Synergistic utilization of waste incineration fly ash and steel slag to prepare high-strength bricks

A waste incineration fly ash, high-strength technology, applied in the field of resource utilization of waste incineration fly ash, can solve the problems of high leaching concentration and low strength of heavy metals, achieve the effect of inhibiting hydrolysis and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

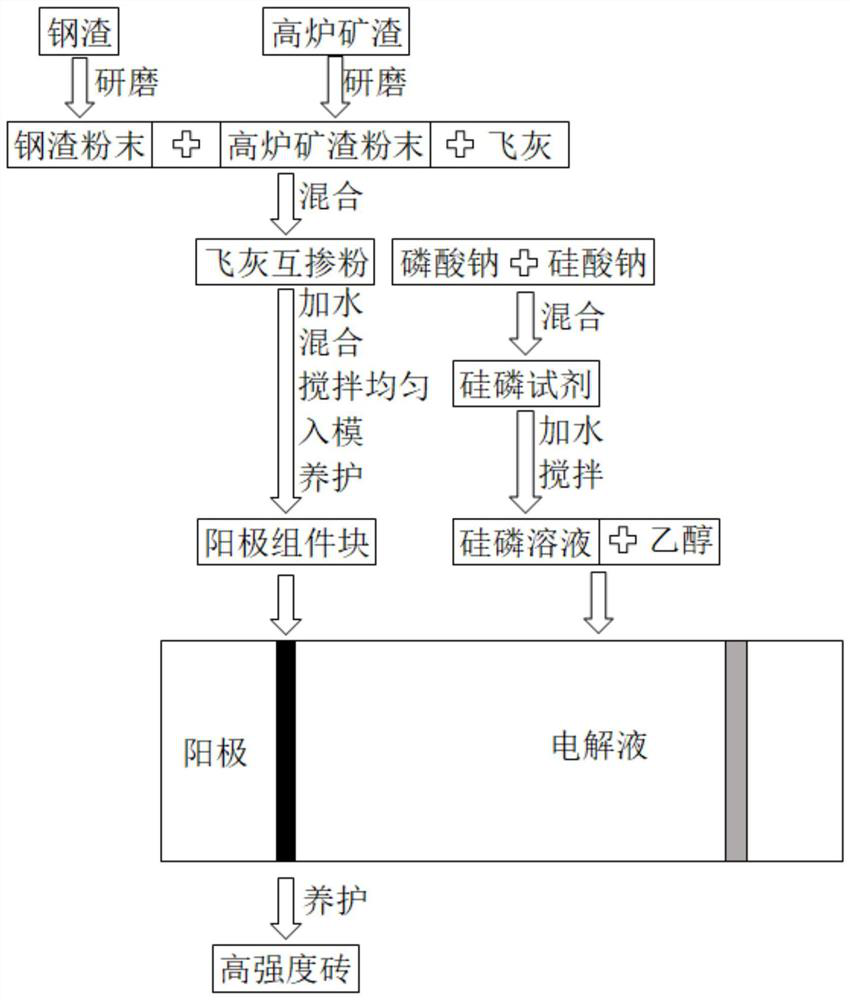

Method used

Image

Examples

Embodiment 1

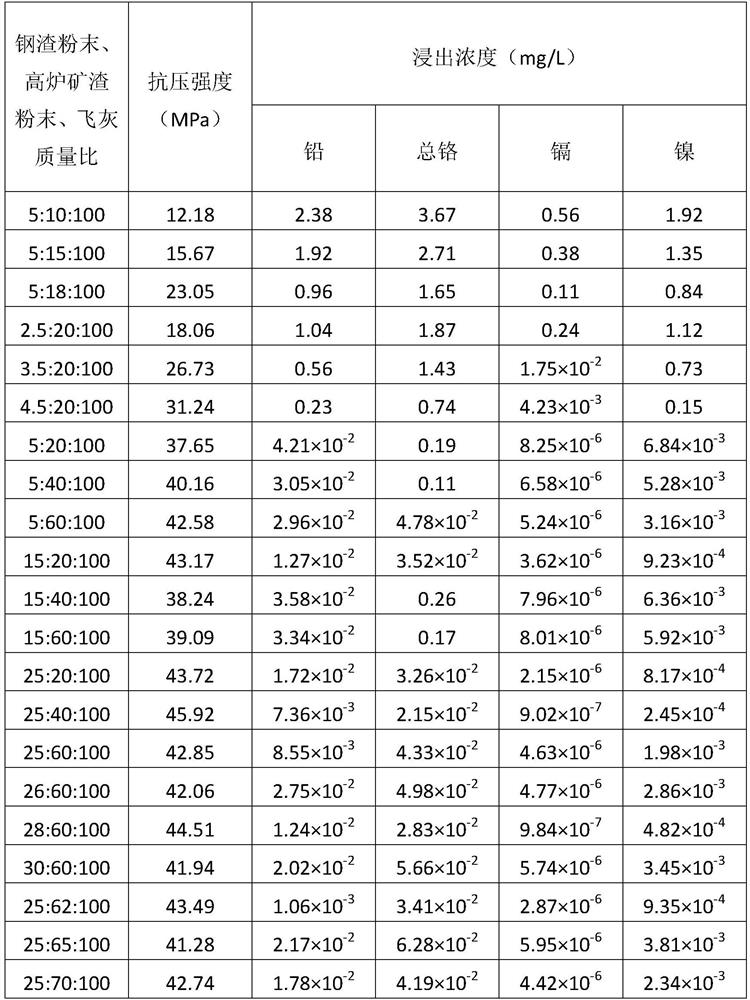

[0027] Influence of the mass ratio of steel slag powder, blast furnace slag powder and fly ash on the strength and leaching concentration of heavy metals of the prepared high-strength bricks

[0028] The steel slag was ground for 1 hour to obtain steel slag powder. The blast furnace slag was ground for 1 hour to obtain blast furnace slag powder. According to the mass ratio of steel slag powder, blast furnace slag powder and fly ash 5:10:100, 5:15:100, 5:18:100, 2.5:20:100, 3.5:20:100, 4.5:20:100, 5: 20:100, 5:40:100, 5:60:100, 15:20:100, 15:40:100, 15:60:100, 25:20:100, 25:40:100, 25:60: 100, 26:60:100, 28:60:100, 30:60:100, 25:62:100, 25:65:100, 25:70:100 Weigh steel slag powder, blast furnace slag powder, fly ash respectively, Mixed to obtain fly ash intermixed powder. According to the water-to-fly ash mixed powder water-cement ratio of 0.2:1, the water and fly ash mixed powder were respectively weighed, mixed, stirred evenly, put into a mold, and cured for 3 days to obta...

Embodiment 2

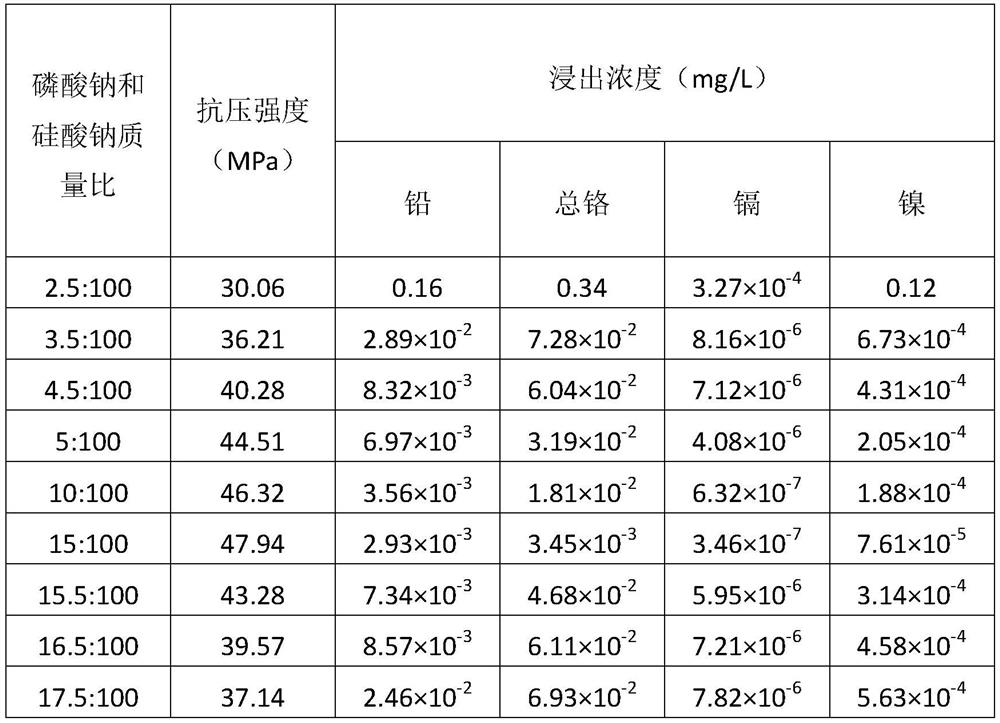

[0036] Influence of the mass ratio of sodium phosphate and sodium silicate on the strength and leaching concentration of heavy metals of the prepared high-strength bricks

[0037] The steel slag was ground for 3.5 hours to obtain steel slag powder. The blast furnace slag was ground for 3.5 hours to obtain blast furnace slag powder. According to the mass ratio of steel slag powder, blast furnace slag powder and fly ash 25:60:100, respectively weigh steel slag powder, blast furnace slag powder and fly ash, and mix them to obtain fly ash mixed powder. According to the water and fly ash intermixed powder water-cement ratio of 0.35:1, respectively weigh water and fly ash intermixed powder, mix, stir evenly, put into a mold, and maintain for 5 days to obtain an anode assembly block. According to the mass ratios of sodium phosphate and sodium silicate of 2.5:100, 3.5:100, 4.5:100, 5:100, 10:100, 15:100, 15.5:100, 16.5:100, 17.5:100, weigh sodium phosphate and sodium silicate respect...

Embodiment 3

[0043] Influence of voltage on the strength and leaching concentration of heavy metals in the prepared high-strength bricks

[0044] The steel slag was ground for 6 hours to obtain steel slag powder. The blast furnace slag was ground for 6 hours to obtain blast furnace slag powder. According to the mass ratio of steel slag powder, blast furnace slag powder and fly ash 25:60:100, respectively weigh steel slag powder, blast furnace slag powder and fly ash, and mix them to obtain fly ash mixed powder. According to the water-to-fly ash mixed powder water-cement ratio of 0.5:1, the water and fly ash mixed powder were respectively weighed, mixed, stirred evenly, put into a mold, and maintained for 7 days to obtain an anode assembly block. According to the mass ratio of sodium phosphate and sodium silicate of 15:100, respectively weigh sodium phosphate and sodium silicate, and mix them to obtain a silicon-phosphorus reagent. According to the mass-liquid ratio of silicon-phosphorus ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com