Process system and method for refining dimethyl formamide serving as extraction solvent of C5 separation device

A dimethylformamide and separation device technology, which is applied in the separation/purification of carboxylic acid amide, vacuum distillation, organic chemistry, etc., can solve the problem of low quality of refined solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

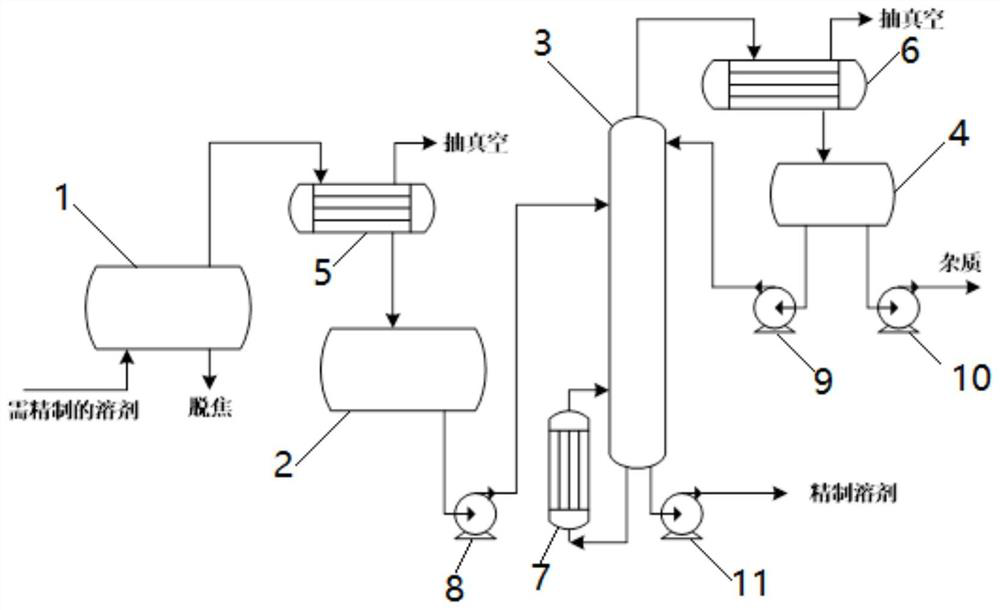

[0026] like figure 1 Shown is a process system for extracting solvent dimethylformamide from a refining carbon five separation device.

[0027] Including: solvent regeneration tank 1, crude solvent tank 2, solvent refining tower 3, reflux tank 4, first condenser 5, second condenser 6, crude solvent pump 8, solvent refining tower reflux pump 9, solvent refining tower top Extraction pump 10 and solvent refining column tank pump 11.

[0028] The top of the solvent regeneration tank 1 is connected to the top inlet of the crude solvent tank 2 through the first condenser 5, the bottom outlet of the crude solvent tank 2 is connected to the solvent refining tower 3 through the first condenser 5, and the top outlet of the solvent refining tower 3 passes through the second condenser 6 is connected to the reflux tank 4, the bottom outlet of the reflux tank 4 is connected to the solvent refining tower 3 through the solvent refining tower reflux pump 9, and the bottom outlet of the reflux...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com