Hydrolyzation tolerant sulfonated polyimide proton exchange membrane and preparation thereof

A sulfonated polyimide, proton exchange membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as loss of proton exchange membrane proton conductivity

Inactive Publication Date: 2010-08-11

SHANGHAI INST OF TECH

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the sulfonic acid-substituted benzene ring in the molecular structure of traditional polyimide proton exchange membranes is directly connected to the imide bond. The amine bond group undergoes ring-opening degradation in the acidic working environment of the proton exchange membrane, thereby losing the proton conductivity of the proton exchange membrane

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation Embodiment 1

preparation Embodiment 2

preparation Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

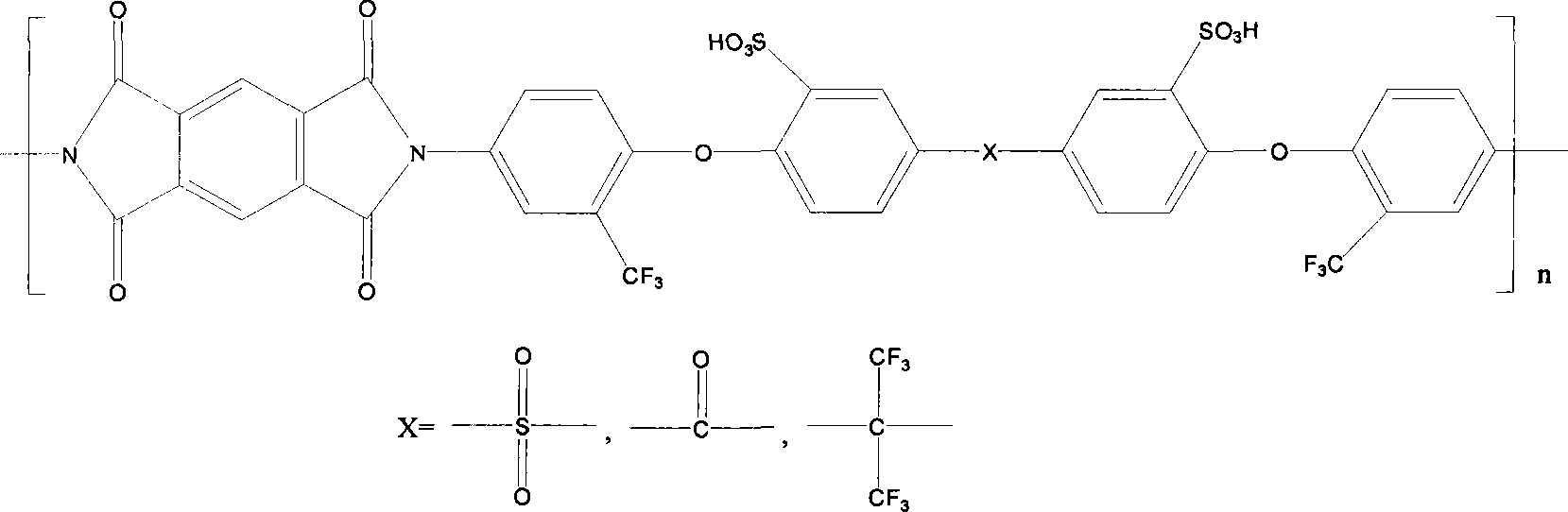

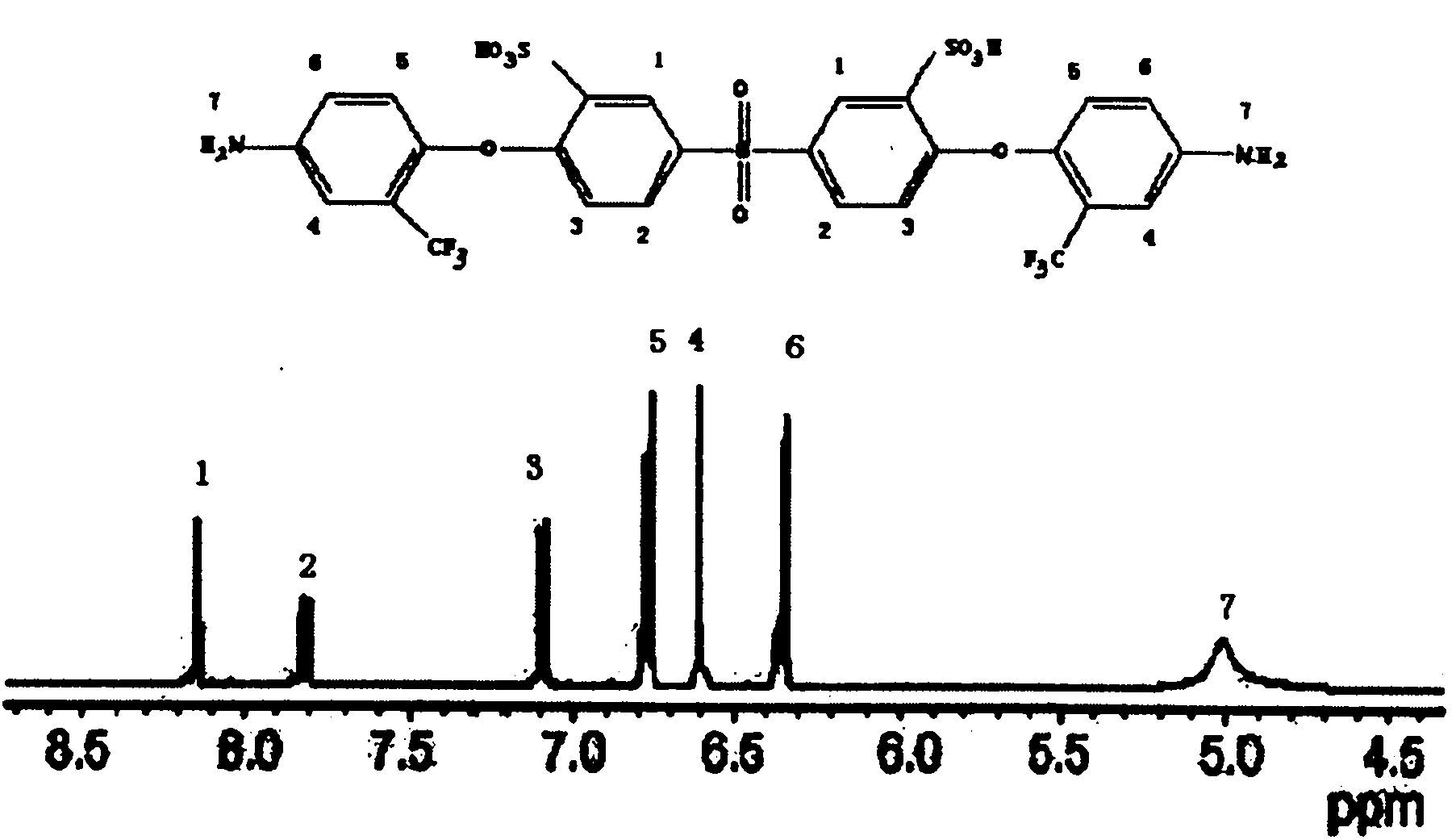

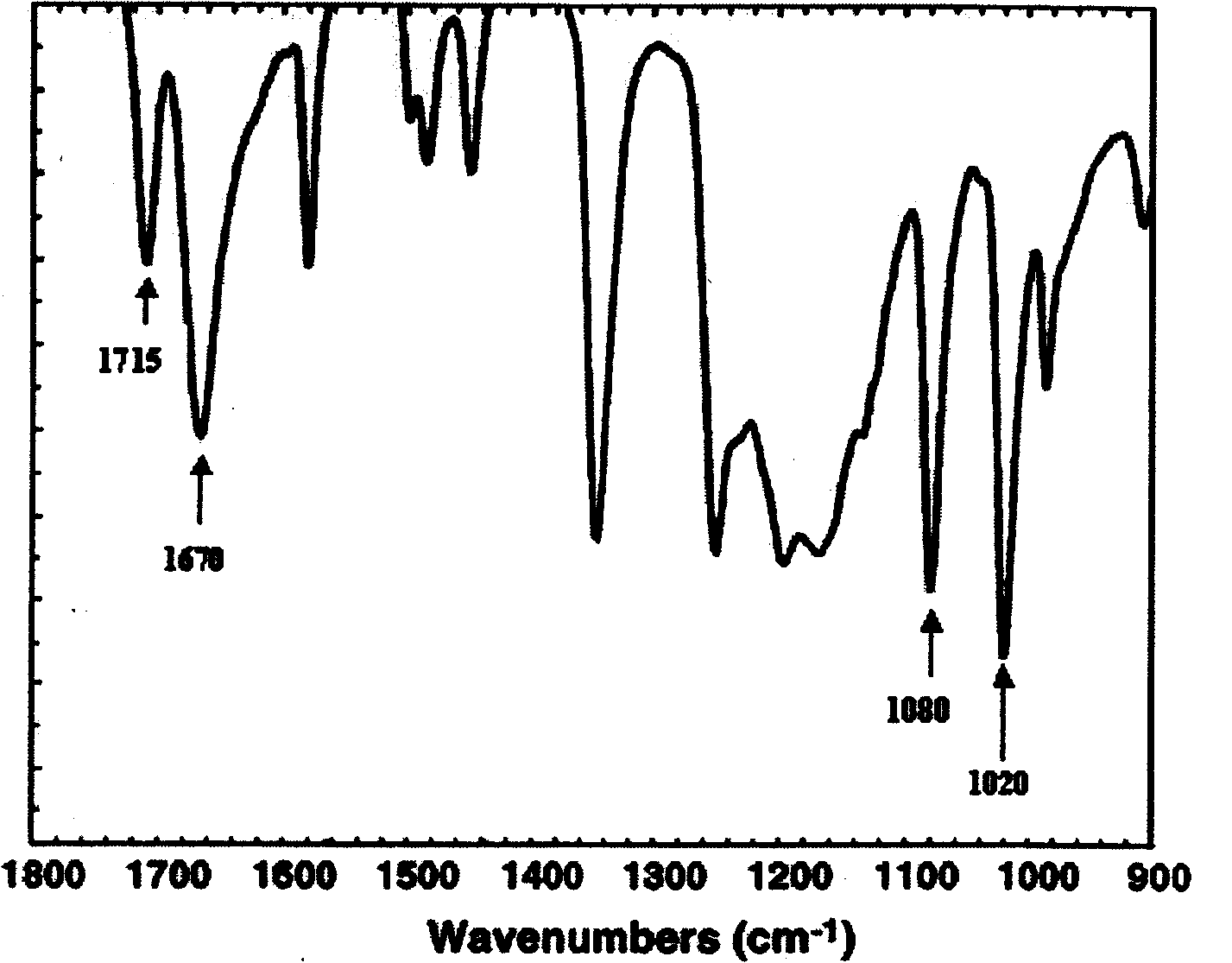

The invention discloses a hydrolysis-resistant sulfonated polyimide proton exchange membrane and a preparation method thereof; the hydrolysis-resistant sulfonated polyimide proton exchange membrane is provided with the following constitutional repeating units. In the invention, a sulfonic acid group and a terminal amino group are respectively connected with different benzene rings by a condensation reaction, and a perfluoro group is introduced to a benzene ring with an amino group, thus strengthening the hydrophobicity of the terminal amino group part, inhibiting ring opening and degradation of the imide bond resulting from the strong hydrophilic sulfonic acid group in a molecular structure of the proton exchange membrane and improving the chemical stability of the proton exchange membrane.

Description

technical field The invention relates to a polymer material membrane and a preparation method thereof, in particular to a hydrolysis-resistant sulfonated polyimide proton exchange membrane for fuel cells and a preparation method thereof. Background technique In direct methanol fuel cell application engineering, if the methanol permeability of the proton exchange membrane is high, a large amount of methanol will permeate to the other side of the membrane to directly react with the oxidant, thereby reducing the energy efficiency of the fuel cell. Sulfonated polyimide proton exchange membrane not only has high proton conductivity, but also has low methanol permeability, so it has attracted extensive attention in the field of proton exchange membrane research. However, the sulfonic acid-substituted benzene ring in the molecular structure of traditional polyimide proton exchange membranes is directly connected to the imide bond. The amine bond group undergoes ring-opening degrad...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01M8/02H01M2/16B01D71/40C08J5/22H01M8/103

CPCY02E60/50

Inventor 韩生

Owner SHANGHAI INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com