High interface compatibility sulphonation medlin proton exchange film for fuel battery and preparation method thereof

A technology of sulfonated polyimide and proton exchange membrane, which can be used in fuel cell parts, fuel cells, solid electrolyte fuel cells, etc., and can solve the problems of poor interface compatibility and affecting the working stability of proton exchange membrane.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

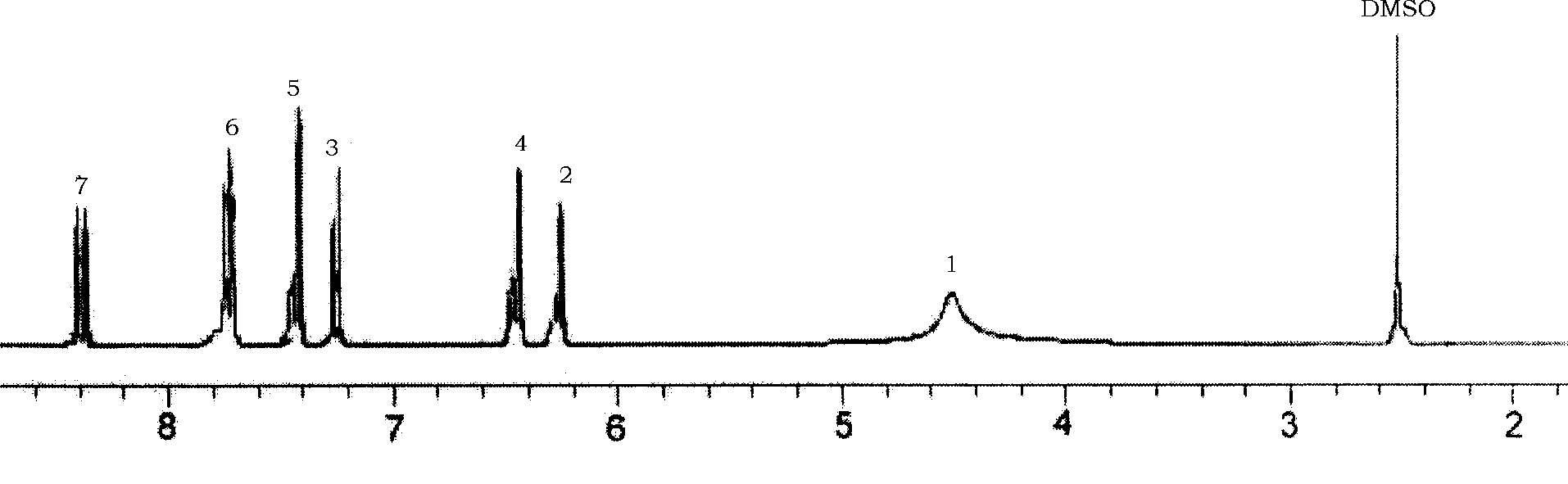

Image

Examples

preparation Embodiment 1

[0031] (a) Dissolve 41g (0.1mol) of 3,3'-disulfonic acid-4,4'-dihydroxydiphenyl sulfone and 27.2g (0.2mol) of 2-fluoro-6-aminobenzonitrile in 100gN at room temperature -In a mixed solvent of methyl-2-pyrrolidone, 150g toluene, 4g sodium hydroxide and 10g deionized water, under nitrogen atmosphere, heat up to 160°C, react for 4 hours, then rise to 190°C for 16 hours, react After the end, cool the reaction product to room temperature, filter it with a Buchner funnel, pour the filtrate into 200g of absolute ethanol solvent, and stir rapidly at the same time to form a precipitate. After suction filtration, put the filter cake in 80°C deionized water Heated and stirred for 3 hours, and then suction filtered to obtain 52 g of amino-terminated nitrile-containing sulfonated aromatic ring polymers, with a yield of 81%;

[0032] (b) 6.42g (10mmol) of amino-terminated nitrile-containing sulfonated aromatic ring polymers and 2.4g of triethylamine are dissolved in 80g of m-cresol at room t...

Embodiment 1

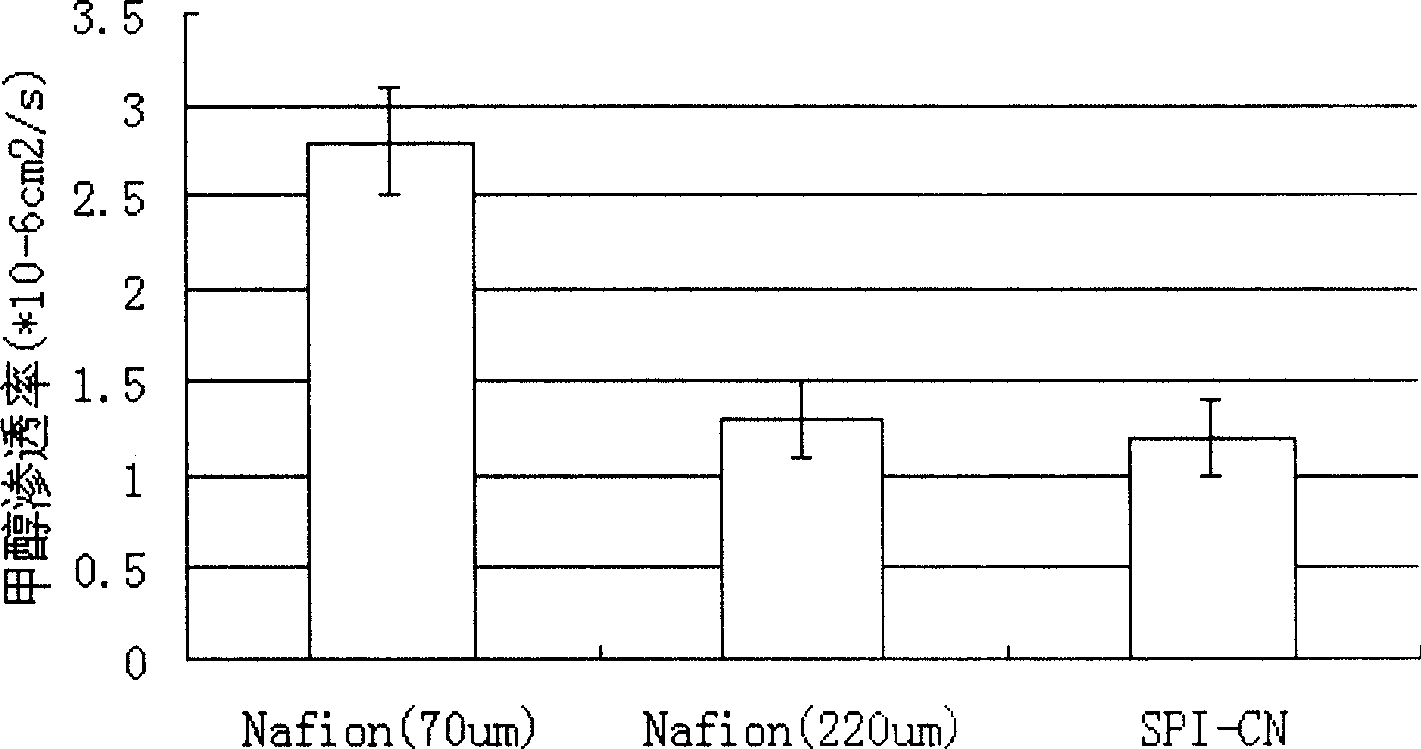

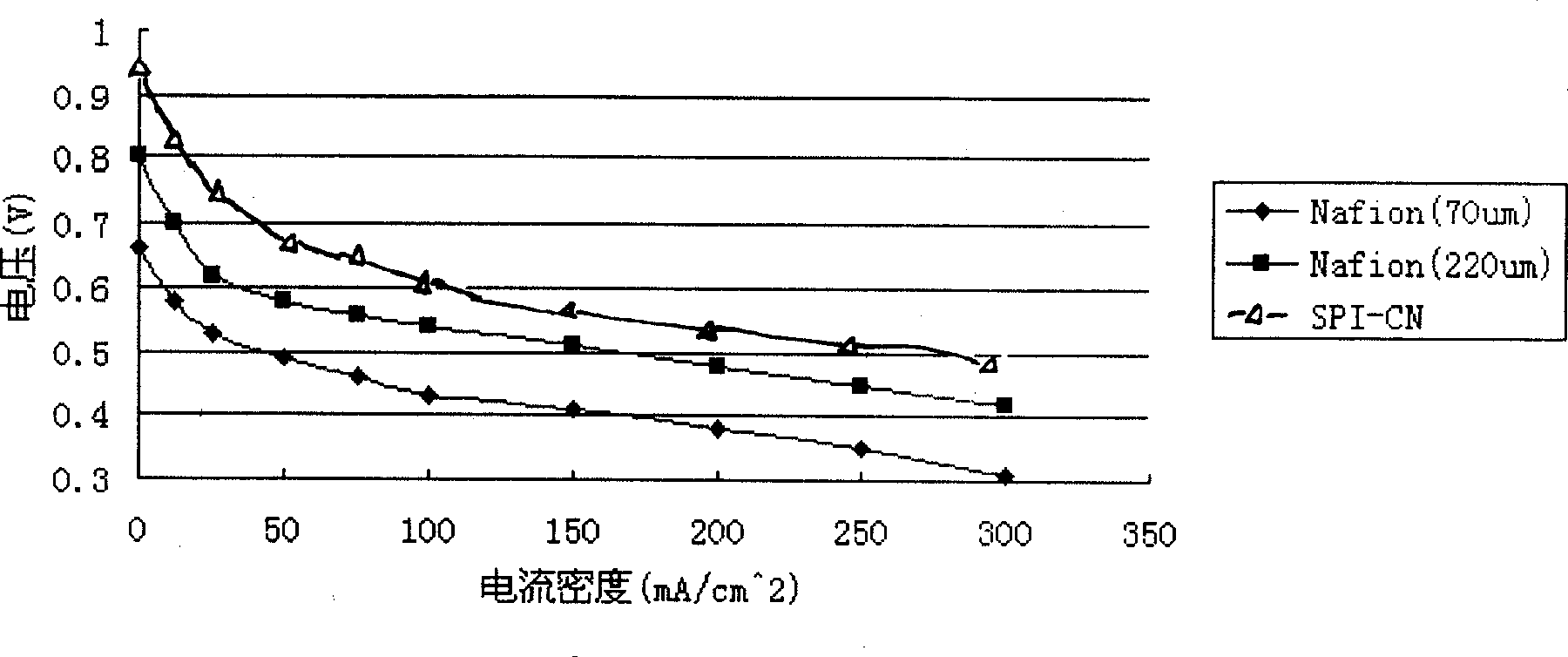

[0038] The thickness of the proton exchange membrane prepared in Example 1 is 73 microns, the ion exchange capacity is 1.90mmol / g, the conductivity is 0.087S / cm (20°C, 100% relative humidity), and the methanol permeability is 1.2×10 -6 cm 2 / s, such as figure 2 , image 3 , Figure 4 shown.

preparation Embodiment 2

[0040] (a) Mix 49.6g (0.1mol) 3,3'-disulfonic acid-4,4'-dihydroxyphenylhexafluoropropane and 27.2g (0.2mol) 2-fluoro-6-aminobenzonitrile at room temperature Dissolve it in a mixed solvent of 100g N,N'-dimethylacetamide, 150g toluene, 6g potassium carbonate and 10g deionized water, raise the temperature to 160°C under nitrogen atmosphere, react for 4 hours, then rise to 190°C for reaction After 16 hours, after the reaction was over, the reaction product was cooled to room temperature, and after suction filtration with a Buchner funnel, the filtrate was poured into 200g of absolute ethanol solvent, while stirring rapidly to generate a precipitate, and after suction filtration, the filter cake was placed in 80 ℃ in deionized water, heated and stirred for 3 hours, and then suction-filtered to obtain 55.3 g of amino-terminated nitrile-containing sulfonated aromatic ring polymers, with a yield of 76%;

[0041] (b) 7.28g (10mmol) of amino-terminated nitrile-containing sulfonated arom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| cation exchange capacity (mol) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com