Composite slow-release scale inhibitor

A scale inhibitor and slow-release technology, applied in the field of scale inhibitor, can solve the problems of poor scale inhibitor effect, too fast digestion of scale inhibitor, good anti-hydrolysis performance, etc. Good hydrolysis performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

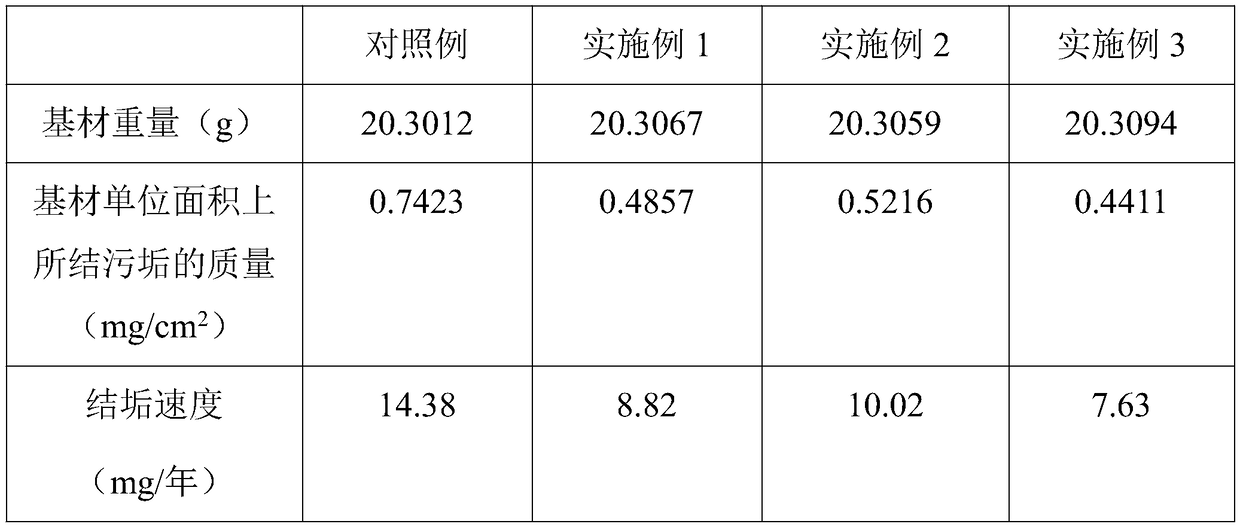

Examples

Embodiment 1

[0022] A composite slow-release antiscalant, according to parts by weight, including the following raw materials:

[0023] 23 parts of polyepoxysuccinic acid, 14 parts of polyacrylic acid, 8 parts of hydrolyzed maleic anhydride, 13 parts of modified chitosan, 5 parts of sodium gluconate, 2 parts of lauryl monoethanolamine and 28 parts of water.

[0024] The degree of substitution of the modified chitosan is 70%, and its preparation method comprises the following steps:

[0025] 1) Dissolving chitosan in a mass concentration of 5% malonic acid aqueous solution is prepared into chitosan malonic acid aqueous solution;

[0026] 2) Heat chitosan-malonic acid aqueous solution to 60°C in a water bath, while stirring for 30 minutes;

[0027] 3) adding dimethylaminoethyl acrylate to the chitosan malonic acid aqueous solution in step 2), after reacting for 6 hours, cooling to room temperature to obtain the reaction product;

[0028] 4) Recrystallize the reaction product, and then dry ...

Embodiment 2

[0031] A composite slow-release antiscalant, according to parts by weight, including the following raw materials:

[0032] 20 parts of polyepoxysuccinic acid, 12 parts of polyacrylic acid, 10 parts of hydrolyzed maleic anhydride, 10 parts of modified chitosan, 6 parts of sodium gluconate, 1 part of fatty alcohol polyoxyethylene ether and 30 parts of water.

[0033] The degree of substitution of modified chitosan is 85%, and its preparation method comprises the following steps:

[0034] 1) dissolving chitosan in a mass concentration of 8% malonic acid aqueous solution is prepared into chitosan malonic acid aqueous solution;

[0035] 2) Heat chitosan-malonic acid aqueous solution in a water bath to 70°C while stirring for 20 minutes;

[0036] 3) adding dimethylaminoethyl acrylate to the chitosan malonate aqueous solution in step 2), after reacting for 3h, cooling to room temperature to obtain the reaction product;

[0037] 4) Recrystallize the reaction product, and then dry th...

Embodiment 3

[0040] A composite slow-release antiscalant, according to parts by weight, including the following raw materials:

[0041] 25 parts of polyepoxysuccinic acid, 16 parts of polyacrylic acid, 6 parts of hydrolyzed maleic anhydride, 15 parts of modified chitosan, 3 parts of sodium gluconate, 3 parts of lauryl glucoside and 25 parts of water.

[0042] The degree of substitution of modified chitosan is 60%, and its preparation method comprises the following steps:

[0043] 1) Dissolving chitosan in a mass concentration of 3% malonic acid aqueous solution is prepared into chitosan malonic acid aqueous solution;

[0044] 2) Heat chitosan-malonic acid aqueous solution in a water bath to 62°C while stirring for 28 minutes;

[0045] 3) adding dimethylaminoethyl acrylate to the chitosan malonate aqueous solution in step 2), after reacting for 3.6h, cooling to room temperature to obtain the reaction product;

[0046] 4) Recrystallize the reaction product, and then dry the crystallized pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com