[0062] S5: Mix 0.0025 mol ammonium metavanadate and 100 mL water to obtain a suspension, stir and heat the suspension to 60°C to form a clear vanadium solution;

[0063] S6: Add 0.00125 mol sodium acetate, 0.000625 mol calcium acetate, and 0.3 g acetic acid to the vanadium solution obtained in S5, and stir to obtain a clear precursor solution;

[0064] S7: Spray-dry the precursor solution obtained in S6 under the conditions of an inlet temperature of 180°C, an outlet temperature of 100°C, and a liquid inlet rate of 300 mL / h to obtain microspheres;

[0065] S8: The microspheres obtained in S7 were sintered at 430°C for 10 h to obtain Na 2 CaV 4 o 12 porous microspheres.

[0066] Electrode materials were prepared by spray drying method, Examples 17-35 are shown in Table 2.

[0067] Table 2

[0068]

[0069]

[0070] image 3 Na prepared by the method described in Example 1 and Example 16 2 CaV 4 o 12 The XRD pattern of the analysis shows that the Na prepared by el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com