Ternary neterogeny structural light degradation organic matter catalyst TiO2-Bi2MoO6/Bi3.64Mo0.36O6.55 and preparation method thereof

A 5%tio2-bi2moo6, heterostructure technology, applied in catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the limitation of industrial application development of nano-TiO2, Low utilization efficiency and other problems, to achieve the effects of low production cost, high yield and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Synthesis of catalyst material of the present invention:

[0015] First disperse 5 mmol of bismuth nitrate evenly into 15 ml of deionized water, then slowly add 10 ml of 0.25 mol / L ammonium molybdate solution into the above aqueous solution, and stir evenly to obtain A solution. Add 0.125 mmol of butyl titanate to 10 ml of ethanol, and stir well to obtain solution B. Then slowly pour B solution into A, stir at room temperature for 30 minutes, add 5 mol / L sodium hydroxide solution, adjust the pH value of the solution to 7.5, and put the above solution into a 100 ml polytetrafluoroethylene reaction kettle , and then placed in a 150°C muffle furnace for calcination for 5 hours. The calcined sample was filtered and washed several times, and then placed in a muffle furnace for calcination at 300° C. for 5 hours to obtain the target catalyst.

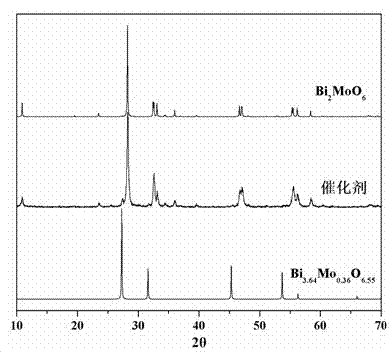

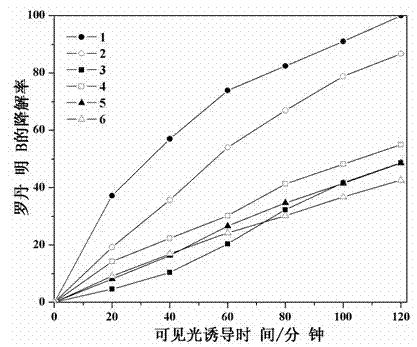

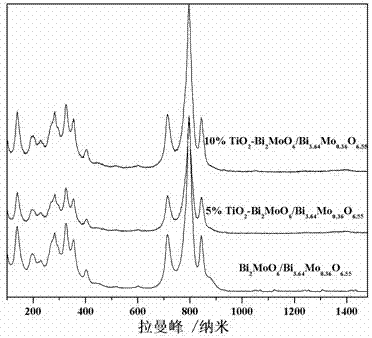

[0016] Such as figure 1 , figure 2 , image 3 Shown, show through X-ray powder diffraction test, the diffractogram of catalyst ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com