Processing technology of safe and environment-friendly PVC (polyvinyl chloride) plastic floor

A plastic flooring, safety and environmental protection technology, applied in the field of plastic flooring, can solve the problems of negative effect on product performance, poor flame retardant effect, etc., achieve the effect of reducing the amount of addition, improving comprehensive performance and market competitiveness, and ensuring mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

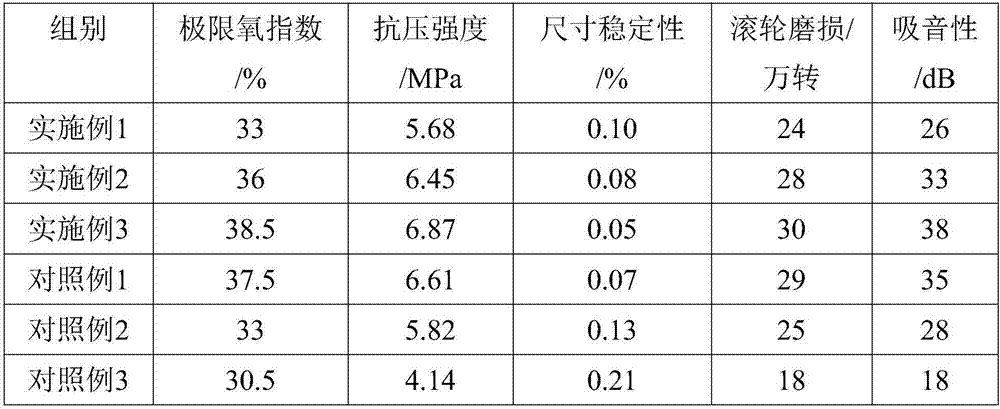

Examples

Embodiment 1

[0027] (1) Preparation of nano-powder filler: 50 parts of PVC powder, 25 parts of aluminum-magnesium hydrotalcite powder, 3 parts of trimethylolpropane triglycidyl ether, and 1.5 parts of hexamethylolmelamine hexamethyl ether are fully mixed and used Microwave treatment with a microwave processor for 10 minutes, then ultrasonic treatment with an ultrasonic processor at 55-60°C for 3 hours, and microwave treatment for 10 minutes again, and natural cooling to room temperature to obtain nano-powder fillers;

[0028] (2) Preparation of organically modified sericite powder: Add 35-40°C deionized water dropwise to 10 parts of N-methylolacrylamide and 2 parts of polyethylene glycol 400 under stirring until completely dissolved, then add 25 parts Sericite powder and 0.05 part of ammonium persulfate, after fully mixing, use a microwave processor for microwave reflux treatment for 5 minutes, continue to microwave reflux treatment for 5 minutes after standing for 5 minutes, and then micro...

Embodiment 2

[0033] (1) Preparation of nano-powder filler: 50 parts of PVC powder, 25 parts of aluminum-magnesium hydrotalcite powder, 3 parts of trimethylolpropane triglycidyl ether, and 1.5 parts of hexamethylolmelamine hexamethyl ether are fully mixed and used Microwave treatment with a microwave processor for 10 minutes, then ultrasonic treatment with an ultrasonic processor at 55-60°C for 3 hours, and microwave treatment for 10 minutes again, and natural cooling to room temperature to obtain nano-powder fillers;

[0034](2) Preparation of organically modified sericite powder: Add 35-40°C deionized water dropwise to 10 parts of N-methylolacrylamide and 2 parts of polyethylene glycol 400 under stirring until completely dissolved, then add 25 parts Sericite powder and 0.05 part of ammonium persulfate, after fully mixing, use a microwave processor for microwave reflux treatment for 5 minutes, continue to microwave reflux treatment for 5 minutes after standing for 5 minutes, and then microw...

Embodiment 3

[0040] (1) Preparation of nano-powder filler: 50 parts of PVC powder, 25 parts of aluminum-magnesium hydrotalcite powder, 3 parts of trimethylolpropane triglycidyl ether, and 1.5 parts of hexamethylolmelamine hexamethyl ether are fully mixed and used Microwave treatment with a microwave processor for 10 minutes, then ultrasonic treatment with an ultrasonic processor at 55-60°C for 3 hours, and microwave treatment for 10 minutes again, and natural cooling to room temperature to obtain nano-powder fillers;

[0041] (2) Preparation of organically modified sericite powder: Add 35-40°C deionized water dropwise to 10 parts of N-methylolacrylamide and 2 parts of polyethylene glycol 400 under stirring until completely dissolved, then add 25 parts Sericite powder and 0.05 part of ammonium persulfate, after fully mixing, use a microwave processor for microwave reflux treatment for 5 minutes, continue to microwave reflux treatment for 5 minutes after standing for 5 minutes, and then micro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com